Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Understanding of Prepress Standards and Protocols interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Understanding of Prepress Standards and Protocols Interview

Q 1. Explain the importance of color profiles (e.g., ICC profiles) in prepress.

Color profiles, specifically International Color Consortium (ICC) profiles, are crucial in prepress because they act like a translator for colors between different devices. Think of it like this: your monitor displays colors using its own unique method, your printer uses a different one, and each has its own interpretation of what, say, ‘Pantone 185 C’ actually looks like.

An ICC profile is a small file that contains a mathematical description of a device’s color space. It helps ensure that when you design something on your screen, the colors will be accurately represented when printed. Without a profile, the colors might appear significantly different on screen versus the final print, leading to costly reprints and dissatisfied clients.

For example, a printer might have a specific ICC profile for their press, and designers should embed the same or a compatible profile into their files. This ensures the colors are translated correctly from the digital space to the printing process. Ignoring color profiles leads to frustrating color shifts, making the final product dramatically different from the design intent.

Q 2. Describe the process of trapping in prepress and its significance.

Trapping in prepress is a technique used to prevent unwanted gaps or white lines from appearing between two adjacent colors during printing. These gaps can happen because the printing plates for each color aren’t perfectly aligned. Trapping compensates for this misregistration by slightly overlapping the colors. Imagine two colored blocks next to each other—trapping ensures that the edges of those blocks slightly extend into each other, preventing a visible gap.

There are different types of trapping, including spread trapping (where the lighter color spreads into the darker color) and choke trapping (where the darker color is choked, or reduced, to overlap the lighter color). The choice of trapping method depends on the color combination and the printing process.

The significance of trapping is huge; it ensures a clean, professional print finish. Without trapping, the misregistration common in printing could result in a final product that is visually unacceptable and compromises the integrity of the design.

Q 3. What are the different types of color separations, and when would you use each?

Color separations are the process of breaking down a full-color image into individual color plates, typically cyan (C), magenta (M), yellow (Y), and black (K), used in CMYK printing. There are a few variations depending on the needs:

- CMYK Separation: The standard four-color process, used for the vast majority of full-color printing. It’s cost-effective and suitable for most applications.

- PMS (Pantone Matching System) Separation: Uses spot colors, where specific pre-mixed inks are identified by Pantone numbers. This is excellent for critical color matching, such as corporate branding or when accuracy is paramount, but it’s more expensive than CMYK.

- Monochromatic Separation: Used for printing in a single color, like black and white or a specific spot color. It’s simple, economical and perfect for projects requiring less color.

Choosing the right separation depends on the project’s requirements. If precise color matching is crucial, use PMS. For large print runs where cost is a factor, CMYK is preferred. Monochromatic separation is ideal for simplicity and cost-effectiveness.

Q 4. Explain the difference between CMYK and RGB color spaces.

CMYK and RGB are two different color models used in different contexts. RGB (Red, Green, Blue) is an additive color model used for screens (monitors, TVs). It works by combining different intensities of red, green, and blue light to create a wide range of colors. The more light added, the brighter the color gets.

CMYK (Cyan, Magenta, Yellow, Black) is a subtractive color model used for printing. It works by subtracting colors from white light reflected off the paper. Ink is laid down, and the colors absorbed by the ink remove elements from the light reflected back, resulting in the perceived color. The more ink laid down, the darker the color gets.

The key difference is how they generate colors. RGB adds light to achieve color, while CMYK subtracts light from white to produce color. This fundamental difference means that a color that looks perfect on a screen may not match perfectly when printed, highlighting the importance of color management and profiles.

Q 5. What are some common prepress file formats (e.g., PDF/X, TIFF)? Discuss their suitability for different print processes.

Several file formats are commonly used in prepress, each with its strengths and weaknesses:

- PDF/X: A standardized PDF format specifically designed for prepress. Different PDF/X versions exist (e.g., PDF/X-1a, PDF/X-4), each with varying levels of features and color management capabilities. PDF/X is widely accepted across different print processes and is ideal for preserving the integrity of the design data.

- TIFF: Tagged Image File Format offers high image quality and supports various color spaces. It’s commonly used for images to be integrated into larger documents, but it can result in larger file sizes compared to PDF/X.

- JPEG: While commonly used for online images, it’s generally not recommended for prepress due to compression artifacts that can degrade print quality. It is also lossy, causing data loss each time the file is saved.

The suitability of a format depends on the print process. PDF/X is a universal choice due to its standardization. TIFF is often used for high-resolution images. For offset printing, PDF/X is generally preferred, while high-resolution TIFF might be useful for specific print elements. For digital printing, PDF/X is often the ideal choice for seamless workflow.

Q 6. How do you ensure color consistency across different print runs?

Maintaining color consistency across different print runs is paramount for brand consistency and quality control. Here’s a multi-pronged approach:

- Color Standards: Establish a clear color standard, using Pantone or other industry-recognized systems, right from the design phase.

- ICC Profiles: Employ consistent ICC profiles throughout the workflow—from design to print—to ensure color accuracy between different devices.

- Proofing: Regularly use calibrated proofs (e.g., soft proofs or hard proofs) to visually verify color accuracy before the main print run. Soft proofs simulate the appearance on specific output devices, while hard proofs offer a physical representation.

- Print Specifications: Create detailed print specifications that include color management settings, paper type, and ink profiles, allowing the printer to maintain consistent settings for every run.

- Color Control Strips: Include color control strips on each printed sheet to monitor the consistency of the color throughout the print run. This gives a visual reference for detecting any color shifts.

By consistently following these procedures, color variations between print runs can be minimized, ensuring high-quality and consistent output.

Q 7. Describe your experience with preflighting and quality control checks in prepress.

Preflighting and quality control are vital aspects of my prepress workflow. Preflighting is essentially a pre-press check that automatically verifies a file’s suitability for printing. I use dedicated preflighting software to perform checks for things like:

- Color Space: Ensuring the correct color space (CMYK) is used.

- Resolution: Verifying sufficient image resolution for sharp output.

- Fonts: Checking for missing or embedded fonts.

- Overprint: Examining and correcting unintended overprinting issues.

- Bleed: Confirming that sufficient bleed is included for trimming.

Beyond preflighting, I conduct manual quality control checks, involving visual inspection of the final file or a proof to identify any errors that preflighting might have missed. These might include subtle color discrepancies, unwanted artifacts, or design inconsistencies. This combination of automated and manual checks ensures that errors are minimized and the print ready files are up to the required standards, preventing costly reprints and ensuring client satisfaction.

Q 8. Explain the concept of imposition and its importance in print production.

Imposition is the process of arranging pages of a document on a printing sheet so that, after printing and folding, the pages fall in the correct order. Think of it like arranging puzzle pieces – each piece (page) needs to be placed precisely to create the final picture (printed document). It’s crucial in print production because it dictates how efficiently the printing press uses materials and ensures the final product is correctly bound and sequenced.

For example, a 16-page booklet might be imposed so that two pages are printed on each side of a sheet of paper. After printing, the sheet is folded in half, then in half again, resulting in the correctly ordered booklet. Incorrect imposition leads to pages out of order or missing pages, significantly impacting the final product’s quality and increasing production costs due to reprints.

Different imposition schemes exist for various page counts and binding methods (e.g., saddle stitch, perfect bound). Software like imposition tools within Adobe InDesign, or dedicated imposition software, helps create these arrangements accurately and efficiently.

Q 9. What are the key considerations for preparing files for different printing methods (e.g., offset, digital)?

Preparing files for different printing methods requires careful attention to detail, as each process has unique specifications. Offset printing, for instance, benefits from high-resolution images (at least 300 dpi) and CMYK color mode. It’s crucial to ensure proper color management, using a calibrated monitor and profile matching to get the desired result. File formats like PDF/X-1a are usually preferred for offset to guarantee color consistency and avoid potential problems during the process.

Digital printing, on the other hand, is often more forgiving in terms of resolution, though higher resolution remains beneficial for quality. While CMYK is still commonly used, RGB can also be accommodated, but color conversion should be carefully managed. Specific file formats recommended vary across digital printers, but PDF is widely used. Understanding the printer’s capabilities and limitations is paramount.

In essence, the key considerations boil down to resolution, color mode, color management, file format, and a thorough understanding of the specific printer’s requirements. Always communicate with the printer early in the process to discuss file specifications and eliminate potential issues.

Q 10. How do you handle color discrepancies between the digital proof and the final printed output?

Color discrepancies between digital proofs and the final print can be frustrating, but are often resolvable. The most common cause is differences in color profiles and rendering intents. Digital proofs are viewed on a screen, which uses RGB, while print uses CMYK. The conversion between these color spaces can introduce variations. In addition, the paper type, ink, and printing process itself influence the final color appearance.

To handle these discrepancies, a robust color management workflow is essential. This involves using calibrated monitors with accurate color profiles, using appropriate color profiles during file conversion, and specifying the correct rendering intent (e.g., perceptual, absolute colorimetric) for the conversion from RGB to CMYK. Proofing with a high-quality color proof (like a soft proof or a hard proof using the same paper stock and inks as the final print) is also strongly recommended to minimize surprises. If discrepancies still exist, communication with the printer is critical – often, small adjustments to the CMYK values can refine the color matching.

Q 11. What is a CIP3 file, and how is it used in prepress workflows?

A CIP3 file is a crucial element in prepress workflows that contains all the necessary information for the imposition, trapping, and other prepress processes. Think of it as a comprehensive instruction manual for the printer. It’s an XML-based file format that stores metadata about the job, including page geometry, color information, and other specifications. This ensures consistency and automation throughout the printing process.

The CIP3 file is generated by prepress software and is used by other systems like the RIP (Raster Image Processor) and the printing platesetter. It eliminates the need for manual data entry and reduces the chances of errors. For example, a CIP3 file might specify the exact location of each page on the printing sheet, the trapping parameters to prevent gaps between colors, and the type of printing plate to be used. This detailed information allows for accurate and efficient production of high-quality prints.

Q 12. Describe your experience with various RIP software and their settings.

My experience encompasses various RIP software including Harlequin, Agfa Apogee, and Kodak Prinergy. Each RIP offers a unique set of features and settings to optimize print quality and workflow. For instance, Harlequin is known for its robust color management capabilities and high-speed processing. Agfa Apogee excels in its ability to manage complex jobs and integrate seamlessly with other prepress systems. Kodak Prinergy offers advanced features for workflow automation and color optimization.

Settings within the RIP software are critical for controlling factors like screen frequencies, halftoning algorithms, and color profiles. These settings directly affect the final printed output’s quality, sharpness, and color accuracy. The optimal settings depend on several variables like the type of printer, the substrate (paper), and the desired print quality. For example, a higher screen frequency might be used for fine detail, but at the cost of potential moiré patterns if not carefully managed. I have extensive experience fine-tuning these settings to achieve optimal results for diverse printing scenarios.

Q 13. How do you handle images with low resolution in prepress?

Handling low-resolution images in prepress is a challenge. Using low-resolution images directly can lead to noticeable pixelation, blurring, and other artifacts in the final print. The best approach is to avoid using low-resolution images altogether. Ideally, images should be sourced or created at the required resolution (at least 300 dpi for offset printing).

If a low-resolution image is unavoidable, some strategies can mitigate the damage. One is intelligent upscaling, using software that attempts to fill in missing detail rather than simply enlarging pixels. However, this can only go so far; severe upscaling will still result in a less-than-ideal image quality. Another strategy is to use the low-resolution image strategically—avoiding large, prominent uses, confining it to smaller areas, or using blurring effects to mask imperfections.

The key is open communication with the client. It’s essential to explain the limitations of using low-resolution images and explore alternative solutions. Often, reshooting or sourcing higher-quality images is the most effective solution.

Q 14. What are the different types of printing plates used in the prepress process?

Several types of printing plates are used in the prepress process, each with its strengths and weaknesses. The choice depends on factors such as the printing process (offset, flexo, etc.), the length of the print run, and budgetary constraints.

- PS Plates (Photosensitive Plates): These are traditional plates that use light-sensitive materials to create the image on the plate. They’re commonly used in offset printing and are relatively cost-effective for longer print runs.

- CTP Plates (Computer-to-Plate): These plates bypass the traditional film stage, allowing the image to be directly written onto the plate using a laser or other imaging systems. CTP plates are more efficient and precise, reducing errors and turnaround times. Different types of CTP plates exist, including thermal plates and violet plates, each suited for specific printing presses.

- Flexographic Plates: Used in flexographic printing, these plates are typically made of photopolymer materials and are designed for flexible packaging or high-speed printing.

The selection of the appropriate plate is crucial for optimizing print quality, efficiency, and cost-effectiveness. Factors to consider include plate resolution, durability, and the printing press’s compatibility. Proper plate handling and storage are also essential to prevent damage and ensure optimal print performance.

Q 15. Explain your understanding of PDF/X standards and their variations.

PDF/X standards are a set of specifications that ensure reliable color reproduction and data exchange between prepress and printing. They define how a PDF file should be structured to prevent problems during the printing process. Think of them as a universal language for print production. Different variations cater to different needs and printing methods.

- PDF/X-1a: This is a baseline standard, suitable for simple documents with embedded fonts and color profiles. It’s great for documents with predominantly spot colors.

- PDF/X-3: Handles more complex documents, allowing for transparency and more advanced color management. It’s ideal for documents with images and gradients.

- PDF/X-4: Builds on PDF/X-3, adding support for features like ICC profiles and embedded JPEG 2000 images. It improves efficiency and image quality.

- PDF/X-5: Offers various levels of compliance, including support for metadata and security features, making it a versatile choice for complex, secure print jobs.

Choosing the right PDF/X standard depends on the complexity of your document and the capabilities of your printing equipment. A mismatch can lead to issues like unexpected color shifts or font substitution during the printing process. For instance, using PDF/X-1a for a document with complex transparency effects will likely result in errors during printing.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure the accuracy of fonts and text in prepress?

Ensuring font accuracy is crucial for a professional print job; imagine a wedding invitation with the wrong font! My approach involves several key steps:

- Font Embedding: I always embed all necessary fonts within the PDF. This prevents font substitution issues on the printer’s side, ensuring consistency. This is particularly critical for unique or less common fonts.

- Font Subsetting: To reduce file size without compromising quality, I subset the fonts, keeping only the characters used in the document. This speeds up processing without sacrificing the integrity of the text.

- Font Validation: I use preflight software to check for any font-related errors, such as missing or corrupted fonts, or fonts that are not suitable for print. This is a preventative measure to catch issues before they reach the printer.

- Outline Fonts: For extremely high-resolution print jobs, I might consider using outline fonts, ensuring sharp and clear text at any magnification.

For text accuracy, I meticulously review the document, checking for typos, grammatical errors and ensuring proper hyphenation. Often, multiple rounds of proofing help catch these errors. I also work closely with the client to confirm the text matches their expectations.

Q 17. Explain the process of creating a bleed for a print job.

Bleed is the area of the document that extends beyond the final trim size. It’s crucial because paper is cut, and never perfectly, creating the potential for unsightly white edges if the design is right to the edge. Think of it as insurance.

Creating bleed involves designing the document larger than the intended final size. The extra area compensates for these slight inaccuracies. For example, a business card might have a final size of 2×3.5 inches but could have a bleed of 0.125 inches on all sides, leading to a design size of 2.25 x 3.75 inches. The printer then trims off the excess, ensuring the final product has clean edges.

The process involves setting up the document in design software like Adobe InDesign or QuarkXPress, ensuring the design elements extend beyond the trim marks which define the final size. The software usually provides tools to add and manage bleed visually. Always confirm the required bleed specifications with the printer beforehand, as they vary depending on the type of printing and paper stock.

Q 18. What is your experience with different types of proofing methods (e.g., soft proof, contract proof)?

I’m proficient in various proofing methods, each serving a different purpose. Soft proofing is a digital preview on screen that gives a reasonable representation of the printed output. This is quick and efficient for initial checks. It helps catch obvious errors such as color issues and font mismatches.

Contract proofing, on the other hand, provides a physical representation of the printed product. It’s closer to the final print and acts as a legally binding document, protecting both the client and me. This might involve using a high-quality inkjet proof or a digital proof that closely mimics the final printing method.

I also have experience with other proofing methods like hard proofs (physical prints on the chosen printing press itself, for most accurate representation) and online proofing platforms, allowing clients to review and approve designs remotely. Each method serves a different stage of the production pipeline.

Q 19. How do you troubleshoot common prepress issues, such as banding or moiré patterns?

Troubleshooting prepress issues requires a systematic approach. Banding, for instance, appears as horizontal or vertical stripes in gradients or smooth color transitions. This is often caused by insufficient resolution in images, incorrect color profiles, or problems with the printing process itself. I would investigate image resolution, ensuring it’s sufficient for the desired print size. I would also examine the color profile settings, ensuring consistency throughout the workflow.

Moiré patterns, on the other hand, are unwanted interference patterns that appear as a shimmering or wavy effect, often stemming from conflicting angles in scanned images or overlapping patterns. This can be resolved by changing the angle or resolution of the problematic images, or by using appropriate screening techniques. Careful preflighting helps identify and often eliminate the root cause of these kinds of problems. Sometimes working with the printer to fine tune the settings helps resolve some of these issues.

My approach involves checking every stage of the process, from image preparation and color management to the printer settings. Often, a combination of techniques, such as resampling images or adjusting color profiles, will resolve these issues.

Q 20. What software and hardware are you proficient with in a prepress environment?

In my prepress work, I’m proficient with a range of industry-standard software and hardware. Software includes:

- Adobe Creative Suite (Photoshop, Illustrator, InDesign): Essential tools for image manipulation, vector graphics, and page layout.

- QuarkXPress: Another leading page layout application, often used for complex publications.

- Preflight software (e.g., PitStop Pro): Crucial for automating quality control and identifying potential printing issues before they become major problems.

- Color management software (e.g., ColorSync): Ensures accurate color reproduction across different devices.

Hardware expertise encompasses:

- High-resolution monitors (color calibrated): Ensures accurate color representation on screen.

- Colorimeters and spectrophotometers: Essential tools for profiling monitors and printing devices, ensuring consistent color accuracy.

- Large-format printers and plotters: For high-quality proofs and presentations.

I’m also familiar with various RIP (Raster Image Processor) software, that bridges the gap between vector-based design files and the raster images needed for printing.

Q 21. Describe your experience with managing large prepress projects.

Managing large prepress projects demands meticulous planning and organization. I’ve successfully handled numerous large-scale projects, employing strategies like:

- Project Breakdown: Dividing the project into smaller, manageable tasks with clear deadlines for each. This approach ensures smooth workflow and allows for easy tracking of progress.

- Team Collaboration: Working effectively with designers, editors, and printers, leveraging their expertise and ensuring everyone is on the same page using project management tools and clear communication channels.

- Workflow Automation: Using automation tools and scripts wherever possible to streamline repetitive tasks, reducing the risk of human error. This also saves valuable time.

- Version Control: Implementing rigorous version control systems to track changes, ensuring clarity and ease of access for all stakeholders.

- Risk Management: Identifying potential risks early on and developing mitigation strategies to avoid delays or issues. This includes contingency planning for unexpected problems.

One example involved managing the prepress for a large-scale book printing project with multiple volumes and tight deadlines. Through careful planning and consistent communication, we successfully delivered the project on time and within budget, meeting the client’s high standards.

Q 22. What are your methods for ensuring efficient and effective prepress workflow?

Efficient and effective prepress workflows hinge on meticulous planning, automation, and robust quality control. My approach involves several key strategies:

- Process Standardization: Implementing standardized processes for file handling, color management, trapping, and imposition ensures consistency and reduces errors. Think of it like a well-oiled machine – each part has a specific function, contributing to the overall efficiency.

- Automation: Utilizing automated preflight checks, imposition software, and workflow management systems significantly reduces manual intervention and potential for human error. For instance, automatically checking for missing fonts or incorrect color spaces saves countless hours of troubleshooting.

- Collaboration Tools: Employing cloud-based collaboration platforms facilitates seamless communication and file sharing among designers, prepress operators, and printers, minimizing delays and misunderstandings. Imagine a central hub where everyone can access and update project information in real-time.

- Quality Control Checks: Implementing rigorous quality control at every stage, from file reception to final output, is crucial. This includes soft proofing, color profiling, and detailed preflight reports to identify and rectify issues proactively. It’s like a thorough medical check-up for the print job, ensuring it’s healthy before going to press.

- Data Management: Implementing a robust digital asset management system ensures efficient organization and retrieval of files, significantly improving workflow speed and reducing the risk of file loss or version conflicts. This is like having a well-organized library for all your project assets, easily searchable and readily accessible.

Q 23. How do you stay updated on the latest advancements in prepress technology and standards?

Staying current in the dynamic world of prepress demands a multi-pronged approach:

- Industry Publications and Websites: I regularly read trade magazines, online journals, and industry-specific websites like WhatTheyThink and Printing Impressions to keep abreast of technological advancements and best practices.

- Conferences and Workshops: Attending industry conferences like drupa and local printing industry events provides opportunities to network with peers and learn from experts, gaining firsthand exposure to cutting-edge solutions.

- Vendor Training and Webinars: Participating in vendor-provided training sessions and online webinars offers valuable insights into new software features, workflow optimization techniques, and emerging industry standards.

- Professional Organizations: Membership in professional organizations like the PIA (Printing Industries of America) keeps me connected to industry trends, best practices, and provides access to valuable resources and networking opportunities.

- Online Communities and Forums: Engaging with online forums and communities allows for the exchange of knowledge and experience with other prepress professionals, providing solutions to common challenges and uncovering new techniques.

Q 24. Explain your understanding of print finishing processes and how they relate to prepress.

Print finishing processes are integral to the final product’s quality and appearance. Prepress plays a vital role in ensuring these processes are successful.

- Die-cutting: Prepress provides the precise die-cut lines for custom shapes, requiring accurate vector artwork. Errors here lead directly to flawed finished products.

- Folding and Binding: Prepress determines the page imposition (arrangement) for efficient folding and binding. Incorrect imposition can result in pages out of order or binding difficulties.

- Embossing and Debossing: The prepress stage creates the digital files that drive these processes; accurate artwork and positioning are critical for the desired effect.

- Laminating and Coating: While the actual application happens post-press, prepress considers the impact of coatings on color and ink density. The prepress professional might adjust color profiles to compensate.

Essentially, the prepress phase acts as a blueprint for finishing, ensuring that the design and file structure are compatible with the intended finishing methods. It’s like preparing a detailed construction plan before starting a building project – all elements must align to avoid complications.

Q 25. Describe a situation where you had to solve a complex prepress problem. What was your approach?

I once encountered a complex problem involving a large-format poster requiring Pantone matching with a metallic ink. The client provided a Pantone swatch that didn’t quite translate correctly on the digital proof.

My approach involved a systematic troubleshooting process:

- Replication: I meticulously recreated the client’s Pantone swatch using various ICC profiles and color management settings to pinpoint the discrepancy.

- Testing: I tested multiple combinations of ink, paper, and printer settings, documenting the results. This involved using test strips to check how the metallic ink reacted with the substrate.

- Consultation: I consulted with the ink supplier and the printing press operator to gain additional insight into the specific properties of the metallic ink and its behavior on the press.

- Refinement: Based on the testing and consultation, I fine-tuned the color profile and made adjustments to the output settings. We also ran a smaller test print before proceeding with the full production run.

- Verification: Finally, I conducted a thorough visual verification of the adjusted print against the client’s Pantone swatch to ensure accuracy.

This methodical approach ensured that the final print accurately reflected the client’s requirements, avoiding costly reprints and delays.

Q 26. What is your experience with automated prepress workflows and workflow management systems?

I have extensive experience with automated prepress workflows and workflow management systems (WFS). My expertise encompasses:

- Preflight Automation: I’m proficient in using automated preflight tools like PitStop and Enfocus Switch to identify and resolve errors before they reach the printing stage. This includes checking for missing fonts, low-resolution images, and color profile inconsistencies.

- Workflow Management Systems (WFS): I’m familiar with using various WFS such as MIS (Management Information System) software to track jobs, manage assets, automate tasks, and improve overall efficiency. Examples include Heidelberg Prinect, Kodak Prinergy and others.

- JDF/JMF: I have working knowledge of Job Definition Format (JDF) and Job Management Format (JMF) standards, allowing for seamless integration between prepress and pressroom systems.

- Automation Scripting: In instances requiring specialized automation, I can leverage scripting languages like Javascript or other tools to create customized workflows for increased efficiency.

My experience has significantly reduced manual intervention, improved turnaround times, and minimized errors in prepress production.

Q 27. How do you ensure the security of prepress files and data?

Securing prepress files and data is paramount. My approach is multi-layered:

- Access Control: Implementing strict access control measures, using role-based permissions within the WFS and network, limits file access to authorized personnel only. This prevents unauthorized modification or disclosure of sensitive information.

- Encryption: Using robust encryption methods for both files at rest and files in transit protects sensitive data from unauthorized access, even if the files are intercepted.

- Regular Backups: Implementing a robust backup system safeguards against data loss due to hardware failure, malware attacks, or other unforeseen events. Regular, incremental backups ensure rapid recovery.

- Version Control: Using version control systems allows for tracking changes made to files, restoring previous versions if necessary and ensuring that only approved versions are used in production. This is analogous to having a history of revisions for important documents.

- Security Audits: Regular security audits assess the effectiveness of existing security measures and identify vulnerabilities, allowing for proactive mitigation of risks.

This comprehensive strategy ensures the confidentiality, integrity, and availability of prepress data.

Q 28. Describe your understanding of different paper types and their impact on the prepress process.

Different paper types significantly impact the prepress process, influencing color reproduction, ink absorption, and overall print quality.

- Coated Papers: These papers have a smooth, glossy surface that produces vibrant colors and sharp details but may require adjustments to ink settings to avoid excessive gloss or trapping issues.

- Uncoated Papers: These papers have a more porous surface, resulting in greater ink absorption and a softer, more textured print. Prepress needs to account for potential color shifts and the risk of feathering (ink bleeding).

- Specialty Papers: Papers like textured, metallic, or recycled stocks demand specific considerations in prepress, including adjustments to color profiles, trap settings, and potential changes in imposition.

Understanding the paper’s characteristics is crucial for optimizing the prepress settings, ensuring accurate color reproduction, and achieving the desired visual outcome. Each paper type is like a different canvas—the techniques for painting on them differ based on texture and absorbency.

Key Topics to Learn for Understanding of Prepress Standards and Protocols Interview

- Color Management: Understanding color spaces (CMYK, RGB, Pantone), color profiles (ICC), and color conversion processes. Practical application: Troubleshooting color discrepancies between digital files and printed output.

- File Formats and Resolution: Knowledge of common file formats (PDF, TIFF, JPEG, AI) and their appropriate uses in prepress. Understanding resolution requirements for different print processes (offset, digital, large format). Practical application: Preparing files for optimal print quality and avoiding common resolution-related issues.

- Image Editing and Retouching: Familiarity with image editing software (Adobe Photoshop, Illustrator) and techniques for preparing images for print, including color correction, image sharpening, and resolution adjustments. Practical application: Identifying and correcting image flaws that could impact print quality.

- Proofing and Quality Control: Understanding different proofing methods (soft proof, hard proof) and quality control checks to ensure consistency and accuracy before printing. Practical application: Implementing a robust quality control process to minimize errors and reduce waste.

- Prepress Workflow and Automation: Knowledge of prepress workflow processes, including trapping, imposition, and color separation. Understanding the role of automation in streamlining prepress tasks. Practical application: Optimizing workflow efficiency and reducing turnaround time.

- Print Production Standards: Familiarity with industry standards and best practices related to print specifications, such as bleed, margins, and imposition. Practical application: Ensuring that print jobs meet client specifications and industry standards.

- Troubleshooting and Problem-Solving: Ability to identify and resolve common prepress issues, such as color inconsistencies, missing fonts, and file format problems. Practical application: Developing effective strategies for troubleshooting and resolving prepress challenges.

Next Steps

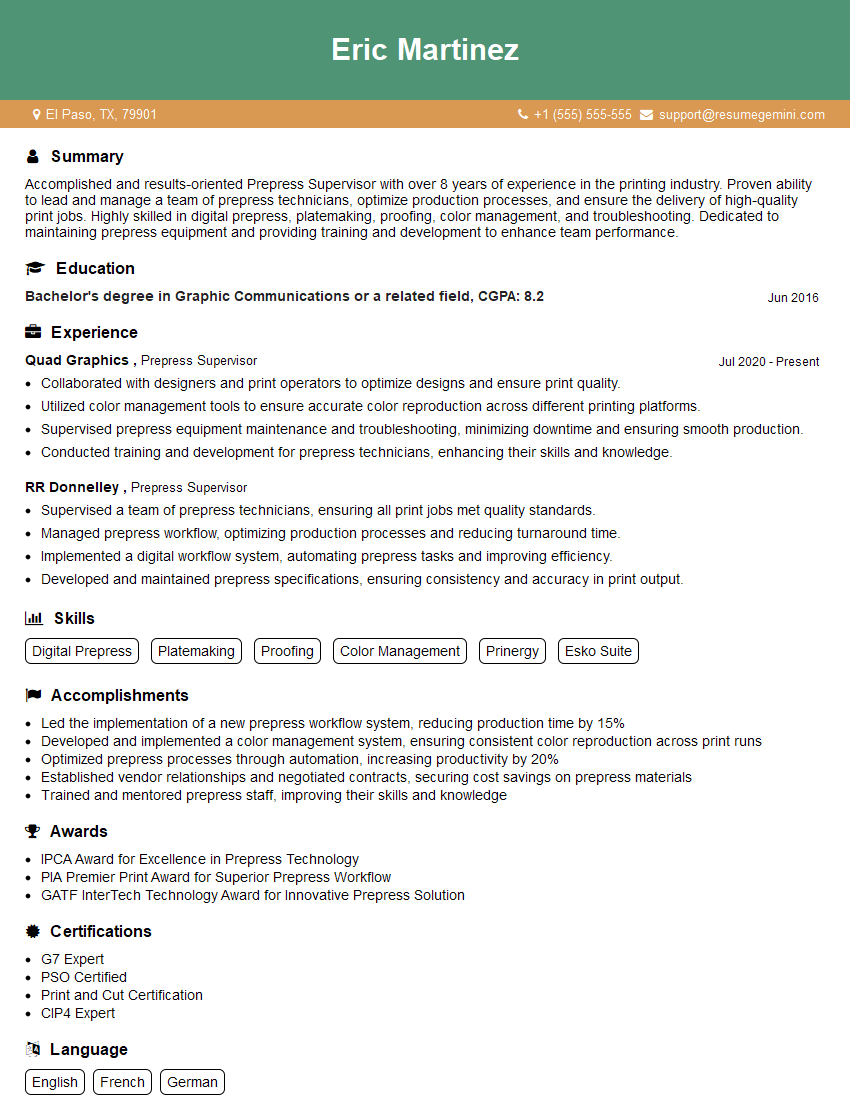

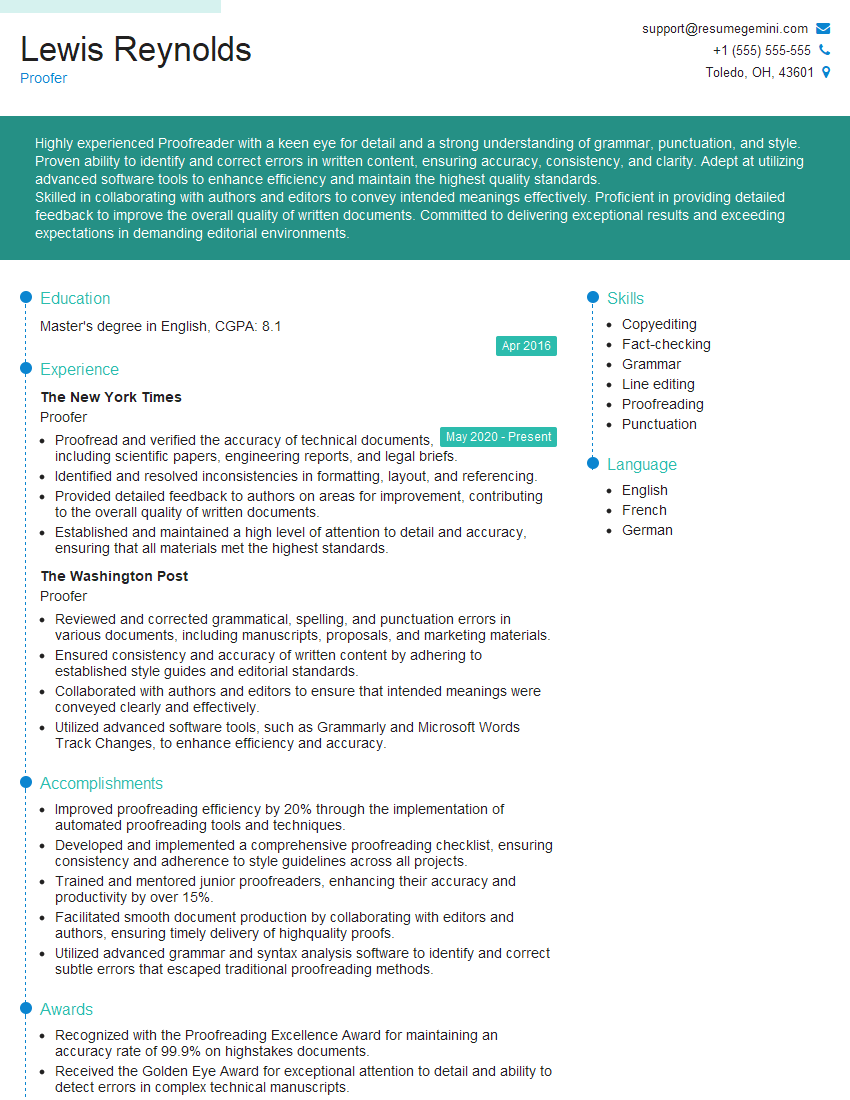

Mastering Understanding of Prepress Standards and Protocols is crucial for career advancement in the printing and publishing industries. A strong understanding of these principles demonstrates your technical expertise and problem-solving abilities, making you a highly valuable asset to any team. To stand out, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume tailored to your specific skills and experience. Examples of resumes tailored to Understanding of Prepress Standards and Protocols are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good