Unlock your full potential by mastering the most common Understanding of Prepress Automation interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Understanding of Prepress Automation Interview

Q 1. Explain the concept of JDF (Job Definition Format) in prepress automation.

JDF, or Job Definition Format, is a crucial XML-based standard in prepress automation. Think of it as a universal language for all the machines and software involved in a print job. Instead of each system needing its own unique instructions, JDF provides a single, standardized description of the job, including everything from the artwork’s specifications to finishing requirements. This allows seamless communication and data transfer between different software and hardware components within a print workflow.

For example, a JDF file might specify the paper size, color profile, number of copies, binding type, and even the finishing instructions (like cutting or folding). This information is then automatically passed along the workflow, ensuring that each machine receives the exact instructions it needs to process the job correctly. This eliminates manual data entry, reduces errors, and speeds up the entire process.

In a real-world scenario, imagine a job going from a design software (like Adobe InDesign) to a RIP (Raster Image Processor) to a printing press. Without JDF, someone would have to manually enter all the job specifications into each system. With JDF, the data flows automatically, reducing the risk of human error and increasing efficiency.

Q 2. Describe your experience with different workflow automation software (e.g., MIS systems).

I have extensive experience with various workflow automation software, including MIS (Management Information Systems) solutions like PrintSmith Vision and Tharstern. These systems are the backbone of prepress automation, managing jobs from order entry to final output. My experience includes implementing these systems, configuring workflows, training users, and troubleshooting issues.

My work with MIS systems has involved tasks such as:

- Customizing workflows to meet specific client needs

- Integrating the MIS with other prepress software (e.g., imposition software, RIPs)

- Developing reporting mechanisms to track production efficiency and costs

- Troubleshooting issues and providing technical support

For example, in one project, I implemented a new MIS system that reduced turnaround time by 15% by streamlining the job approval process and automating the creation of job tickets. The key to success was careful planning, thorough user training, and ongoing monitoring of the system’s performance.

Q 3. How do you ensure color consistency across different printing processes?

Maintaining color consistency across different printing processes is critical for achieving the desired results. This involves a multi-faceted approach:

- Color Management System (CMS): Implementing a robust CMS is fundamental. This involves using ICC profiles to accurately characterize the color capabilities of each device (scanner, monitor, printer, press) in the workflow.

- Proofing: Soft proofing using accurate monitor profiles and hard proofing (e.g., using a calibrated proofing device) are essential for verifying color accuracy before printing.

- Standardized Color Spaces: Working consistently in a standardized color space, like sRGB or Adobe RGB, helps minimize color variations.

- Calibration and Profiling: Regular calibration and profiling of all color-related devices are necessary to maintain accuracy over time.

- Press Calibration: Working closely with the printing press operator to calibrate the press for color accuracy is crucial.

For instance, if a client requires a specific Pantone color, we would use a Pantone color book and a spectrophotometer to measure the color and create an ICC profile ensuring consistent reproduction across different print methods.

Q 4. What are the common file formats used in prepress and their strengths/weaknesses?

Several file formats are common in prepress, each with its strengths and weaknesses:

- PDF (Portable Document Format): A ubiquitous format, excellent for preserving layouts and fonts. Weaknesses include potential for color discrepancies depending on how it’s created and the embedded color profiles.

- TIFF (Tagged Image File Format): A lossless image format ideal for high-resolution images. Can be large in file size.

- JPEG (Joint Photographic Experts Group): A lossy compressed image format, good for smaller file sizes, but unsuitable for print because of compression artifacts.

- EPS (Encapsulated PostScript): A vector-based format often used for illustrations and logos; good for scalability but can be less compatible with some software.

- PS (PostScript): A page description language, often used for complex jobs but less common now due to PDF’s dominance.

Choosing the right format is crucial. For example, I would always prefer TIFF for high-resolution images destined for print, while PDF is more suitable for layout files.

Q 5. Explain your understanding of color profiles (e.g., ICC profiles) and their importance.

Color profiles, especially ICC (International Color Consortium) profiles, are numerical representations of a device’s color characteristics. Think of them as a translator between different devices. An ICC profile describes how a particular device (e.g., monitor, printer, scanner) represents color, allowing for accurate color translation between devices.

For instance, a monitor’s ICC profile tells the computer how the monitor displays colors, while a printer’s ICC profile details how the printer renders colors. By using these profiles, a CMS can convert colors accurately from one device to another, ensuring color consistency across the workflow. Without accurate profiles, the colors on your screen may differ significantly from the final printed output.

In a practical example, I would use the ICC profile of the client’s printer to render the colours correctly and to ensure a reliable soft proof matches the final hard proof.

Q 6. Describe your experience with image editing and preflighting software (e.g., Adobe Acrobat, Photoshop).

I’m highly proficient in Adobe Photoshop and Acrobat, essential tools in prepress. In Photoshop, I routinely perform image retouching, color correction, and image preparation for print. I use Acrobat for preflighting, ensuring files are print-ready by checking for font issues, missing images, low-resolution images, and color management inconsistencies.

Preflighting is a critical step to prevent costly reprints. Using Acrobat’s preflight profiles, I automatically check a variety of parameters that can compromise print quality. For example, I’ve frequently detected and fixed low resolution images before they went to the printing press, significantly saving time and money.

My experience extends beyond basic tasks; I’ve also used automated preflighting workflows to streamline the process for large volumes of files and used scripting to customize preflight checks for specific client needs.

Q 7. How do you handle color separations for different printing techniques?

Color separation is the process of splitting a full-color image into individual color plates (typically Cyan, Magenta, Yellow, and Black – CMYK) for printing. The method varies depending on the printing technique.

- Offset Printing: For offset printing, I’d typically use CMYK separations, creating four separate plates for each color. The process might involve specialized software for optimizing separations and managing dot gain (the expansion of ink dots during printing).

- Digital Printing: Digital printing often doesn’t require explicit color separation as the printer handles the process internally. However, accurate color profiles are crucial to ensure the final output matches the design intent.

- Screen Printing: For screen printing, color separations involve creating individual screens for each color, and the process is often more manual and relies on the skill of the screen printer.

For instance, if we have a job for offset printing requiring Pantone colors, we would create a spot color separation in addition to the standard CMYK separations. This ensures the accurate reproduction of those specific brand colours.

Q 8. Explain the role of trapping in prepress and its practical application.

Trapping in prepress is a crucial technique used to prevent gaps between colors or ink during the printing process. Imagine trying to perfectly align two differently colored pieces of paper – there’s a high chance of a tiny white gap showing through. Trapping ensures that these gaps are minimized or eliminated, resulting in a clean and professional print. It involves intentionally overlapping colors, usually by a very small amount (1-5 points), so that the printed result is seamless.

Practical Application: Consider a logo with thin lines of different colors. Without trapping, these thin lines would likely show gaps between the colors during printing, leading to a flawed logo. Trapping ensures a solid and clean look, even with intricate designs. There are several types of trapping; spread trapping expands the lighter color into the darker one, choke trapping expands the darker color into the lighter color, and mixed trapping uses a combination based on color proximity.

Q 9. What are the different types of printing plates and their uses?

Printing plates are the intermediary between the digital design and the printed product. Different types exist, each optimized for specific printing processes and needs:

- PS Plates (Photosensitive Plates): These are commonly used in offset printing and are created by exposing a photosensitive layer on an aluminum plate to a laser or UV light source. They’re relatively inexpensive and widely used for high-volume printing.

- CTP Plates (Computer-to-Plate): These are also frequently used in offset printing and created digitally, eliminating the need for film. They offer high precision and efficiency, reducing processing time and waste. Various types exist within this category, including thermal and violet CTP plates.

- Flexographic Plates: These are used in flexographic printing, a process commonly used on flexible packaging like bags and labels. They’re usually made from photopolymer and are durable and resilient for printing on non-porous materials.

- Gravure Plates: These are used in gravure printing, a process that uses etched cylinders. They’re ideal for high-volume, high-quality printing on various substrates and known for their ability to produce high-fidelity images.

The choice of plate depends on factors like print run size, printing technique, substrate type, and budget. Higher quality plates offer better image fidelity and longer life but often come with a higher price.

Q 10. How do you troubleshoot common prepress issues, such as missing fonts or incorrect color spaces?

Troubleshooting prepress issues requires a systematic approach. For missing fonts, I would first identify the missing font in the design file (often indicated by warnings in the software). Then, I would either replace it with an available substitute, ensuring it matches the original font’s appearance as closely as possible, or contact the designer to obtain the correct font. If the issue is during output, it may be necessary to embed fonts for reliable rendering on all target systems.

Incorrect color spaces are more complex. The first step is to identify the used color space (e.g., RGB, CMYK) and the expected color space for the intended printing method. A mismatch can lead to significant color discrepancies. Conversion to the correct color space (usually CMYK for offset printing) is often necessary, but this must be done carefully to maintain visual accuracy. Color management tools and profiles are essential to control the conversion process, and a color proof is extremely useful to verify the color before printing.

Q 11. Describe your experience with Computer-to-Plate (CTP) technology.

I have extensive experience with Computer-to-Plate (CTP) technology, having worked with various CTP systems from leading manufacturers, such as Heidelberg, Kodak, and Creo. My experience includes platemaking, workflow integration, and troubleshooting. I’m proficient in managing plate specifications, including screen ruling, resolution, and exposure settings. For instance, on a recent project involving a high-volume print job, we successfully transitioned to a newer CTP system, boosting our throughput by 20% by optimizing plate-making time and minimizing the need for manual intervention. I’m well-versed in troubleshooting issues such as image irregularities, plate defects, and workflow integration problems.

Q 12. Explain your understanding of imposition and its impact on print efficiency.

Imposition is the process of arranging pages of a document for printing on a press sheet. Think of it like creating a puzzle where each piece represents a page, and the entire puzzle fits onto the printing sheet. This is crucial because most printing presses print multiple pages simultaneously on a single sheet to improve efficiency. Efficient imposition minimizes paper waste and maximizes press sheet utilization.

Impact on Print Efficiency: Proper imposition significantly reduces printing costs by maximizing the use of each sheet of paper and decreasing the number of sheets needed for a given print run. It can also significantly reduce makeready time on the printing press. Poor imposition, on the other hand, leads to substantial waste, increased costs, and production delays.

I use specialized software to plan imposition, and my experience lets me optimize the arrangement based on the document’s size, page count, and the press sheet’s dimensions. This ensures minimal waste and maximizes throughput.

Q 13. How do you manage and optimize the prepress workflow for large-scale projects?

Managing and optimizing the prepress workflow for large-scale projects involves careful planning and the use of automation tools. This includes establishing clear project specifications, creating comprehensive checklists, setting up a robust file management system, and using automated workflow software. For instance, we implemented a workflow system that automatically checks files for errors, converts color spaces, and generates printing plates, cutting down on manual intervention and reducing errors. We also use project management software to track progress, deadlines, and resource allocation, ensuring smooth collaboration between designers, prepress operators, and printers.

Communication is key. I work closely with clients to ensure clear expectations and timely feedback throughout the prepress stages. Regular progress reports and project meetings are scheduled to proactively address any issues that may arise.

Q 14. What are some common challenges in prepress automation and how have you overcome them?

Common challenges in prepress automation include integrating different software systems, ensuring data consistency across platforms, and managing the complexity of large-scale projects. One frequent challenge is dealing with legacy systems that don’t integrate well with newer automation tools. I’ve overcome this by creating custom scripts and workflows to bridge the gap between the old and new systems, ensuring smooth data flow.

Another challenge is maintaining data integrity and consistency throughout the workflow. Implementing robust quality control checks and using standardized file formats helps address this. For example, we enforce strict file naming conventions and implement automated checks for color profiles, resolution, and other crucial parameters before the files proceed to the next stage. These measures minimize errors and ensure high-quality results consistently.

Q 15. What are your experiences with different RIP software and their features?

My experience encompasses a wide range of RIP (Raster Image Processor) software, including industry-leading solutions like Adobe Acrobat, Esko Suite, and others depending on the specific printing needs. Each RIP offers unique features tailored to different printing processes and output devices.

- Adobe Acrobat: Excellent for preflighting and creating high-quality PDFs for digital printing. Its features include advanced color management, trapping, and imposition capabilities.

- Esko Suite: A comprehensive suite ideal for larger print operations, offering advanced features such as automated color separation, preflighting, imposition, and workflow automation. I’ve utilized this extensively for large-format print jobs and packaging projects, leveraging its automation capabilities to dramatically improve efficiency.

- Other RIPs: I’m also familiar with RIP software specific to particular print technologies such as those used for screen printing or large-format inkjet systems. The selection often depends on the specific requirements of the job and the printing hardware involved.

Beyond the core functionality of rasterizing images, these RIPs also offer crucial features such as color profile management (ensuring consistent color across various devices), halftoning algorithms (optimizing the appearance of continuous-tone images on printing presses), and advanced proofing options (allowing for accurate visual representation of the final printed output before actual production).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure the accuracy and quality of prepress output?

Ensuring accuracy and quality in prepress involves a multi-stage process. It starts with meticulous file preparation and continues through rigorous quality checks at every step.

- Preflighting: Before any processing, I conduct thorough preflight checks using software like Acrobat Pro or Esko’s preflight tools to identify potential problems such as missing fonts, low-resolution images, color inconsistencies, and other errors that can impact the final print output. This proactive approach significantly reduces the risk of costly reprints.

- Color Management: I utilize ICC profiles to accurately translate color data between different devices. This ensures the colors seen on screen accurately reflect the final printed product. This process includes carefully calibrating and profiling monitors and printers.

- Proofing: Soft proofs are reviewed meticulously on calibrated screens, followed by hard proofs (physical samples) for critical jobs. Soft proofing allows for a quick evaluation, while hard proofing provides the closest representation of the final printed piece.

- Imposition and Trapping: Careful imposition ensures correct page order and alignment on the final sheet. Trapping is used to prevent gaps between colors and ensure sharp transitions in the printed image.

Addressing issues early in the process is vital. A methodical approach, utilizing a checklist, and collaboration with the design team are essential to prevent errors that may only become apparent at the final print stage.

Q 17. Explain your understanding of PDF workflows and best practices.

PDF workflows are the backbone of modern prepress. A well-structured PDF workflow ensures efficient communication, accurate color representation, and consistent results.

- PDF/X Standards: Adherence to PDF/X standards is crucial for reliable color and data exchange. Different PDF/X versions cater to different printing needs. I ensure that the appropriate standard is used based on the print method.

- Embedding Fonts and Images: I always embed all necessary fonts and images into the PDF to prevent font substitution or missing image issues on the printer’s end. This ensures consistency across various platforms.

- High-Resolution Images: Using high-resolution images at the appropriate resolution for the intended printing method is critical. Using low-resolution images can result in significant loss of detail and quality during printing.

- Compression: Proper use of compression methods allows for efficient file sizes without compromising image quality. I carefully balance the need for small file sizes with the preservation of image detail.

- Preflight Checks: Regular preflight checks throughout the PDF workflow ensure early detection of potential issues, saving time and resources.

In practice, I often work with clients to establish a consistent workflow ensuring consistent results and minimizes problems down the line.

Q 18. How do you collaborate effectively with designers and printers during the prepress process?

Effective collaboration with designers and printers is critical to a successful prepress workflow. Clear communication and a shared understanding of the project requirements are paramount.

- Regular Communication: Consistent updates, feedback sessions, and clear communication channels (e.g., email, project management software) are crucial. I make sure to be available to answer questions and address concerns promptly.

- Design Specifications: Collaborating with designers early to establish clear specifications, such as color profiles, image resolutions, and bleed requirements, ensures the design is suitable for print. I provide guidance on best practices for print-ready artwork.

- Proof Approval Processes: Implementing a clear proof approval process, including digital soft proofs and physical hard proofs, ensures everyone agrees on the final output before proceeding to print.

- Printer Consultation: Regular communication with the printer ensures the files are compatible with their equipment and processes. This avoids last-minute surprises and potential problems during the printing stage.

Open communication and a collaborative spirit are key to successfully navigating the prepress process and ensuring a smooth and efficient production process.

Q 19. Describe your experience with automated quality control checks in prepress.

Automated quality control (QC) checks are invaluable in prepress for ensuring accuracy and consistency. Many RIPs and prepress software packages incorporate automated QC features.

- Automated Preflight: Software automatically checks for missing fonts, low-resolution images, color issues, and other common problems. This dramatically reduces manual intervention, leading to increased efficiency and accuracy.

- Color Verification: Software can automate color profile verification, ensuring consistency between the digital and printed output.

- Imposition Verification: Automated checks can validate the accuracy and alignment of imposed pages, preventing misprints and wasted materials.

- Trap Verification: Software can automatically identify and highlight potential trapping issues, enabling correction before printing.

For instance, in one project involving hundreds of pages, automated preflighting saved numerous hours of manual review, avoiding a potential delay in project delivery.

Q 20. What is your experience with MIS systems and their integration with prepress workflows?

Management Information Systems (MIS) are crucial for integrating and streamlining prepress workflows. An effectively integrated MIS system provides real-time tracking of jobs, improves resource allocation, and reduces manual data entry.

- Job Tracking: MIS systems track jobs from inception to completion, providing insights into progress, bottlenecks, and potential delays.

- Cost Estimation: They allow for accurate cost estimation and tracking, providing valuable data for budgeting and profitability analysis.

- Automated Data Entry: Integration with prepress software reduces the need for manual data entry, minimizing errors and streamlining the process. This allows for automatic transfers of key job information between systems.

- Reporting and Analytics: MIS systems generate comprehensive reports and analytics, providing crucial data for process improvement and decision-making.

In my previous role, integrating our prepress system with the MIS resulted in a 20% reduction in turnaround time and a significant improvement in overall efficiency.

Q 21. How do you handle version control and asset management in a prepress environment?

Version control and asset management are crucial for maintaining organization and preventing errors in a prepress environment. This is particularly important in collaborative projects where multiple people may be working on the same files.

- Version Control Systems: Employing version control software (like Git, though not directly in prepress, it’s a crucial component in managing design files) allows for tracking changes, reverting to previous versions if needed, and collaborating efficiently.

- Digital Asset Management (DAM): Using a DAM system allows for centralized storage, organization, and retrieval of all project assets (images, fonts, documents). This ensures everyone is working with the most up-to-date versions.

- Metadata Tagging: Consistent metadata tagging of assets allows for easy searching and retrieval. This improves workflow efficiency and reduces the time spent searching for specific files.

- Workflow Automation: Integrating version control and asset management with prepress automation software streamlines workflows and minimizes errors. This allows the automated transfer and tracking of changes.

Without a proper version control and asset management system, it is very easy to end up with multiple versions of a file, increasing the risk of using the wrong version during the production process.

Q 22. Explain your understanding of print finishing processes and how they relate to prepress.

Print finishing processes are the final steps in the printing workflow, transforming the printed sheets into the desired end product. This includes operations like cutting, folding, binding, laminating, and more. Prepress, on the other hand, encompasses all the steps that prepare the files for printing, ensuring they are correctly formatted and ready for the press. The two are intrinsically linked because the choices made during prepress directly impact the feasibility and efficiency of finishing. For example, the imposition (arrangement of pages on a sheet) in prepress determines how the sheet will be cut and folded in finishing. Poor prepress planning can lead to costly errors and delays in finishing. Consider a booklet: The prepress stage dictates the page order and the imposition to create a press sheet which then directly influences the final folding and binding stages. Incorrect imposition in prepress could lead to pages being out of order in the final booklet, necessitating costly reprint.

Q 23. Describe a time you had to solve a complex prepress problem. What was your approach?

In a previous role, we faced a complex issue with a client’s large-format poster design. The client provided high-resolution images, but the file sizes were significantly larger than the press could handle. This would result in extremely slow processing times and potential for errors. My approach was systematic: First, I thoroughly analyzed the file structure and image resolution, identifying the bottlenecks. I then explored different solutions, including image compression techniques without sacrificing print quality. I tested several different compression methods, measuring file size and image quality changes. I presented the client with these options, explaining the trade-offs between file size, print quality, and processing time. We ultimately agreed on a compression strategy that minimized file size without noticeably impacting image quality on the final print. This involved using lossy compression techniques, carefully choosing the level of compression and closely monitoring print quality. Successful resolution required strong communication, technical expertise, and a focus on achieving the client’s expectations while working within the capabilities of our print technology.

Q 24. What are your preferred methods for ensuring consistent quality control throughout the prepress workflow?

Consistent quality control is paramount in prepress. My preferred methods involve a multi-layered approach. Firstly, I implement rigorous preflight checks using automated software to catch potential issues like missing fonts, incorrect color profiles, and low-resolution images early on. Secondly, I employ a visual proofing process, meticulously reviewing every design element for accuracy and consistency before sending files to the press. This includes both soft proofs (on-screen) and hard proofs (printed samples). Thirdly, a standardized workflow with clear checkpoints and approval processes is crucial. This ensures that every step is documented and reviewed, leaving an audit trail. Finally, a detailed color management system is implemented, using profiles to ensure color accuracy across various devices and stages of production. This reduces the risk of color discrepancies between the digital file and the final printed output. These combined efforts significantly reduce the likelihood of errors and ensure a consistent, high-quality final product.

Q 25. How familiar are you with different types of printing presses and their prepress requirements?

I’m very familiar with various printing presses, including offset, digital, flexographic, and screen printing. Each has unique prepress requirements. Offset printing, for instance, necessitates the creation of plates, demanding specific file formats and resolutions. Digital printing is more flexible but requires careful attention to color profiles and file optimization. Flexographic printing needs specific artwork considerations for screen ruling and halftone dot shapes. Screen printing requires artwork tailored for screen creation and the limitations of the process. My experience encompasses working with various prepress software and workflows optimized for these diverse printing methods. Understanding these nuances is crucial for ensuring the print job’s success and avoiding costly mistakes. For example, you wouldn’t use the same prepress settings for a high-quality fine art print intended for offset lithography as you would for a simple promotional leaflet going through a digital printer. Understanding these nuances is a crucial aspect of effective prepress.

Q 26. What are your strategies for minimizing errors and maximizing efficiency in prepress production?

Minimizing errors and maximizing efficiency involves a combination of strategies. Firstly, automation is key. Implementing automated preflight checks, imposition software, and workflow systems drastically reduces manual intervention and the chance of human error. Secondly, standardized templates and style guides create consistency and reduce the need for repeated decisions. Thirdly, a robust training program for prepress operators ensures everyone understands the workflow and quality standards. Regularly scheduled quality checks and audits are essential to identify and address potential problems before they escalate. Fourthly, utilizing version control systems allows for efficient tracking of file changes and prevents accidental overwrites. Implementing these measures leads to a smoother, more efficient workflow with fewer errors. Think of it like building a house: A standardized plan and skilled workers produce a superior result compared to an improvised approach with unpredictable outcomes.

Q 27. How do you stay updated on the latest technologies and trends in prepress automation?

Staying updated is an ongoing process. I actively participate in industry conferences and webinars, attend workshops, and read trade publications like Printing Impressions and WhatTheyThink. I follow key industry influencers and companies on social media platforms like LinkedIn. Membership in professional organizations provides access to cutting-edge information and networking opportunities. I also dedicate time to online courses and tutorials, focusing on software updates and emerging technologies. Regularly testing new software and hardware is also part of this strategy. This ensures I maintain a thorough understanding of best practices and emerging trends in prepress automation, enabling me to adopt the most efficient and effective technologies.

Q 28. Describe your experience with implementing new prepress technologies or workflows.

I’ve been involved in several successful implementations of new prepress technologies. One example is the transition from a manual imposition system to an automated one using a specialized software package. This significantly reduced turnaround time and the risk of errors associated with manual imposition. The process involved initial training for the team, testing the software with sample files, and developing standardized workflows to integrate the new software into our existing system. We carefully monitored performance metrics during and after implementation. The result was a significant improvement in efficiency and accuracy. Another example is integrating a new color management system, which improved color consistency across different devices and platforms. Implementing new technologies requires careful planning, thorough training, and monitoring of the results, ensuring a smooth transition and maximum benefit from the investment. Thorough communication with the team and meticulous planning are crucial for a successful integration of any new workflow or technology.

Key Topics to Learn for Understanding of Prepress Automation Interview

- Workflow Automation: Understanding the different stages of prepress automation, from file reception to platemaking, and the software and hardware involved. Consider the benefits and challenges of various automation solutions.

- Color Management: Mastering color profiles, color conversion processes (e.g., CMYK, RGB, spot colors), and ensuring color consistency across different print processes. Be prepared to discuss practical color correction techniques.

- File Preparation and Pre-flighting: Deep dive into file formats (PDF, TIFF, etc.), image resolution, trapping, and the importance of pre-flighting to identify and correct potential printing errors. Discuss different preflighting software and their capabilities.

- Proofing and Quality Control: Understanding different proofing methods (soft proof, hard proof), their applications, limitations and how to assess print quality. Be ready to discuss quality control procedures and best practices.

- Digital Asset Management (DAM): Discuss the role of DAM systems in managing and organizing prepress assets, improving workflow efficiency, and reducing errors. Be familiar with different DAM solutions and their features.

- Print Production Technologies: Gain a solid understanding of various printing technologies (offset, digital, etc.) and how automation integrates with each. Be prepared to discuss the advantages and disadvantages of different technologies.

- Problem-solving and Troubleshooting: Practice identifying and resolving common prepress issues, such as color discrepancies, file format problems, and workflow bottlenecks. Develop a structured approach to troubleshooting.

Next Steps

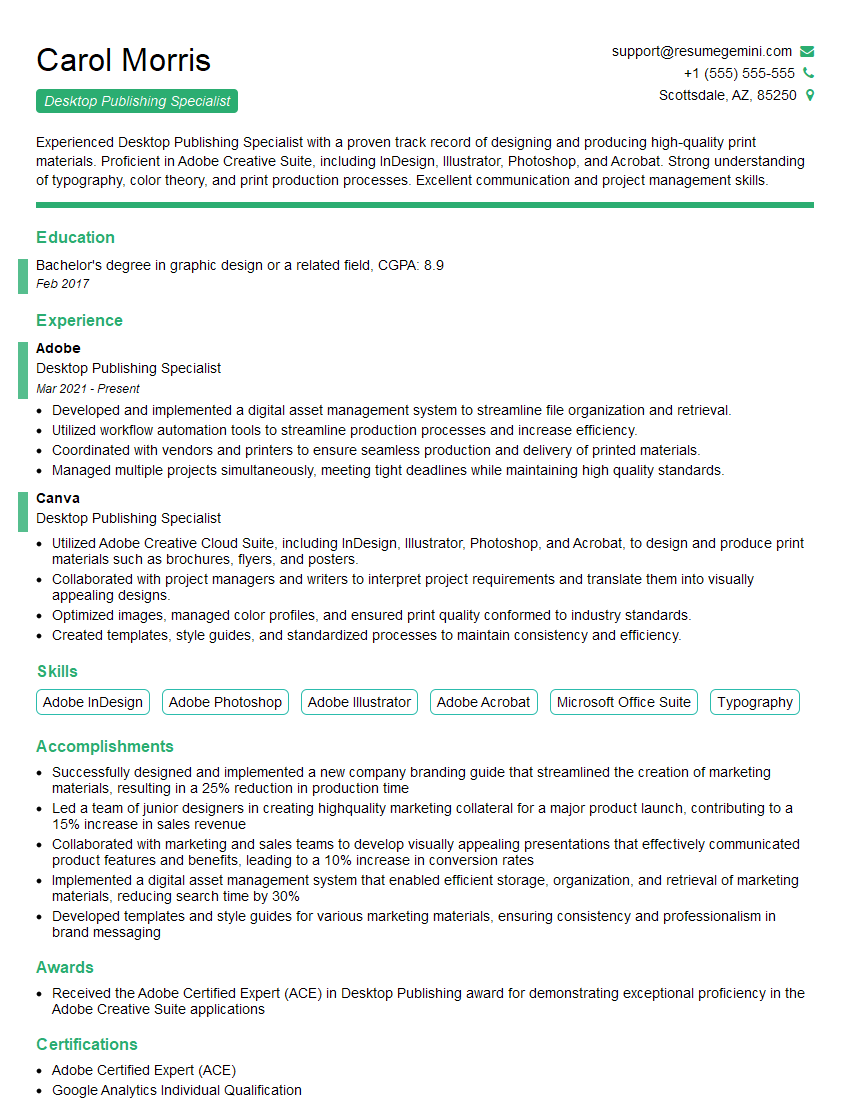

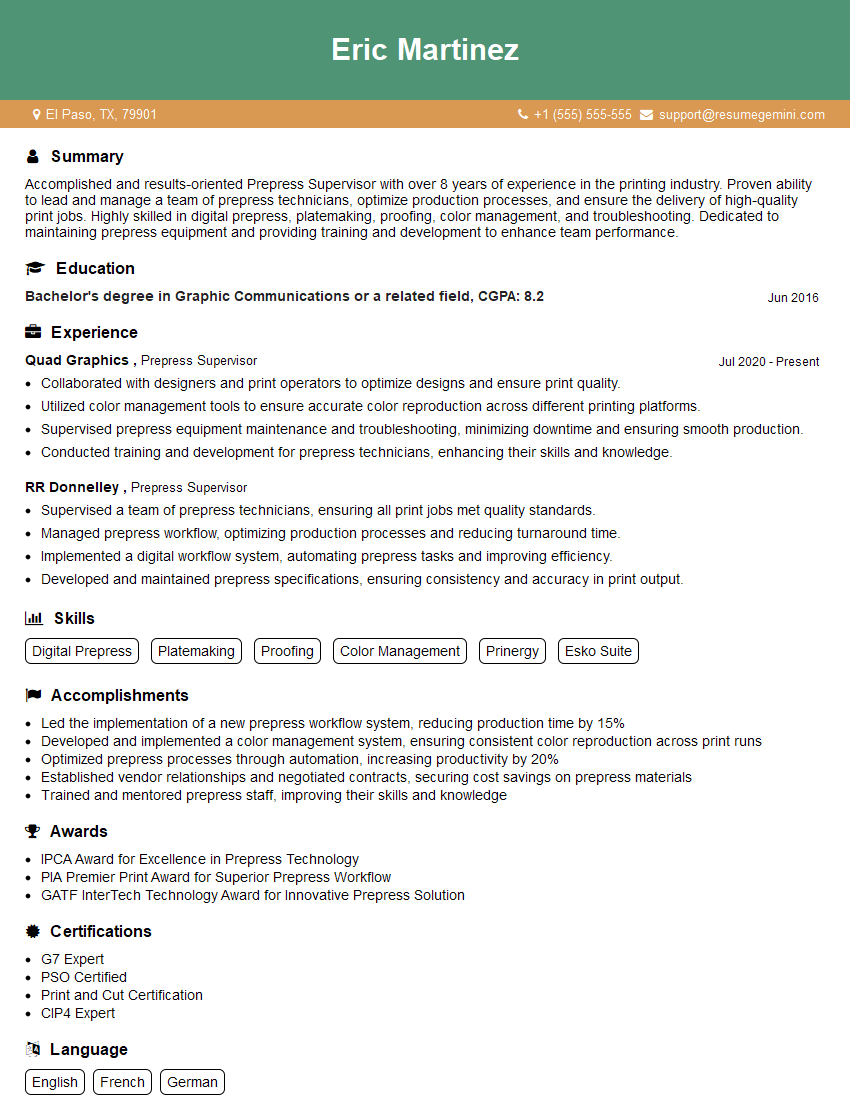

Mastering prepress automation is crucial for career advancement in the printing and publishing industries, opening doors to higher-paying roles and greater responsibility. A well-crafted resume is your key to unlocking these opportunities. An ATS-friendly resume, optimized for Applicant Tracking Systems, significantly increases your chances of getting noticed by recruiters. We strongly recommend using ResumeGemini to build a professional and effective resume that showcases your skills and experience in Understanding of Prepress Automation. ResumeGemini provides examples of resumes tailored specifically to this field, giving you a head start in crafting a compelling application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good