The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Understanding of Binding Techniques interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Understanding of Binding Techniques Interview

Q 1. Explain the difference between perfect binding and saddle stitching.

Perfect binding and saddle stitching are two common bookbinding methods, but they differ significantly in their construction and suitability for different projects. Think of it like this: perfect binding is like a glued spine, ideal for novels; saddle stitching is like stapling, best for magazines.

- Perfect Binding: This method involves gluing the edges of the pages together to create a smooth spine. The cover is then wrapped around this glued block of pages. It’s ideal for books with a higher page count (typically 48 pages or more) and a thicker spine, such as novels or textbooks. The pages are usually trimmed to create a square spine before gluing.

- Saddle Stitching: This is a simpler method where pages are folded in half and secured through the fold line with wire staples. It’s suitable for documents with a lower page count (typically fewer than 64 pages), such as brochures, magazines, or booklets. It results in a flatter spine, but it can only accommodate a limited number of pages and thicker paper stock can be difficult to staple.

In short, perfect binding offers a more professional and durable finish for thicker books, while saddle stitching is a quick, cost-effective option for smaller projects.

Q 2. Describe the process of case binding.

Case binding is a high-quality binding method often used for high-value books, journals, and legal documents. It’s a more robust and sophisticated process compared to other methods like perfect binding. Imagine creating a custom hard cover for a treasured heirloom.

- Gathering and Sewing: The pages are gathered in the correct order and sewn together using a variety of techniques (e.g., sewing along the spine, side-stitching). This creates a durable and flexible spine.

- Adhesive application: A thin layer of adhesive is often applied to the spine to further enhance the strength and stability.

- Pressing: The sewn sections are pressed flat to ensure a neat and even spine.

- Cover Making: The book cover (the case) is constructed separately using heavy cardstock or boards. This involves cutting, scoring, and folding the cover material.

- Case Attachment: The spine is glued to the inside of the cover using an appropriate adhesive.

- Headbands and Endpapers: Headbands (decorative cloth covering at the top and bottom of the spine) and endpapers (decorative papers connecting the cover to the text block) are added to enhance the aesthetic appeal and durability.

- Finishing: This involves trimming the excess materials and applying any decorative elements.

Case binding is a complex process often carried out by specialized bookbinders due to the high level of precision and skill required. The result is a very durable and high-quality bound document that is meant to last.

Q 3. What are the advantages and disadvantages of wire-O binding?

Wire-O binding, also known as double-loop wire binding, uses double-loop wire to hold the pages together. It creates a professional and durable finish, allowing for 360-degree lay-flat opening, and is often used for calendars, notebooks, and reports. However, it does have limitations.

- Advantages:

- Lay-flat functionality: Allows the book to lay completely flat, which is excellent for writing or presentations.

- Durability: The double-loop wire is strong and resistant to damage.

- Professional appearance: Provides a clean and polished look.

- Cost-effective for moderate page counts: Relatively inexpensive compared to other methods for books with a medium page count.

- Disadvantages:

- Limited page capacity: Not suitable for very thick documents.

- Potential for page damage: The wire can sometimes cause slight damage or indentations to the pages.

- Not suitable for all paper types: Heavier stocks may be difficult to punch.

- Less aesthetic for high-end products: May not be suitable for premium publications where a more sophisticated binding is desired.

Q 4. How do you determine the appropriate binding method for a particular project?

Choosing the right binding method depends on several factors. It’s like choosing the right tool for a job – a hammer won’t work for every task.

- Page count: Saddle stitching is best for fewer pages, perfect binding for moderate to high page counts, and case binding for very high page counts.

- Budget: Saddle stitching is the most economical, followed by perfect binding and wire-O, with case binding being the most expensive.

- Desired aesthetic: Case binding provides the most luxurious look, while saddle stitching and wire-O offer clean, functional styles.

- Functionality: If the document needs to lay flat, wire-O binding is ideal. If a high degree of durability is needed, case binding is superior.

- Paper stock: Heavier papers might not be suitable for all methods. For example, very thick paper stock can be difficult to staple or punch for wire-O.

Consider these factors carefully to choose the binding method that best suits your project’s requirements and budget.

Q 5. What are common issues encountered during the perfect binding process and how are they resolved?

Perfect binding, while efficient, is prone to certain issues.

- Spine cracking: This often occurs due to insufficient adhesive, uneven gluing, or using paper that is too thick or brittle. Solution: Use appropriate adhesive, ensure even application, and consider thinner paper stock.

- Page misalignment: Inconsistent trimming or improper stacking can lead to uneven pages. Solution: Ensure accurate trimming and careful attention to page alignment during the gluing process.

- Loose pages: Insufficient adhesive is the primary cause. Solution: Use more glue or a stronger adhesive and ensure proper pressure during the binding process.

- Cover adhesion issues: Weak glue or incorrect application leads to cover detachment. Solution: Use a high-quality, appropriate adhesive and apply it evenly to the spine and cover.

Careful attention to detail throughout the perfect binding process and using high-quality materials is crucial to minimizing these problems.

Q 6. Explain the role of adhesives in different binding methods.

Adhesives play a critical role in many binding methods, acting as the ‘glue’ that holds the project together. The choice of adhesive depends on the binding method and the materials used.

- Perfect binding: Requires a strong, flexible adhesive that can create a durable bond between the pages and the cover. PUR (Polyurethane Reactive) adhesives are commonly used for their superior strength and flexibility.

- Case binding: Uses adhesives to secure the sewn sections together and attach the cover to the text block. Animal glues (for their flexibility) and high-quality PVA (Polyvinyl Acetate) are common choices.

- Saddle stitching: Does not rely on adhesives; it uses mechanical fasteners (staples).

- Wire-O binding: The double-loop wire itself provides the binding and does not rely on adhesives.

Choosing the right adhesive is crucial for achieving a strong, lasting bond. Consider factors such as drying time, strength, and flexibility when selecting an adhesive for a particular binding method.

Q 7. Describe the process of spiral binding.

Spiral binding, also known as coil binding, uses a plastic or metal comb to hold pages together. It’s a quick and easy method, often used for documents that need to lay flat, like notebooks or reports. Imagine a plastic comb holding the pages together.

- Punching: Holes are punched along the spine of the document using a specialized machine.

- Coil insertion: A plastic or metal coil is inserted into the punched holes.

- Closing the coil: The ends of the coil are crimped or closed to securely bind the document.

The process is relatively straightforward and can be done quickly, making it ideal for smaller projects where speed and cost-effectiveness are priorities. The ability to turn pages 360 degrees is a key advantage.

Q 8. What are the quality control checks you perform during the binding process?

Quality control in binding is crucial for a professional finish. We perform checks at several stages. Before binding, we meticulously inspect the document for any defects like misaligned pages, creased sheets, or damaged corners. This pre-binding check prevents problems from propagating through the entire binding process. During the binding process itself, we monitor the machine’s performance, checking for consistent pressure, accurate stitching, or glue application. For example, in perfect binding, we verify the spine’s evenness and the robustness of the adhesive bond. After binding, a final inspection ensures the cover is correctly attached, the spine is flawlessly finished, and the overall presentation meets the highest standards. This might involve checking for page-number consistency and ensuring there are no loose pages or visible glue marks.

We also use statistical process control methods to track key metrics like the number of defective products per batch. This allows for early identification of potential issues in the process and helps us make adjustments to maintain consistently high quality.

Q 9. How do you handle large-volume binding projects efficiently?

Handling high-volume binding projects efficiently requires a well-structured approach. Firstly, we optimize the workflow by employing efficient pre-press techniques such as digital imposition and automated page numbering. Secondly, we utilize high-speed binding machinery designed for bulk processing. For example, we might use saddle-stitching machines with high-capacity feeders or automated perfect binding systems. Thirdly, we implement robust quality control checks at every stage to ensure consistency and prevent bottlenecks. Finally, we carefully plan the production schedule, ensuring enough time for each step, and prioritize tasks based on deadlines and project urgency. This integrated approach ensures we meet deadlines while maintaining the required quality level even for large-scale projects.

Q 10. What are the safety precautions you take when operating binding machinery?

Safety is paramount when operating binding machinery. Before starting any machine, we always ensure that all guards are in place and functioning correctly. We wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and hearing protection, depending on the machinery and the process. Loose clothing and jewelry are strictly avoided to prevent entanglement. We receive regular safety training on the specific machines we operate, covering emergency shutdown procedures and potential hazards. Regular machine maintenance is crucial for safety, preventing malfunctions that could lead to injury. We always follow the manufacturer’s instructions and report any safety concerns immediately to our supervisor. Think of it like driving a car: following the rules and being aware of your surroundings is essential to prevent accidents.

Q 11. What types of paper are best suited for different binding methods?

The suitability of paper for different binding methods depends on its weight, thickness, and texture. For example, saddle stitching is best suited for lightweight papers (around 60-80gsm) which can be easily folded and stitched without tearing. Heavier papers are generally better suited for methods like perfect binding or case binding. Perfect binding, where the pages are glued to the spine, often works well with coated papers that provide a smooth surface for strong adhesion. Case binding, the most robust method, can handle a wide range of paper weights and types, offering superior durability.

The paper’s texture also plays a role. Rough or textured paper may not fold as well for saddle stitching, whereas smooth paper is ideal for perfect binding to ensure clean glue adhesion. Considering these factors ensures the chosen binding method complements the paper’s characteristics, resulting in a durable and aesthetically pleasing final product.

Q 12. Explain the importance of pre-press preparation for efficient binding.

Pre-press preparation is vital for efficient binding. Thorough pre-press work minimizes issues during the binding process, saving time and resources. It involves tasks like accurate imposition (arranging pages for efficient printing and folding), precise page numbering, and careful checking for any errors or inconsistencies in the document. Proper imposition, for instance, can significantly reduce the time spent during the finishing process. Accurate page numbering ensures the correct sequence of pages before binding; otherwise, you would need to spend time re-sorting pages after printing, which is highly inefficient. Identifying and correcting any errors at the pre-press stage reduces costly rework and prevents delays later on.

Q 13. How do you troubleshoot common malfunctions in binding machines?

Troubleshooting binding machine malfunctions requires a systematic approach. First, we identify the specific problem: Is the machine jamming? Is the glue not applying correctly? Is the stitching inconsistent? Once the problem is identified, we consult the machine’s manual for potential causes and solutions. Common issues often involve simple fixes such as clearing a paper jam, adjusting the glue level or temperature, or replacing a worn part. However, for more complex problems, we might need to contact the manufacturer’s technical support or a qualified repair technician. We document all troubleshooting steps and solutions to aid in future problem-solving and prevent recurrence of similar issues. A methodical approach minimizes downtime and ensures the machine’s continued efficient operation.

Q 14. What are some alternative binding methods you are familiar with?

Beyond the common methods, I’m familiar with several alternative binding techniques. These include wire-o binding, which creates a professional look with pages that lay flat; spiral binding, a cost-effective method ideal for reports or documents; and thermal binding, which uses a heat-activated adhesive to create a durable, neat finish. Each of these methods offers a unique aesthetic and functional advantage, suited to specific document types and required durability. For example, wire-o binding is perfect for calendars, while spiral binding might be ideal for student notebooks. Choosing the right alternative method depends on the project’s specific needs, budget, and desired final look.

Q 15. Describe your experience with different types of binding equipment.

My experience with binding equipment encompasses a wide range of technologies, from traditional hand-held tools to fully automated systems. I’m proficient with various types of stitching equipment, including saddle stitchers for brochures and magazines, perfect binders for books with a sewn or glued spine, and case binding machines for hardcover books. I’ve also worked extensively with wire-o and coil binding machines for smaller projects, and even specialized equipment like PUR (Polyurethane Reactive) binding machines for high-quality, durable results. For example, in a previous role, we used a Heidelberg Stitchmaster ST450 for high-speed saddle stitching and a Muller Martini Alegro perfect binder for high-volume book production. This experience allows me to select the most appropriate equipment for a specific project based on factors like budget, volume, and desired quality.

- Saddle Stitchers: Ideal for brochures and magazines with a low page count.

- Perfect Binders: Suitable for books with a glued spine; often used for mass-market paperbacks.

- Case Binders: Used for creating hardcover books with a robust cover and spine.

- Wire-O and Coil Binding: Best suited for documents that need to lay flat, such as calendars or notebooks.

- PUR Binding: Offers superior durability and lay-flat capabilities, ideal for high-end books and manuals.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure consistent quality in a high-volume production environment?

Maintaining consistent quality in high-volume production requires a multi-faceted approach. It starts with meticulous planning and standardization of processes. We establish clear quality control checkpoints at each stage of the binding process, from pre-press to post-production. This includes regular calibration of machinery, using standardized materials, and employing rigorous quality checks at every stage. For example, we might implement a statistical process control (SPC) system to monitor key variables like binding strength or cover adhesion, and to immediately identify and correct any deviations from pre-set parameters. Furthermore, consistent operator training is vital. We regularly train our team on best practices, troubleshooting, and identifying defects. Finally, having a robust system for tracking and tracing materials and products allows for pinpointing the source of any inconsistencies if they arise. Think of it like baking a cake – consistent ingredients, accurate measurements, and a well-calibrated oven are crucial to achieving the same delicious result every time.

Q 17. What is your experience with different types of cover materials?

My experience covers a wide range of cover materials, each with its own unique properties and suitability for different applications. I’m familiar with various papers, including coated and uncoated stocks, textured papers, and specialty papers like linen or leatherette. For hardcover books, I’ve worked with different types of boards, including chipboard, binder’s board, and even custom-made boards for high-end projects. Understanding the properties of these materials – their weight, thickness, durability, and printability – is essential for choosing the right one for each project. For instance, coated paper provides a smoother surface ideal for vibrant printing, while linen offers a more luxurious, textured feel. The choice depends on factors such as budget, aesthetic appeal, and the book’s intended use. I also have experience working with fabrics and other non-paper cover materials for bespoke projects, ensuring a beautiful and durable finish.

Q 18. Explain the significance of spine preparation in bookbinding.

Spine preparation is crucial for a well-bound book, significantly impacting its durability and aesthetics. Proper spine preparation involves several steps designed to ensure that the sections or leaves are held securely together and that the cover adheres correctly. It starts with creating a stable and even spine for the book’s text block. This might involve techniques like sewing the sections together (for traditional case binding), creating a perfectly glued spine (for perfect binding), or preparing the spine for wire-o or coil binding. The spine’s shape and the treatment of the surface (e.g., applying adhesive) directly influence the final look and feel of the finished product. A properly prepared spine prevents the book from falling apart, ensures the cover adheres flawlessly, and contributes to its overall structural integrity. Imagine the spine as the backbone of the book – a strong, well-prepared spine is critical for a healthy and long-lasting ‘body.’

Q 19. How do you manage different types of finishing processes?

Managing diverse finishing processes requires a detailed understanding of each technique and its application. This includes foil stamping, embossing, die-cutting, UV coating, and various other techniques to enhance the book’s aesthetic appeal and durability. I coordinate these processes seamlessly within the overall production workflow. This involves careful scheduling to ensure efficient use of resources and minimal downtime. I’m adept at selecting appropriate finishing techniques based on project requirements and budget. For example, a high-end book might warrant foil stamping for a luxurious touch, whereas a mass-market paperback might only need a simple UV coating for protection. Effective management involves close collaboration with the finishing team, pre-planning the exact specifications, and ensuring a smooth transition between binding and finishing stages.

Q 20. What software or tools are you familiar with for binding planning or design?

I’m proficient with various software tools used in binding planning and design. This includes Adobe Acrobat for pre-flight checks and PDF manipulation, ensuring the document is ready for binding. I use software such as QuarkXPress and InDesign for layout and design, ensuring the correct page size and margins for the chosen binding method. For specialized tasks, such as creating cutting dies for die-cutting, I’m familiar with CAD software. Furthermore, I utilize project management software to track progress, manage deadlines, and maintain communication with clients and the production team. This coordinated approach allows for a streamlined workflow, resulting in accurate binding specifications and efficient production. The right software is instrumental in ensuring a successful outcome for every project.

Q 21. Describe your experience with quality control in the binding process.

Quality control is an integral part of my workflow, starting from the initial assessment of the project’s requirements. This involves establishing clear quality metrics specific to the binding method and type of materials being used. Throughout the production process, I implement regular quality checks at each stage, employing visual inspection, physical testing (such as measuring binding strength), and statistical process control (SPC) techniques. This allows for early detection of any flaws or inconsistencies, enabling timely corrective actions. Documentation and record-keeping are crucial; this includes maintaining detailed logs of materials used, machine settings, and any quality issues encountered. This systematic approach to quality control ensures the creation of consistently high-quality bound products. It’s like a quality assurance net, making sure nothing slips through the cracks.

Q 22. How do you ensure accurate and timely completion of binding projects?

Accurate and timely completion of binding projects hinges on meticulous planning and efficient execution. It starts with a thorough understanding of the client’s specifications, including the type of binding (e.g., perfect binding, saddle stitch, spiral binding), the number of pages, the paper stock, and the desired turnaround time.

- Project Scheduling: I utilize project management software to create detailed schedules, allocating sufficient time for each stage—from pre-press preparation to finishing. This includes buffer time to account for unforeseen delays.

- Resource Allocation: I carefully assess the required resources – personnel, equipment, and materials – ensuring their availability throughout the project lifecycle. This might involve coordinating with different departments or external vendors.

- Quality Control Checks: Implementing rigorous quality control measures at each stage prevents errors from propagating. This includes regular inspections of the print quality, binding accuracy, and overall finishing.

- Communication: Maintaining open communication with the client and the internal team is crucial. Regular updates on project progress keep everyone informed and allows for timely intervention if issues arise.

For example, on a recent large-volume perfect binding project, we implemented a phased approach, binding smaller batches and conducting quality checks at each phase. This strategy allowed for faster identification and rectification of any minor issues, preventing major delays at the final stage.

Q 23. How do you handle client feedback regarding binding specifications?

Client feedback is paramount. I handle it by actively listening and understanding their concerns. This often involves asking clarifying questions to fully grasp their perspective.

- Documentation: All client specifications are meticulously documented. This serves as a reference point for comparing the final product against expectations.

- Problem Solving: I work collaboratively with the client to find solutions that meet their needs while remaining feasible within the project constraints. This might involve minor adjustments to the binding specifications or exploring alternative binding methods.

- Transparency: I keep clients informed throughout the process, providing regular updates and clearly explaining any necessary adjustments or delays.

- Compromise: Sometimes, complete satisfaction requires compromise. Finding a balance between client expectations and practical limitations is key to maintaining a positive working relationship.

In one instance, a client requested a specific type of binding that was technically challenging and potentially costly. After a thorough discussion, we explored alternative options that offered similar aesthetics at a more manageable cost. The client was happy with the proposed solution and the project was successfully completed.

Q 24. Explain your problem-solving approach in a binding production issue.

My problem-solving approach in binding production issues follows a structured methodology:

- Identify the Problem: The first step is a thorough investigation to pinpoint the exact nature of the issue. This might involve examining the faulty products, reviewing the production process, and checking equipment settings.

- Analyze the Root Cause: Once identified, I analyze the root cause. Was it a machine malfunction? An error in the binding process? A problem with materials? This requires a systematic approach, possibly including data analysis.

- Develop Solutions: Based on the root cause analysis, I brainstorm potential solutions. This often involves consulting colleagues, technical manuals, or seeking advice from equipment suppliers.

- Implement the Solution: The chosen solution is implemented carefully, often in a controlled test environment before widespread adoption.

- Monitor and Evaluate: After implementation, the solution is monitored closely to ensure effectiveness and to identify any unintended consequences. This includes collecting data to assess its impact on efficiency and product quality.

For instance, if we encounter frequent jams in a perfect binding machine, I would first investigate the cause – perhaps worn rollers or incorrect paper alignment. Then, based on the findings, I might adjust the machine settings, replace parts, or even retrain the operating staff on the correct procedures.

Q 25. How do you stay up-to-date on the latest trends in binding techniques?

Staying current in the rapidly evolving world of binding techniques is crucial. I employ several strategies:

- Industry Publications: I regularly read trade publications, journals, and online resources dedicated to the printing and binding industry. These publications highlight new technologies, trends, and best practices.

- Industry Events: Attending trade shows, conferences, and workshops allows me to network with other professionals and learn about the latest innovations firsthand.

- Online Courses and Webinars: Many online platforms offer courses and webinars on advanced binding techniques. This provides structured learning opportunities, often with hands-on components.

- Manufacturer Websites: I regularly check the websites of major equipment manufacturers to stay informed about new product releases and technological advancements.

- Networking: Engaging with colleagues and other professionals through industry forums and social media groups helps to share knowledge and stay informed about emerging trends.

For example, recently, I learned about a new automated stitching system through an industry webinar and subsequently integrated this knowledge into our operations, improving efficiency and quality.

Q 26. What is your experience with automated binding systems?

My experience with automated binding systems spans several years. I’m proficient in operating and maintaining various automated binding machines, including perfect binding systems, case binding machines, and wire-o binding machines.

- Troubleshooting: I possess the skills to troubleshoot common malfunctions in automated systems, identifying and resolving problems efficiently to minimize downtime.

- Maintenance: I understand the importance of regular maintenance to ensure optimal machine performance and longevity. This includes preventative maintenance schedules and familiarity with routine cleaning and adjustments.

- Programming: Depending on the specific machine, I have experience programming or configuring automated systems to meet specific binding requirements, such as page counts, cover thicknesses, and spine widths.

- Safety Protocols: I am well-versed in adhering to all safety protocols and regulations associated with operating automated binding equipment.

In a previous role, I played a key role in implementing a new automated perfect binding system. This resulted in a significant increase in production capacity and a notable reduction in production costs.

Q 27. Describe your experience with manual binding techniques.

My experience with manual binding techniques is extensive and provides a valuable foundation for understanding the intricacies of the binding process. This includes proficiency in techniques like:

- Saddle Stitch Binding: This involves folding and stitching pages together to create a booklet. I’m experienced in selecting appropriate needle sizes and thread types for different paper weights.

- Perfect Binding: While often automated, I understand the manual aspects, such as preparing the spine for adhesive application and ensuring even pressure during the binding process.

- Spiral Binding (Coil Binding): I’m skilled in punching accurate holes and efficiently inserting and closing the coils.

- Hand Sewing: I have experience with various hand-sewing techniques for specialized binding projects.

Manual binding skills are incredibly valuable because they provide a deeper understanding of the mechanical processes involved. This knowledge aids in troubleshooting automated systems and allows for effective problem-solving when facing unusual binding requests.

Q 28. How would you train a new employee on binding procedures?

Training a new employee on binding procedures involves a structured and hands-on approach:

- Safety First: The training begins with a thorough review of safety procedures and regulations related to operating binding equipment and handling materials.

- Theory and Overview: I provide a comprehensive overview of different binding techniques, explaining the advantages and disadvantages of each method. This includes discussions of paper types, adhesives, and finishing options.

- Hands-on Training: Practical, hands-on training is crucial. I guide the employee through each binding process step-by-step, starting with simple tasks and gradually increasing complexity.

- Quality Control: I emphasize the importance of quality control at each stage of the process, showing the employee how to identify defects and rectify errors. This involves visual inspection, tactile checks, and using measuring tools.

- Troubleshooting: I teach the employee how to identify and solve common problems, such as machine jams, misaligned pages, or incorrect adhesive application.

- Mentorship and Supervision: Ongoing mentorship and supervision ensure the employee builds confidence and competence. This might include regular check-ins, performance reviews, and opportunities to work on increasingly complex projects.

Regular assessments and feedback sessions track the employee’s progress and allow for personalized adjustments to the training program. The goal is to develop a fully competent and confident binding professional.

Key Topics to Learn for Understanding of Binding Techniques Interview

- Types of Binding: Explore different binding techniques, their strengths, weaknesses, and appropriate applications (e.g., hardback, paperback, spiral, perfect, saddle stitch).

- Material Selection: Understand the properties of various binding materials (e.g., adhesives, threads, covers) and how to choose the optimal materials for different projects and binding methods.

- Equipment and Tools: Familiarize yourself with the machinery and hand tools used in various binding processes, including their operation and maintenance.

- Production Processes: Gain a comprehensive understanding of the entire binding workflow, from pre-press preparation to finishing, including quality control checkpoints.

- Cost Analysis and Budgeting: Learn how to estimate costs associated with different binding techniques and materials to create efficient budgets.

- Troubleshooting and Problem Solving: Develop the ability to identify and resolve common binding issues, ensuring a high-quality final product.

- Sustainability and Ethical Considerations: Explore environmentally friendly binding options and ethical sourcing of materials.

- Industry Best Practices and Standards: Understand industry standards and best practices related to safety, quality, and efficiency in binding operations.

Next Steps

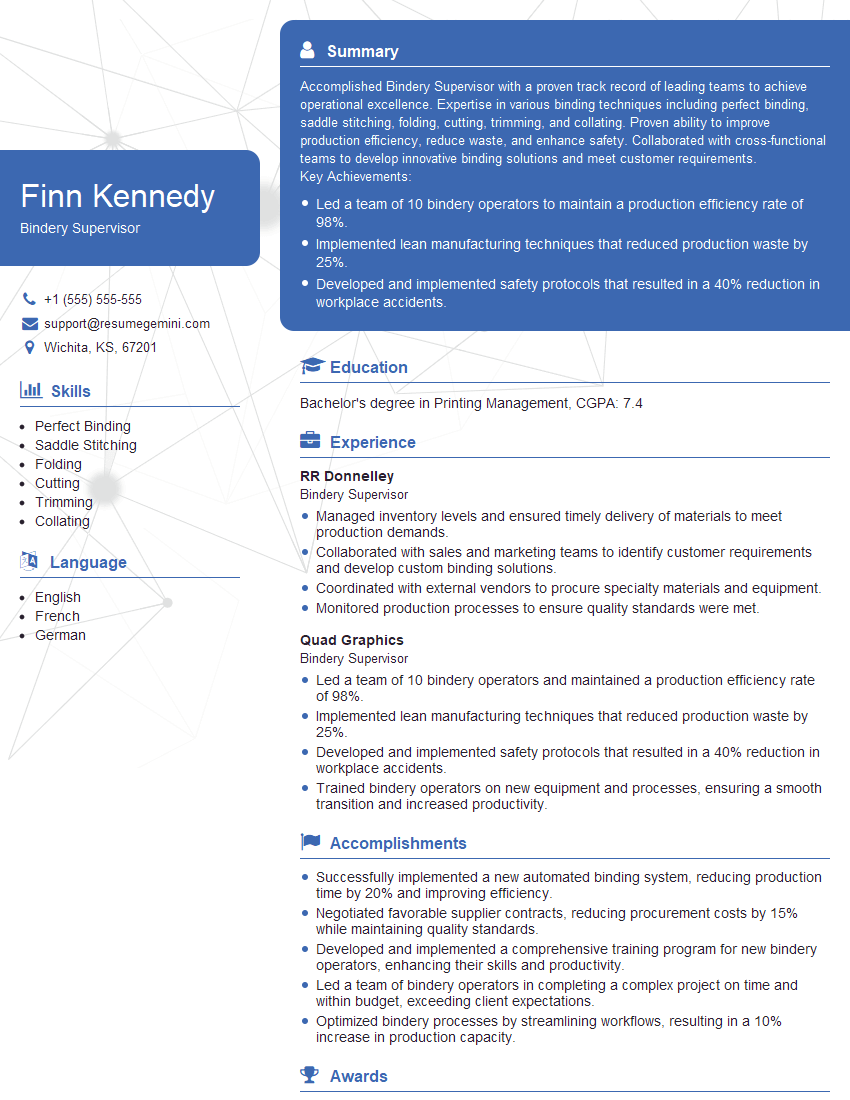

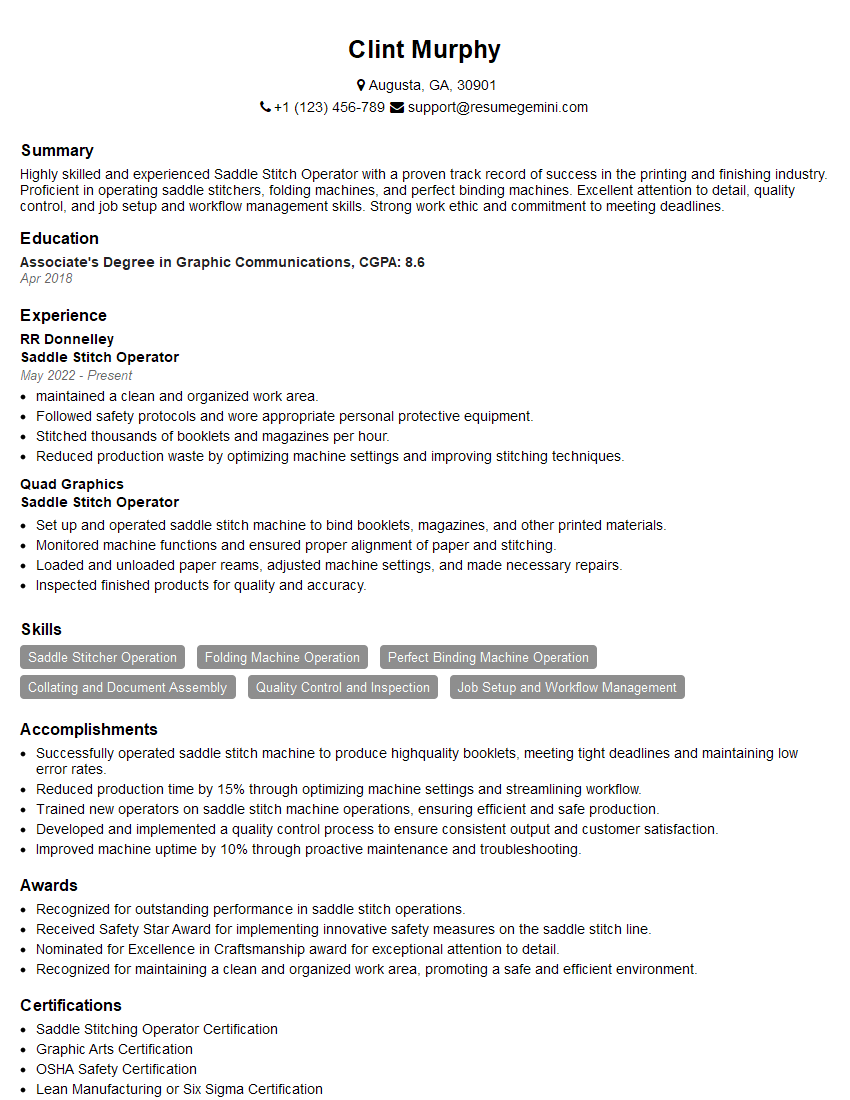

Mastering binding techniques opens doors to exciting career opportunities in publishing, printing, and related fields. A strong understanding of these techniques demonstrates valuable skills and attention to detail, making you a highly sought-after candidate. To maximize your job prospects, focus on creating an ATS-friendly resume that highlights your expertise. ResumeGemini is a trusted resource that can help you build a professional and impactful resume, showcasing your skills effectively. Examples of resumes tailored to Understanding of Binding Techniques are available, providing you with valuable templates and guidance to make your application stand out.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good