Are you ready to stand out in your next interview? Understanding and preparing for Understanding of Furniture Assembly and Disassembly interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Understanding of Furniture Assembly and Disassembly Interview

Q 1. Describe your experience with different types of furniture assembly hardware.

My experience encompasses a wide range of furniture assembly hardware, from the simplest cam locks and dowels to more complex systems like metal-to-metal fasteners, threaded inserts, and even specialized joinery techniques for higher-end pieces. I’m familiar with the strengths and weaknesses of each. For instance, cam locks are quick and easy but can be less robust than dowels and glue, while metal fasteners offer superior strength but require more precise tools and techniques. I’ve worked with various types of screws, including wood screws, self-tapping screws, and confirmat screws (a type of European screw known for its strength and clean appearance), each suited for different materials and applications. My experience extends to understanding different types of wood plugs and cover caps used to conceal fasteners for a polished look.

For example, I once assembled a complex entertainment center that utilized a combination of cam locks for the main structure, confirmat screws for increased stability in key joints, and wood dowels reinforced with glue for a strong and visually appealing joinery. Understanding the nuances of these different hardware types allowed me to efficiently and effectively assemble the unit to the manufacturer’s specifications.

Q 2. What are the common tools used in furniture assembly and disassembly?

The tools required for furniture assembly and disassembly vary depending on the furniture’s complexity, but a basic toolkit usually includes:

- Screwdrivers: Phillips and flathead screwdrivers in various sizes are essential. A cordless drill with different bits can significantly speed up the process.

- Wrenches: Depending on the hardware, you might need open-end, adjustable, or socket wrenches.

- Allen Wrenches (Hex Keys): These are frequently used for cam locks and other specialized fasteners.

- Rubber Mallet: This helps gently tap parts into place without damaging them. Avoid using a metal hammer unless absolutely necessary, and then always protect the wood.

- Measuring Tape: Crucial for verifying dimensions and ensuring accurate alignment.

- Level: Ensures shelves and other components are installed correctly to prevent wobble or instability.

- Pliers: Helpful for gripping stubborn fasteners or removing bent hardware.

Safety glasses should always be worn to protect against flying debris.

Q 3. Explain the process of assembling a typical flat-pack desk.

Assembling a flat-pack desk typically involves these steps:

- Inventory and Organization: Carefully lay out all components and hardware. Check against the instructions to ensure everything is present and accounted for. This saves time and frustration later.

- Identify Key Components: Find the main desk panels and legs. Often these are clearly marked.

- Attach Legs: Most desks use cam locks, screws, or a combination for attaching legs to the desk frame. Follow the instructions precisely to achieve correct alignment.

- Install Drawers (if applicable): Drawer installation involves sliding the drawer runners into designated slots and then installing the drawers themselves. Make sure the runners are level.

- Attach any additional components: This might include shelves, cable management features, or other accessories.

- Final Inspection: Double check all connections, ensuring everything is secure and level. Look for any protruding hardware or uneven surfaces.

Think of it like building with LEGOs – each step builds upon the last. A methodical approach ensures a successful assembly.

Q 4. How do you identify and resolve common assembly issues?

Common assembly issues include stripped screw holes, misaligned parts, missing or damaged hardware, and unclear instructions. Problem-solving strategies vary depending on the specific issue.

- Stripped Screw Holes: Use wood filler to fill the hole, allow it to dry, and then drill a new pilot hole for a slightly larger screw.

- Misaligned Parts: Carefully examine the instructions, ensuring all parts are positioned correctly before tightening fasteners. A slight adjustment might be necessary to achieve correct alignment.

- Missing/Damaged Hardware: Contact the manufacturer immediately for replacement parts. Improvising can lead to structural instability and safety hazards.

- Unclear Instructions: Refer to online videos, diagrams, or contact customer support for assistance. Sometimes a different perspective can clarify confusion.

I always approach these problems methodically, using my experience to assess the situation and then choose the most appropriate solution.

Q 5. Describe your experience working with instruction manuals.

Instruction manuals are crucial for successful furniture assembly. My experience involves working with manuals of varying quality, from extremely clear and detailed ones with multiple diagrams to those that are vague or even contradictory. I have developed strategies to approach them effectively.

- Thorough Review: I always read the entire manual before beginning assembly to get an overview of the process.

- Diagram Interpretation: I carefully study diagrams, paying attention to labels and part numbers.

- Step-by-Step Approach: I follow instructions sequentially, ensuring each step is completed accurately before proceeding to the next.

- Troubleshooting: If I encounter any ambiguity, I seek clarification through online resources or customer support.

I find that a patient and organized approach is essential for navigating even the most challenging instruction manuals.

Q 6. How do you handle missing or damaged parts during furniture assembly?

Missing or damaged parts are a frustrating but common occurrence. My approach is to first carefully check all packaging materials to make sure the parts weren’t accidentally misplaced. Then:

- Contact the Manufacturer: I reach out to the manufacturer’s customer service, providing the model number and a description of the missing or damaged components.

- Document the Problem: I take photos of the damaged parts and any relevant information from the packaging or instruction manual.

- Await Replacement: Once the replacement parts arrive, I carefully assemble the remaining parts and then integrate the replacements. I thoroughly check for proper alignment and stability.

It’s important to avoid attempts to improvise replacements. This could weaken the furniture and create safety hazards.

Q 7. What safety precautions do you take during furniture assembly and disassembly?

Safety is paramount during furniture assembly and disassembly. My practices include:

- Proper Workspace: I assemble furniture in a well-lit, spacious area free from clutter and obstructions.

- Protective Gear: I always wear safety glasses to protect my eyes from flying debris. Gloves can be useful for protecting hands from splinters.

- Tool Safety: I ensure all tools are in good working order and are used according to their intended purpose.

- Lifting Techniques: I use proper lifting techniques to avoid injuries, especially when handling heavy components. This involves bending at the knees and lifting with my legs instead of my back.

- Careful Handling: I handle all materials carefully to avoid scratches, dents, or other damage.

- Child Safety: If working around children, I maintain a safe distance to prevent accidental injuries.

Safety is not just a matter of following rules; it is a mindset that shapes every aspect of the assembly process.

Q 8. What is your experience with different types of wood and materials?

My experience encompasses a wide range of wood types and materials commonly used in furniture construction. I’m familiar with hardwoods like oak, maple, cherry, and walnut, each possessing unique properties influencing both assembly and durability. Softer woods like pine and fir are also within my expertise, often used for less demanding applications or where cost-effectiveness is prioritized. Beyond wood, I have extensive experience working with engineered wood products such as plywood, MDF (medium-density fiberboard), and particleboard, understanding their strengths and limitations in various furniture designs. I also have experience with various metal components, including steel and aluminum, frequently used for hardware, frames, and accents. My knowledge extends to working with upholstery fabrics, foams, and other materials used in soft furnishings.

For example, assembling a solid oak dining table requires different techniques than assembling a piece made from particleboard and veneer. Oak is sturdy and requires precise joinery, whereas particleboard may rely more on cam locks and screws for stability. Understanding these material differences is crucial for effective and safe assembly.

Q 9. How do you ensure the stability and safety of assembled furniture?

Ensuring stability and safety in assembled furniture is paramount. My approach involves a multi-faceted strategy starting with careful examination of the instructions and components before beginning assembly. I meticulously check for any damage or missing parts. Correct alignment of components is critical; using measuring tools and levelers ensures that all parts fit accurately and securely. I prioritize using the right fasteners for the materials involved, choosing screws, dowels, or other hardware appropriate to the wood type and its intended use. Over-tightening is avoided to prevent damage; I use a torque wrench or apply appropriate pressure to ensure a snug but not overly stressed connection. Finally, I always perform a stability check after assembly, ensuring that the furniture is sturdy and free from wobble. Any potential safety hazards, such as sharp edges or exposed fasteners, are addressed.

For instance, when assembling a tall bookcase, I carefully ensure the shelves are properly supported and evenly spaced to prevent racking or collapse. I use wall anchors to secure it to the wall, adding a significant safety measure, especially in earthquake-prone regions.

Q 10. Explain your approach to disassembling furniture for relocation.

Disassembling furniture for relocation demands a systematic approach, prioritizing safety and preservation of the components. I begin by carefully documenting the disassembly process, often taking photographs at each step. This aids significantly in reassembly. The order of disassembly is crucial, starting with the less critical components, gradually removing parts that hold the structure together. All hardware is carefully collected and labeled, preventing loss and confusion during reassembly. I always protect the surfaces of the furniture by padding with blankets, bubble wrap, or other protective materials during disassembly, especially delicate areas such as veneers or intricate carvings.

For example, when disassembling a large armoire, I would first remove shelves and drawers, then carefully detach the doors, ensuring hinges are not forced or damaged. I would systematically note how each part was connected, taking pictures as needed. Each component is meticulously wrapped to prevent scratching or damage during transportation.

Q 11. How do you protect furniture during disassembly and reassembly?

Protecting furniture during disassembly and reassembly is vital to maintain its condition. I employ several strategies depending on the furniture’s material and complexity. Furniture surfaces are covered with soft padding such as blankets or moving pads to prevent scratches and dings. Delicate areas like edges, corners, and veneers are given extra protection, potentially using corner protectors or bubble wrap. Hardware is stored in labeled bags or containers to prevent loss or damage. Tools used during disassembly and reassembly are handled carefully to avoid accidental damage to the furniture. In the case of antique or highly valuable pieces, I may consider using specialized protective materials and employing extra caution.

Imagine disassembling an antique dresser with intricate inlay work – I would meticulously wrap each drawer individually in acid-free tissue paper and then bubble wrap, securing them to prevent movement during transport. I’d also pad the corners and edges of the dresser itself with foam padding before wrapping it in a blanket.

Q 12. Describe your experience with power tools used in furniture assembly.

My experience with power tools in furniture assembly is extensive and includes the safe and efficient use of drills (both cordless and corded), impact drivers, sanders, and saws (circular and jigsaw). I’m proficient in selecting the appropriate bits and blades for various materials and tasks, ensuring precision and minimizing damage. I always prioritize safety by utilizing appropriate safety equipment, such as eye protection, hearing protection, and dust masks, especially when working with power tools. I’m familiar with the proper techniques for using each tool, including controlling speed and pressure to avoid damaging the material or causing injury.

For example, when using a drill to create pilot holes before driving screws into hardwood, I use a bit slightly smaller than the screw diameter to prevent splitting the wood. I also adjust the drill speed to a suitable level, reducing the chance of the bit slipping and causing damage or injury.

Q 13. How do you manage time effectively during furniture assembly projects?

Effective time management in furniture assembly hinges on careful planning and organization. I start by thoroughly reviewing the instructions and identifying any potential challenges. I gather all necessary tools and materials before I begin, avoiding interruptions mid-project. I prioritize tasks, tackling the most complex aspects early, making sure to leave ample time for those areas. I maintain a consistent workflow, avoiding distractions and staying focused. I break down large projects into smaller, manageable stages, making the process less daunting and allowing for more efficient tracking of progress. I also frequently check my work against the instructions, identifying and addressing any errors quickly.

Imagine assembling a complex shelving unit – I would first lay out all the parts and hardware, then assemble the frame, followed by installing the shelves. This systematic approach, combined with a realistic schedule, ensures timely and efficient completion.

Q 14. What is your experience with various types of furniture joints (e.g., dowel, mortise and tenon)?

My experience includes a broad range of furniture joints, each with its own strengths and applications. Dowel joints are simple and relatively strong, often used in less-demanding furniture pieces. Mortise and tenon joints, a classic woodworking technique, are significantly stronger and more durable, commonly found in high-quality furniture. I’m familiar with variations such as through tenons, half-lap joints, and dovetail joints, each suited for specific applications. I also understand the use of more modern joinery techniques, like cam locks, pocket holes, and biscuits, which offer speed and efficiency in mass-produced furniture. Understanding the principles of each joint type allows me to choose the optimal method based on the project’s demands and material properties.

For instance, I would use a mortise and tenon joint for a chair leg’s connection to the seat for maximum strength and durability, while I might use dowel joints for assembling a simple bookshelf where strength demands are less critical.

Q 15. How do you handle customer inquiries or complaints related to furniture assembly?

Handling customer inquiries about furniture assembly starts with active listening. I aim to understand their specific concern, whether it’s a missing part, unclear instructions, or a damaged piece. I then calmly guide them through troubleshooting steps, often referencing the manufacturer’s instructions or diagrams. For example, if they’re struggling with a cam lock, I’ll explain the proper insertion technique and offer tips for applying even pressure. If the issue is more complex, like a misaligned joint, I’ll walk them through checking for any potential errors in their assembly steps. If the problem persists, I ensure to document the issue thoroughly and escalate it to the appropriate department for replacement parts or further assistance. Ultimately, the goal is to resolve the issue quickly and efficiently, ensuring customer satisfaction.

For complaints, I maintain a professional and empathetic approach. I validate their feelings, acknowledging their frustration, and then work towards a solution collaboratively. I’ll gather details about the problem, potentially requesting photos or videos to better understand the situation. I then propose solutions, ranging from providing clarification to arranging for a technician to visit if needed. Following up after the issue is resolved ensures the customer feels heard and valued.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with different types of furniture (e.g., wood, metal, plastic).

My experience spans various furniture materials, each presenting unique assembly challenges. Working with wood requires precision and care to avoid damaging delicate pieces. I’m proficient in using various wood joinery techniques, from dowels and cam locks to more intricate mortise and tenon joints. Metal furniture often involves bolts, screws, and nuts, necessitating the use of appropriate tools and techniques to avoid stripping threads. I’m familiar with different types of metal finishes and understand how to handle them to avoid scratching or damage. Plastic furniture is typically simpler to assemble, often using click-together mechanisms or simple screw fastenings. I understand the importance of aligning pieces correctly to ensure a sturdy and aesthetically pleasing final product, paying attention to avoiding breakage given its material properties.

I’ve worked on furniture ranging from simple shelving units to complex, multi-piece bedroom sets, always adapting my approach to the specific materials and construction methods involved.

Q 17. How do you ensure the furniture is assembled according to manufacturer instructions?

Adhering to manufacturer instructions is paramount. Before starting any assembly, I meticulously review the entire set of instructions, including diagrams, parts lists, and safety precautions. I organize all the parts according to the list provided and cross-reference them with the diagrams to ensure I have everything needed. I carefully follow the steps sequentially, making sure each stage is completed correctly before proceeding. If there’s any ambiguity, I pause to thoroughly examine the instructions or contact the manufacturer for clarification. This methodical approach minimizes errors and ensures the final product matches the manufacturer’s specifications.

For example, if the instructions call for a specific type of screw, I make sure to use that precise type to prevent damage or instability.

Q 18. What are your problem-solving skills when faced with unexpected issues during assembly?

Problem-solving is a crucial aspect of furniture assembly. When unexpected issues arise, my approach is systematic. First, I identify the exact problem – is it a missing part, a damaged component, or an assembly error? Then, I carefully review the instructions again, often step-by-step, to see if I’ve missed anything. I might utilize different tools or techniques to address the challenge. For instance, if a screw is stripped, I might try using a larger screw or a different type of fastener. If a part is damaged, I’ll consult the manufacturer’s warranty information for replacement options.

I always prioritize safety and avoid using force that could cause further damage. If I’m unable to resolve the issue independently, I document the problem and seek assistance from more experienced colleagues or the manufacturer.

Q 19. How do you maintain organization and cleanliness during the assembly process?

Maintaining organization and cleanliness is essential for efficient and safe assembly. Before starting, I clear a spacious work area. I sort all parts systematically, often using labeled containers or bags to separate them according to the manufacturer’s instructions. As I work, I keep the area tidy, disposing of packaging materials and removing excess debris regularly. Tools are kept organized and readily accessible, preventing delays and ensuring the workspace remains safe. This not only streamlines the assembly process but also reduces the risk of damaging parts or injuring myself.

For instance, I might use a designated area for discarded packing peanuts, keeping small parts in containers to prevent loss, and wiping down tools and surfaces as I complete each stage. This methodical approach creates a more pleasant and productive working environment.

Q 20. Describe a time you had to troubleshoot a complex furniture assembly problem.

I once encountered a complex assembly problem with a modern, high-end entertainment center. The instructions were poorly written, and the diagrams were confusing. The main challenge involved a concealed mechanism for the doors, which was not clearly illustrated in the manual. Initially, I tried following the instructions literally, but it led to misaligned components and near-damage to the unit. I then decided to systematically take the issue apart, carefully examining each piece and its relation to the others. Using a combination of visual inspection, logic, and trial and error (with careful consideration not to damage parts), I carefully identified the correct alignment for each component within the concealed mechanism. After a few hours of methodical work, and a few temporary fixes to aid visibility, I managed to complete the assembly successfully and even improved on the instructions, detailing the correct process for future use.

Q 21. What is your experience with working independently versus on a team?

I’m comfortable working both independently and as part of a team. Independent work requires self-motivation, strong organizational skills, and effective problem-solving abilities, all of which I possess. Working alone often allows for a more focused and efficient approach to assembly, especially for simpler projects. However, working on a team offers the benefit of shared knowledge and expertise. Teamwork allows for faster assembly of complex pieces and the opportunity to learn from others. In a team setting, I readily collaborate, contributing my skills and assisting my colleagues, always prioritizing efficient workflow and communication. I adapt my approach to the specific needs of the task and the team environment.

Q 22. How do you prioritize tasks when working on multiple furniture assembly projects?

Prioritizing multiple furniture assembly projects requires a systematic approach. I typically start by assessing the urgency of each project, considering deadlines and customer expectations. For example, if one project is for a client moving in next week, it takes precedence over a project with a less pressing deadline. Next, I evaluate the complexity of each project. A large, intricate piece will naturally take longer than a simple bookshelf. Finally, I factor in the resources required – if two projects need the same specialized tool, I’ll schedule them to minimize downtime. I use a project management system, often a simple spreadsheet, to track progress, deadlines, and resource allocation, ensuring optimal workflow and timely completion of all projects.

Think of it like a chef managing multiple dishes – some need immediate attention (the urgently needed project), others can simmer a bit longer (the less urgent one), and all need their ingredients (tools and parts) organized efficiently.

Q 23. What are your preferred methods for organizing tools and parts during assembly?

Organizing tools and parts is crucial for efficient and error-free assembly. My preferred method is a combination of techniques. First, I thoroughly unpack all components, laying them out on a clean, spacious surface like a large workbench or drop cloth. I then carefully group similar parts together—all screws of the same size in one container, all dowels together, etc. I use labeled containers and bags to prevent confusion. My tools are kept in a well-organized toolbox, with each tool having its designated place. This allows me to quickly locate any needed tool without searching. I also use a visual checklist to mark off components as they’re used, minimizing the risk of missing parts. This process resembles a well-stocked kitchen, where every utensil and ingredient is easily accessible and ready to use.

Q 24. Describe your experience with using measuring tapes and other measuring tools accurately.

Accurate measuring is paramount in furniture assembly. I’m proficient in using various measuring tools such as tape measures, rulers, and square levels. I always double-check measurements, especially when dealing with critical dimensions like shelf spacing or leg placement. For example, I may measure a distance three times using different parts of the tape measure to ensure precision. I understand the limitations of each tool and choose the most appropriate one for the task. I also take into account the material’s thickness when making measurements, preventing common errors associated with inaccurate measurements. This meticulous approach ensures that all pieces align perfectly, leading to a strong and aesthetically pleasing finished product.

In one instance, a slight error in measurement could have led to a significant gap between two cabinet doors. By triple-checking my measurements, I prevented this issue and ensured a flawless finish.

Q 25. How do you handle different customer preferences and requests during furniture assembly?

Handling diverse customer preferences is essential. Open communication is key. I always clarify requests upfront, confirming their vision before starting. Some clients prefer a specific assembly sequence or placement of components, while others might have special requests for cable management or additional customizations. I actively listen, ask clarifying questions, and document every unique instruction to ensure I meet their expectations precisely. Flexibility and a customer-centric approach are vital in accommodating individual needs, creating a positive assembly experience.

For instance, one client requested specific placement of their router, requiring modifications to the cable routing. By understanding their needs and adapting my approach, I delivered a finished product that exceeded their expectations.

Q 26. What is your understanding of warranty and liability concerning furniture assembly?

I have a strong understanding of warranty and liability related to furniture assembly. I’m aware that damage caused during assembly may fall under the manufacturer’s warranty or my own liability depending on the circumstances. I carefully inspect all components for pre-existing damage before starting, documenting any issues with photos. I meticulously follow the manufacturer’s instructions to avoid errors leading to damage. I also maintain insurance coverage to protect against unforeseen accidents or damages that may occur during the assembly process. Informing the client about the limitations of the warranty and my role in assembly is crucial for transparency.

Q 27. How do you dispose of packaging materials responsibly after furniture assembly?

Responsible disposal of packaging materials is a top priority. I always separate materials according to local recycling guidelines—cardboard, plastic, Styrofoam, etc. I carefully remove any staples or other metal pieces from cardboard to prevent damage to recycling equipment. I utilize local recycling centers or waste management services for proper disposal, minimizing environmental impact. For larger pieces or materials that can’t be easily recycled, I explore options for donation or reuse to reduce landfill waste. My commitment to responsible disposal reflects my commitment to sustainable practices.

Q 28. Describe your experience with using pneumatic tools in furniture assembly

I have experience using pneumatic tools, such as nail guns and staple guns, in furniture assembly, particularly for projects involving upholstery or wood paneling. These tools significantly speed up the process and increase accuracy when used correctly. Safety is paramount when using pneumatic tools. I always ensure proper ventilation in the workspace and use appropriate safety gear, including eye protection, ear protection, and gloves. I regularly check the air pressure and ensure the tool is in good working condition before use to avoid malfunctions. The increased speed and accuracy afforded by pneumatic tools are invaluable in efficiently completing projects requiring extensive fastening.

For example, using a pneumatic nail gun for attaching fabric to a frame is much faster and more precise than using a hammer and nails, resulting in a cleaner finish.

Key Topics to Learn for Understanding of Furniture Assembly and Disassembly Interview

- Tool Identification and Usage: Understanding the function and safe operation of various tools used in furniture assembly and disassembly (e.g., screwdrivers, wrenches, power drills, etc.). This includes recognizing different types of fasteners.

- Reading Assembly Instructions: Interpreting diagrams, schematics, and written instructions accurately to follow assembly/disassembly procedures effectively.

- Material Recognition and Handling: Familiarity with common furniture materials (wood, metal, particleboard, etc.) and their properties, and understanding appropriate handling techniques to avoid damage.

- Joint Types and Construction: Recognizing different types of furniture joints (e.g., dowel joints, mortise and tenon joints, cam locks) and understanding their strengths and weaknesses.

- Troubleshooting and Problem Solving: Identifying and resolving common assembly issues, such as misaligned parts, stripped screws, or damaged components. This includes developing strategies for efficient problem-solving.

- Safety Procedures: Adherence to safety regulations and best practices to prevent injuries during assembly and disassembly, including proper use of Personal Protective Equipment (PPE).

- Efficient Work Practices: Understanding techniques for optimizing workflow and minimizing assembly/disassembly time, including efficient organization and part management.

- Quality Control: Inspecting assembled furniture for stability, functionality, and overall quality, identifying and addressing defects.

Next Steps

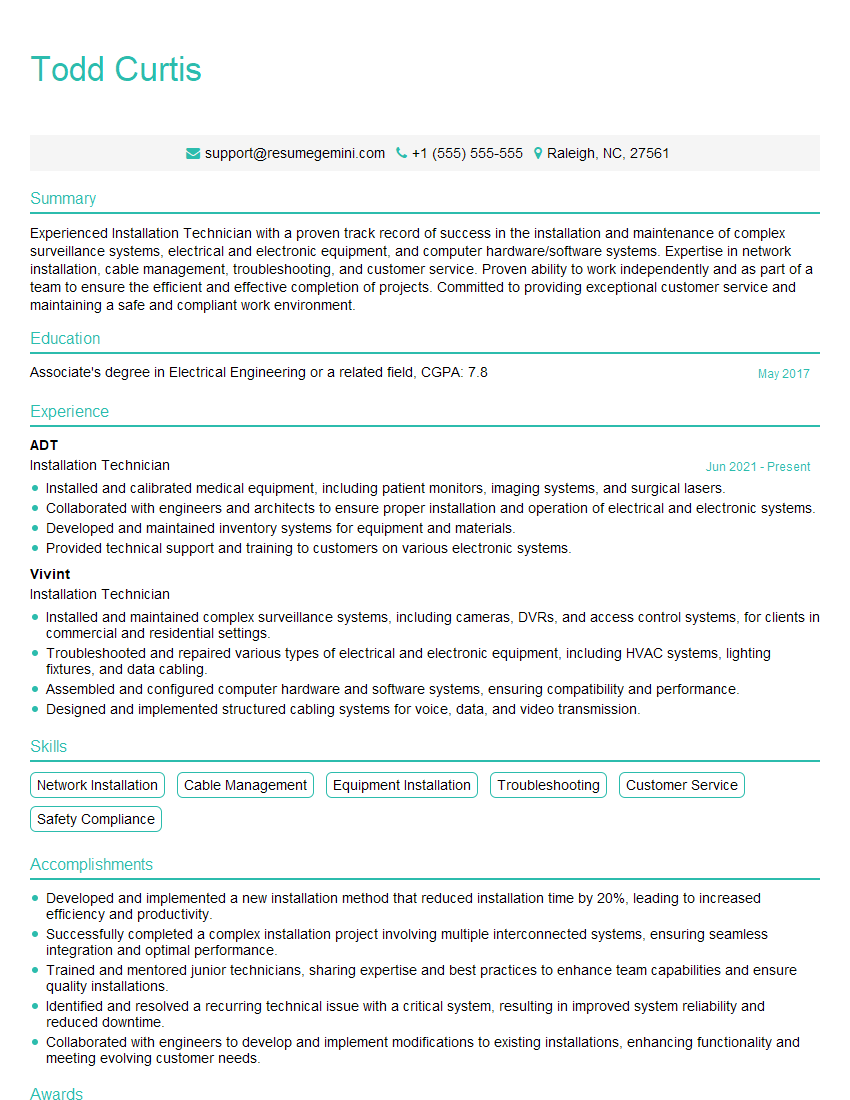

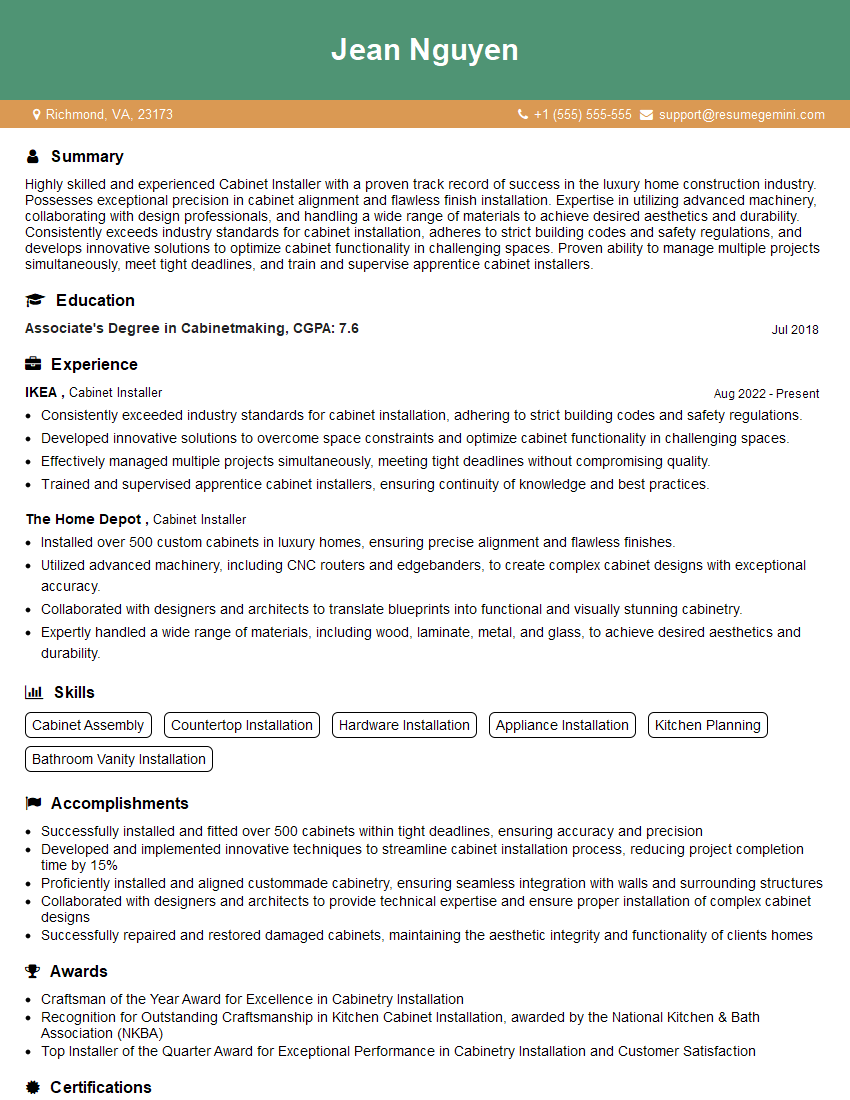

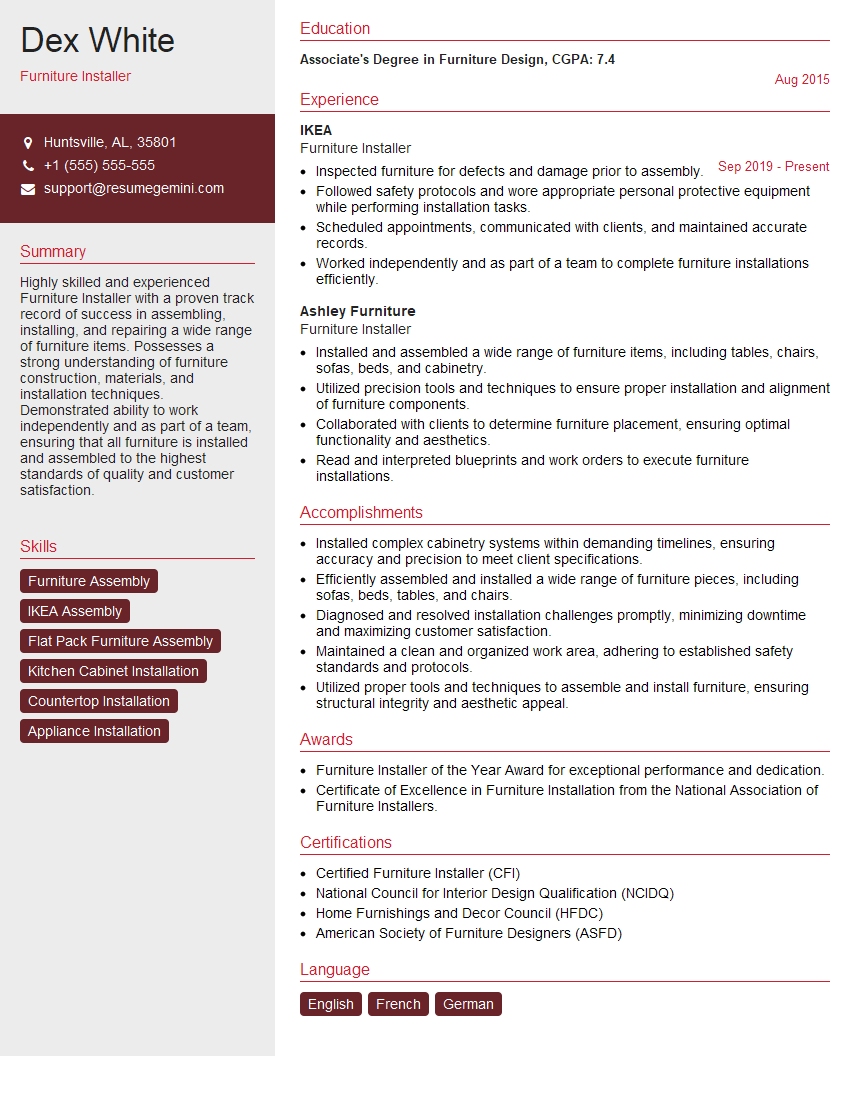

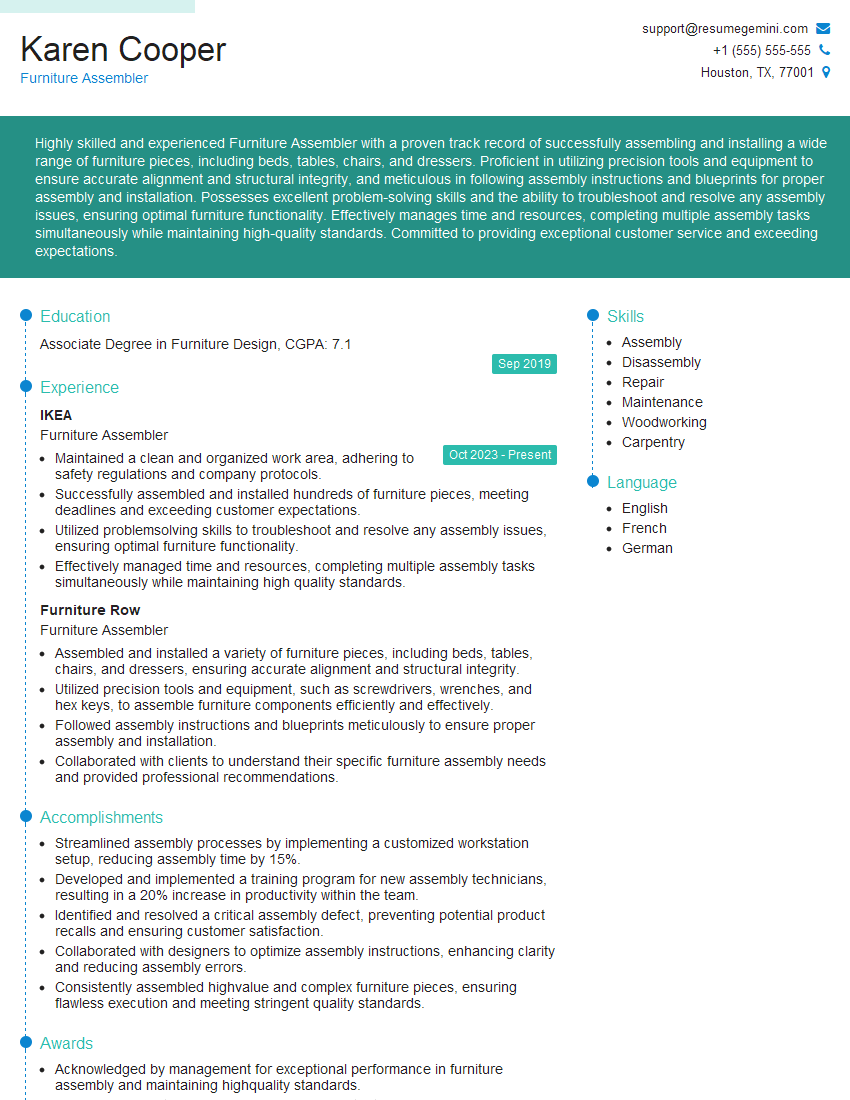

Mastering furniture assembly and disassembly is a highly valuable skill applicable across various industries, demonstrating practical skills, attention to detail, and problem-solving abilities. These are all highly sought-after qualities that can significantly boost your career prospects. To maximize your job search success, create an ATS-friendly resume that clearly highlights your relevant skills and experience. ResumeGemini is a trusted resource to help you build a professional and impactful resume that stands out to potential employers. We offer examples of resumes tailored to showcasing expertise in Understanding of Furniture Assembly and Disassembly to guide you in creating your own.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi I am a troller at The aquatic interview center and I suddenly went so fast in Roblox and it was gone when I reset.

Hi,

Business owners spend hours every week worrying about their website—or avoiding it because it feels overwhelming.

We’d like to take that off your plate:

$69/month. Everything handled.

Our team will:

Design a custom website—or completely overhaul your current one

Take care of hosting as an option

Handle edits and improvements—up to 60 minutes of work included every month

No setup fees, no annual commitments. Just a site that makes a strong first impression.

Find out if it’s right for you:

https://websolutionsgenius.com/awardwinningwebsites

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good