Preparation is the key to success in any interview. In this post, we’ll explore crucial Use of forestry equipment interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Use of forestry equipment Interview

Q 1. Describe your experience operating a feller buncher.

My experience with feller bunchers spans over eight years, encompassing various machine models and diverse forestry conditions. I’m proficient in operating both shear-equipped and saw-equipped bunchers. Initially, I focused on smaller, more maneuverable machines in dense stands, learning the nuances of precise cutting and efficient bunching in challenging terrain. As my skills progressed, I transitioned to larger machines capable of handling larger timber volumes in more open areas. A key skill I’ve developed is adapting my technique to the specific tree species and site conditions – adjusting cutting height, bunching techniques, and machine speed to optimize both productivity and minimize damage. For instance, in areas with steep slopes, I’ve mastered the art of careful positioning and controlled movements to prevent rollovers or machine instability. I also have experience with preventative maintenance, troubleshooting minor mechanical issues, and conducting daily pre-operational checks.

One memorable experience involved working in a particularly challenging area with dense undergrowth and varying tree sizes. By carefully adjusting the shear settings and employing strategic bunching techniques, I significantly increased efficiency, proving the adaptability and expertise I possess in operating these machines.

Q 2. Explain the safety procedures for operating a skidder.

Safety is paramount when operating a skidder. Before starting, a thorough pre-operational inspection is essential, checking brakes, hydraulics, tires, and the grapple’s functionality. This is followed by ensuring the area is clear of obstacles and personnel, and that the communication system is operational. While operating, maintaining a safe speed appropriate for terrain and visibility is crucial. Sudden stops and sharp turns should be avoided, especially on slopes. The operator should always be aware of their surroundings, actively looking for potential hazards such as hidden stumps, rocks, or uneven ground. Proper use of the seatbelt is mandatory, and always ensuring the grapple is securely closed when moving logs to prevent them from shifting and causing accidents. Following designated haul roads and avoiding shortcuts through dense vegetation or across unstable ground is vital. When working near others, clear communication and pre-determined signal systems are essential to coordinate movements and prevent collisions. Regular training and adherence to company safety protocols are non-negotiable aspects of my operation.

Think of it like driving a car – you wouldn’t speed around blind corners, and you certainly wouldn’t drive without your seatbelt. The same principles apply, but with much heavier equipment and potentially more severe consequences.

Q 3. What are the different types of harvesting heads and their applications?

Harvesting heads are crucial for efficient timber harvesting, and different types cater to various needs.

- Shear heads are ideal for cutting smaller trees and delimbing them, creating clean, compact bundles. They are efficient in dense stands but less effective with larger diameter trees.

- Saw heads are better suited for larger trees, offering precise cutting and less damage to the wood. However, they are typically slower than shear heads.

- Processor heads combine cutting, delimbing, and bunching functions into a single unit, maximizing efficiency but often at a higher initial cost and complexity.

- Grapple heads primarily deal with moving felled logs; while not technically a harvesting head in the same sense, they are essential for the logging process. They are used to lift and maneuver logs in the yard and onto trucks.

The choice of harvesting head depends on factors like tree size, species, terrain, and harvesting goals. For example, in a plantation of small-diameter trees, a shear head might be preferable due to its speed. In a selective logging operation in a mixed hardwood stand, a saw head might be more appropriate to minimize damage to the remaining trees. Using the correct harvesting head optimized for the current operation directly translates to better productivity and less material damage.

Q 4. How do you maintain the chain and bar on a chainsaw?

Maintaining a chainsaw’s chain and bar is crucial for safety and performance. This involves regular sharpening, lubrication, and inspection.

- Sharpening is done using a file or electric sharpener, ensuring the teeth are consistently sized and shaped to maintain a proper cutting angle. Regular sharpening prevents kickback, increases cutting speed, and reduces the effort required during operation. A dull chain requires more force and increases the risk of accidents.

- Lubrication is essential to reduce friction and prevent overheating. The bar oil reservoir needs to be regularly checked and refilled as needed during operation, which is done via a pump system.

- Inspection should be done before each use, checking for damage to the chain, such as stretched or broken links, and to the bar, looking for cracks or excessive wear. A damaged chain can break, causing serious injury, while a damaged bar can lead to poor cutting and increased risk of accidents.

Imagine trying to cut wood with a dull knife – it’s difficult, inefficient, and dangerous. Regular maintenance of your chainsaw is like keeping your knife sharp, ensuring smooth, safe, and effective operation.

Q 5. Describe your experience with pre-harvest planning and site preparation.

My experience with pre-harvest planning encompasses a detailed understanding of the whole process, from initial site assessment to final cleanup. I’m involved in reviewing maps, aerial photographs, and ground surveys to identify boundaries, access points, and potential hazards, such as steep slopes or wetlands. Based on this assessment, harvesting plans that detail the method of harvesting and the equipment required are created. This would consider tree size and density, along with considerations to ensure the work is performed in an environmentally sustainable way. Prior to harvesting, appropriate site preparation ensures efficient and safe operations. This might involve creating access roads, clearing underbrush, and marking trees for felling. Careful planning minimizes environmental impact and enhances operational efficiency by ensuring the machines can access the site and operate safely.

For example, on one project, careful pre-harvest planning identified a sensitive wetland area. By adjusting the harvesting layout, we were able to avoid disturbing the wetland and maintain our operational efficiency without impacting environmental considerations.

Q 6. What are the common causes of equipment malfunctions and how do you troubleshoot them?

Equipment malfunctions are common in forestry. Some common causes include:

- Hydraulic system failures often stem from leaks, damaged hoses, or faulty pumps. Troubleshooting involves checking fluid levels, inspecting hoses for damage, and testing the pump’s functionality.

- Engine problems can result from insufficient fuel, faulty ignition systems, or damaged components. Diagnosis typically includes checking fuel levels, spark plugs, and air filters.

- Electrical issues, such as faulty wiring or damaged sensors, can cause various malfunctions. Troubleshooting involves systematic checking of electrical components and wiring diagrams.

- Mechanical problems may involve worn parts, broken components, or issues with linkages. This often requires more in-depth diagnostics and potentially part replacement.

Troubleshooting usually follows a methodical approach: checking the obvious (fuel, oil, hydraulic fluid levels), then carefully listening for unusual sounds, observing for leaks or unusual behavior, and consulting the machine’s service manual for guidance. For more complex issues, I’m skilled in utilizing diagnostic tools and know when to seek professional assistance.

Q 7. How do you ensure the safety of yourself and others while operating forestry equipment?

Ensuring safety for myself and others is my top priority. This begins with comprehensive training on the equipment and adherence to all safety regulations. Daily pre-operational checks are conducted meticulously to identify and address any potential issues before starting work. I always wear appropriate Personal Protective Equipment (PPE), including helmets, safety glasses, hearing protection, and high-visibility clothing. Clear communication with other crew members is maintained throughout the operation, using established signal systems or radio communication to coordinate movements and avoid collisions. Strict adherence to safe operating procedures, such as maintaining a safe distance from other equipment and personnel, avoiding risky maneuvers, and promptly reporting any safety concerns are essential. Regular maintenance ensures equipment remains in good operating condition, reducing the risk of mechanical failure. Understanding the limitations of both the equipment and myself is essential to maintaining a safe operating environment for all involved.

Safety is not just a set of rules; it’s a mindset and a commitment. By embracing a culture of safety, we protect ourselves, our colleagues and the environment.

Q 8. What are the different types of forestry tractors and their uses?

Forestry tractors are the workhorses of the logging industry, varying greatly in size, power, and capabilities depending on their intended use. They’re categorized primarily by their function and the terrain they operate in.

- Skidders: These are primarily used for dragging felled logs from the felling site to a landing area. They typically have a winch and grapple for grabbing and pulling logs. Smaller skidders might be used in more challenging terrain, while larger ones are used in flatter, more accessible areas. Think of them as the ‘heavy lifters’ of the logging operation.

- Forwarders: Forwarders are designed to carry logs directly from the felling site to the landing. They have a hydraulic loading crane and a carrying platform, allowing for a more efficient process, especially in areas with longer distances to the landing. They are like mobile log-carrying trucks, but designed for rough terrain.

- Feller Bunchers: These are massive machines that fell trees and gather them into bundles. They are equipped with cutting heads that can cut multiple trees at once, greatly increasing efficiency. Their powerful hydraulic arms bunch the felled trees together for easier removal by a skidder or forwarder. They’re excellent for large-scale clear-cutting operations.

- Harvesters: These are highly specialized machines that combine the functions of felling, limbing, and delimbing trees, often in a single operation. They are highly automated and increase productivity significantly, but are also expensive and require skilled operators. Imagine them as ‘all-in-one’ logging machines.

The choice of tractor depends heavily on factors like terrain, tree size, harvesting volume, and the overall logging strategy employed.

Q 9. Explain the process of felling a tree safely.

Safe tree felling is paramount. It’s a multi-step process that prioritizes worker safety and environmental protection. Before even touching the saw, proper planning is crucial.

- Assess the tree: Check for dead branches, leaning, disease, and any potential hazards like neighboring trees or power lines. The direction of the fall must be carefully planned to avoid damage.

- Clear the felling area: A safe working zone (typically a radius of twice the tree’s height) should be completely cleared of obstacles and personnel.

- Make the undercut: This controlled cut creates a hinge, influencing the direction of the fall. The size and angle of the undercut depends on the tree’s size, lean, and the desired direction of the fall.

- Make the back cut: This cut severs the tree, leaving a hinge that controls the falling direction. The cut should be slightly higher than the undercut, leaving enough wood for a hinge.

- Felling wedges: If needed, wooden or metal wedges are used to help guide the tree’s fall and ensure a controlled drop. They can help prevent binding or unexpected changes in direction.

- Escape route: The operator must establish a clear escape route, ensuring they can retreat quickly and safely once the tree starts to fall.

Experience and proper training are essential to ensure safe and efficient tree felling.

Q 10. How do you identify and mitigate risks associated with operating forestry equipment?

Risk mitigation in forestry operations is critical. It’s a multifaceted process that begins with pre-operational planning and continues throughout the entire operation.

- Pre-operational checks: Thoroughly inspect all equipment for mechanical issues, loose parts, and any signs of damage. This includes checking hydraulics, brakes, and safety systems.

- Site assessment: Evaluate the terrain for potential hazards such as unstable ground, steep slopes, and obstacles. Consider weather conditions like wind and rain, which significantly impact safety.

- Operator training and certification: Ensuring operators are properly trained and certified on the specific equipment they’re using is paramount. Regular refresher courses are beneficial.

- Communication protocols: Clear communication is crucial, particularly in team environments. Establish visual and auditory signals for indicating potential hazards.

- Personal Protective Equipment (PPE): Every operator should wear appropriate PPE, including helmets, safety glasses, hearing protection, and high-visibility clothing.

- Emergency procedures: Develop and regularly review emergency procedures, including communication plans and first aid protocols. Have a first aid kit readily available.

Proactive risk identification and mitigation minimize accidents and ensure a safe working environment.

Q 11. What are your experiences with GPS-guided forestry equipment?

My experience with GPS-guided forestry equipment is extensive. I’ve worked with several systems that provide real-time location data, allowing for precise machine control and improved efficiency.

These systems are instrumental in:

- Precision harvesting: GPS guidance allows for more precise cutting and reduces waste by minimizing damage to surrounding trees.

- Optimized routes: The GPS systems can plan efficient routes through the logging area, reducing travel time and fuel consumption.

- Data collection and analysis: Many systems record valuable data like tree locations, felling patterns, and machine performance, which enables better operational planning and assessment.

- Improved safety: By automating certain aspects of machine operation and providing detailed mapping, these systems contribute to safer working conditions.

For example, I’ve used GPS-guided harvesters that automatically adjust their cutting positions based on real-time GPS data, ensuring accurate felling and minimizing errors. This significantly improves productivity and reduces the potential for accidents.

Q 12. Describe your understanding of forestry regulations and safety standards.

Forestry regulations and safety standards vary by jurisdiction, but common themes include environmental protection, worker safety, and responsible resource management.

My understanding includes:

- Environmental regulations: These address issues such as soil erosion, water quality, wildlife habitat protection, and reforestation requirements. Compliance often necessitates adherence to specific logging practices and environmental impact assessments.

- Occupational safety and health (OSH) regulations: These cover aspects like operator training, equipment safety, and hazard mitigation. These standards often mandate the use of specific safety equipment and procedures.

- Transportation regulations: Regulations regarding the transport of logs, including load limits, securing methods, and vehicle maintenance, are crucial for ensuring safe transportation of harvested materials.

Staying current on these regulations is crucial for ensuring legal and ethical operations. Regular review of local and national standards is necessary to ensure compliance.

Q 13. How do you handle challenging terrain while operating forestry equipment?

Operating forestry equipment on challenging terrain requires skill, experience, and caution. My approach involves a combination of careful planning and skillful machine operation.

- Terrain assessment: Before starting any operation, I thoroughly assess the terrain, identifying potential hazards like steep slopes, soft ground, and obstacles. This includes considering factors like visibility, weather conditions, and ground stability.

- Machine selection: The choice of equipment is critical. Smaller, more agile machines are better suited for rough terrain, whereas larger machines might be more suitable for flatter areas.

- Appropriate speed and technique: I maintain a slow and controlled speed, especially on slopes and uneven ground. Smooth operation reduces stress on the machine and improves stability.

- Utilizing features: Many modern machines have features designed to aid operation in challenging terrain, such as differential locks, traction control, and advanced suspension systems. Leveraging these features is vital.

- Awareness of limitations: Understanding the limitations of both the machine and the operator is crucial. Don’t attempt maneuvers that are beyond the capabilities of the equipment or operator.

Experience plays a significant role. Knowing when to adjust your approach based on changing conditions is key to successful and safe operation.

Q 14. Explain your experience with different types of forestry attachments.

My experience encompasses a wide array of forestry attachments, each designed for a specific task.

- Grapples: These are used for grasping and carrying logs, offering varying sizes and designs depending on the size and type of log being handled. Some are designed for delicate handling, while others are more robust.

- Cutting heads (for harvesters and feller bunchers): These range from shear-style heads that cut trees cleanly to disc-style heads which are more suitable for smaller trees or thick brush. The choice depends on tree size and the desired level of precision.

- Delimbing heads: These specialized attachments remove branches from felled trees, optimizing the final log quality and increasing efficiency.

- Winches: These are critical for skidders, providing the pulling power needed to drag logs from the felling site. Their capacity varies based on the terrain and the weight of the logs being transported.

- Buckets: While less specialized than others, buckets are useful for general tasks, including clearing debris and assisting in site preparation.

The effective utilization of these attachments significantly impacts operational efficiency, safety, and the overall quality of the harvested timber. Choosing the right attachment for the job is paramount for optimal performance.

Q 15. How do you perform preventative maintenance on forestry equipment?

Preventative maintenance on forestry equipment is crucial for ensuring safety, maximizing uptime, and extending the lifespan of these often expensive machines. It’s not just about fixing problems; it’s about preventing them in the first place. My approach involves a multi-faceted strategy focusing on regular inspections, scheduled servicing, and operator diligence.

Daily Inspections: Before each shift, I perform a thorough visual inspection, checking for loose bolts, leaks (oil, fuel, hydraulic fluid), worn parts (belts, chains, tyres), and any unusual noises or vibrations. This is akin to a doctor checking a patient’s vital signs – catching small issues before they become major problems. For example, a small oil leak ignored could lead to a catastrophic engine failure.

Scheduled Servicing: Following the manufacturer’s recommended service schedule is paramount. This typically involves tasks such as oil changes, filter replacements, greasing of moving parts, and more involved checks like inspecting brake systems and hydraulic components. Think of it like getting your car serviced – regular maintenance keeps it running smoothly and prevents bigger, more costly repairs later.

Operator Training and Maintenance Logs: Proper operator training is essential. Operators should understand basic maintenance procedures and be responsible for reporting any issues immediately. Maintaining detailed maintenance logs is also critical for tracking service history, identifying recurring problems, and ensuring compliance with safety regulations.

For example, on a feller buncher, I’d pay close attention to the hydraulic system, ensuring proper fluid levels and checking for leaks. With a skidder, I’d focus on the tires, checking for wear and tear, and ensuring proper inflation pressure. This combination of daily checks, scheduled servicing, and meticulous record-keeping ensures my equipment operates safely and efficiently.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the environmental considerations when operating forestry equipment?

Environmental considerations are paramount when operating forestry equipment. Our industry has a significant impact on the environment, and minimizing that impact is crucial for sustainable forestry. My approach incorporates several key aspects:

Minimizing Soil Compaction: Heavy equipment can compact soil, leading to reduced water infiltration and harming forest regeneration. We use techniques like employing lighter machines where possible, using wider tracks or tires to distribute weight, and avoiding operations on wet ground.

Protecting Water Resources: Erosion and sedimentation from forestry operations can pollute waterways. We use erosion control measures such as constructing temporary water bars and minimizing disturbance near streams and rivers.

Reducing Greenhouse Gas Emissions: Forestry equipment contributes to greenhouse gas emissions. We prioritize fuel-efficient machines, proper maintenance to optimize fuel consumption, and explore alternative fuels whenever feasible.

Protecting Biodiversity: We carefully plan operations to minimize habitat disturbance and protect sensitive ecosystems. This involves avoiding nesting sites during sensitive periods and following prescribed burning protocols if necessary.

Waste Management: Proper disposal of fuel and oil containers and minimizing waste is vital. We ensure compliance with all waste disposal regulations.

For instance, I always choose the appropriate machine for the job to reduce unnecessary ground disturbance. If the terrain is sensitive, we might use a smaller skidder or even manual methods. Moreover, regular maintenance helps minimize emissions by ensuring optimal engine performance.

Q 17. Describe your experience with different cutting techniques.

My experience encompasses various cutting techniques, each tailored to specific tree species, terrain, and harvesting objectives. The choice of technique significantly impacts efficiency, safety, and the quality of the harvested timber.

Selective Cutting: This method involves removing only mature or specific trees, leaving the remaining forest intact. It is crucial for maintaining forest health and biodiversity. The technique requires precision and skillful maneuvering of equipment to avoid damaging surrounding trees.

Clear-Cutting: This involves removing all trees from a designated area. While efficient, it can have significant environmental impacts. Careful planning and post-harvest management are critical to mitigate negative consequences.

Shelterwood Cutting: This technique involves removing trees in stages, leaving a protective cover of trees to provide shade and shelter for regeneration. This method promotes natural regeneration and minimizes soil erosion.

Seed-Tree Cutting: Similar to shelterwood, this leaves behind a small number of seed-producing trees to regenerate the stand.

For example, in a steep slope, I might employ directional felling to minimize the risk of trees rolling downhill and damaging equipment or causing injury. In a dense stand, using a feller buncher allows for rapid and efficient clearing, whereas in a less dense stand, a chainsaw might be more appropriate.

Q 18. How do you manage fuel efficiency while operating forestry equipment?

Managing fuel efficiency is vital for both economic and environmental reasons. It significantly impacts operational costs and reduces our carbon footprint.

Proper Machine Maintenance: Regular servicing, including tune-ups, ensures optimal engine performance and minimizes fuel consumption. A well-maintained engine burns fuel more efficiently.

Operator Skill and Technique: Experienced operators know how to maneuver equipment efficiently, avoiding unnecessary idling and aggressive acceleration. Smooth operation saves fuel.

Route Planning: Careful planning of logging routes minimizes unnecessary travel and reduces fuel consumption. Efficient route planning reduces wasted time and fuel.

Using Appropriate Equipment: Selecting the right machine for the job is crucial. Oversized equipment uses more fuel than needed for the task.

Fuel Monitoring: Regularly checking fuel levels prevents running out of fuel and reduces unnecessary idling during refueling.

For instance, I might use GPS technology to optimize logging routes, minimizing travel distances. I also ensure all equipment has regularly scheduled maintenance to maintain optimal performance. Smooth operation and careful planning are key aspects of my fuel-efficiency strategy.

Q 19. What is your experience with different types of logging systems?

My experience includes working with various logging systems, each with its advantages and disadvantages depending on the site conditions, timber species, and harvesting objectives.

Conventional Logging: This involves using a combination of felling machines (chainsaws or feller bunchers), skidders (to move logs), and loaders (to load logs onto trucks). This system is widely used and adaptable to various conditions.

Full-Tree Logging: The entire tree is harvested and transported to a processing site for delimbing and bucking (cutting into logs). This system is efficient for short distances but may create more waste.

Short-Wood Logging: Trees are cut into shorter lengths at the felling site, reducing transportation costs and facilitating easier handling, especially in rough terrain. It is often used in conjunction with grapple skidders.

Pre-commercial Thinning: This involves removing smaller trees to improve the growth of remaining trees, enhancing forest health and future timber yields. This requires careful planning and selection of trees to remove.

For example, in areas with steep slopes, I might prefer short-wood logging to minimize the risk of log rollovers. In areas with relatively flat terrain and easy access, full-tree logging might be more cost-effective. Each system has its place, and the choice depends on many factors.

Q 20. How do you ensure the proper transportation of harvested timber?

Safe and efficient transportation of harvested timber is crucial to prevent damage, delays, and accidents. My approach incorporates several key elements:

Proper Loading and Securing: Logs must be loaded and secured correctly to prevent shifting during transit. This involves using appropriate binding techniques, ensuring even weight distribution, and adhering to load limits.

Vehicle Maintenance: Trucks and trailers used for timber transport need regular maintenance to ensure safe braking and operational efficiency. This prevents breakdowns and improves safety.

Route Planning: Routes should be planned to consider road conditions, weight limits, and potential hazards. This minimizes the risk of accidents and delays.

Compliance with Regulations: All transportation must adhere to relevant safety regulations, including load limits, transportation permits, and proper signage.

Driver Training: Drivers need specific training to handle the weight and size of timber loads safely and efficiently. This is crucial for road safety.

For example, I always ensure logs are properly chained and secured to the trailer, and we carefully monitor weight limits to ensure the truck isn’t overloaded. We also ensure our drivers are properly trained and understand the necessary safety precautions for transporting timber.

Q 21. Explain your understanding of different wood species and their properties.

Understanding different wood species and their properties is fundamental to effective forestry operations. The choice of harvesting and processing techniques, as well as the end-use of the timber, is directly influenced by these properties.

Density: This influences the weight and strength of the wood. Denser woods like oak are stronger and heavier than lighter woods like pine.

Strength: Different species have varying levels of strength and durability, affecting their suitability for various applications. Hardwoods like maple are known for their strength.

Workability: Some woods are easier to work with than others. Softwoods like pine are generally easier to work with than hardwoods like oak.

Durability: Some species are more resistant to decay and insect attack than others. Cedar is known for its resistance to rot.

Grain Pattern: The grain pattern affects the appearance and workability of the wood. Straight grain is generally easier to work with than curly or figured grain.

For example, when harvesting oak, we would use different techniques and potentially heavier equipment compared to harvesting pine, due to oak’s higher density and strength. Knowledge of these properties is crucial for efficient and safe operation and to ensure the wood is utilized for its appropriate purpose.

Q 22. How do you deal with equipment breakdowns in remote locations?

Equipment breakdowns in remote locations are a serious concern. My approach is proactive and multi-faceted. First, I meticulously maintain my equipment, adhering to strict preventative maintenance schedules. This includes regular checks of vital components, prompt oil changes, and careful inspection for wear and tear. Think of it like regular check-ups at the doctor – it prevents larger problems later.

Second, I always carry a comprehensive toolkit, including spare parts for common failures I’ve encountered in the past on this particular equipment and terrain. This allows me to handle many smaller repairs on-site. For example, I always carry spare belts, spark plugs, and fuel filters for my chainsaw and skid steer.

However, sometimes repairs exceed my capabilities. In those cases, I have established communication protocols. My team and I always carry satellite phones to contact our support base in case of a major breakdown. We also pre-plan emergency routes and have established communication checkpoints for daily check-ins. Clear communication is essential for timely assistance and minimizes downtime. Finally, I’m proficient in using diagnostic tools to pinpoint the problem, which assists mechanics in getting the equipment up and running quickly.

Q 23. What is your experience with using different types of lubricants and fuels?

My experience with lubricants and fuels is extensive. I understand the importance of using the correct type and grade for each piece of equipment. Using the wrong lubricant can lead to serious damage, significantly reducing the lifespan of critical components such as engines and hydraulic systems. This is like using the wrong type of oil in your car; you’d risk engine failure.

For example, I’m familiar with the different viscosity grades of engine oils (like 10W-30, 15W-40) and their impact on performance in various temperatures. I also understand the characteristics of different fuels such as gasoline, diesel, and biofuels, their proper storage and handling, and the implications of using contaminated fuel. I know the dangers of mixing different fuels and the importance of preventing fuel contamination, which can lead to severe engine damage. I meticulously follow the manufacturer’s recommendations for each machine and constantly stay updated on the latest fuel and lubricant technology to ensure optimal equipment performance and longevity.

Q 24. Describe your experience with emergency procedures and first aid.

Safety is paramount in forestry work. I hold a valid first aid and CPR certification, and I regularly refresh my skills. I’m well-versed in emergency procedures, from dealing with minor cuts and bruises to more serious injuries like broken bones or severe bleeding. I know the importance of promptly reporting any incident and following established safety protocols.

For instance, I’m trained in using emergency communication devices, administering first aid, and evacuating injured personnel. We conduct regular safety training exercises simulating different scenarios, ensuring everyone is well-prepared to respond effectively during emergencies. My experience includes managing emergency situations in remote locations, highlighting the importance of quick thinking and resourcefulness. We always have a comprehensive first-aid kit readily accessible and are trained to use it properly.

Q 25. How do you prioritize tasks and manage your time effectively on a forestry job?

Effective task prioritization and time management are essential in forestry. I use a combination of techniques. Firstly, I carefully review the job plan, identifying critical tasks and their dependencies. I then break down large tasks into smaller, manageable steps, creating a detailed schedule that outlines daily and weekly goals. This is similar to project management techniques used in other industries.

Secondly, I utilize technology to my advantage. I use job scheduling applications and GPS technology to track progress and optimize routes. This allows for efficient movement between work sites and minimizes travel time. Finally, I’m adept at adapting to unexpected changes. Weather conditions or equipment malfunctions can disrupt plans, so flexibility and the ability to re-prioritize tasks are crucial. I constantly monitor progress, adjust my schedule as needed, and communicate effectively with my team to ensure everyone is on the same page.

Q 26. What are your strengths and weaknesses as a forestry equipment operator?

My strengths as a forestry equipment operator lie in my proficiency with a wide range of equipment, my commitment to safety, and my problem-solving skills. I am experienced in operating various machines, including chainsaws, skidders, feller bunchers, and excavators, always adhering to strict safety procedures. I pride myself on my ability to quickly diagnose and fix minor equipment issues.

However, like any professional, I have areas for improvement. One area I am actively working on is improving my efficiency in managing larger-scale projects. While I am proficient in handling daily tasks, further developing my organizational skills for larger projects would enhance my overall effectiveness. This involves learning better project management techniques and leveraging project management software.

Q 27. Describe a time you had to solve a complex problem related to forestry equipment.

During a large-scale logging operation, our feller buncher experienced a major hydraulic failure in a remote location. This threatened to significantly delay the project and resulted in substantial financial losses. Initially, we attempted a temporary fix, but it proved unsuccessful. I then systematically assessed the problem, carefully checking all hydraulic lines, pumps, and valves.

After pinpointing a leak in a high-pressure line, we faced another challenge. We lacked the specific replacement part on-site. However, remembering a similar part from another machine, I proposed adapting it. I carefully measured both parts, confirming compatibility, and subsequently made the necessary modifications on-site using specialized tools. This creative problem-solving approach allowed us to restart the machine and minimize project downtime, demonstrating my adaptability and resourcefulness.

Q 28. What are your salary expectations for this position?

My salary expectations are in line with the industry standards for an experienced forestry equipment operator with my skill set and experience. I am open to discussing a competitive compensation package that reflects my contributions to the company’s success.

Key Topics to Learn for Use of Forestry Equipment Interview

- Safety Procedures and Regulations: Understanding and applying safety protocols for operating various forestry equipment, including pre-operational checks, personal protective equipment (PPE) usage, and emergency procedures.

- Equipment Operation and Maintenance: Practical knowledge of operating different types of forestry equipment (e.g., chainsaws, feller bunchers, skidders, harvesters) including their functionalities, limitations, and routine maintenance checks.

- Harvesting Techniques and Best Practices: Understanding different harvesting methods (e.g., clear-cutting, selective harvesting), their environmental impact, and how to apply best practices for efficient and sustainable forestry operations.

- Timber Measurement and Estimation: Knowledge of techniques for accurately measuring timber volume, assessing tree health, and estimating timber yield for efficient resource management.

- Environmental Considerations: Understanding the environmental impact of forestry operations and implementing sustainable practices to minimize damage to ecosystems and biodiversity.

- Troubleshooting and Problem-Solving: Ability to identify and diagnose common equipment malfunctions, perform basic repairs, and implement effective problem-solving strategies in challenging field situations.

- GPS and Mapping Technologies: Familiarity with using GPS systems and other mapping technologies for navigation, precision forestry, and data collection in forestry operations.

Next Steps

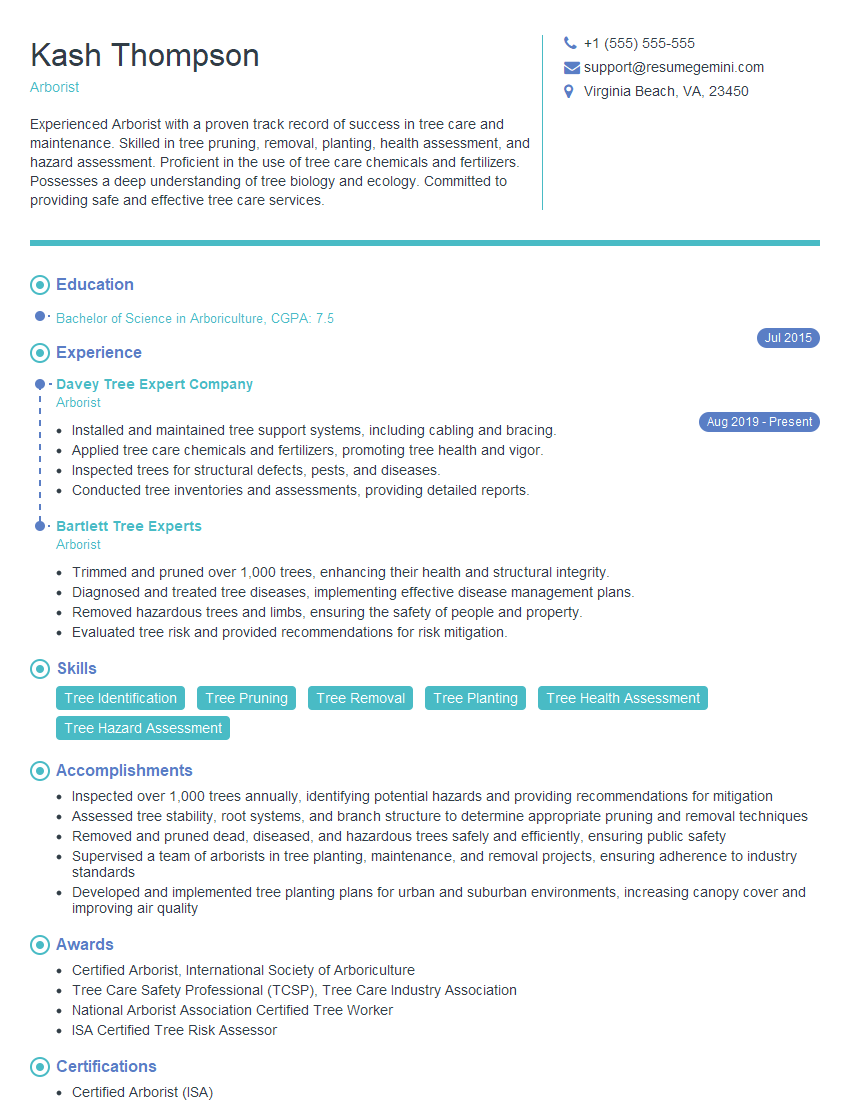

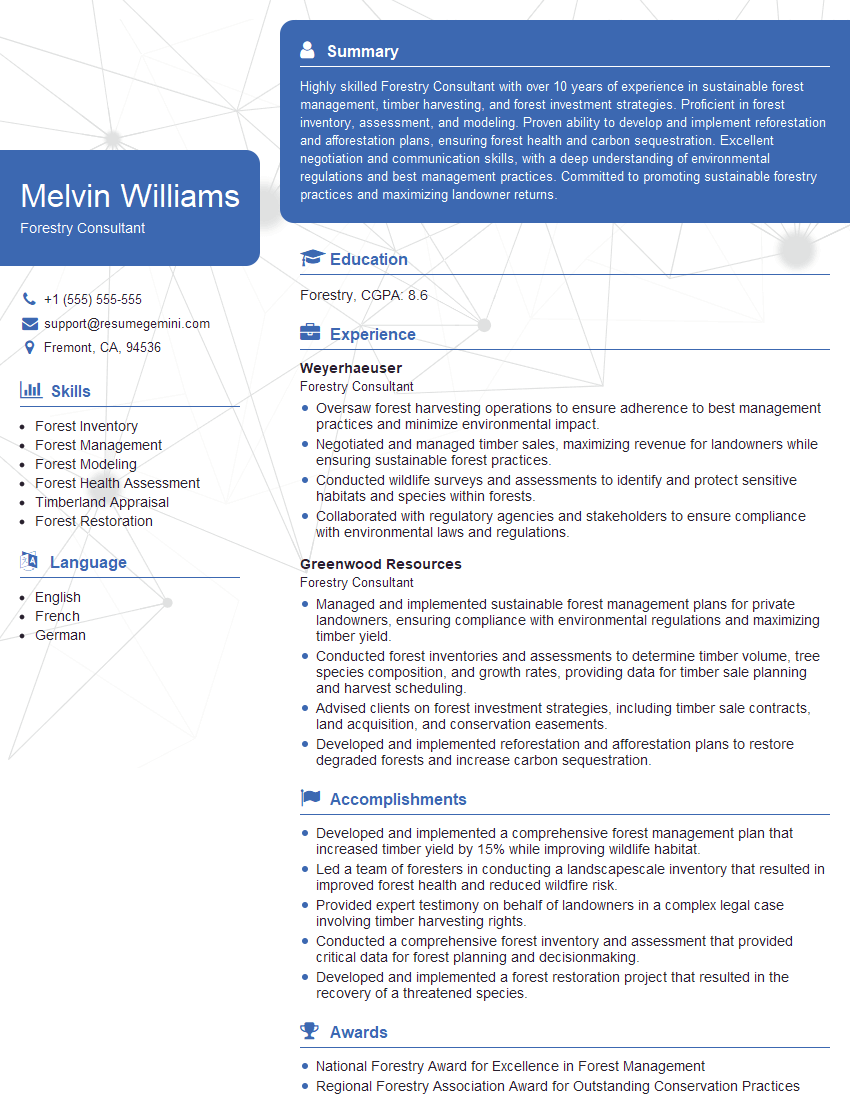

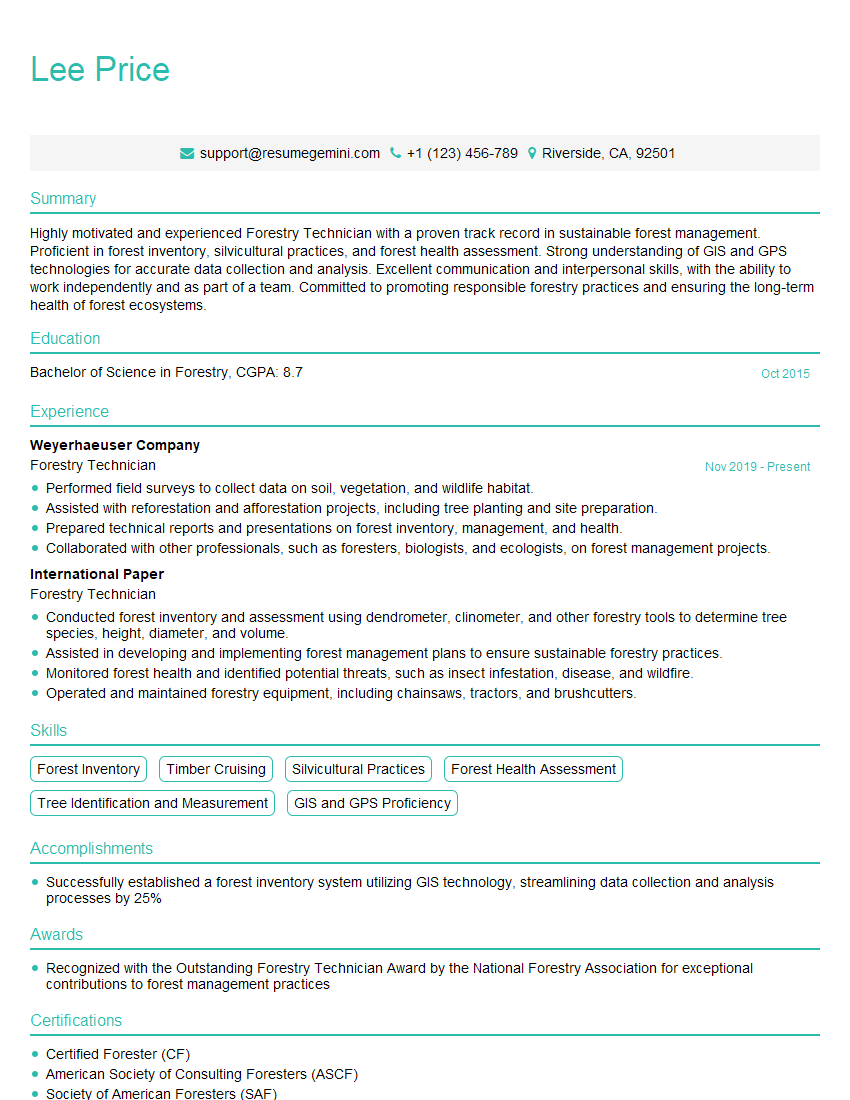

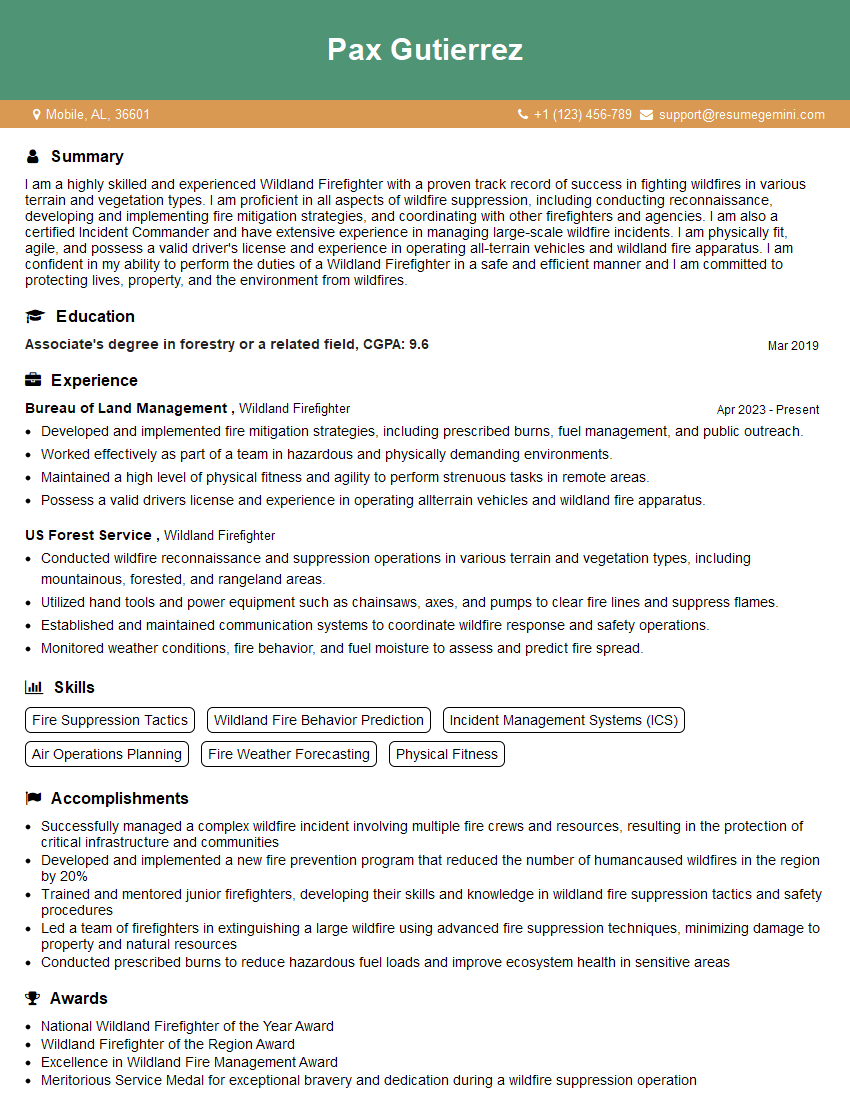

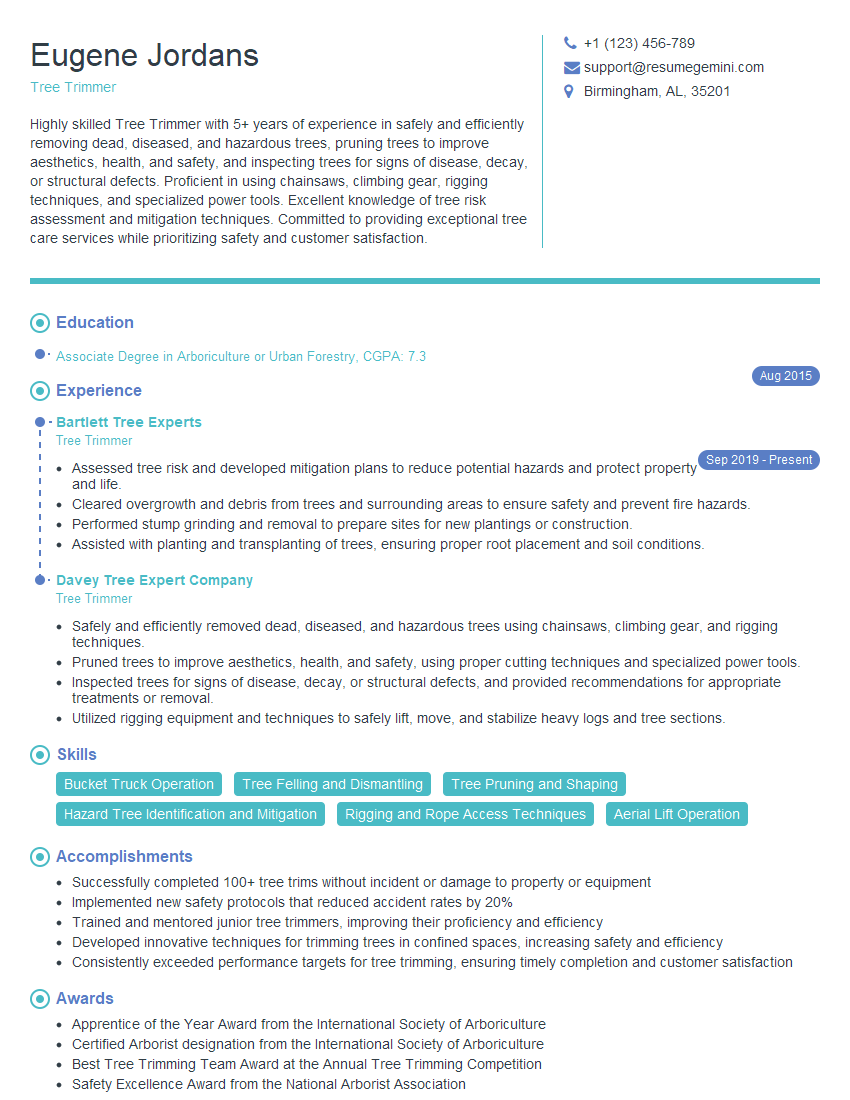

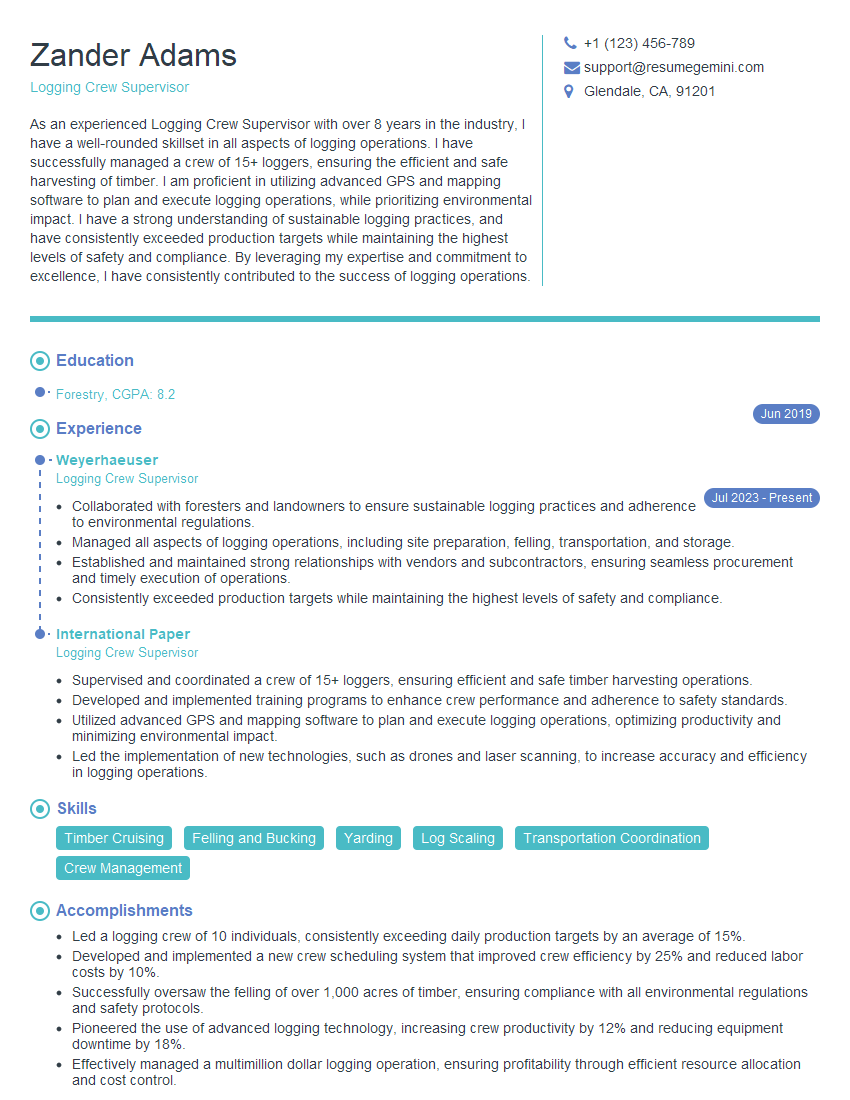

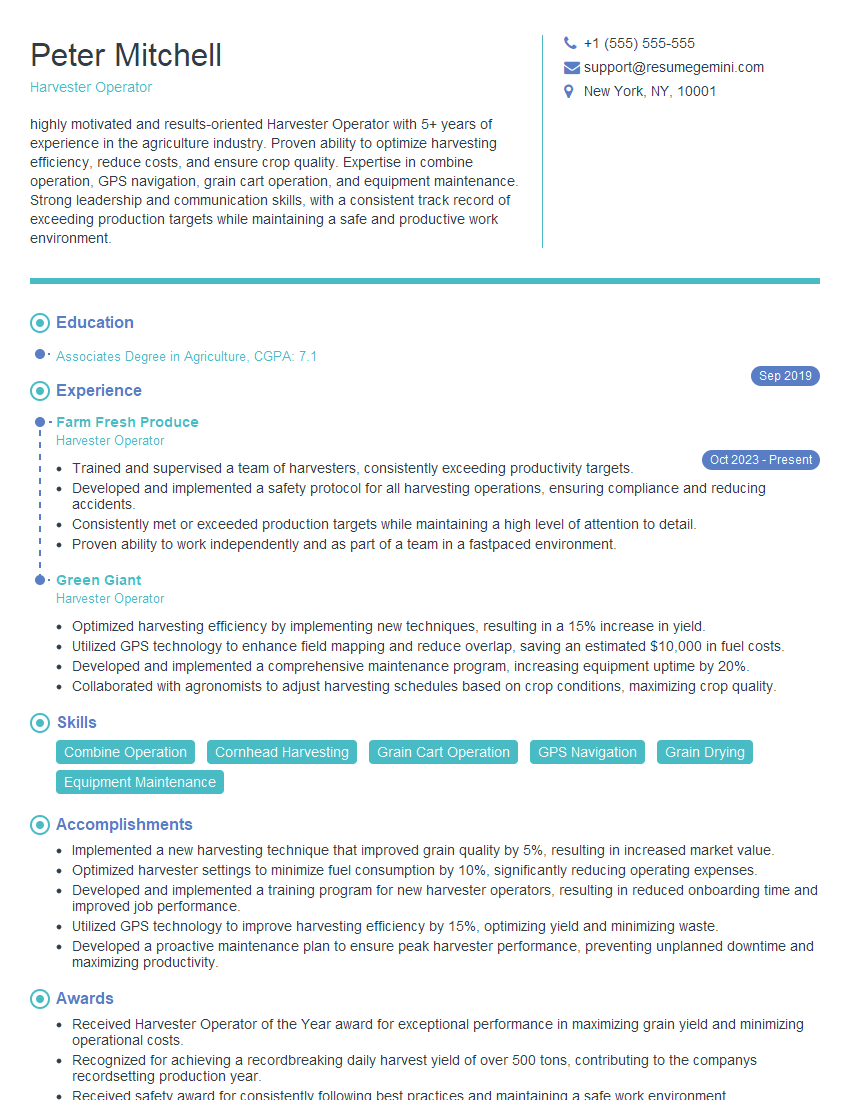

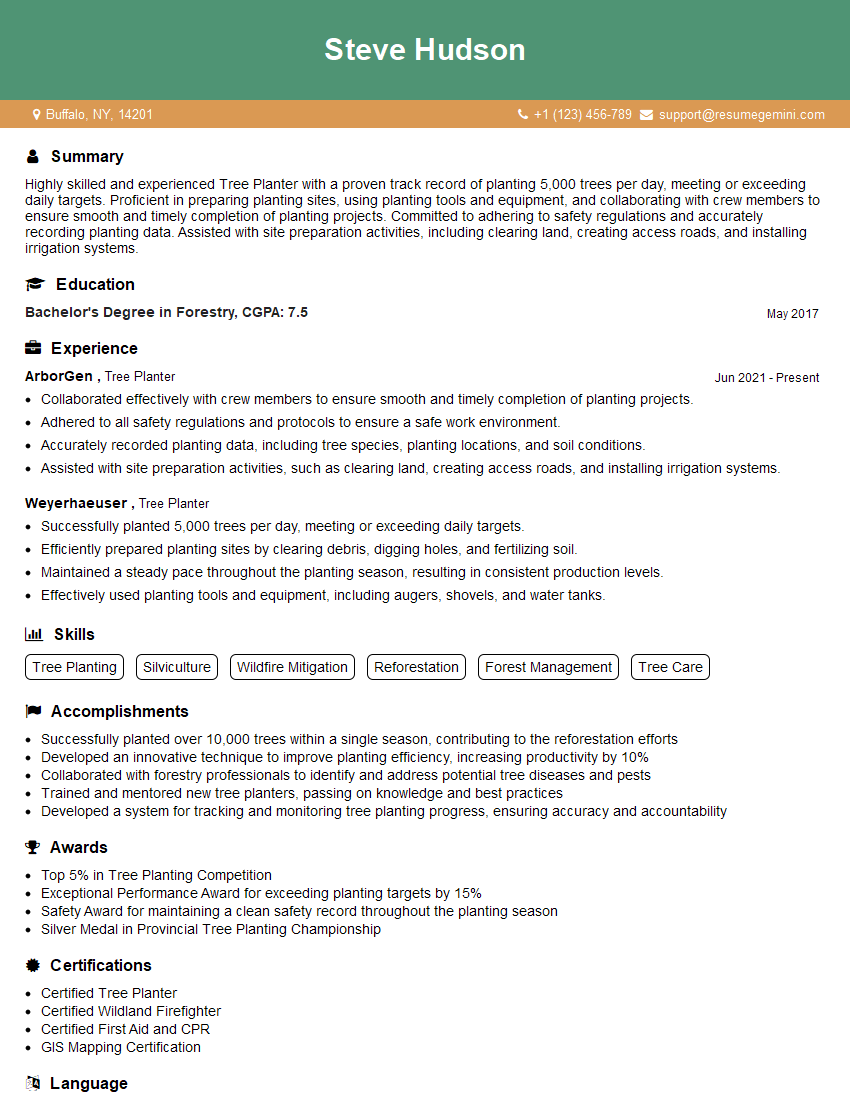

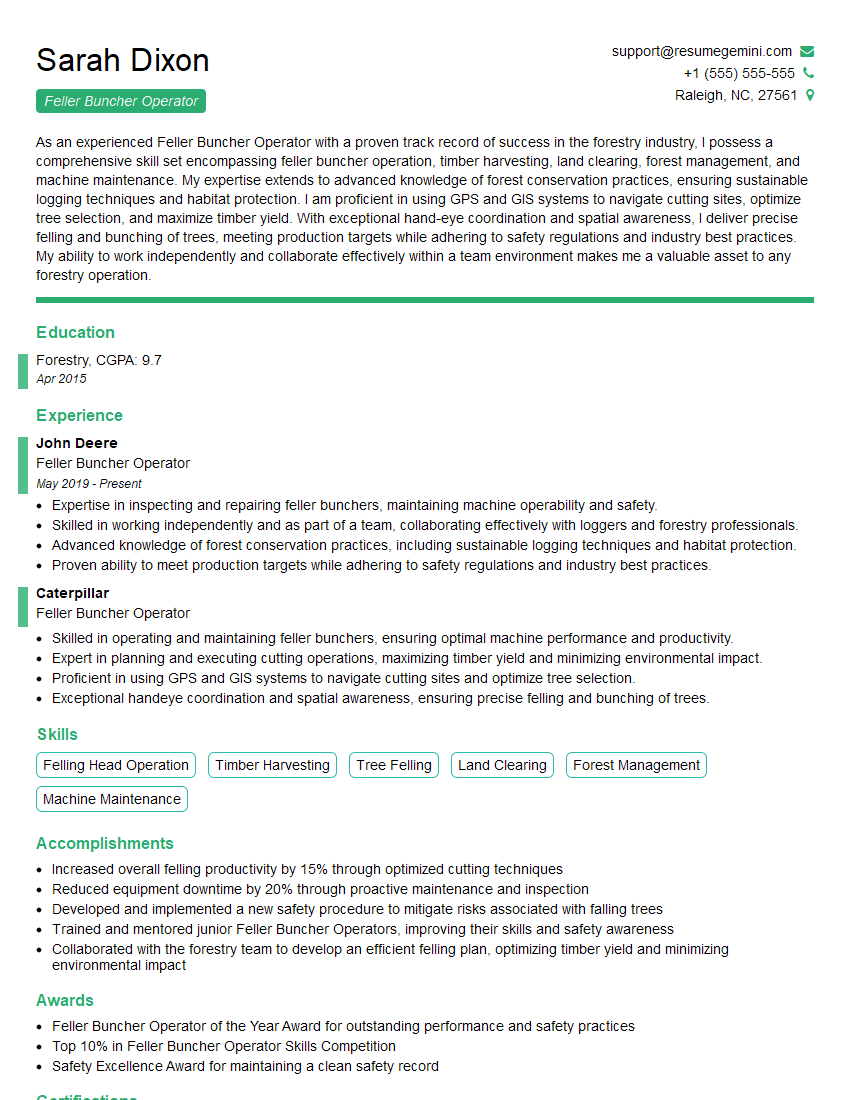

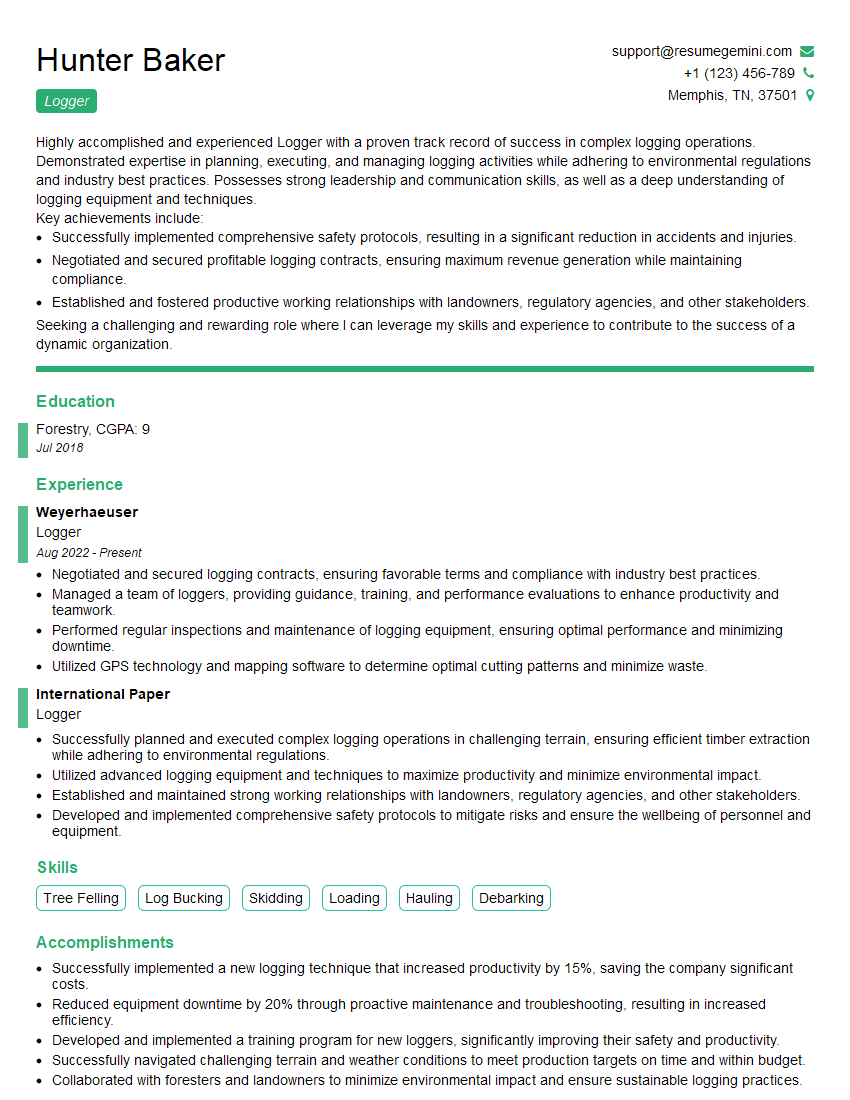

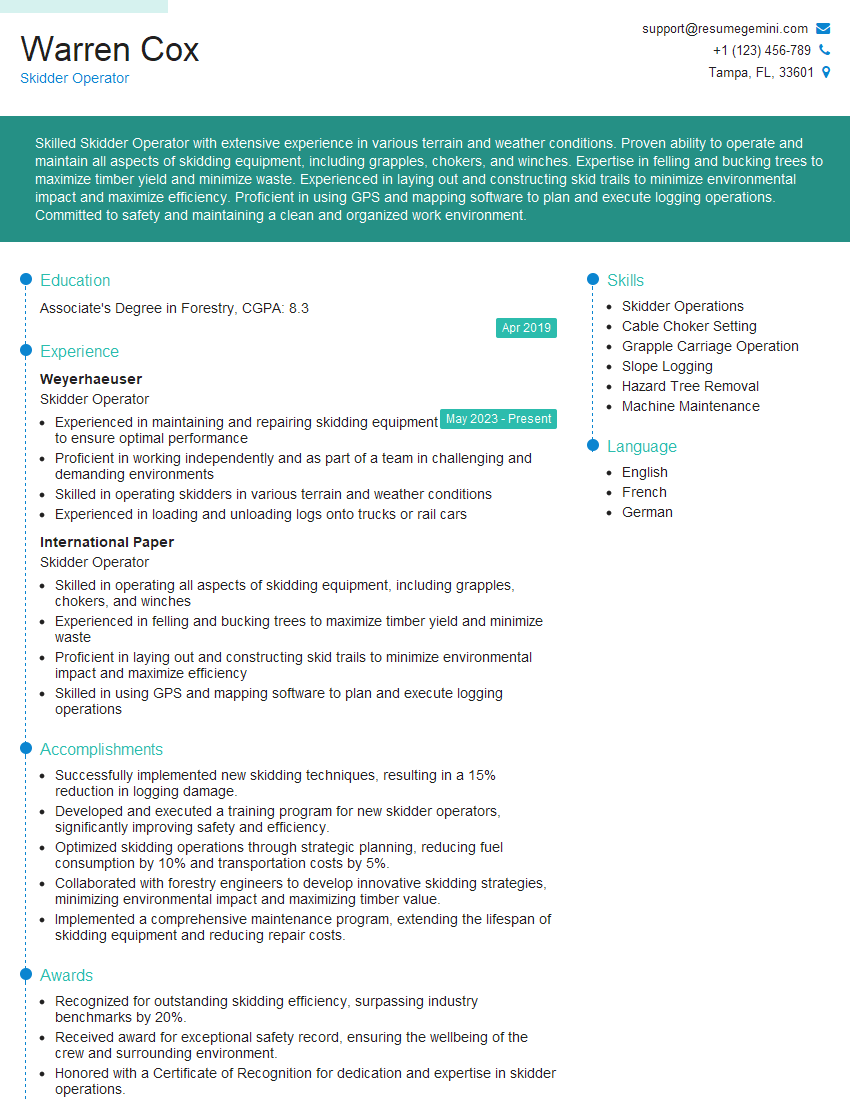

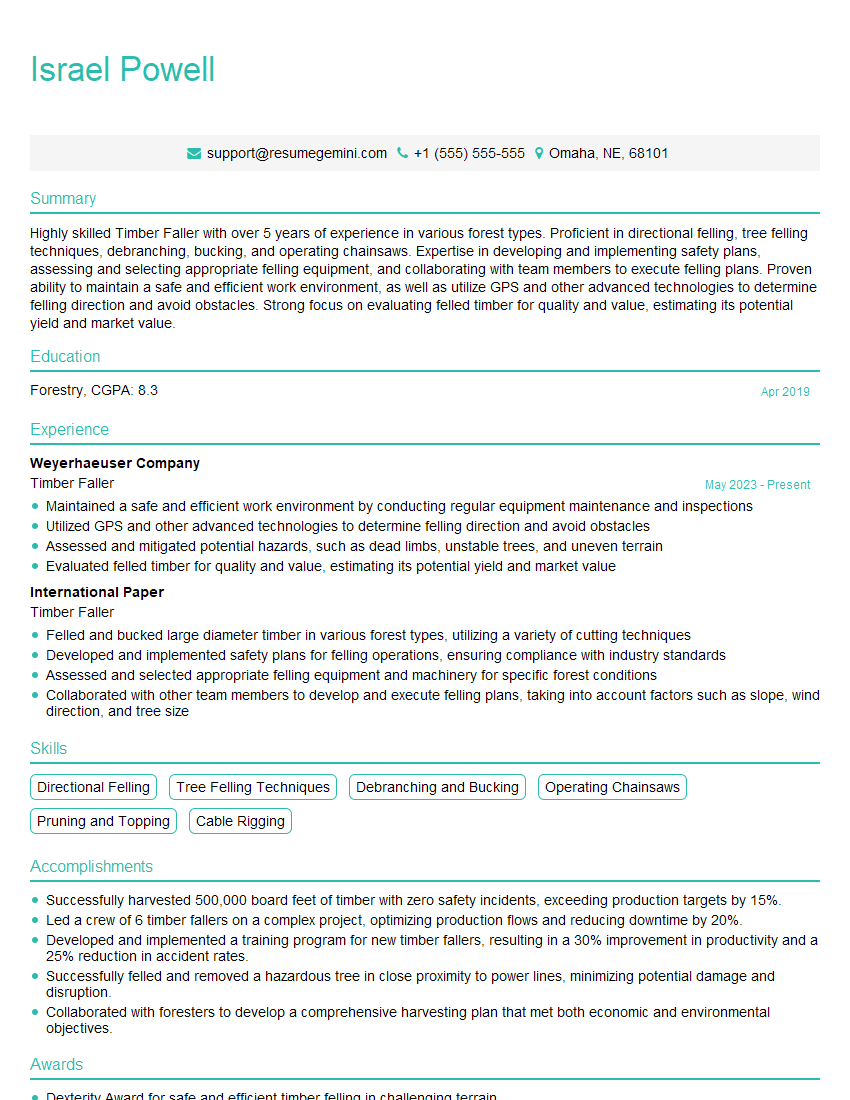

Mastering the use of forestry equipment is crucial for career advancement in this dynamic field. Proficiency in operating and maintaining this equipment demonstrates essential skills valued by employers, leading to increased job opportunities and higher earning potential. To significantly boost your job prospects, focus on crafting an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional, impactful resume tailored to the forestry industry. Examples of resumes specifically designed for Use of Forestry Equipment roles are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good