The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Use of Analytical Equipment interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Use of Analytical Equipment Interview

Q 1. Describe your experience with HPLC and its applications.

High-Performance Liquid Chromatography (HPLC) is a powerful analytical technique used to separate, identify, and quantify components in a mixture. It’s like a highly efficient sorting machine for molecules dissolved in a liquid. My experience spans diverse applications, including pharmaceutical analysis (measuring drug purity and identifying impurities), environmental monitoring (detecting pollutants in water samples), and food analysis (analyzing the composition of food products).

In pharmaceutical analysis, for example, I’ve used HPLC to ensure the purity of active pharmaceutical ingredients (APIs). We inject a sample of the drug onto the HPLC column, and the different components are separated based on their interactions with the stationary phase (the column packing material) and the mobile phase (the solvent flowing through the column). A detector then measures the amount of each component, providing a precise quantification of the API and any impurities present. This is crucial for ensuring drug safety and efficacy. Another application involved using reversed-phase HPLC with UV detection to analyze the different flavonoids in a herbal extract. The method required careful optimization of the mobile phase composition to achieve baseline separation of the various components.

Beyond pharmaceutical applications, I have extensive experience using HPLC for quality control in food and beverage manufacturing, ensuring product consistency and safety. For example, I have used HPLC to monitor sugar content in various drinks. Different HPLC detectors can be chosen depending on the characteristics of the compound to be measured. For instance, if a compound has a chromophore, a UV-Vis detector would be ideal.

Q 2. Explain the principles of Gas Chromatography-Mass Spectrometry (GC-MS).

Gas Chromatography-Mass Spectrometry (GC-MS) combines two powerful analytical techniques to identify and quantify volatile compounds in a sample. Think of it as a two-stage process: first, gas chromatography separates the mixture into individual components, and then mass spectrometry identifies each component based on its mass-to-charge ratio.

In GC, the sample is vaporized and injected into a column, where the components are separated based on their boiling points and interactions with the stationary phase (a thin layer of liquid inside the column). The separated components then exit the column and enter the mass spectrometer. The mass spectrometer ionizes the molecules, sorts them based on their mass-to-charge ratio, and produces a mass spectrum, a unique fingerprint for each compound. By comparing the mass spectrum to a database of known compounds, we can identify the components in the original mixture.

For example, I’ve used GC-MS to analyze the volatile organic compounds (VOCs) in air samples, helping identify potential pollutants or contaminants. Another real-world application involved analyzing the pesticide residues in food products. In this case, we employed a solid-phase microextraction (SPME) technique to concentrate the analytes prior to GC-MS analysis. The method was validated to ensure the accuracy and precision of the pesticide residue measurement.

Q 3. How do you calibrate and validate analytical instruments?

Calibrating and validating analytical instruments is essential for ensuring accurate and reliable results. Calibration involves adjusting the instrument to produce accurate readings by using standards of known concentration. Validation ensures the instrument is suitable for its intended use, meeting predetermined accuracy, precision, and other quality control parameters.

- Calibration: This typically involves running a series of standards of known concentrations through the instrument and generating a calibration curve. The calibration curve relates the instrument’s response (e.g., peak area in chromatography) to the concentration of the analyte. For example, in spectrophotometry, we might use a set of standard solutions of known concentrations of a particular compound to create a calibration curve that relates absorbance to concentration. This curve will be used to determine the concentration of unknown samples.

- Validation: This is a more comprehensive process that includes several parameters such as linearity, range, accuracy, precision, limit of detection (LOD), and limit of quantification (LOQ). We use certified reference materials (CRMs) and quality control (QC) samples to evaluate the instrument’s performance and to demonstrate that it meets the required specifications for its intended use. For example, the accuracy and precision of the method are tested by analyzing the quality control samples.

For example, in my work, we regularly calibrate and validate our HPLC systems using certified standards, ensuring consistent and reliable results in our pharmaceutical analysis. Regular maintenance and calibration schedules are also adhered to. A comprehensive validation report is compiled documenting all the validation results.

Q 4. What are the common troubleshooting steps for a malfunctioning spectrophotometer?

Troubleshooting a malfunctioning spectrophotometer involves a systematic approach. First, we need to identify the nature of the malfunction—is it a reading error, a calibration issue, or something more significant?

- Check the basics: Ensure the instrument is properly switched on, warmed up, and that the light source is functioning. Check for any obvious physical damage.

- Verify the cuvettes: Clean the cuvettes thoroughly and ensure they are free of scratches or fingerprints. Use matched cuvettes for accurate measurements.

- Examine the calibration: If the instrument is not reading correctly, recalibrate it using appropriate standards. Follow the manufacturer’s instructions carefully.

- Check the wavelength: Ensure the correct wavelength is selected for the analysis. The wavelength selected should correspond to the maximum absorption of the analyte.

- Check the sample preparation: Confirm that the sample is appropriately prepared and free of particulate matter.

- Check the detector: If the above steps do not resolve the issue, there may be a problem with the detector. Contact a service technician for further assistance.

For example, if a spectrophotometer consistently shows higher than expected absorbance readings, a possible cause could be a dirty cuvette or a problem with the detector itself. If the readings are erratic, a possible cause might be an issue with the light source or stray light entering the instrument. Systematic troubleshooting helps pinpoint and address these problems, often leading to a quick resolution.

Q 5. Describe your experience with different types of chromatography (e.g., HPLC, GC, TLC).

My experience encompasses various chromatographic techniques, each with its strengths and weaknesses. I have already mentioned HPLC and GC-MS. Thin-Layer Chromatography (TLC) is a simpler, less expensive technique ideal for quick separations and qualitative analysis.

- HPLC: Best suited for separating and quantifying non-volatile or thermally labile compounds in solution. Its high resolution and sensitivity make it ideal for complex mixtures.

- GC: Ideal for volatile and thermally stable compounds. GC offers excellent separation power and is often coupled with mass spectrometry for compound identification.

- TLC: A simple, rapid method for initial screening or monitoring reactions. It provides a quick visual separation of components but lacks the quantitative accuracy of HPLC and GC.

Imagine you are working with a complex natural product extract. You might start with TLC to get a general idea of the number of compounds present and then move on to HPLC or GC for more detailed separation and quantification. The choice of chromatographic technique depends entirely on the nature of the sample and the information needed.

Q 6. How do you ensure the accuracy and precision of analytical measurements?

Accuracy and precision in analytical measurements are paramount. Accuracy refers to how close a measurement is to the true value, while precision refers to the reproducibility of the measurements. To ensure both, we employ several strategies:

- Proper instrument calibration and validation: As discussed earlier, regular calibration and validation are critical. This ensures the instrument is functioning correctly and producing reliable results.

- Use of certified reference materials (CRMs): CRMs provide traceable and accurate values, allowing for the assessment of accuracy and helping to identify any systematic errors.

- Employing appropriate quality control (QC) samples: Regularly analyzing QC samples helps monitor the precision and stability of the analysis. Any significant deviation from expected values signals a potential problem that needs investigation.

- Careful sample preparation: Proper sample preparation is crucial to minimize errors. This includes steps such as homogenization, extraction, and dilution, all performed according to validated protocols.

- Multiple measurements and statistical analysis: Taking multiple measurements and applying statistical analysis provides a measure of precision and allows for the detection of outliers.

For example, in a pharmaceutical quality control setting, we might analyze multiple samples of a batch of tablets to determine the average concentration of the active ingredient and its variability. We calculate statistics such as standard deviation and relative standard deviation to evaluate the precision of the results. The accuracy is checked using CRMs.

Q 7. Explain the importance of quality control in analytical testing.

Quality control (QC) in analytical testing is not just about producing accurate results; it’s about ensuring the reliability and integrity of the entire analytical process. It’s like a safety net that catches potential mistakes before they affect final conclusions. Without robust QC, the results could be misleading, potentially leading to wrong decisions with significant consequences.

QC measures are implemented at every stage, from sample collection and preparation to instrument calibration, analysis, and data reporting. These include using QC samples at regular intervals during the analysis, regularly checking instrument performance using calibration standards, and maintaining detailed records of all procedures and results. Statistical process control (SPC) charts are often used to monitor the performance of the analytical process over time, alerting us to any trends or deviations that might indicate a problem. Deviations from established protocols are thoroughly investigated and documented.

In a clinical laboratory setting, for instance, failure to implement rigorous QC measures could result in misdiagnosis or inappropriate treatment for patients, highlighting the critical importance of this aspect in ensuring reliable and trustworthy data.

Q 8. What are the different types of analytical balances and their applications?

Analytical balances are precision instruments used to measure mass accurately. Different types cater to varying needs in terms of precision and capacity.

- Macrobalances: These are the most common type, offering a readability of 0.1 mg to 1 mg and a capacity ranging from 100 g to 300 g. They are suitable for routine weighing in many laboratory settings, like measuring out reagents for chemical experiments or determining the mass of samples before analysis.

- Semi-microbalances: These offer a higher level of precision than macrobalances, with readability typically in the range of 0.01 mg. Their capacity is usually smaller, around 100 g. Semi-microbalances are ideal for precise measurements required in many analytical procedures, such as in pharmaceutical analysis where small quantities are crucial.

- Microbalances: Providing the highest level of precision, microbalances usually have a readability of 0.001 mg (1 µg) or better. Their capacity is relatively small, typically less than 100 g. Microbalances find application in extremely precise measurements, for example, in trace analysis or research involving nanomaterials.

- Ultra-microbalances: These are specialized instruments capable of measuring masses with a readability of 0.0001 mg (0.1 µg) or even better, but with very limited capacity. These are often employed in highly specialized scientific research.

The choice of balance depends entirely on the application’s required precision and the mass of the samples being weighed. A high-precision microbalance is unnecessary for weighing large amounts of reagents, while a macrobalance won’t suffice for microanalysis.

Q 9. How do you handle instrument downtime and maintenance?

Instrument downtime is minimized through a proactive maintenance strategy. This involves regular calibration, preventative maintenance schedules, and a thorough understanding of the equipment’s operational limits.

My approach begins with a detailed understanding of the manufacturer’s recommended maintenance protocols. This includes regular checks of critical components, such as the weighing pan on an analytical balance or the detector in a HPLC.

When downtime occurs due to malfunction, I follow a troubleshooting protocol. This typically starts with a visual inspection, followed by checking the instrument’s log files for error messages. If the problem is not readily apparent, I consult the instrument’s manual and may contact the manufacturer’s technical support for assistance. I meticulously document all maintenance activities and any issues encountered, ensuring traceability and allowing for efficient problem-solving in the future. We maintain a well-stocked inventory of spare parts to reduce repair time.

Q 10. Describe your experience with data analysis software (e.g., Empower, Chromeleon).

I have extensive experience with Empower and Chromeleon, two of the leading chromatography data systems (CDS). Empower is known for its intuitive interface and robust data management capabilities, while Chromeleon offers excellent flexibility and customization options.

In my previous role, I routinely used Empower for processing HPLC and UPLC data, performing peak integration, method validation, and generating comprehensive reports. I developed and validated analytical methods using both systems, ensuring data integrity and compliance with regulatory guidelines. A specific example involved using Empower to develop a method for quantifying impurities in a pharmaceutical product. I wrote macros in Empower to automate repetitive tasks, saving significant time and increasing efficiency. My expertise extends to data manipulation, peak identification, troubleshooting integration issues, and applying various data analysis techniques. I’m also proficient in using Chromeleon’s advanced features like spectral analysis and instrument control for complex analyses.

Q 11. What are the safety procedures you follow when operating analytical equipment?

Safety is paramount when operating analytical equipment. My approach to safety is multi-faceted and begins with a thorough understanding of the specific hazards associated with each instrument.

- Personal Protective Equipment (PPE): I always wear appropriate PPE, including lab coats, safety glasses, and gloves, depending on the chemicals or samples being handled.

- Proper Handling of Chemicals: I am proficient in handling hazardous chemicals safely, following established procedures for storage, disposal, and spill cleanup. Safety Data Sheets (SDS) are always consulted before handling any unknown substance.

- Instrument-Specific Procedures: I carefully follow the manufacturer’s instructions for operating each instrument, paying particular attention to safety warnings and precautions. This includes understanding emergency shutdown procedures.

- Housekeeping: Maintaining a clean and organized workspace is crucial to prevent accidents. I make sure to clean up spills immediately and dispose of waste appropriately.

- Regular Inspections: Regular visual inspections of instruments and equipment are conducted before operation to ensure no damage is present that could compromise safety.

I always prioritize safety and ensure my actions do not pose a risk to myself or others in the lab. Safety training is regularly updated to remain compliant with all regulations.

Q 12. Explain the difference between qualitative and quantitative analysis.

Qualitative analysis identifies the components present in a sample, while quantitative analysis determines the amount of each component.

Think of it like this: Imagine you have a bag of candies. Qualitative analysis would tell you that the bag contains red, blue, and green candies. Quantitative analysis would tell you the exact number of each color—for example, 10 red, 5 blue, and 15 green candies.

Qualitative techniques often involve techniques like chromatography (identifying compounds based on their retention time) or spectroscopy (identifying compounds based on their interaction with electromagnetic radiation). Quantitative analysis usually employs techniques like titration (measuring the volume of a reactant needed for a complete reaction) or spectroscopy (measuring the intensity of a signal to determine the concentration).

Q 13. Describe your experience with sample preparation techniques.

Sample preparation is a critical step in analytical chemistry, often impacting the accuracy and reliability of the results. My experience includes a wide range of techniques tailored to the specific analytical method and sample matrix.

- Solid-state samples: These might require grinding, sieving, or extraction techniques, such as Soxhlet extraction, to isolate the analyte of interest.

- Liquid samples: Often require filtration, dilution, or derivatization to prepare the sample for analysis. Derivatization is a crucial step if the analyte does not possess suitable properties for the chosen analytical technique.

- Biological samples: Such as blood or tissue, require specific protocols to prevent degradation or contamination. Protein precipitation, solid-phase extraction (SPE), or liquid-liquid extraction are commonly used techniques here.

I’m adept at selecting the most appropriate sample preparation technique based on the sample type, the analyte’s properties, and the chosen analytical method. I ensure consistent and reproducible sample preparation to minimize the introduction of error into the analytical process. For example, when analyzing trace metals in environmental samples, meticulous cleaning of glassware and use of ultrapure reagents is crucial to avoid contamination.

Q 14. How do you interpret analytical results and identify potential sources of error?

Interpreting analytical results involves more than just looking at the numbers; it requires a critical assessment of the data, considering potential sources of error. I approach this systematically:

- Data Validation: I first check for outliers and inconsistencies within the dataset. Statistical methods may be employed to identify potential errors.

- Method Validation: The analytical method’s accuracy, precision, and linearity are assessed to ensure reliable results. I often prepare quality control (QC) samples to monitor the performance of the method.

- Instrument Performance: The instrument’s performance is checked through regular calibration and maintenance logs. Any deviations from expected instrument performance are considered.

- Sample Preparation: The impact of sample preparation on the final results is critically examined. Any potential sources of error during sample preparation are meticulously evaluated.

- External Factors: Environmental factors like temperature fluctuations and humidity can sometimes affect the analytical process and results. These factors are considered, if relevant.

Identifying sources of error involves a combination of methodical investigation, critical thinking, and a deep understanding of the analytical process. For instance, consistently high values in a series of measurements might indicate a systematic error, such as a contaminated reagent, while random fluctuations might suggest a problem with the instrument’s precision. I document all observations and findings in a detailed report to aid in understanding the results.

Q 15. What are the limitations of different analytical techniques?

Every analytical technique has its strengths and weaknesses. Limitations often stem from the fundamental principles of the method, the instrument’s design, or the sample matrix itself. For instance, Gas Chromatography (GC) excels at separating volatile compounds but struggles with high molecular weight or thermally labile substances. High-Performance Liquid Chromatography (HPLC), on the other hand, handles a wider range of compounds but can be slower and more complex. Spectroscopic techniques like UV-Vis are susceptible to spectral interferences from other components in the sample, while Mass Spectrometry (MS), despite its high sensitivity, can be expensive and requires specialized expertise.

- Sensitivity: Some techniques lack the sensitivity to detect trace amounts of analytes.

- Selectivity: Interfering compounds in the sample matrix can impact accuracy and precision.

- Linearity: The analytical response may not be linear over the entire concentration range.

- Sample preparation: Some methods require extensive and time-consuming sample preparation.

- Cost and maintenance: Advanced instrumentation often has high purchase and maintenance costs.

Consider a scenario where we need to analyze pesticide residues in fruits. GC-MS might be ideal for volatile pesticides, but for less volatile compounds, HPLC coupled with MS might be necessary. The choice depends on the specific pesticides and the limitations of each method.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure the proper handling and storage of samples and reagents?

Proper handling and storage of samples and reagents are crucial for maintaining data integrity and ensuring accurate results. This involves adhering to strict protocols to prevent contamination, degradation, or loss of analytes. It’s like baking a cake – if you don’t use the correct ingredients and store them properly, the final product won’t be as expected!

- Sample Collection: Using clean, appropriate containers and avoiding cross-contamination during collection.

- Sample Storage: Storing samples at appropriate temperatures (refrigeration, freezing) to prevent degradation. Light-sensitive samples need protection from light.

- Reagent Handling: Using clean glassware and following manufacturer’s instructions for handling and storage. Many reagents are sensitive to air or moisture and need to be stored under inert gas or desiccated conditions.

- Chain of Custody: Maintaining a detailed record of sample handling to track its movement and ensure its integrity.

- Inventory Management: Regularly checking expiration dates of reagents and samples.

For example, in environmental analysis, water samples need to be stored in pre-cleaned bottles, often with preservatives to prevent microbial growth and analyte degradation. Improper storage can lead to inaccurate results and potentially misleading conclusions about environmental quality.

Q 17. Describe your experience with method validation and verification.

Method validation and verification are essential steps in ensuring that an analytical method is fit for its intended purpose. Validation establishes that the method is accurate, precise, and reliable, while verification confirms that the method continues to perform as expected over time. Think of it as building a house (validation) and then regularly inspecting it to make sure it’s still standing strong (verification).

Validation involves parameters like linearity, accuracy, precision, limit of detection (LOD), limit of quantification (LOQ), and robustness. I have extensive experience in validating methods using standard operating procedures (SOPs) and following regulatory guidelines like those from the FDA or EPA. My experience encompasses various techniques, including HPLC, GC-MS, and ICP-OES.

Verification is ongoing, involving periodic checks of the method’s performance using quality control samples. I’ve developed and implemented quality control charts and other statistical tools to monitor method performance and identify potential drifts or problems.

For example, in a pharmaceutical laboratory, validating a HPLC method for analyzing the potency of a drug requires demonstrating that the method consistently provides accurate and precise results within acceptable limits. Regular verification ensures that the HPLC system is properly calibrated and the method still meets validation criteria.

Q 18. What are the regulatory requirements for analytical testing in your field?

Regulatory requirements for analytical testing vary depending on the industry and the analyte of interest. In pharmaceutical analysis, the FDA’s guidelines are paramount. In environmental testing, the EPA sets standards. Good Laboratory Practices (GLP) and Good Manufacturing Practices (GMP) are widely applicable frameworks for ensuring data quality and compliance.

- Data Integrity: Maintaining accurate, complete, and reliable data throughout the testing process.

- Documentation: Detailed records of all procedures, results, and instrument calibrations are essential.

- Quality Control: Implementing quality control measures throughout the analysis, including the use of standards, blanks, and quality control samples.

- Personnel Training: Analysts must be properly trained and qualified to perform the analyses.

- Instrument Calibration and Maintenance: Regular calibration and maintenance of instruments are crucial for ensuring accurate results.

Non-compliance can lead to serious consequences, such as product recalls, fines, and legal action. A robust quality management system (QMS) is key to adhering to these regulations and avoiding problems.

Q 19. How do you troubleshoot spectral interferences in spectroscopy?

Spectral interferences in spectroscopy arise when the signal from an analyte overlaps with the signal from another component in the sample. This can lead to inaccurate quantification. Troubleshooting requires a systematic approach.

- Background Correction: Techniques like baseline correction or using a blank sample can help subtract background interference.

- Wavelength Selection: Choosing a wavelength where the analyte’s absorbance is maximized and the interference is minimized.

- Chemical Separation: Techniques like chromatography can separate the analyte from interfering substances before spectroscopic analysis.

- Derivative Spectroscopy: Taking the derivative of the spectrum can enhance the resolution and reduce interference.

- Matrix Matching: Using a matrix-matched calibration standard can compensate for matrix effects.

Imagine analyzing a sample containing iron and copper. If their absorbance peaks overlap, we might use a chemical separation technique to separate them before measuring their individual concentrations using atomic absorption spectroscopy.

Q 20. Explain the principle of atomic absorption spectroscopy (AAS).

Atomic Absorption Spectroscopy (AAS) is a quantitative technique used to determine the concentration of elements in a sample. It relies on the principle of atomic absorption: atoms of a particular element absorb light at specific wavelengths when they are in their ground state. The amount of light absorbed is directly proportional to the concentration of the element in the sample.

The process involves atomizing the sample (typically using a flame or graphite furnace), then passing a beam of light from a hollow cathode lamp (specific to the element being analyzed) through the atomized sample. A detector measures the amount of light absorbed, and this is related to the concentration using a calibration curve.

AAS is widely used in various fields, including environmental monitoring, food safety, and clinical chemistry, to determine the concentration of trace metals in samples. For example, it’s used to measure lead levels in drinking water or to analyze the metal content in biological samples.

Q 21. Describe your experience with inductively coupled plasma mass spectrometry (ICP-MS).

Inductively Coupled Plasma Mass Spectrometry (ICP-MS) is a powerful technique for determining the elemental composition of a sample. It combines the ability of ICP to efficiently ionize samples with the mass-analyzing power of MS to separate and quantify the ions produced. Imagine it as a super-charged, highly sensitive version of AAS, capable of identifying and measuring a much wider range of elements and isotopes.

The process involves introducing the sample into an inductively coupled plasma (ICP), which is a high-temperature plasma generated by passing argon gas through a radio-frequency field. This plasma ionizes the atoms in the sample. The ions are then passed into a mass spectrometer, which separates the ions based on their mass-to-charge ratio. A detector measures the abundance of each ion, providing quantitative information on the elemental composition.

My experience with ICP-MS includes method development, validation, and routine analysis of various samples, such as environmental samples (water, soil), geological samples, and biological materials. It’s a very versatile tool with excellent sensitivity and the ability to determine isotopic ratios, making it invaluable for many applications. For example, it’s used to measure trace elements in food to assess nutritional content or to analyze the elemental composition of semiconductor materials.

Q 22. How do you maintain instrument logs and records?

Maintaining accurate instrument logs and records is crucial for data integrity, regulatory compliance, and troubleshooting. We utilize a combination of electronic and paper-based systems, depending on the instrument and regulatory requirements. For example, high-performance liquid chromatography (HPLC) systems often have built-in electronic logging capabilities, automatically recording parameters like flow rate, pressure, temperature, and injection volume. This data is then exported to a secure database, often linked to our laboratory information management system (LIMS). For instruments lacking electronic logging, we maintain detailed paper logs, meticulously recording each use, including date, time, operator, sample information, maintenance performed, and any deviations from the standard operating procedure (SOP).

Our SOPs dictate that all entries are made in indelible ink and any errors are corrected by striking through, initialing, and dating. Regular audits ensure the integrity and accuracy of our records, and we have a defined retention policy complying with relevant regulations, such as GLP (Good Laboratory Practice) and GMP (Good Manufacturing Practice) guidelines. This comprehensive approach ensures traceability and facilitates troubleshooting in case of discrepancies or unexpected results.

Q 23. What are the key performance indicators (KPIs) for analytical equipment?

Key Performance Indicators (KPIs) for analytical equipment are metrics used to assess its effectiveness, efficiency, and reliability. These vary depending on the instrument but generally include:

- Uptime: The percentage of time the instrument is operational and available for use. A high uptime indicates minimal downtime due to maintenance or repairs.

- Throughput: The number of samples processed per unit of time. This reflects the efficiency of the instrument and the workflow.

- Accuracy: How closely the instrument’s measurements match the true values. This is typically assessed through calibration and validation processes.

- Precision: The reproducibility of the instrument’s measurements. Low precision indicates variability in results, even for the same sample.

- Detection Limit (LOD) and Quantification Limit (LOQ): The lowest concentration of an analyte that can be reliably detected and quantified, respectively. These are critical for assessing the sensitivity of the instrument.

- Maintenance frequency and cost: Tracking the frequency of preventive maintenance and the associated costs helps to optimize maintenance schedules and budget allocation.

By monitoring these KPIs, we can identify areas for improvement, optimize instrument performance, and ensure compliance with quality standards.

Q 24. Explain the concept of limit of detection (LOD) and limit of quantification (LOQ).

The Limit of Detection (LOD) and Limit of Quantification (LOQ) are critical parameters in analytical chemistry that define the lowest concentration of an analyte that can be reliably measured. Think of it like trying to see a faint star in the night sky. LOD is the point where you can just barely see the star (detect it), while LOQ is the point where you can reliably determine its brightness (quantify it).

LOD represents the lowest concentration of an analyte that can be distinguished from the background noise. It’s typically defined as three times the standard deviation of the blank signal. A low LOD indicates high sensitivity.

LOQ represents the lowest concentration of an analyte that can be reliably measured with acceptable accuracy and precision. It’s typically defined as ten times the standard deviation of the blank signal. A low LOQ indicates high sensitivity and precision.

For example, in environmental monitoring, a low LOD for a particular pollutant in water is critical for detecting even trace amounts and preventing health risks. The LOQ ensures that the measured concentration is accurate enough for regulatory reporting.

Q 25. How do you prepare standard solutions for analytical testing?

Preparing accurate standard solutions is fundamental to analytical chemistry. The process involves carefully weighing a known amount of a primary standard (a highly pure substance with known composition) and dissolving it in a precise volume of solvent to obtain a solution of known concentration. This requires meticulous attention to detail and the use of calibrated glassware.

Steps involved:

- Weighing: Accurately weigh the required amount of primary standard using an analytical balance. Ensure the balance is calibrated and tared properly.

- Dissolution: Carefully transfer the weighed standard to a volumetric flask of appropriate size. Add a small amount of solvent to dissolve the standard, swirling gently to avoid loss. Then fill the flask to the marked line with solvent, ensuring the meniscus is precisely aligned.

- Mixing: Thoroughly mix the solution by inverting the flask several times to ensure homogeneity. This is critical for accurate concentration.

- Dilution (if needed): If a lower concentration standard solution is needed, precisely dilute the stock solution using volumetric pipettes and flasks, following proper dilution techniques.

Example: To prepare 100 mL of a 1000 ppm (parts per million) standard solution of sodium chloride (NaCl), you would weigh 0.05844 g of NaCl (its molar mass is 58.44 g/mol) and dissolve it in 100 mL of deionized water. This calculation considers the desired concentration, molecular weight, and volume.

Q 26. Describe your experience with different types of detectors used in chromatography.

My experience encompasses a range of detectors used in chromatography, each with its own strengths and weaknesses. These include:

- UV-Vis detectors: These are widely used and relatively inexpensive, offering good sensitivity for compounds that absorb UV or visible light. They are robust and easy to maintain but lack selectivity and may not be suitable for all compounds.

- Fluorescence detectors: These offer higher sensitivity and selectivity than UV-Vis detectors for compounds that fluoresce. They are particularly useful for trace analysis but require compounds to possess the appropriate fluorescence properties.

- Refractive index (RI) detectors: These are universal detectors, meaning they respond to all analytes, but they have lower sensitivity than other detectors and are often used for applications where other detectors are not suitable.

- Electrochemical detectors: These are highly selective and sensitive for electroactive compounds. They are particularly valuable in analyzing pharmaceuticals and environmental samples but require specialized knowledge and expertise to operate effectively.

- Mass spectrometers (MS): Coupled with chromatography, MS offers excellent sensitivity, specificity, and structural information about the analytes. It’s a powerful tool but requires significant investment and expertise in operation and data analysis.

The choice of detector depends on the specific application, the properties of the analytes, required sensitivity, and available resources. In my experience, understanding the limitations and capabilities of each detector is crucial for selecting the appropriate one and achieving accurate and reliable results.

Q 27. Explain the importance of method development and optimization in analytical chemistry.

Method development and optimization are critical steps in analytical chemistry ensuring accurate, precise, and reliable results. It involves selecting the appropriate analytical technique, optimizing the instrumental parameters, and validating the method to demonstrate its fitness for purpose. This is like building a house; you need a solid plan (method) and the right tools (equipment and parameters) to construct a sturdy and functional structure.

Importance:

- Accuracy and Precision: Proper method development ensures the method is accurate (close to the true value) and precise (reproducible results).

- Sensitivity and Selectivity: Optimization leads to high sensitivity (ability to detect low concentrations) and selectivity (ability to distinguish target analyte from interfering substances).

- Efficiency: Well-optimized methods reduce analysis time and resource consumption.

- Regulatory Compliance: Method validation demonstrates that the method meets regulatory requirements and produces reliable data for compliance purposes.

Process: Method development typically involves iterative steps of experimentation, optimization, and validation, using techniques such as Design of Experiments (DoE) to efficiently explore the parameter space. The end result is a robust and validated method suitable for the specific application.

Q 28. How do you handle unexpected results or outliers in your analysis?

Handling unexpected results or outliers requires a systematic and thorough approach. It’s vital to avoid simply discarding data without investigation, as this can lead to incorrect conclusions. The process usually involves:

- Reviewing the data: Carefully examine the outliers and look for patterns or trends. Are there multiple outliers, or is it an isolated instance? Are there any obvious instrumental or procedural errors?

- Investigating potential causes: Check instrument calibration, maintenance records, and sample preparation procedures. Were there any deviations from the SOP? Could matrix effects or interferences be involved? Were there any environmental factors that could have affected the results?

- Repeating the analysis: If a procedural or instrumental error is suspected, repeat the analysis with fresh samples and carefully control all experimental parameters. This helps to confirm or rule out random errors.

- Data validation and statistical analysis: Apply statistical tests, such as Grubbs’ test or Dixon’s Q-test, to determine if outliers are statistically significant. This helps to decide whether to exclude data.

- Documenting findings: Meticulously document all steps taken, including the investigation, corrective actions, and the final decision on how to handle the outliers. This maintains transparency and data integrity.

Ultimately, the decision to include or exclude outliers depends on a thorough investigation and a scientific judgment, ensuring the accuracy and reliability of the reported results. It’s often a collaborative process, discussing the findings with colleagues to reach a well-informed decision.

Key Topics to Learn for Use of Analytical Equipment Interview

- Understanding Analytical Techniques: Grasp the fundamental principles behind various analytical methods, including their strengths, limitations, and appropriate applications. This includes understanding the underlying chemistry or physics involved.

- Instrument Operation and Calibration: Demonstrate proficiency in operating different analytical instruments, such as spectrophotometers, chromatographs (GC, HPLC), and mass spectrometers. This includes proper calibration procedures and troubleshooting common issues.

- Data Analysis and Interpretation: Master the skills needed to analyze the data generated by these instruments. This includes understanding statistical analysis, identifying potential errors, and drawing meaningful conclusions from the results.

- Quality Control and Assurance: Familiarize yourself with quality control measures, ensuring data accuracy and reliability. Understanding regulatory compliance (e.g., GLP/GMP) is crucial.

- Sample Preparation and Handling: Demonstrate knowledge of appropriate sample preparation techniques to ensure accurate and reliable results. This includes understanding the importance of minimizing contamination and handling different sample matrices.

- Troubleshooting and Problem Solving: Be prepared to discuss your approach to troubleshooting instrument malfunctions and addressing inconsistencies in data. This showcases analytical and problem-solving skills.

- Safety Procedures and Regulations: Understand and be able to articulate the importance of adhering to safety protocols when handling chemicals and operating analytical equipment.

Next Steps

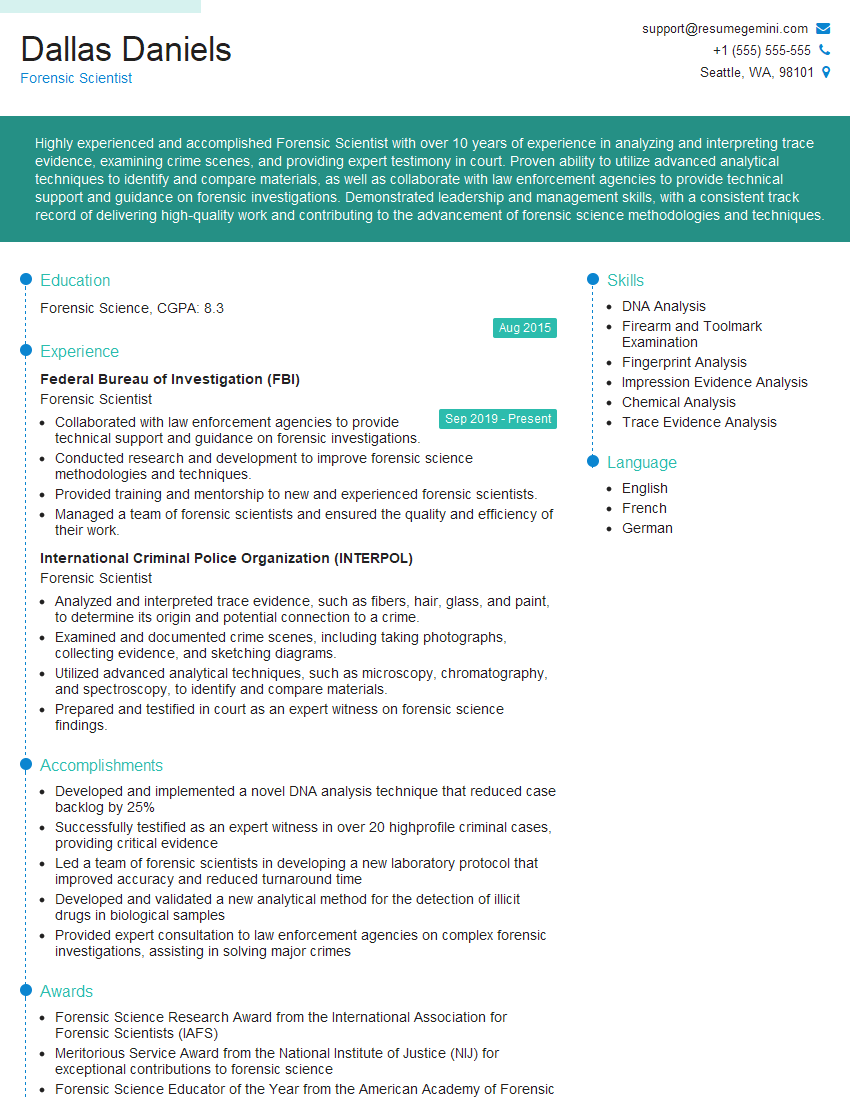

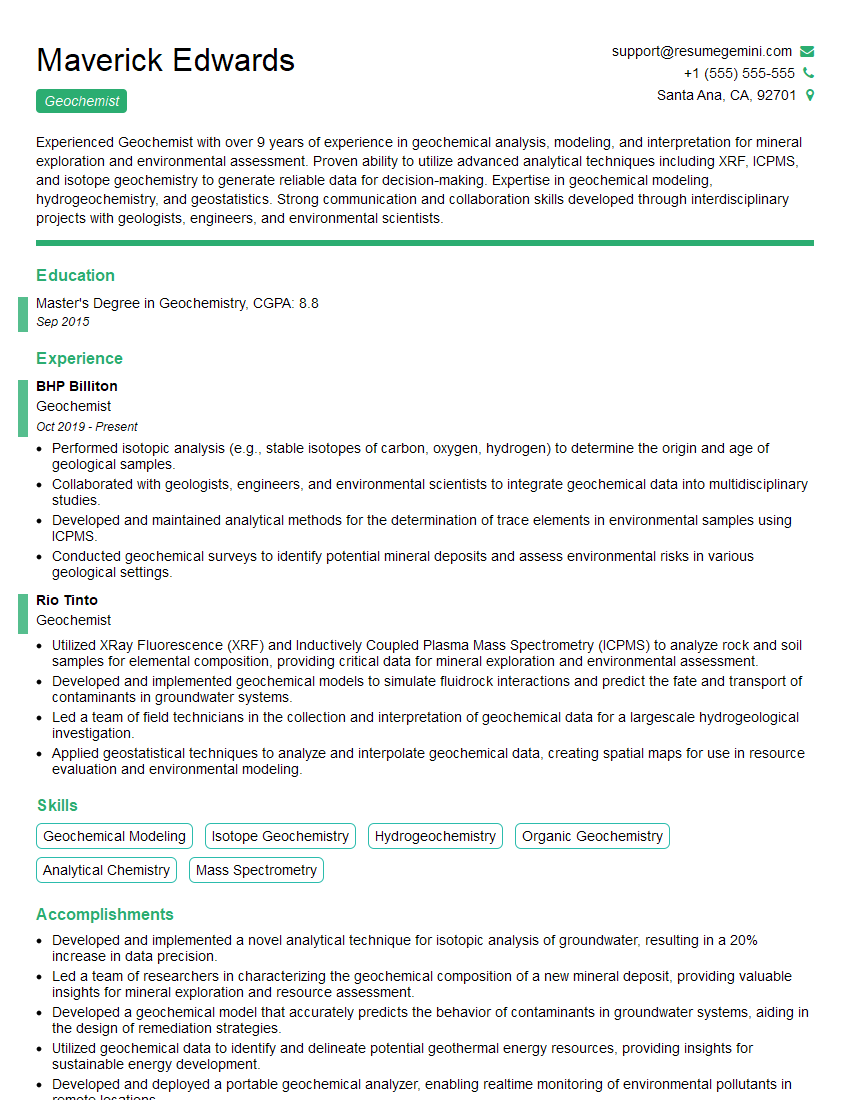

Mastering the use of analytical equipment is crucial for advancement in many scientific and technical fields, opening doors to exciting career opportunities and higher earning potential. A strong resume is your first step to securing these opportunities. Creating an ATS-friendly resume significantly increases your chances of getting noticed by recruiters and employers. To help you craft a compelling and effective resume, we recommend using ResumeGemini, a trusted resource for building professional resumes. ResumeGemini provides examples of resumes tailored to the Use of Analytical Equipment field, helping you present your skills and experience in the best possible light.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good