Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Warehouse Management System (WMS) Familiarity interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Warehouse Management System (WMS) Familiarity Interview

Q 1. Explain your experience with different WMS systems (e.g., SAP EWM, Oracle WMS, Blue Yonder).

My experience spans several leading WMS platforms. I’ve worked extensively with SAP Extended Warehouse Management (EWM), implementing and optimizing processes for a large-scale distribution center. This involved configuring the system for slotting optimization, wave management, and labor management. With Oracle WMS, I’ve been involved in projects focusing on inventory control and advanced shipping notice (ASN) processing, particularly in a fast-moving consumer goods (FMCG) environment. Finally, my work with Blue Yonder WMS has centered around its robust reporting and analytics capabilities, enabling data-driven decision-making for optimizing warehouse operations. Each system offers unique strengths; SAP EWM excels in its integration capabilities within the broader SAP ecosystem, Oracle WMS provides strong functionality for multi-site management, while Blue Yonder stands out with its sophisticated predictive analytics.

For instance, in the SAP EWM project, we successfully reduced order cycle time by 15% by implementing a sophisticated wave picking strategy and optimizing putaway locations. In the Oracle WMS project, we improved inventory accuracy by over 98% by integrating cycle counting procedures directly within the system.

Q 2. Describe your experience implementing or migrating to a new WMS.

Implementing or migrating to a new WMS is a complex undertaking requiring meticulous planning and execution. My approach involves a phased rollout to minimize disruption. This begins with a comprehensive needs assessment to clearly define the business requirements and the desired functionalities from the new system. Next, we map the existing processes to the new system, identifying gaps and potential areas for improvement. A critical step is data migration, where we meticulously cleanse and transform existing inventory and master data to ensure accuracy and completeness. This phase often involves data validation checks and reconciliation steps. Then comes the system configuration and testing, where we create workflows, customize user interfaces, and conduct thorough testing in a sandbox environment before live deployment. Post-implementation support is crucial to address any unforeseen issues and facilitate user training and adoption.

In one project, we migrated a client from a legacy system to Blue Yonder WMS. We used a phased approach, migrating different warehouse zones sequentially to reduce the risk of system-wide disruptions. Post-migration, we conducted intensive training programs for warehouse staff and provided ongoing support through dedicated help desk channels. This ensured minimal productivity loss during the transition and enabled the client to fully utilize the capabilities of the new system.

Q 3. How do you ensure data accuracy within a WMS?

Data accuracy is paramount in a WMS. We achieve this through a multi-pronged approach. Firstly, we implement robust data validation rules within the system to prevent entry of incorrect or incomplete data. This might include checks for valid product IDs, location codes, and quantity ranges. Secondly, we incorporate barcode scanning at every stage of the warehouse process—receiving, putaway, picking, and shipping—to minimize manual data entry errors. Regular cycle counting, integrated directly with the WMS, helps to identify and reconcile inventory discrepancies. Automated reconciliation processes compare physical inventory counts with system records to automatically highlight discrepancies requiring investigation. Finally, rigorous user training and access controls are implemented to minimize human error and ensure data integrity. Employing a combination of these techniques, we aim for an inventory accuracy exceeding 99.5%.

Q 4. Explain your understanding of different warehouse layout strategies and how they impact WMS functionality.

Warehouse layout strategies significantly impact WMS functionality. Different strategies are suited to different products, operations, and volumes. A U-shaped layout is efficient for single-product processing lines and minimizes travel distance. A L-shaped layout offers a good balance between efficiency and flexibility. A I-shaped layout is simple but may not be as space-efficient. Zone picking, often implemented in large warehouses, divides the warehouse into zones, assigning pickers to specific zones to optimize efficiency. These layouts directly affect how the WMS manages putaway strategies, picking routes, and overall workflow optimization. For example, a zone picking layout requires the WMS to intelligently route orders to the appropriate picking zones, minimize travel times between zones, and optimize batching logic to maximize picker productivity. The WMS needs to be configured to match the chosen layout and leverage its strengths while mitigating any weaknesses.

Q 5. How do you handle inventory discrepancies within a WMS?

Inventory discrepancies are inevitable but should be addressed promptly. The first step is identifying the discrepancy—whether it’s a shortage, surplus, or location mismatch. The WMS itself will often highlight these discrepancies through reports and alerts. The next step is investigation: reviewing picking and putaway records, conducting physical inventory checks in the affected areas, and verifying system data for accuracy. After the cause is identified (e.g., picking errors, damaged goods, data entry mistakes), corrective actions are taken. This might involve adjusting inventory levels in the system, initiating investigations into potential errors, and implementing preventative measures to avoid future occurrences. Regular cycle counting reduces the magnitude of any discrepancy before it becomes a major problem. Detailed root cause analysis following significant discrepancies helps prevent recurrence.

Q 6. Describe your experience with WMS reporting and analysis.

WMS reporting and analysis is crucial for optimizing warehouse performance. My experience includes designing and implementing custom reports and dashboards to monitor key performance indicators (KPIs) and identify areas for improvement. I’m proficient in using the built-in reporting tools within different WMS systems, as well as leveraging external business intelligence (BI) tools to create more sophisticated visualizations and analyses. For example, we might generate reports on order fulfillment rates, picking accuracy, inventory turnover, and storage utilization. These reports help track warehouse productivity, identify bottlenecks, and inform operational decision-making. In one project, we used data analysis to identify an issue with slow-moving inventory, leading to process changes that improved warehouse space utilization by 10%.

Q 7. Explain your understanding of key WMS performance metrics (e.g., order fulfillment rate, picking accuracy).

Key WMS performance metrics provide critical insights into warehouse efficiency and effectiveness. Order fulfillment rate measures the percentage of orders fulfilled on time and completely. Picking accuracy tracks the percentage of items picked correctly. Inventory accuracy measures the degree to which the system’s inventory records match physical inventory. Put away accuracy monitors the percentage of items put away to the correct location. Order cycle time measures the time it takes to fulfill an order, from receipt to shipment. Storage utilization indicates how effectively warehouse space is being used. Labor productivity measures the output per labor hour. Tracking these metrics, often through customized dashboards, allows for continuous monitoring and improvement of warehouse operations. Analyzing trends in these metrics provides valuable information that can be used to identify and address inefficiencies. For instance, a low picking accuracy rate might indicate a need for improved training or better barcode scanning technology.

Q 8. How do you troubleshoot WMS-related issues?

Troubleshooting WMS issues requires a systematic approach. I typically start by identifying the nature of the problem – is it a system error, a user error, a process bottleneck, or an integration issue? I then utilize a combination of techniques.

- Check System Logs: WMS systems maintain detailed logs that record events and errors. Analyzing these logs often pinpoints the root cause. For instance, a recurring database error might indicate a need for database maintenance or a code fix.

- User Interviews & Observation: Talking to users and observing their workflows can reveal human error or process inefficiencies contributing to the problem. Perhaps a user is incorrectly inputting data, leading to inaccurate inventory counts.

- Data Analysis: Examining data related to the issue is critical. For example, if order fulfillment times are unexpectedly high, I would analyze order volume, picking routes, and the time spent on each stage of the fulfillment process to identify bottlenecks.

- Testing & Validation: Once I’ve identified a potential cause, I’ll perform tests to validate my hypothesis. This might involve replicating the error in a test environment or running a controlled experiment to isolate the problem.

- Escalation: If the problem is beyond my immediate expertise, I know when and how to escalate the issue to the appropriate team, such as the vendor’s support team or the IT department.

For example, I once solved a recurring inventory discrepancy by analyzing system logs that revealed a synchronization issue between the WMS and the ERP system. Identifying the specific data fields causing the mismatch allowed us to implement a data cleansing process and fix the integration point.

Q 9. Explain your experience with WMS integrations with other systems (e.g., ERP, TMS).

I have extensive experience integrating WMS with various systems, primarily ERP and TMS. Successful integration hinges on understanding the data flow and mapping the relevant fields between systems. For example, integrating with an ERP involves mapping product information, customer orders, and inventory levels.

With ERP systems, we typically leverage APIs (Application Programming Interfaces) to facilitate real-time data exchange. This allows for seamless order management, where orders placed in the ERP automatically appear in the WMS, triggering the fulfillment process. We might use standard protocols like EDI (Electronic Data Interchange) or custom APIs depending on the ERP system’s capabilities.

Integrating with a TMS is crucial for optimizing transportation and delivery. Here, the WMS shares shipment details – including order information, quantity, and destination – with the TMS. This allows the TMS to plan optimal routes, manage carrier assignments, and track shipments. I’ve worked with several TMS integrations using various methods, such as XML data exchange, custom APIs, and cloud-based integration platforms.

During integrations, proper testing is crucial. We usually employ a phased approach, starting with testing individual components and gradually moving to integrated end-to-end testing. Thorough testing ensures a smooth transition and minimizes disruptions during go-live.

Q 10. Describe your experience with warehouse automation and its integration with WMS.

My experience includes working with various warehouse automation technologies and their integration with WMS. This ranges from simpler automated guided vehicles (AGVs) to complex automated storage and retrieval systems (AS/RS).

Integrating automation with a WMS necessitates configuring the WMS to interact with the automation system’s control software. This often involves real-time data exchange to manage tasks such as directing AGVs to pick locations, updating inventory statuses as items are moved, and triggering alerts for maintenance needs. For example, I worked on a project that integrated a WMS with an AS/RS. The WMS directed the AS/RS to retrieve specific items, and the AS/RS sent real-time feedback to the WMS regarding its status and the completion of retrieval tasks. This real-time feedback was essential for accurate inventory management and efficient order fulfillment.

The benefits of this integration are significant, including improved accuracy, reduced labor costs, and faster order fulfillment. However, thorough planning and testing are essential to ensure smooth operation and avoid costly downtime. Effective integration requires careful consideration of data mapping, error handling, and security.

Q 11. How do you manage user access and security within a WMS?

Managing user access and security in a WMS is paramount to maintain data integrity and prevent unauthorized access. A multi-layered approach is essential.

- Role-Based Access Control (RBAC): We assign users to roles with specific permissions. For example, a warehouse manager might have full access, while a picker might only have access to picking lists. This granular control ensures that users only access the information and functionality necessary for their jobs.

- Password Management: Strong password policies are crucial, often including password complexity requirements, regular password changes, and account lockout mechanisms after multiple failed login attempts.

- Audit Trails: Maintaining detailed audit trails of all user activities provides a record of who accessed what data and when. This is critical for identifying potential security breaches and tracking down data discrepancies.

- Authentication Methods: Secure authentication methods, such as multi-factor authentication (MFA), add an extra layer of security, requiring users to provide multiple forms of verification before accessing the system.

- Data Encryption: Encryption protects sensitive data both in transit and at rest, minimizing the impact of a potential data breach.

In practice, we use the WMS’s built-in security features and potentially supplement them with additional security tools, such as intrusion detection systems, to monitor for suspicious activity. Regular security audits and vulnerability assessments are vital to identify and address potential weaknesses.

Q 12. How do you handle peak season demands within a WMS environment?

Peak season demands require proactive planning and adjustments within the WMS environment. It’s not simply about increasing capacity; it’s about managing resources efficiently and mitigating potential bottlenecks.

- Capacity Planning: We begin by forecasting peak season demand and determining the necessary resources – staffing, equipment, and warehouse space. This helps us proactively address potential shortfalls.

- WMS Configuration: We optimize WMS settings to handle the increased volume. This might include adjusting wave picking parameters, optimizing picking routes, and configuring the system to prioritize high-demand items.

- Staffing & Training: We often need to increase staffing levels during peak season. Proper training ensures temporary staff can effectively utilize the WMS.

- Real-time Monitoring: Continuous monitoring of key metrics, such as order fulfillment time, inventory levels, and warehouse capacity, allows us to identify and address potential issues promptly.

- Contingency Planning: Having a contingency plan in place for unexpected events, such as equipment failure or supply chain disruptions, is critical for maintaining operational continuity.

For instance, in a previous role, we implemented a surge capacity plan for peak season, which included hiring temporary staff, optimizing picking routes with the WMS, and implementing a real-time dashboard to monitor order fulfillment performance. This allowed us to handle a 50% increase in order volume without significant delays.

Q 13. Describe your experience with slotting optimization within a WMS.

Slotting optimization is about strategically placing inventory within the warehouse to minimize travel time and improve picking efficiency. A well-optimized slotting plan significantly impacts productivity and reduces labor costs.

My experience involves using both manual and automated methods for slotting optimization. Manual methods often involve analyzing historical data, considering factors such as item velocity, size, and weight. This approach is suitable for smaller warehouses or when a detailed analysis isn’t feasible. Automated slotting optimization tools use algorithms to analyze vast amounts of data and propose optimal slotting plans. These tools consider various factors, including order profile, storage capacity, and product dimensions, resulting in a more efficient layout.

The benefits of slotting optimization are numerous. It reduces travel time for pickers, leading to faster order fulfillment. It can also improve storage utilization by maximizing space efficiency. Finally, optimized slotting can reduce picking errors by making it easier for pickers to locate items.

For example, I once used a slotting optimization tool to reorganize a warehouse’s layout. This resulted in a 15% reduction in picking time and a 10% increase in overall warehouse throughput. The key was accurately modeling warehouse characteristics and order patterns within the slotting tool to produce a realistic and effective layout.

Q 14. Explain your understanding of different inventory management methods (e.g., FIFO, LIFO).

Different inventory management methods dictate the order in which inventory is used. The two most common are FIFO (First-In, First-Out) and LIFO (Last-In, First-Out).

- FIFO (First-In, First-Out): This method prioritizes the oldest inventory. Items that were received first are shipped first. This is ideal for perishable goods or items with expiration dates, preventing waste and spoilage. Think of a bakery – the oldest bread is sold first.

- LIFO (Last-In, First-Out): This method uses the most recently received inventory first. This method is often used for non-perishable items where inventory doesn’t have an expiration date. LIFO can be beneficial for accounting purposes, particularly during periods of inflation as it can lower the cost of goods sold.

The choice between FIFO and LIFO depends on several factors including the type of inventory, industry regulations, and accounting practices. A WMS should be flexible enough to support both methods, allowing businesses to select the approach that best suits their needs. The WMS typically manages inventory tracking and reporting based on the selected method, ensuring accurate accounting and inventory control.

Q 15. How do you ensure compliance with relevant regulations (e.g., safety, traceability) within a WMS?

Ensuring compliance within a WMS is paramount. It involves integrating regulatory requirements directly into the system’s workflows and reporting. This isn’t just about ticking boxes; it’s about building a culture of compliance.

Safety Regulations: We can configure the WMS to track equipment maintenance schedules, ensuring timely servicing to prevent accidents. For example, forklifts could have their service dates logged within the system, triggering alerts when maintenance is due. This also integrates with employee training records, ensuring only certified operators can use specific equipment. The system might also restrict access to hazardous areas based on employee permissions.

Traceability: A robust WMS is crucial for maintaining a complete audit trail. Every product movement—from receiving to shipping—is logged with timestamps and user IDs. This allows us to instantly trace a product’s journey through the warehouse, crucial for recalls or quality investigations. For instance, if a batch of goods is found to be defective, the WMS can pinpoint exactly which products are affected and where they are located, allowing for swift and efficient removal.

Data Integrity: We employ rigorous data validation checks within the WMS to prevent errors and ensure data accuracy. This is crucial for compliance because inaccurate data can lead to non-compliance. For instance, incorrect weight measurements on incoming goods could violate regulations.

Regular audits and employee training are vital to maintaining compliance. We use the WMS data itself to perform internal audits, identifying potential compliance gaps.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with cycle counting and its impact on inventory accuracy.

Cycle counting is a crucial inventory control technique, where a small portion of the inventory is counted regularly, instead of a full inventory count. This minimizes disruption to warehouse operations. My experience shows that it significantly improves inventory accuracy.

In previous roles, I implemented a cycle counting system that targeted high-value or high-movement items more frequently. This allowed us to identify discrepancies early and correct them promptly, minimizing the impact of inventory inaccuracies on order fulfillment and financial reporting.

We used the WMS to schedule cycle counts, assign tasks to warehouse staff, and record the results. The system automatically flagged discrepancies and generated reports to highlight areas needing attention. For example, if the cycle count showed a significant difference between the system’s record and the physical count of a particular SKU, this would trigger an investigation into potential causes like data entry errors, theft, or damage.

The impact on inventory accuracy was dramatic. We reduced inventory discrepancies by over 60% within six months of implementing the improved cycle counting system. This directly translated into reduced waste, improved order fulfillment rates, and greater financial accuracy.

Q 17. How do you utilize WMS data for continuous improvement initiatives?

WMS data is a goldmine for continuous improvement. It provides a detailed picture of warehouse operations, allowing us to identify bottlenecks, inefficiencies, and areas ripe for optimization.

Identifying Bottlenecks: Analyzing data on picking times, travel distances, and order fulfillment rates can reveal bottlenecks. For example, if we see consistently long picking times in a specific zone, we can investigate the layout, staffing levels, or picking methods to address the issue.

Optimizing Processes: The data might show that a particular product is frequently misplaced. This could lead to changes in storage locations, better labeling practices, or improved training for warehouse staff.

Improving Space Utilization: WMS data helps analyze storage capacity and optimize the use of available space. It might reveal areas where we can consolidate storage, improve slotting, or reduce unnecessary aisle space.

Performance Metrics: The system provides key performance indicators (KPIs) such as order fulfillment rates, picking accuracy, and inventory turnover. Tracking these KPIs over time allows us to monitor the effectiveness of our improvements.

I’ve used this data-driven approach to implement several successful improvements, including the redesign of warehouse layouts and the implementation of new picking strategies, ultimately boosting warehouse efficiency and reducing operational costs.

Q 18. Explain your understanding of different picking methods (e.g., zone picking, batch picking).

Different picking methods cater to varying warehouse needs and order profiles. The choice depends on factors like order volume, product variety, and warehouse layout.

Zone Picking: The warehouse is divided into zones, and each picker is responsible for a specific zone. This is efficient for high-volume orders with many SKUs. Imagine a large grocery warehouse: each picker might be assigned a section (zone) – produce, dairy, etc., greatly reducing travel time across the entire warehouse.

Batch Picking: Pickers collect multiple orders simultaneously. This minimizes travel time, as they gather items for several orders during a single trip, particularly useful for orders with similar items.

Wave Picking: Orders are grouped into waves based on due dates or delivery routes. This improves efficiency by prioritizing orders and coordinating picker activities. This is similar to batch picking but includes an additional layer of organization based on timing.

Discrete Picking: Each order is picked individually. This method is best suited for smaller warehouses or orders with unique items. It prioritizes order accuracy over efficiency, suitable for high-value or bespoke orders.

Understanding these methods allows for the selection of the most efficient strategy for a given operation. Often, a hybrid approach, combining multiple methods, is the optimal solution.

Q 19. How do you train new employees on the use of the WMS?

Training new employees on a WMS requires a structured and multi-faceted approach.

Classroom Training: Initial training involves classroom sessions covering the WMS interface, key functionalities, and relevant warehouse procedures. This often includes interactive presentations and demonstrations.

Hands-on Training: Practical training follows, where employees work with the system in a simulated or real warehouse environment, guided by experienced trainers. This approach builds confidence and practical skills. We use role-playing to simulate real-world scenarios like order fulfillment, inventory adjustments, and problem resolution.

On-the-Job Training: Ongoing support is provided through mentoring and on-the-job coaching. Senior staff members provide guidance and assistance as new employees gain experience.

Documentation and Resources: Comprehensive documentation, including user manuals, FAQs, and video tutorials, is readily available to support employees. We also maintain a knowledge base to readily access frequently asked questions and troubleshooting tips.

Ongoing Assessment and Feedback: Regular assessments and feedback sessions help identify training gaps and improve the effectiveness of the training program.

This layered approach ensures that new employees are well-equipped to use the WMS effectively and contribute to warehouse operations from day one. We track employee performance through the WMS to identify areas where additional training might be needed.

Q 20. Describe your experience with RF scanning and mobile devices in a WMS environment.

RF scanning and mobile devices are fundamental to modern WMS operations. They significantly enhance efficiency and accuracy.

In previous roles, we used RF scanners and handheld mobile devices equipped with the WMS software to manage all aspects of warehouse operations, from receiving and putaway to picking, packing, and shipping. This real-time data capture eliminates manual data entry, reducing errors and improving overall speed.

The devices streamline tasks such as:

- Receiving: Scanning barcodes on incoming items verifies quantities and ensures accurate updates to inventory.

- Putaway: Scanners guide the operator to the correct storage location, reducing misplacement and search time.

- Picking: The system directs pickers to the correct location, displaying item details and quantities on the screen, minimizing errors and improving picking speed.

- Shipping: Scanning items during packing and shipping validates orders and prevents errors.

We regularly updated the firmware and software on these devices to ensure optimal performance and security. We also implemented robust security protocols to prevent unauthorized access to the WMS data.

Q 21. How do you manage and resolve WMS system downtime?

WMS downtime is unacceptable, impacting productivity and order fulfillment. We have procedures in place to minimize disruption and resolve issues quickly.

Proactive Maintenance: Regular system maintenance, including software updates, database backups, and hardware checks, is crucial in preventing unexpected downtime. This includes scheduled maintenance windows to minimize disruption.

Redundancy and Failover: We implement redundant systems and failover mechanisms to ensure business continuity. This means having backup systems in place that automatically take over if the primary system fails.

Monitoring and Alerts: Real-time monitoring tools alert us to potential issues before they escalate. This allows for proactive intervention and minimizes downtime.

Incident Management: A well-defined incident management process, including escalation procedures, ensures that issues are addressed promptly and effectively. This often includes a detailed checklist and communication protocol to ensure all stakeholders are informed.

Disaster Recovery Plan: A comprehensive disaster recovery plan outlines procedures for restoring the system in the event of a major outage or disaster. This plan includes backup data storage in a separate location and protocols for restoring the system in a new environment if necessary.

We regularly test our disaster recovery plan to ensure it’s effective and to identify any weaknesses. Thorough documentation, including system diagrams, technical specifications, and troubleshooting guides, is crucial for efficient problem resolution during downtime.

Q 22. What are some common challenges faced when implementing a new WMS?

Implementing a new Warehouse Management System (WMS) presents several challenges. One major hurdle is data migration. Moving existing inventory data, order history, and customer information from legacy systems to the new WMS can be complex and time-consuming, requiring meticulous planning and potentially custom scripts. Inaccurate or incomplete data can severely hinder the system’s effectiveness.

Another significant challenge is user adoption. Training warehouse staff on the new system is crucial for success. Resistance to change is common, so a phased rollout with comprehensive training and ongoing support is essential. Failure to adequately train users can lead to errors, low productivity, and system abandonment.

Integration with existing systems is also a key concern. The new WMS needs to seamlessly integrate with other enterprise systems like ERP (Enterprise Resource Planning), transportation management systems (TMS), and e-commerce platforms. Poor integration can create data silos and hinder workflow efficiency. Finally, project scope creep can easily derail a WMS implementation. Defining clear requirements upfront and adhering to the project plan is critical to avoid delays and cost overruns.

Q 23. How do you ensure the WMS is optimized for efficiency and productivity?

Optimizing a WMS for efficiency and productivity involves a multi-pronged approach. First, process optimization is paramount. This involves analyzing current warehouse processes, identifying bottlenecks, and streamlining workflows. For instance, implementing efficient putaway strategies, optimizing picking routes, and utilizing cross-docking can significantly improve throughput. This often involves leveraging the WMS’s reporting and analytics capabilities to identify areas for improvement.

Secondly, system configuration plays a vital role. The WMS should be configured to reflect the specific warehouse layout, inventory characteristics, and operational requirements. This might include setting up custom rules for putaway locations, defining specific picking strategies (e.g., zone picking, batch picking), and configuring reporting to track key metrics.

Finally, continuous monitoring and improvement are key. Regularly reviewing key performance indicators (KPIs) like order fulfillment rate, picking accuracy, and inventory accuracy allows for continuous fine-tuning of the system and processes. Employing a culture of continuous improvement ensures that the WMS remains a valuable tool for boosting efficiency.

Q 24. Describe your experience with WMS configuration and customization.

I have extensive experience configuring and customizing WMS solutions, primarily using [mention specific WMS software, e.g., Manhattan Associates, Blue Yonder]. My experience spans various aspects, from basic parameter setups to complex script development and integration with third-party systems. For example, I once customized a WMS to integrate with a bespoke order management system, requiring the development of custom APIs to ensure seamless data exchange.

Another project involved configuring a WMS for a client with a highly complex warehouse layout, involving multiple zones, different storage types (pallet racking, shelving, bulk storage), and specialized handling requirements for certain products. This required careful planning and detailed configuration of the system’s location management features, including the creation of custom location types and assignment rules.

My approach to WMS configuration always starts with a thorough understanding of the client’s specific needs and operational processes. This involves careful requirements gathering, process mapping, and data analysis. I prioritize a modular approach, allowing for flexibility and scalability as the warehouse’s needs evolve.

Q 25. How do you maintain the integrity and security of WMS data?

Maintaining the integrity and security of WMS data is crucial for accurate reporting, efficient operations, and compliance. Several strategies are employed. First, access control is paramount. User roles and permissions are strictly defined, ensuring that only authorized personnel can access and modify sensitive data.

Second, data validation is implemented at multiple points in the system, checking for inconsistencies and preventing invalid data from entering the database. This includes data type validation, range checks, and cross-referencing with other data sources.

Third, regular data backups are essential to protect against data loss. A robust backup and recovery plan should be in place, including both on-site and off-site backups.

Finally, audit trails provide a record of all data changes, allowing for tracking and investigation of any potential discrepancies or security breaches. This enhances accountability and facilitates compliance audits.

Q 26. Explain your understanding of different warehouse processes (e.g., receiving, putaway, picking, packing, shipping).

Warehouse processes are interconnected and crucial for efficient order fulfillment. Receiving involves the inbound process, including checking incoming shipments against purchase orders, inspecting goods for damage, and updating inventory levels in the WMS. Putaway involves strategically placing received goods into designated storage locations based on factors like product type, demand, and storage capacity, optimizing space utilization.

Picking is the process of retrieving goods from storage locations to fulfill customer orders. Efficient picking strategies are essential for productivity, and WMS systems often guide pickers through optimized routes. Packing involves preparing picked goods for shipment, including packaging, labeling, and adding any necessary documentation. Finally, shipping encompasses the outbound process, including generating shipping labels, scheduling carriers, and updating order statuses within the WMS.

Q 27. How do you use WMS to track and manage warehouse KPIs?

WMS systems provide powerful tools for tracking and managing warehouse KPIs. Key metrics, such as order fulfillment rate, picking accuracy, and inventory accuracy, are readily monitored through built-in reporting features. These dashboards offer real-time visibility into warehouse performance, allowing managers to quickly identify areas for improvement.

For example, if the order fulfillment rate drops below a predefined threshold, the WMS can generate alerts, highlighting potential bottlenecks or issues that need attention. Similarly, tracking picking accuracy helps to pinpoint any training needs or process inefficiencies. Analyzing inventory accuracy helps prevent stockouts and overstocking, optimizing inventory levels and reducing costs.

Q 28. Describe a situation where you had to solve a complex problem related to the WMS.

In a previous role, we faced a significant challenge when a major system upgrade caused unexpected errors in our WMS’s order fulfillment process. Orders were being incorrectly routed to the wrong picking locations, leading to significant delays and customer dissatisfaction.

My initial step was to systematically isolate the problem, analyzing the system logs and working closely with the IT team to identify the root cause. We discovered a bug in the newly implemented routing algorithm. While a full system rollback was considered, the potential for data loss was high.

Instead, I developed a temporary workaround by creating a custom script that bypassed the faulty algorithm and manually routed the orders based on the original system’s logic. This immediate solution mitigated the impact on operations while the IT team worked on a permanent fix for the underlying bug. The situation demonstrated the importance of thorough testing during system upgrades and the need for agile problem-solving in high-pressure environments.

Key Topics to Learn for Warehouse Management System (WMS) Familiarity Interview

- WMS Functionality Overview: Understand the core functions of a WMS, including receiving, putaway, picking, packing, shipping, and inventory management. Consider the different types of WMS systems (cloud-based, on-premise) and their advantages/disadvantages.

- Inventory Management Techniques: Explore various inventory control methods like FIFO, LIFO, and FEFO. Be prepared to discuss their practical applications and the impact on warehouse efficiency and cost.

- Order Fulfillment Processes: Delve into the different order fulfillment strategies (e.g., batch picking, zone picking, wave picking) and their implications for optimizing throughput and minimizing errors. Be ready to explain how to choose the right strategy for a given warehouse environment.

- Warehouse Layout and Design: Understand the principles of efficient warehouse design, including slotting optimization, aisle configuration, and the impact of technology on layout decisions (e.g., automated guided vehicles).

- Reporting and Analytics: Learn about the key performance indicators (KPIs) used in warehouse management and how WMS data is utilized for performance analysis and continuous improvement. Discuss common reporting tools and data analysis techniques.

- Integration with Other Systems: Understand how a WMS integrates with other enterprise systems like ERP, TMS, and eCommerce platforms. Discuss the importance of data exchange and system compatibility.

- Problem-Solving and Troubleshooting: Be prepared to discuss common WMS challenges and how to approach troubleshooting scenarios. This could include dealing with system errors, resolving inventory discrepancies, or optimizing inefficient processes.

Next Steps

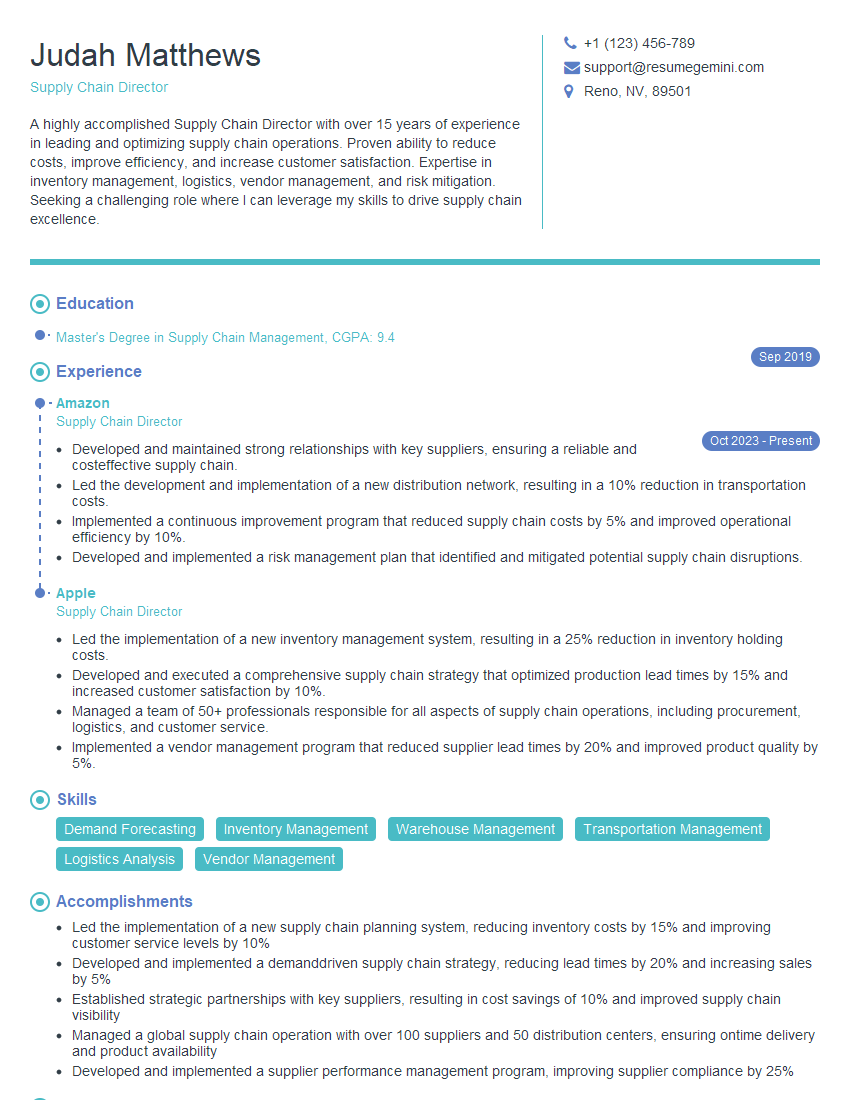

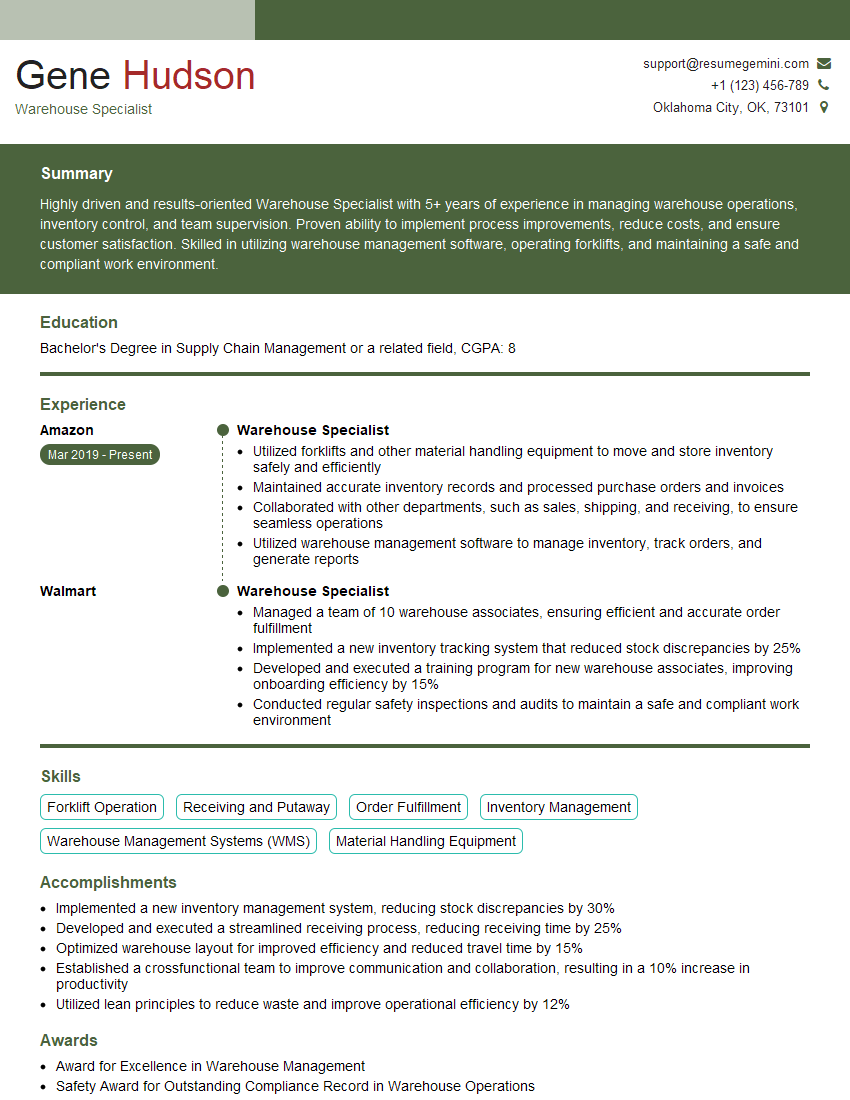

Mastering Warehouse Management System (WMS) familiarity is crucial for career advancement in logistics and supply chain management. A strong understanding of WMS principles significantly enhances your value to potential employers. To maximize your job prospects, crafting a compelling and ATS-friendly resume is essential. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your WMS knowledge. We provide examples of resumes tailored to WMS familiarity to help you showcase your skills effectively. Take the next step in your career journey – build a winning resume today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good