The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Use of Equipment interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Use of Equipment Interview

Q 1. Describe your experience operating heavy machinery.

My experience with heavy machinery spans over 10 years, encompassing a wide range of equipment including excavators, bulldozers, and loaders. I’ve worked on various construction sites, from small-scale residential projects to large-scale infrastructure developments. This experience has provided me with a deep understanding of the nuances of each machine, their capabilities, and limitations. For instance, I’ve successfully used an excavator to dig precise trenches for utility lines, requiring careful control and precision. On another project, I operated a bulldozer to level vast areas of land, demanding a strong understanding of terrain management and machine power optimization. I’m proficient in both operating and maintaining these machines, ensuring optimal efficiency and safety.

Q 2. Explain the pre-operational checks you perform before using equipment.

Before operating any equipment, I perform a comprehensive pre-operational check, akin to a pilot conducting a pre-flight check. This involves several key steps:

- Visual Inspection: A thorough examination of the machine for any visible damage, leaks, or loose parts. This includes checking tires, hydraulic lines, and the overall structural integrity.

- Fluid Levels: Checking and topping off engine oil, hydraulic fluid, coolant, and fuel levels as needed. Low fluid levels can significantly impact performance and lead to malfunctions.

- Operational Systems Check: Testing all controls, including the steering, brakes, throttle, and attachments. Ensuring each function operates smoothly and responsively is crucial for safety.

- Safety Features Check: Verifying the functionality of safety features such as lights, horns, seatbelts, and emergency shut-off systems. These features are paramount for preventing accidents.

- Documentation Review: Reviewing any relevant documentation or operation manuals to refresh my memory on specific machine procedures and safety guidelines.

Failing to conduct these checks can lead to serious accidents or equipment malfunction. For example, a leak in a hydraulic line could lead to a loss of control, while faulty brakes could result in a collision.

Q 3. How do you ensure the safety of yourself and others when operating equipment?

Ensuring the safety of myself and others while operating heavy machinery is my top priority. It’s not just about following regulations; it’s about developing a safety-first mindset. My approach involves:

- Site Awareness: Maintaining constant awareness of my surroundings, including other personnel, pedestrians, and obstacles. This requires careful observation and anticipation.

- Communication: Utilizing clear and effective communication methods, such as hand signals or radios, to coordinate with other workers on the site. Miscommunication can be very dangerous.

- Safe Operating Practices: Adhering to established safe operating procedures, including maintaining a safe distance from other equipment and personnel. Following speed limits and avoiding sharp turns are also crucial.

- Personal Protective Equipment (PPE): Consistently using appropriate PPE, such as safety helmets, high-visibility clothing, and safety boots. PPE significantly reduces the risk of injury.

- Emergency Procedures: Being familiar with and prepared to execute emergency procedures in case of an accident or equipment malfunction. Knowing how to safely shut down the equipment and call for help is vital.

For example, I once noticed a worker inadvertently wandering into the path of my excavator. By using hand signals to signal a stop and communicating through the radio, I was able to avoid a potential accident.

Q 4. What are the common maintenance procedures for [specific equipment type]?

Let’s take excavators as an example. Common maintenance procedures include:

- Daily Checks: Checking fluid levels (engine oil, hydraulic oil, coolant), inspecting tires, and lubricating moving parts.

- Weekly Checks: More thorough inspection of hydraulic lines for leaks, checking the condition of the tracks or wheels, and tightening any loose bolts or nuts.

- Monthly Checks: Inspecting the engine and performing a more detailed lubrication of critical components.

- Regular Servicing: Scheduled servicing by qualified technicians, including oil changes, filter replacements, and thorough inspections of the entire machine. This usually includes a detailed check of the engine, hydraulic system, and undercarriage.

- Component Replacements: Replacing worn-out parts as needed, such as tracks, filters, and hydraulic hoses. Preventative replacement is crucial to avoid catastrophic failure.

Neglecting these procedures can lead to costly repairs, breakdowns, and safety hazards. A seemingly small issue like a worn track can lead to serious damage if not addressed promptly.

Q 5. How do you troubleshoot malfunctions in equipment?

Troubleshooting equipment malfunctions requires a systematic approach. I typically follow these steps:

- Identify the Problem: Carefully observe the symptoms of the malfunction. Is there a noise, a leak, or a failure to function?

- Check the Obvious: First, check the simple things—fuel levels, fluid levels, and loose connections. Often, the problem is something straightforward.

- Consult Documentation: Review the operator’s manual for troubleshooting guides and common problems for that specific piece of equipment.

- Systematic Inspection: If the problem isn’t obvious, start a systematic inspection, checking each component relevant to the malfunctioning system. This may involve checking sensors, wiring, hydraulic components, or the engine itself.

- Seek Expert Assistance: If I can’t resolve the problem, I seek help from qualified mechanics or technicians.

For instance, if the excavator’s bucket isn’t responding, I would first check the hydraulic fluid level, then inspect the hydraulic lines for leaks, and finally check the control system for malfunctions. This systematic approach helps to quickly pinpoint the source of the issue.

Q 6. Describe your experience with preventative maintenance.

Preventative maintenance is crucial for maximizing equipment lifespan and preventing unexpected breakdowns. My experience in preventative maintenance involves:

- Regular Inspections: Conducting routine inspections based on manufacturer recommendations or established maintenance schedules. This includes visual inspections and functional tests.

- Lubrication: Regularly lubricating moving parts to reduce wear and tear and improve efficiency.

- Fluid Changes: Changing fluids such as engine oil, hydraulic oil, and coolant at the recommended intervals to maintain optimal performance and prevent damage.

- Filter Replacements: Replacing filters (air, fuel, hydraulic) as scheduled to prevent contamination of vital systems.

- Component Monitoring: Monitoring the wear and tear of critical components and replacing them proactively before they fail. This includes things like tracks, belts, and hydraulic hoses.

By proactively addressing potential issues, I significantly reduce downtime and extend the service life of the equipment. It’s much cheaper to replace a worn part than to repair a catastrophic failure caused by neglect.

Q 7. What safety regulations do you adhere to when using equipment?

Safety regulations are paramount in my work. I meticulously adhere to all relevant regulations, which may vary depending on the location and the specific type of equipment. These regulations typically cover:

- Operator Licensing and Certification: Holding the necessary licenses and certifications to operate specific types of heavy machinery.

- Safe Operating Procedures: Following all established safe operating procedures for the equipment and the worksite.

- Personal Protective Equipment (PPE): Wearing and utilizing all required PPE, including helmets, safety glasses, high-visibility clothing, and safety boots.

- Site Safety Regulations: Adhering to all site-specific safety regulations, which may include speed limits, designated traffic routes, and communication protocols.

- Emergency Procedures: Being aware of and prepared to execute emergency procedures, including knowing where to find emergency equipment and how to contact emergency services.

Ignoring safety regulations can lead to serious accidents and legal consequences. Safety is not just a guideline; it’s a non-negotiable requirement.

Q 8. How do you handle unexpected equipment failures?

Unexpected equipment failures are an inevitable part of working with machinery. My approach is systematic and prioritizes safety. First, I ensure the safety of myself and others by immediately shutting down the equipment if possible and securing the area. Then, I follow a structured troubleshooting process.

- Identify the problem: I carefully observe the equipment to pinpoint the nature of the failure. Is there a visible malfunction, an error code displayed, or an unusual sound? This initial assessment is crucial.

- Consult documentation: I refer to the equipment’s manual, troubleshooting guides, and online resources (if available) to identify potential causes and solutions. This step is key to resolving common issues quickly.

- Systematic checks: I systematically check power supplies, connections, and other components. I might use diagnostic tools such as multimeters to measure voltage or current. This process is about eliminating potential causes one by one.

- Escalate if necessary: If I can’t resolve the problem, I escalate it to a supervisor or a specialist, providing them with detailed information about the issue and my troubleshooting steps. Teamwork is vital for complex problems.

- Record keeping: I meticulously document the entire process—the failure, my actions, and the outcome—for future reference and to improve our preventative maintenance strategy.

For example, during a recent project involving a CNC milling machine, a sudden power outage led to a tool jamming. Following this procedure, I successfully identified a loose power connection and restored operation, minimizing downtime.

Q 9. Explain your experience with specific software or systems used to control equipment.

I have extensive experience using Supervisory Control and Data Acquisition (SCADA) systems and Programmable Logic Controllers (PLCs) to control and monitor equipment. SCADA systems provide a centralized interface for managing multiple devices, allowing for remote monitoring and control. PLCs, on the other hand, are programmable devices that automate industrial processes.

In my previous role, I used a SCADA system called Wonderware Intouch to manage a water treatment plant’s pumping and filtration systems. I programmed PLCs using Siemens TIA Portal to automate processes within a manufacturing environment. This involved writing ladder logic programs to control robotic arms and conveyor belts.

My proficiency extends to understanding various communication protocols such as Modbus, Profibus, and Ethernet/IP, which are crucial for connecting and controlling industrial equipment. This allows me to seamlessly integrate new equipment into existing systems.

Q 10. Describe a time you had to repair or fix equipment.

During a field operation with a survey team, our total station—a critical piece of surveying equipment—malfunctioned. The display went blank, and the device wouldn’t power on. This threatened to significantly delay the project. I knew immediate action was necessary.

After confirming the battery was charged, I carefully examined the unit for any physical damage, such as loose connectors or water ingress. Finding nothing, I consulted the service manual, focusing on power supply issues. I found a diagram showing the internal power circuitry. Following the troubleshooting flowchart, I checked the internal fuses.

One fuse had blown. After replacing the fuse with a properly rated one, I tested the power supply and the total station restarted normally. This was a quick fix, but it required careful attention to detail, a clear understanding of the device, and the ability to interpret technical documentation. The project was saved from a potentially significant delay.

Q 11. How do you interpret technical manuals and diagrams?

Interpreting technical manuals and diagrams is a fundamental skill for anyone working with equipment. My approach involves a combination of methodical reading, visual analysis, and practical application.

- Sequential Reading: I start by reading the introductory sections and safety precautions before diving into the specific details. Safety is paramount.

- Visual Analysis: I carefully examine diagrams—circuit diagrams, wiring schematics, exploded views—to understand the equipment’s components and their relationships. I find that sketching key parts often aids in comprehension.

- Cross-referencing: I often cross-reference information from different sections of the manual to gain a holistic understanding. Sometimes, one section will provide a clue missing in another.

- Practical Application: I try to relate the information in the manual to the physical equipment. This hands-on approach solidifies my understanding and helps identify discrepancies.

Think of it like assembling a complex piece of furniture. The manual provides the instructions, but using your hands to put it together improves comprehension far beyond simply reading the directions.

Q 12. What is your experience with different types of equipment?

My experience encompasses a wide range of equipment, including:

- Heavy machinery: I’ve worked with excavators, bulldozers, and loaders on construction sites, understanding their operation, maintenance, and safety protocols.

- Precision instruments: My experience includes using surveying equipment like total stations and GPS receivers, which require a high degree of accuracy and technical understanding.

- Industrial machinery: I’ve operated and maintained CNC machines, robots, and automated assembly lines in manufacturing settings. This requires knowledge of PLC programming and SCADA systems.

- Laboratory equipment: I have experience with various laboratory instruments, including analytical balances, spectrometers, and chromatography systems. This work emphasized precision and adherence to safety regulations.

This broad experience allows me to adapt quickly to new equipment and technologies, leveraging my existing knowledge and applying it effectively in various contexts.

Q 13. What are the common causes of equipment breakdowns?

Equipment breakdowns are usually caused by a combination of factors, including:

- Wear and tear: Mechanical parts wear down over time, leading to malfunctions. Regular maintenance helps mitigate this.

- Improper use: Operating equipment outside its specified parameters can cause damage and premature failure.

- Lack of maintenance: Neglecting regular maintenance checks and repairs increases the likelihood of breakdowns.

- Environmental factors: Extreme temperatures, humidity, or dust can negatively impact equipment performance and lifespan.

- Power surges: Sudden voltage fluctuations can damage sensitive electronic components.

- Human error: Mistakes during operation, maintenance, or repair can contribute to equipment failure.

A proactive approach to maintenance, including regular inspections, lubrication, and component replacements, can significantly reduce the frequency and severity of breakdowns.

Q 14. How familiar are you with different types of safety equipment?

I’m very familiar with a wide array of safety equipment, its proper use, and its importance in preventing accidents. My familiarity includes:

- Personal Protective Equipment (PPE): This includes hard hats, safety glasses, hearing protection, gloves, and safety footwear, crucial for protecting against various hazards.

- Fire safety equipment: I’m trained in the use of fire extinguishers, fire blankets, and emergency escape procedures. Knowing how to respond to a fire is essential.

- Lockout/Tagout (LOTO) procedures: I’m proficient in LOTO procedures for safely isolating equipment during maintenance or repair, preventing accidental energization.

- Emergency shut-off devices: I’m familiar with emergency stop buttons, circuit breakers, and other devices designed to quickly shut down equipment in emergency situations.

- Respiratory protection: I understand the use of respirators and other respiratory protection devices when working in environments with hazardous substances or dust.

Safety is paramount in my work, and I am committed to adhering to all relevant safety regulations and procedures.

Q 15. Explain your experience with calibration and testing of equipment.

Calibration and testing are crucial for ensuring equipment accuracy and reliability. My experience spans various methods, from using certified standards to compare readings to performing diagnostic tests to identify potential issues. For example, when working with spectrophotometers, I’d regularly calibrate using certified wavelength and absorbance standards, meticulously documenting each step. In cases of deviation, I’d systematically troubleshoot, checking for factors like lamp aging, stray light, or cuvette cleanliness. This involved following manufacturer-provided protocols and, in some instances, consulting with calibration specialists for complex instruments. I’m proficient in interpreting calibration certificates and understanding associated uncertainties. This systematic approach ensures the equipment produces dependable and accurate results, vital for the integrity of any experiment or analysis.

Career Expert Tips:

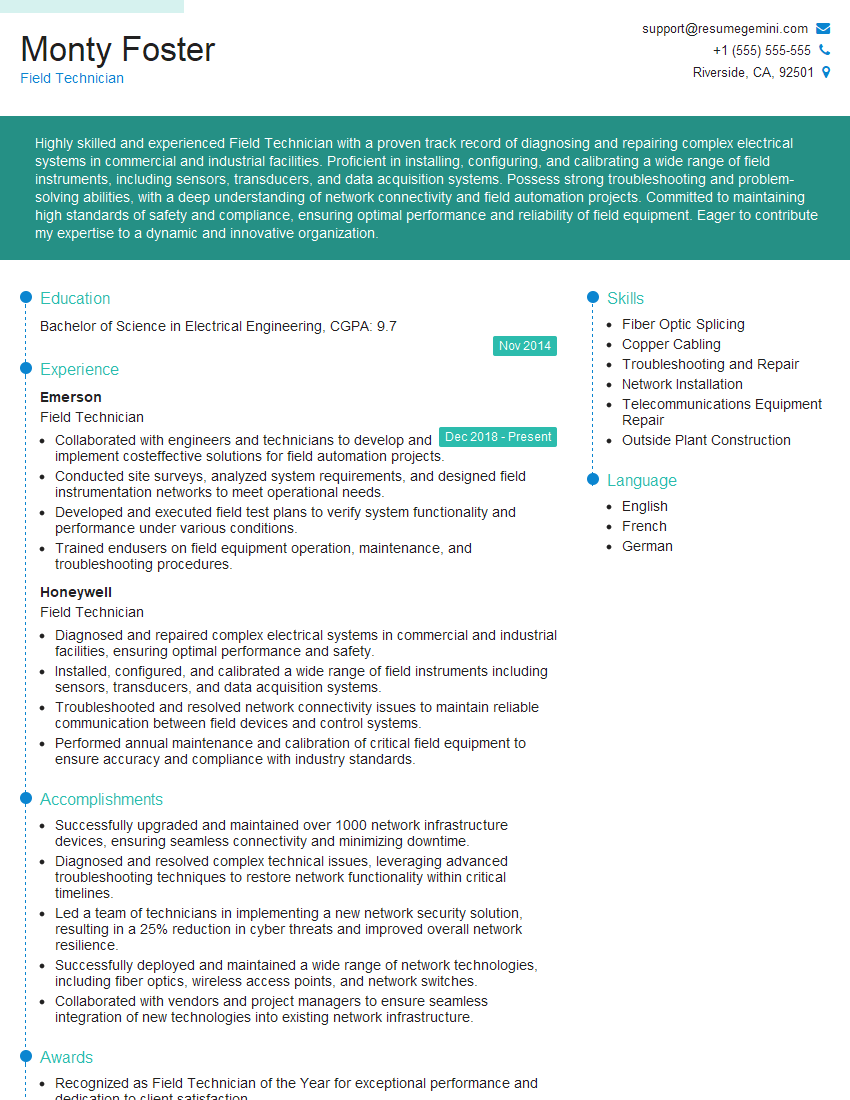

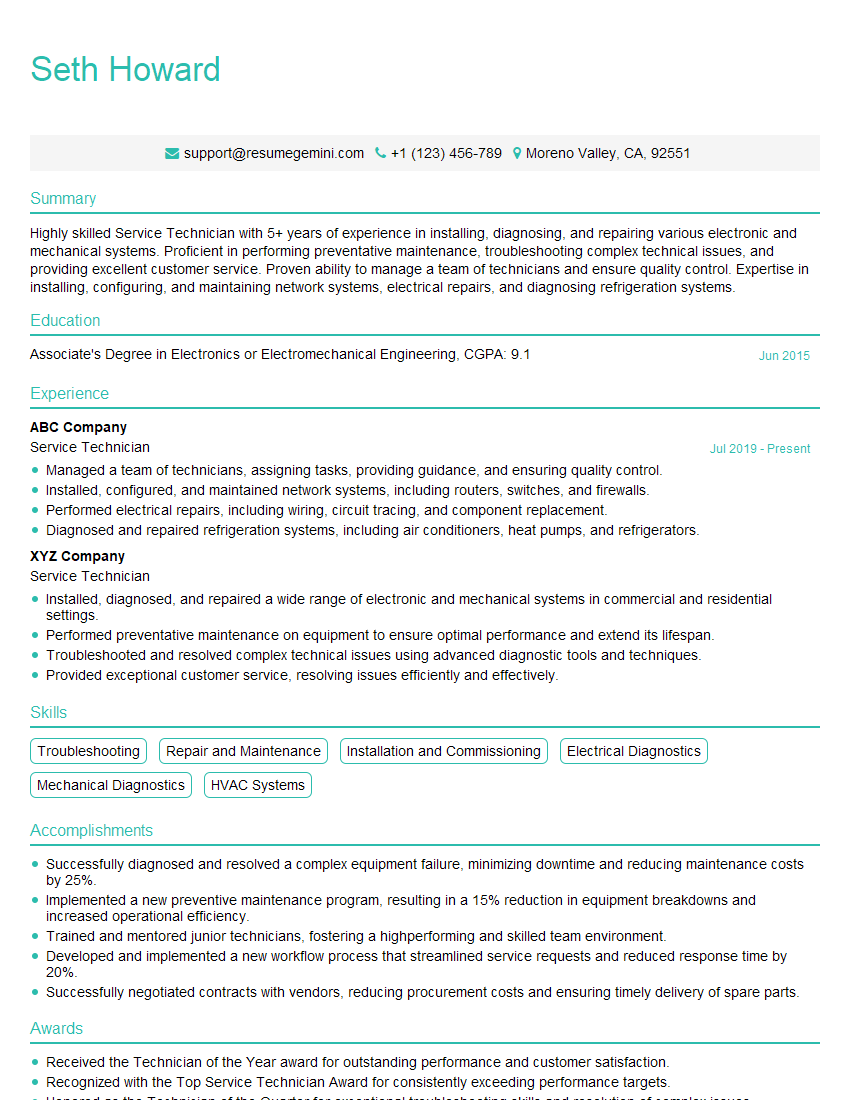

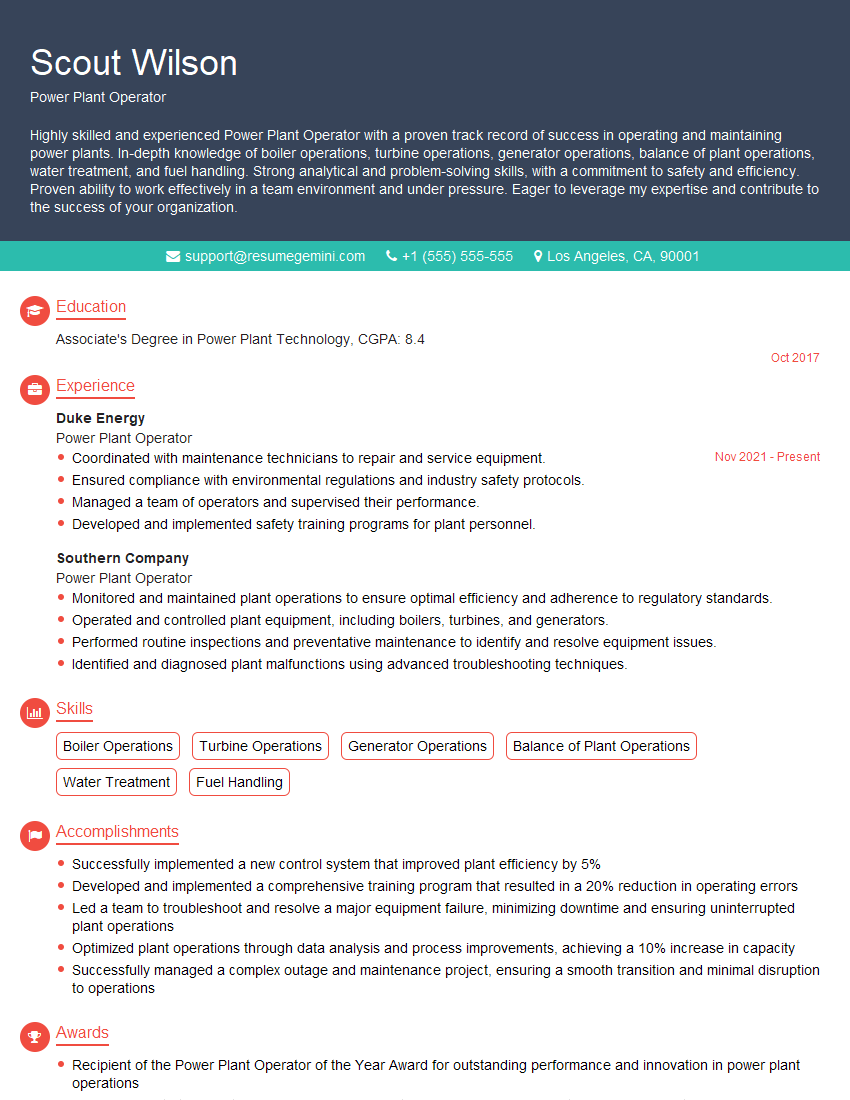

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure accurate measurements and readings?

Accurate measurements hinge on a multi-faceted approach. It starts with selecting the right instrument for the task – a high-precision scale for weighing fine chemicals, for instance, versus a more basic scale for larger quantities. Proper instrument handling is key; this includes ensuring the equipment is level, properly warmed up (if necessary), and that the environment is stable (temperature and humidity). I meticulously follow established procedures, repeating measurements multiple times to identify and mitigate random errors. When dealing with complex data, I’ll often employ statistical analysis to assess the reliability of my readings. For example, calculating standard deviations helps pinpoint outliers and assess the overall precision of my measurements. Furthermore, regular maintenance and calibration of the equipment play a pivotal role in maintaining accuracy. Regular preventative maintenance helps avoid unexpected downtime and costly repairs. This whole process ensures trust and confidence in the data gathered.

Q 17. Describe your experience with data logging and reporting.

My data logging and reporting experience involves both manual and automated methods. I’m proficient in using various software packages to capture data directly from equipment, such as LabVIEW or specialized instrument software. For manual data entry, I use spreadsheets (Excel) to maintain organized records and perform initial data analysis. I’m very detail-oriented and ensure data integrity by implementing double-checking methods. Reports are always clearly structured, including relevant metadata like date, time, equipment used, and calibration information. I use graphs and charts to visualize data effectively, making trends and anomalies readily apparent. For example, in a recent project involving environmental monitoring, I developed a system to automatically log sensor readings at regular intervals and generate weekly reports with graphical summaries of key parameters like temperature and humidity. These reports were then used for quality control, decision-making and compliance.

Q 18. How do you maintain a clean and organized workspace?

Maintaining a clean and organized workspace is paramount for safety and efficiency. I believe in the ‘5S’ methodology – Sort, Set in Order, Shine, Standardize, Sustain. This involves regularly decluttering, organizing tools and equipment logically, keeping surfaces clean, and establishing standardized procedures for material handling and storage. I label everything clearly, making it easy to locate necessary materials. A clean workspace minimizes the risk of accidents caused by tripping hazards or misplaced items, and it allows me to locate tools and materials quickly, improving work efficiency significantly. This also ensures that instruments are kept free of dust and debris, which can affect their performance. In practice, I regularly wipe down surfaces, properly store chemicals, and dispose of waste according to safety regulations.

Q 19. How do you work effectively in a team environment while operating equipment?

Effective teamwork when operating equipment involves clear communication, shared responsibility, and mutual respect. Before starting any operation, I ensure everyone understands the procedure, their roles, and the safety protocols. I actively participate in discussions, sharing my knowledge and experience to help the team overcome challenges. I’m comfortable delegating tasks and providing guidance to team members as needed, always ensuring proper supervision, particularly for complex or potentially hazardous operations. For instance, in a large-scale experiment, I worked collaboratively with technicians to ensure all equipment was properly set up, calibrated, and operated according to safety standards. Open communication and mutual support helped to maintain a safe and efficient workflow.

Q 20. Describe your experience working with different types of materials.

My experience encompasses working with a wide range of materials, from delicate biological samples requiring specialized handling to corrosive chemicals demanding stringent safety precautions. I’m familiar with the properties of various materials and understand the appropriate handling and safety procedures for each. This includes proper storage, disposal, and the use of personal protective equipment (PPE). For example, when working with volatile organic compounds (VOCs), I would use a fume hood and wear appropriate gloves and eye protection. When handling fragile biological samples, I would use sterile techniques and specialized equipment to minimize contamination. Understanding material properties is crucial for avoiding damage to both the materials and the equipment. This ensures experiment integrity and my safety, and the safety of others.

Q 21. What are your strengths and weaknesses when it comes to using equipment?

One of my greatest strengths is my meticulous attention to detail and my commitment to following established procedures. I’m always thorough in my work, ensuring accuracy and reliability. I am also a quick learner and adapt easily to new equipment and technologies. However, a weakness I’m actively working on is multitasking in high-pressure situations. While I can handle multiple tasks effectively, I sometimes struggle when faced with multiple urgent requests simultaneously. To address this, I’m developing better prioritization skills and time management strategies. I’ve found that breaking down complex tasks into smaller, manageable steps helps me stay organized and focused, even under pressure.

Q 22. How do you adapt to using new equipment or technologies?

Adapting to new equipment and technologies involves a structured approach. First, I thoroughly review all provided documentation, including manuals, safety guidelines, and training materials. This provides a foundational understanding of the equipment’s capabilities and limitations. Then, I prioritize hands-on practice, starting with simple operations and gradually increasing complexity. I find that a combination of guided training and independent experimentation is most effective. I also actively seek feedback from experienced colleagues or supervisors, incorporating their insights to refine my technique. For example, when our lab acquired a new electron microscope, I spent a week undergoing formal training, followed by a period of supervised operation before tackling independent projects. This staged approach minimized errors and maximized efficiency.

Q 23. How do you prioritize tasks when operating multiple pieces of equipment?

Prioritizing tasks with multiple pieces of equipment demands efficient time management and risk assessment. I utilize a system that prioritizes tasks based on urgency and criticality. Tasks with tight deadlines or significant consequences are tackled first. I also consider the interdependencies between tasks; if one task needs to be completed before another can begin, it receives higher priority. For example, if I’m operating a CNC machine, a 3D printer, and a laser cutter simultaneously, I’d first ensure the CNC machine is properly set up for a long, critical job, then move to a shorter, less critical laser cutting task, and then finally operate the 3D printer which is less time-sensitive. This ensures the most efficient workflow and minimizes potential conflicts.

Q 24. How do you handle pressure and tight deadlines when using equipment?

Handling pressure and tight deadlines requires a calm and methodical approach. First, I assess the situation, breaking down the task into smaller, manageable steps. This helps avoid feeling overwhelmed. Next, I focus on efficient execution, minimizing downtime and avoiding unnecessary errors. I communicate transparently with my supervisors or team if I encounter unexpected delays or challenges. Finally, I utilize time management techniques like the Pomodoro method, focusing intensely for short periods with brief breaks to maintain concentration. For example, during a product launch where we faced a tight deadline, I utilized this strategy; focusing intently on the assembly line for 25 minutes and taking a 5 minute break. This structure helped to maintain efficiency without compromising quality or safety.

Q 25. Describe your experience with specific tools and techniques.

My experience spans a variety of tools and techniques. I’m proficient in operating CNC milling machines (including programming using G-code), 3D printers (both FDM and SLA technologies), laser cutters, various hand tools (soldering irons, multimeters, etc.), and precision measurement equipment (calipers, micrometers). I have extensive experience with CAD software (Solidworks, Fusion 360) for designing and preparing models for fabrication. I am also familiar with various welding techniques, including MIG and TIG welding. My experience also includes using advanced software for analyzing data acquired from sophisticated equipment such as spectrophotometers. Each requires different skills but they all rely on a foundation of precision, accuracy, and attention to detail.

Q 26. How familiar are you with the relevant industry standards and regulations?

I am very familiar with relevant industry standards and regulations. My understanding encompasses OSHA safety protocols, relevant machinery safety regulations, and environmental protection guidelines. For example, I’m well-versed in the safe handling and disposal of hazardous materials used in various processes. I regularly review updates to these standards to ensure my practices remain current and compliant. Continuous professional development, including industry-specific training, is key to staying updated on these constantly evolving regulations. This awareness is critical to not only ensure safety but also to maintain a high level of compliance.

Q 27. Describe a time you had to improvise to solve an equipment-related problem.

During a critical project, our primary 3D printer malfunctioned, causing significant delays. Instead of waiting for repairs, I improvised by using a combination of smaller, less precise 3D printers and manual assembly techniques. I divided the larger print job into smaller components that could be printed on the available machines. Then, I painstakingly assembled these components using adhesive and meticulous hand-fitting. Though this process was more time-consuming, it allowed us to meet the deadline and demonstrate adaptability under pressure. This experience highlighted the importance of both problem-solving skills and thorough knowledge of alternative equipment capabilities.

Q 28. What is your experience with quality control procedures for equipment use?

Quality control procedures are integral to my workflow. This begins with pre-operation checks of all equipment, ensuring calibration, proper functionality and the absence of any defects. During operation, I meticulously monitor the process, regularly inspecting outputs for any discrepancies from the specifications. Post-operation, I conduct thorough inspections, often using precision measurement tools to verify dimensions and tolerances. Data logging and documentation are crucial for tracking performance and identifying potential issues. In case of anomalies, a comprehensive investigation is conducted to determine the root cause and implement corrective actions. This rigorous approach ensures high-quality outputs and continuous improvement in operational efficiency.

Key Topics to Learn for Use of Equipment Interview

- Equipment Operation & Maintenance: Understanding the theoretical principles behind the equipment’s functionality, including safety procedures and routine maintenance checks. This includes preventative maintenance schedules and troubleshooting common issues.

- Practical Application & Troubleshooting: Describe scenarios where you’ve successfully used specific equipment, highlighting your problem-solving skills when facing technical challenges. Be prepared to discuss how you diagnosed and resolved equipment malfunctions.

- Safety Protocols & Regulations: Demonstrate your knowledge of relevant safety regulations and procedures associated with operating the equipment. Explain how you ensure a safe working environment for yourself and others.

- Calibration & Accuracy: Discuss the importance of equipment calibration and its impact on the accuracy of results. Explain how you ensure accurate measurements and data collection using the equipment.

- Data Analysis & Interpretation: Explain how you interpret data generated by the equipment and use it to make informed decisions or draw conclusions. This includes understanding potential sources of error and their impact on the data.

- Advanced Techniques & Technologies: If applicable, showcase your proficiency in advanced techniques or technologies related to the equipment, such as automation, data logging, or specialized software.

Next Steps

Mastering the use of equipment is crucial for career advancement in many fields, opening doors to more challenging and rewarding roles. A strong resume is your key to unlocking these opportunities. To ensure your qualifications shine, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume. We provide examples of resumes tailored to the Use of Equipment field to guide you in crafting the perfect application. Let ResumeGemini help you showcase your expertise and land your dream job!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good