The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Water Distribution System Troubleshooting interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Water Distribution System Troubleshooting Interview

Q 1. Explain the principles of water hammer and how to mitigate it.

Water hammer is a significant problem in water distribution systems. It occurs when the rapid closure of a valve or pump causes a pressure surge, like a sudden stop of a speeding train. This surge travels through the pipes as a pressure wave, potentially causing damage. Imagine a water-filled pipe as a long, flexible hose. When you quickly shut off the flow at one end, the water’s momentum doesn’t stop instantly; it slams into the valve, creating a shockwave that travels back and forth along the pipeline. This pressure spike can be several times the normal operating pressure.

Mitigation involves several strategies:

- Slow Valve Closure: Installing slow-closing valves that gradually reduce flow prevents sudden pressure changes. Think of gently applying the brakes on a car instead of slamming them.

- Air Chambers or Surge Tanks: These are installed near valves or pumps to absorb the pressure surge. They act like shock absorbers, cushioning the impact of the pressure wave.

- Pressure Relief Valves: These valves automatically open when pressure exceeds a set limit, releasing excess pressure to prevent damage to the system.

- Proper Pipe Sizing and Material Selection: Using adequately sized pipes with appropriate material properties reduces the risk of excessive pressure fluctuations. Think of choosing a sturdy hose instead of a flimsy one.

- Non-Return Valves (Check Valves): These prevent water from flowing back into the system after the valve is closed, further reducing the impact of the pressure surge.

For example, during a water main break repair, carefully closing down the valves step by step will minimize water hammer and damage. Ignoring this can lead to pipe bursts or joint failures, causing further disruptions and additional repair costs.

Q 2. Describe different methods for detecting leaks in water distribution systems.

Detecting leaks in water distribution systems requires a multi-pronged approach. We utilize various methods based on the suspected location and severity of the leak.

- Visual Inspection: This is the simplest method, involving careful observation for signs of wet ground, unusual vegetation growth, or bubbling water. Often, this method detects surface leaks.

- Leak Noise Correlation: Specialized listening devices are used to pinpoint leak locations by detecting the high-frequency sounds emitted by escaping water. This method is effective for finding underground leaks.

- Pressure Monitoring: Regular pressure monitoring across the system helps identify unusual pressure drops, often indicating leaks. A consistent pressure drop in a specific area can be a strong indicator of a leak.

- Water Balance Analysis: This involves comparing the total water input to the system with the total water consumption to identify any discrepancies. A significant difference suggests undetected leakage in the system.

- Tracer Dye Testing: In some cases, a non-toxic dye is added to the water upstream, and the leak location is identified by detecting the dye downstream. This is useful in pinpointing leaks in hard-to-reach areas.

- Leak Detection Cameras: This advanced method utilizes small cameras that are introduced into the pipe for visual inspection.

For instance, I once used leak noise correlation to locate a buried leak that was causing significant water loss in a residential area. The system pinpointed the leak within a few feet, allowing for targeted excavation and repair.

Q 3. How do you interpret water pressure readings and identify potential problems?

Interpreting water pressure readings is crucial for maintaining a healthy water distribution system. Regular monitoring provides insights into system performance and potential issues. Pressure gauges installed throughout the system provide the data.

- Consistent Low Pressure: This could indicate a leak, partially closed valve, or insufficient pump capacity. It may signal a wider problem that needs immediate attention.

- Fluctuating Pressure: This might suggest pump problems, air in the lines, or problems with water supply from the source. The changes in pressure may be indicators of system overload.

- High Pressure in Specific Areas: This may indicate a blockage or closed valve downstream, leading to pressure buildup. This can be a warning sign of potential pipe failure.

- Sudden Pressure Drops: These usually indicate a burst pipe or significant leak. This requires rapid response to prevent major water loss and potential damage.

Example: A sudden, significant pressure drop in a specific zone immediately suggests a main break and necessitates an emergency response. The pressure readings help prioritize the response by identifying the extent and location of the problem.

Q 4. What are the common causes of water main breaks, and how are they repaired?

Water main breaks are a serious concern in water distribution systems. Several factors contribute to these failures:

- Corrosion: Over time, the pipes corrode internally and externally, weakening their structure and making them prone to failure. This is especially true for older cast iron pipes.

- Soil Conditions: Changes in soil conditions, such as shifting ground or erosion, can put stress on the pipes, leading to cracking or breakage. This is particularly problematic in areas with significant seismic activity or unstable soil.

- Pipe Age and Material: Older pipes are more susceptible to failure due to age-related deterioration and material fatigue. Modern materials are more resistant, but even those can fail under extreme conditions.

- External Forces: Construction activities, heavy traffic, or ground movement can damage the pipes from the outside.

- Water Hammer: As mentioned before, the repeated pressure surges can weaken pipes over time, making them susceptible to breaks.

Repairing a water main break is a complex process that typically involves:

- Isolation: Quickly isolating the affected section by closing down valves to minimize water loss and disruption to the service area.

- Excavation: Carefully excavating the area to expose the broken pipe.

- Repair or Replacement: Repairing the damaged section or replacing the entire section, depending on the extent of the damage. This often involves specialized tools and materials.

- Testing and Pressure Check: Thoroughly testing the repaired section before restoring water service to ensure there are no further leaks.

- Restoration: Repairing the excavated area and restoring the surface to its original condition.

Recently, I oversaw the repair of a major water main break caused by corrosion. The timely isolation of the affected section minimized service disruption, and a rapid repair prevented wider damage.

Q 5. Explain the importance of regular hydrant flushing and testing.

Regular hydrant flushing and testing are vital for maintaining a healthy water distribution system. They play a crucial role in ensuring water quality and system reliability.

- Water Quality: Flushing removes sediment and stagnant water that can build up in the pipes, improving water clarity and reducing the risk of bacterial growth. Imagine cleaning out a dirty water bottle to remove sediment and bacteria.

- System Maintenance: Flushing helps identify leaks, blockages, and other problems in the distribution system. By regularly flushing, we can detect even the smallest leaks before they become major issues.

- Hydrant Functionality: Testing hydrants ensures they are operational and readily available in case of emergencies, such as fire fighting. Regular testing helps maintain the equipment’s readiness.

- Pressure Management: Flushing can help manage pressure within the distribution system and ensure an even distribution of pressure to all areas.

For example, during routine flushing, we detected a small leak in a section of pipe that would have otherwise gone unnoticed, allowing for preventative repair before it escalated into a costly emergency.

Q 6. Describe your experience with SCADA systems in water distribution.

I have extensive experience working with Supervisory Control and Data Acquisition (SCADA) systems in water distribution. SCADA systems are the backbone of modern water management, providing real-time monitoring and control of the entire distribution network.

My experience includes:

- Data Acquisition and Monitoring: Using SCADA systems to monitor water pressure, flow rates, tank levels, and pump performance across the entire distribution network.

- Remote Control: Utilizing SCADA to remotely control valves, pumps, and other system components, allowing for efficient operation and response to emergencies.

- Data Analysis and Reporting: Utilizing SCADA’s data analysis capabilities to identify trends, patterns, and anomalies in system behavior, helping in predictive maintenance and leak detection.

- Alarm Management: Configuring and managing SCADA alarms to alert operators of critical events such as pressure drops, pump failures, or high water levels.

- System Integration: Integrating SCADA with other systems, such as Geographic Information Systems (GIS), to provide a comprehensive view of the water distribution infrastructure.

For instance, during a recent storm, the SCADA system alerted us to a significant pressure drop in a particular area. We were able to identify and isolate the problem quickly, minimizing service disruption.

Q 7. How do you prioritize repairs in a water distribution system during an emergency?

Prioritizing repairs during a water distribution emergency requires a structured approach to ensure the most critical issues are addressed first. The process usually involves several steps.

- Assessment: Quickly assess the extent and impact of the emergency, identifying the affected areas and the number of customers without service.

- Risk Assessment: Determine the level of risk associated with each problem, considering factors such as potential health hazards, safety risks, and economic impact.

- Impact Prioritization: Prioritize repairs based on the number of affected customers and the criticality of the service disruption. Hospitals, schools, and other essential services are typically given top priority.

- Resource Allocation: Allocate available personnel, equipment, and materials to address the highest priority issues first, ensuring efficient use of resources.

- Communication: Maintain open communication with the affected customers, keeping them informed of the progress and anticipated restoration times.

- Post-Incident Analysis: After the emergency is over, a thorough analysis is conducted to learn from the event, identify areas for improvement, and develop preventive measures for future emergencies.

During a major storm last year, we prioritized the repairs based on the number of customers without water and the presence of critical facilities such as hospitals in affected zones, ensuring a quick and efficient emergency response.

Q 8. What are the different types of water pipes and their respective strengths and weaknesses?

Water pipes are chosen based on factors like pressure, flow rate, soil conditions, and budget. Different materials offer varying strengths and weaknesses.

- Ductile Iron: High strength, durability, and resistance to corrosion. Common in high-pressure mains. However, it’s more expensive than some alternatives and can be susceptible to damage from external forces like ground movement.

- PVC (Polyvinyl Chloride): Lightweight, easy to install, and relatively inexpensive. Suitable for lower-pressure applications. Less durable than ductile iron and can be affected by extreme temperature changes or UV radiation.

- High-Density Polyethylene (HDPE): Flexible, resistant to corrosion, and relatively easy to install. Excellent for areas with frequent ground movement. Can be more expensive than PVC and may be susceptible to damage from certain chemicals.

- Copper: Excellent corrosion resistance and long lifespan. Used in service lines and smaller diameter pipes. Can be expensive and susceptible to damage from certain chemicals and electrolysis.

- Concrete: Often used in large diameter gravity mains, where strength and longevity are prioritized. Less common for high-pressure lines and is generally a more static system due to inflexibility. Susceptible to cracking under stress.

Example: In a high-pressure main supplying a large residential area, ductile iron would be preferred due to its strength and durability. However, in a low-pressure subdivision using smaller diameter pipes, PVC might be a more cost-effective choice.

Q 9. How do you perform a water quality analysis and interpret the results?

Water quality analysis involves testing water samples for various physical, chemical, and biological parameters to ensure it meets regulatory standards and is safe for consumption. This often involves a multi-step process.

- Sample Collection: Samples are collected from representative points throughout the distribution system, following strict protocols to avoid contamination.

- Laboratory Analysis: Samples are analyzed for parameters like pH, turbidity, chlorine residual, coliform bacteria, heavy metals, and various other contaminants. Specific tests depend on suspected issues or regulatory requirements.

- Data Interpretation: Results are compared against regulatory limits and standards. Deviations indicate potential problems, necessitating further investigation.

Interpreting Results: High turbidity indicates suspended solids, potentially indicating sediment or pipe corrosion. Low or absent chlorine residual suggests insufficient disinfection. Presence of coliform bacteria signals fecal contamination. Elevated levels of heavy metals may point to industrial discharge or leaching from old pipes.

Example: If a water sample shows high levels of iron, this points to corrosion within the pipes or high iron content in the source water. We would then investigate the pipe material, water source, and implement corrosion control measures or water treatment strategies, such as filtration or iron removal.

Q 10. Explain the concept of water loss control and its importance.

Water loss control is the process of identifying, quantifying, and reducing water losses from a distribution system. This is crucial for several reasons:

- Economic Savings: Reducing leakage saves water, energy, and treatment costs.

- Environmental Protection: Minimizes wasted resources and helps conserve water for future use.

- Improved System Performance: Reduces pressure fluctuations and improves water quality by minimizing stagnation in the pipes.

- Enhanced System Reliability: Lower leakage helps maintain sufficient pressure during peak demand and reduces the chance of water main breaks.

Methods of Water Loss Control: These can include leak detection surveys (acoustic and pressure monitoring), district metering, pressure management, and regular maintenance of pipes and valves.

Example: A district metering program can help pinpoint areas with high unaccounted-for water, signaling the need for more intensive leak detection efforts in that specific section of the network.

Q 11. Describe your experience with water distribution modeling software.

I have extensive experience using water distribution modeling software such as EPANET, WaterCAD, and InfoWorks WS. These programs are invaluable tools for analyzing and optimizing water distribution systems.

Applications: I use these tools for:

- Hydraulic Modeling: Simulating water flow and pressure within the network under various scenarios (peak demand, pipe breaks, etc.).

- Leak Detection: Identifying potential locations of leaks based on pressure and flow data.

- Network Optimization: Evaluating the impact of different upgrades or modifications to the system, such as pipe replacements or the addition of new pumps.

- Water Quality Modeling: Simulating the transport of contaminants within the distribution system.

Example: Using EPANET, I once modeled the impact of a proposed pipe replacement on pressure fluctuations in a critical section of the network. This allowed me to optimize the design and minimize disruptions during construction.

Q 12. How do you manage and respond to customer complaints related to water service?

Managing customer complaints efficiently is essential for maintaining public trust and ensuring system reliability. My approach is:

- Prompt Acknowledgement: Quickly acknowledge the complaint and assure the customer that their issue will be addressed.

- Thorough Investigation: Gather all relevant information—location, nature of the problem, time of occurrence, etc. This often involves checking pressure readings, inspecting the area, and reviewing maintenance logs.

- Effective Communication: Keep the customer informed of the progress and anticipated resolution time.

- Appropriate Action: Depending on the nature of the complaint (low pressure, discoloration, leaks, etc.), initiate the necessary repairs, adjustments, or investigations.

- Follow-up: Once the issue is resolved, follow up with the customer to ensure satisfaction.

Example: I recently handled numerous complaints about discolored water following a main break. We promptly informed customers of the situation, implemented flushing procedures, and provided regular updates until the water quality returned to normal.

Q 13. What are the common causes of water discoloration and how are they addressed?

Water discoloration is a common customer complaint, often caused by several factors:

- Main Breaks: Disturbances in the system can stir up sediment, leading to temporary discoloration.

- Pipe Corrosion: Corrosion of iron or manganese pipes can release these materials into the water.

- High Iron or Manganese Content in Source Water: Elevated levels of these naturally occurring minerals in the source water can lead to staining.

- Hydrant Flushing: Routine flushing of hydrants can temporarily discolour water in nearby areas.

- Construction Activities: Construction near water mains can disturb sediment.

Addressing Discoloration: The appropriate response depends on the cause. For main breaks, flushing the affected lines is typically sufficient. If corrosion is the issue, more extensive pipe rehabilitation or replacement may be necessary. High iron or manganese levels in the source water may require water treatment adjustments.

Example: Following a main break, we implemented a targeted flushing program to remove sediment and restore clear water to affected areas, regularly updating customers on our progress.

Q 14. Describe your experience with trenchless repair techniques for water mains.

Trenchless repair techniques offer significant advantages over traditional open-cut methods for repairing water mains, minimizing disruption and environmental impact.

Techniques I have experience with include:

- Pipe Bursting: A new pipe is pulled through the existing one, breaking it apart.

- Cured-in-Place Pipe (CIPP): A resin-soaked liner is inserted into the damaged pipe and cured to create a new pipe within the old one.

- Sliplining: A smaller diameter pipe is inserted into the existing pipe.

Advantages: Reduced excavation, faster repairs, less traffic disruption, lower environmental impact (less ground disturbance), lower costs (in many situations).

Example: I oversaw a project using CIPP to rehabilitate a section of aging cast iron water main. This minimized the disruption to traffic and residents, and resulted in a quicker and more cost-effective repair compared to traditional open-cut replacement.

Q 15. How do you ensure the safety of workers during water main repairs?

Worker safety during water main repairs is paramount. It requires a multi-faceted approach encompassing thorough planning, adherence to strict safety protocols, and ongoing training.

- Pre-work planning: This includes identifying potential hazards like traffic, underground utilities (besides the water main itself!), and confined spaces. Detailed excavation plans and safe access routes are crucial. We use utility locating services to precisely mark underground lines, preventing accidental damage.

- Site safety measures: This involves establishing a well-defined work zone with appropriate barricades, warning signs, and traffic control measures. The area needs proper lighting, especially during night repairs. Personal Protective Equipment (PPE) – hard hats, safety glasses, gloves, high-visibility clothing, and appropriate respiratory protection – is mandatory for all workers.

- Confined space entry procedures: If repairs involve working in confined spaces like manholes, strict protocols for atmospheric monitoring, ventilation, and rescue plans are essential. Workers must undergo specific confined space entry training.

- Emergency response plan: A detailed emergency response plan, including communication procedures and emergency contact information, must be in place and practiced regularly. This ensures prompt and efficient response to any incidents.

- Ongoing training and supervision: Workers receive regular safety training on relevant OSHA regulations and best practices. Experienced supervisors oversee all aspects of the repair work, ensuring compliance with safety regulations.

For instance, during a recent main break repair in a busy downtown area, we implemented a comprehensive traffic management plan, including detours and flaggers, to ensure both worker and public safety. We also used specialized vacuum trucks to remove excess water, minimizing the risk of slips and falls.

Career Expert Tips:

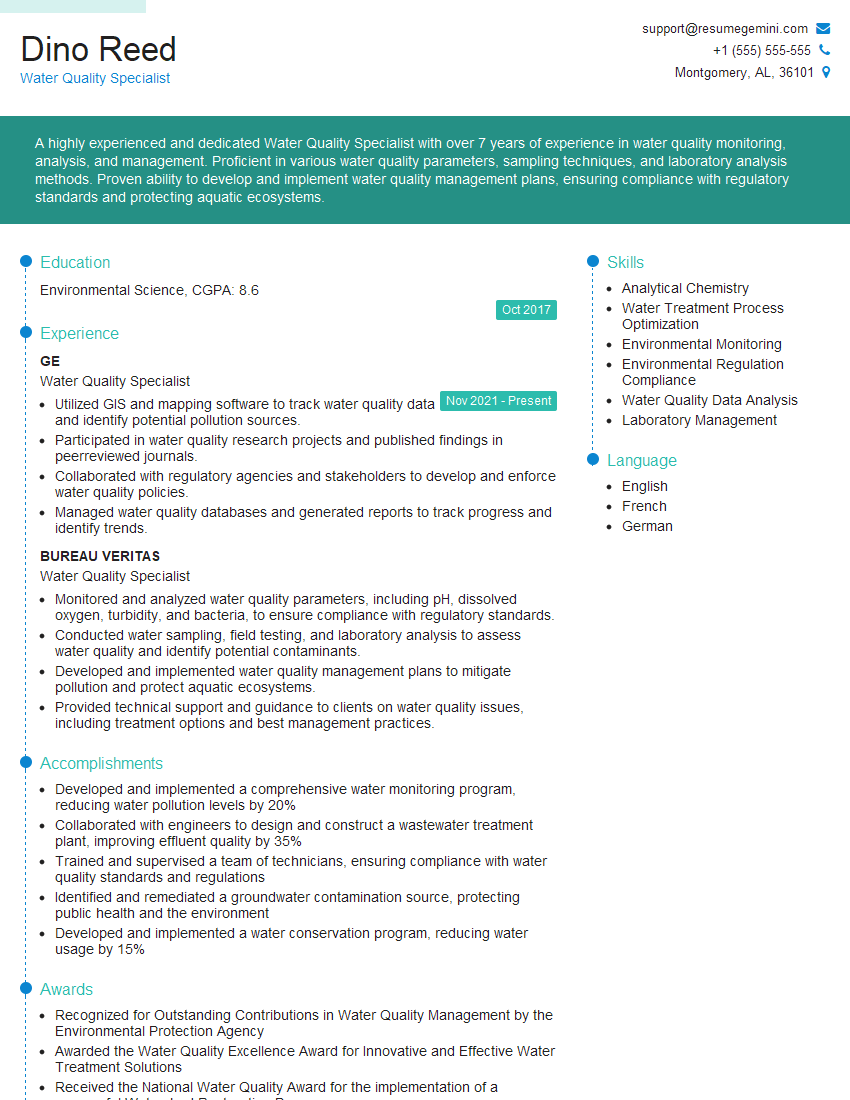

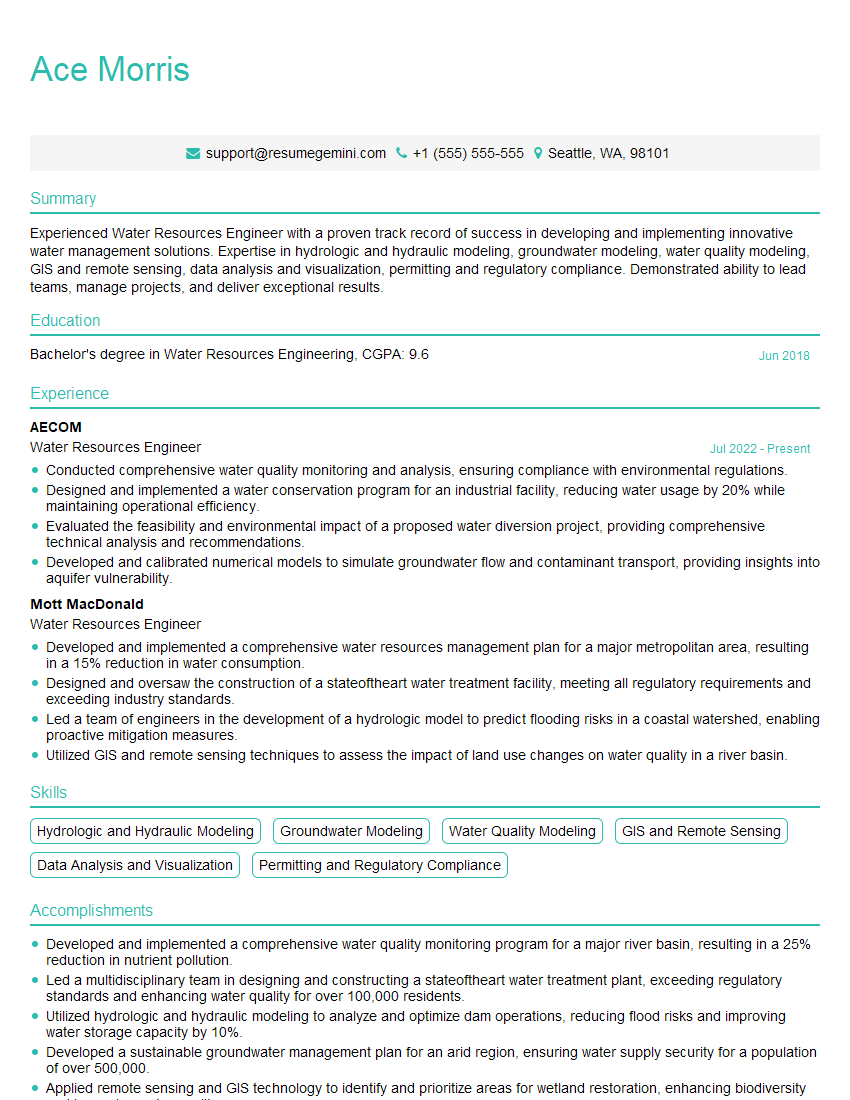

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the role of pressure reducing valves in water distribution systems.

Pressure reducing valves (PRVs) are critical components in water distribution systems, maintaining optimal water pressure within designated zones. Think of them as pressure regulators for your water system.

Their main role is to prevent excessive pressure in areas where high pressure could damage pipes, fittings, and appliances, or lead to water leaks. They achieve this by automatically reducing the pressure of the water entering a particular section of the system.

- Protecting infrastructure: PRVs safeguard water mains and service lines from over-pressurization, reducing the risk of bursts and leaks, which can lead to significant water loss and costly repairs.

- Ensuring consistent pressure: By maintaining consistent pressure within a specific zone, PRVs help ensure reliable water supply to customers. This prevents low-pressure issues that affect water quality and service.

- Managing pressure zones: They are particularly important in systems with significant elevation changes, where water pressure naturally increases with elevation. PRVs allow for the creation of multiple pressure zones, optimizing pressure throughout the distribution network.

For example, in a hilly region, a PRV might be installed at the top of a hill to reduce the high pressure caused by gravity, protecting lower-lying areas from excessive pressure. Without PRVs, the lower areas might experience extremely high pressure while the higher areas experience lower pressure.

Q 17. How do you identify and address issues related to water distribution system disinfection?

Maintaining adequate disinfection in a water distribution system is crucial for public health. Issues can arise from various sources, requiring a systematic approach to identification and resolution.

- Regular monitoring: We routinely monitor water quality parameters, including free chlorine residual, turbidity, and bacterial counts (e.g., coliform bacteria). This involves collecting samples at strategically located points throughout the distribution system and analyzing them in an accredited laboratory.

- Identifying issues: Deviations from established water quality standards indicate potential problems. For instance, low free chlorine residual might signal insufficient disinfection, while increased turbidity suggests possible contamination. Bacterial contamination needs immediate action.

- Addressing issues: Depending on the issue identified, solutions may include adjusting chlorine dosing rates, flushing mains to remove sediment, investigating potential sources of contamination (e.g., leaks), or undertaking a system-wide disinfection campaign.

- Leak detection: Leaks can compromise disinfection by reducing pressure and providing pathways for contamination. We use advanced leak detection techniques, such as acoustic monitoring and pressure mapping, to locate and repair leaks promptly.

For instance, if we detect high coliform counts in a particular area, we would immediately initiate a flushing program, followed by targeted chlorination, and investigate the potential sources such as a damaged pipe section or cross connection. We would also increase monitoring frequency in the affected area.

Q 18. What are the different types of valves used in water distribution systems and their functions?

Water distribution systems utilize various valves to control water flow, pressure, and isolate sections for maintenance or repairs. Each valve type serves a specific purpose.

- Gate valves: These valves are primarily used for on/off control of water flow. They are less suited for frequent operation but are effective for completely shutting off flow in a section of the pipeline.

- Globe valves: These valves provide precise flow control. They are used for regulating the flow rate but can be prone to wear and tear if used for on/off control frequently.

- Butterfly valves: These offer a compact, cost-effective solution for on/off control, particularly in larger diameter pipelines. They are less precise in regulating flow than globe valves.

- Check valves: These valves prevent backflow in the pipeline. They automatically close when the flow direction reverses, protecting against contamination or pressure surges.

- Pressure reducing valves (PRVs): As discussed earlier, these valves regulate pressure in specific sections of the system.

- Air release valves: These valves automatically release trapped air from the pipeline, preventing air pockets that can disrupt flow or cause pressure problems.

Each valve type is strategically placed in the system based on its function and the specific needs of the area it serves. For example, gate valves might be used to isolate a section of the main for repairs, while globe valves regulate flow to individual customer services. Check valves ensure that contamination from a broken pipe doesn’t flow back into the rest of the system.

Q 19. Describe your experience with GIS mapping in water distribution system management.

Geographic Information System (GIS) mapping is indispensable in modern water distribution system management. It provides a powerful visual representation of the entire system, enabling efficient planning, maintenance, and emergency response.

My experience with GIS involves using it for:

- Asset management: Mapping the location of all assets, including pipes, valves, hydrants, and other infrastructure components, allowing for easy tracking of their condition and maintenance schedules.

- Leak detection and repair: GIS helps in visualizing water pressure data and pinpointing potential leak locations based on pressure drops. This accelerates leak identification and facilitates faster repairs.

- Hydraulic modeling: Integrating GIS data with hydraulic models enables simulating different scenarios, such as pipe breaks or planned infrastructure changes, improving system optimization and planning.

- Emergency response: GIS provides a real-time overview of the system during emergencies, allowing for quick identification of affected areas, isolation of damaged sections, and optimized deployment of crews.

- Customer service: GIS can be used to quickly locate customer service lines and respond to their needs.

For example, we once used GIS to identify a cluster of leaks in a particular area by analyzing pressure data overlaid on the pipe network map. This led to the discovery of a compromised section of the main that was not immediately apparent through traditional inspection methods. The repair using the GIS data was highly effective and saved time and resources.

Q 20. How do you maintain accurate records and documentation for water distribution system maintenance?

Maintaining accurate records and documentation is crucial for efficient water distribution system management. It ensures accountability, facilitates decision-making, and supports regulatory compliance. Our approach involves:

- Centralized database: We use a centralized database system to store all relevant information, including asset details (size, material, age, condition), maintenance history, repair records, and water quality data. This ensures easy accessibility and prevents data duplication.

- Computerized Maintenance Management System (CMMS): We employ a CMMS to track maintenance schedules, work orders, and inventory. This helps in scheduling preventative maintenance and optimizing resource allocation.

- GIS integration: As previously mentioned, integrating GIS with our database provides a visual link between physical assets and their associated data. This improves data management and enhances overall understanding of the system.

- Regular audits: We conduct periodic audits of our records to ensure data accuracy, completeness, and consistency. This helps in identifying and rectifying any discrepancies.

- Standardized procedures: We follow standardized procedures for data entry and documentation to ensure uniformity and minimize errors.

This comprehensive system allows us to easily access historical data for trend analysis, aiding in preventative maintenance strategies and long-term planning. For example, we can track the frequency of repairs on specific pipe types to identify sections that require proactive replacement or rehabilitation.

Q 21. What are the different methods for disinfecting a newly installed water main?

Disinfecting a newly installed water main is vital to ensure the safety of the water supply. Several methods are employed, depending on the specific circumstances and local regulations.

- Chlorination: This is the most common method. A chlorine solution of a specific concentration is introduced into the pipeline and allowed to circulate for a specific contact time (usually a minimum of 24 hours). This kills any potential bacteria or microorganisms.

- Chloramination: A combination of chlorine and ammonia is used. Chloramine provides longer-lasting disinfection compared to chlorine alone, which can be advantageous in larger systems.

- Ultraviolet (UV) disinfection: UV light can be used to disinfect the water as it passes through the pipeline. This method is particularly useful where chlorine is undesirable, but it requires careful monitoring and maintenance of the UV lamps.

- Other methods: Other disinfectants, such as chlorine dioxide or ozone, may be used in specific situations, particularly if chlorine is unsuitable.

Before disinfection, the pipeline must be thoroughly flushed to remove any sediment or debris. After disinfection, the water is tested to ensure the disinfectant residual is within acceptable limits and the water is free from microbial contamination before being put into service. For example, during a recent project, we used a combination of chlorination followed by flushing and then water quality testing before connecting the new main to the existing system.

Q 22. Explain the impact of water age on water quality within a distribution system.

Water age, or the time water remains in the distribution system, significantly impacts its quality. As water sits in pipes, several factors degrade its quality. Think of it like leaving a glass of water out in the sun – it changes over time.

- Disinfection Byproduct Formation: Disinfectants like chlorine react with organic matter in the water, forming disinfection byproducts (DBPs). Prolonged contact increases DBP concentrations, some of which can be harmful to human health. This is a critical aspect we constantly monitor.

- Changes in pH and Temperature: Water’s pH and temperature can shift, affecting its corrosiveness and the potential for leaching of metals from pipes. Older water might become more corrosive, leading to increased lead or copper levels, particularly in older systems.

- Biological Growth: Stagnant water can foster bacterial growth, leading to taste and odor issues and potential health risks. Regular flushing programs help mitigate this.

- Increased Turbidity: Sedimentation can occur over time, leading to increased turbidity or cloudiness in the water.

Managing water age is crucial for maintaining water quality. Techniques like network modeling and optimized flow control help to minimize the time water spends in the pipes. For example, we use hydraulic modeling software to identify areas prone to stagnation and implement strategies like targeted flushing to improve water turnover.

Q 23. How do you calculate water flow rates and pressure drops in a pipeline?

Calculating water flow rates and pressure drops in pipelines involves applying fundamental hydraulic principles, primarily using the Hazen-Williams equation or Darcy-Weisbach equation. The choice depends on the pipe material and flow regime.

The Hazen-Williams equation is commonly used for water distribution systems and is relatively simple to use. It relates flow rate (Q), pipe diameter (D), pipe length (L), and the Hazen-Williams coefficient (Ch), which accounts for pipe roughness:

Q = 0.849 * Ch * D2.63 * S0.54 / L0.54where S is the pipe slope (head loss per unit length).

The Darcy-Weisbach equation is more complex but more accurate, particularly for turbulent flow. It requires the friction factor (f), which depends on the Reynolds number and pipe roughness:

hf = f * (L/D) * (V2 / 2g)where hf is the head loss, V is the flow velocity, and g is the acceleration due to gravity. This equation requires iterative calculations or use of Moody diagrams to determine the friction factor.

In practice, we use specialized software that incorporates these equations and considers the entire network’s complexity, including pumps, valves, and various pipe diameters to accurately predict flow and pressure in the distribution system. This allows us to identify pressure zones and potential problems before they impact consumers.

Q 24. What are the regulatory compliance requirements for water distribution systems in your area?

Regulatory compliance for water distribution systems is paramount and varies slightly by region, but generally includes adherence to:

- Safe Drinking Water Act (SDWA) and its associated regulations: These regulations set maximum contaminant levels (MCLs) for various substances, like lead, copper, and disinfection byproducts. We meticulously monitor these parameters.

- State-specific regulations: Many states have their own standards and requirements for water quality, infrastructure maintenance, and emergency response protocols. We must stay fully updated on these.

- Cross-connection control regulations: These regulations mandate measures to prevent backflow of non-potable water into the potable water system. This includes regular inspections and testing of backflow preventers.

- Water Loss Control Programs: Minimizing water loss through leaks and other inefficiencies is a key aspect of many regulations. We implement advanced metering infrastructure and leakage detection strategies to address this.

Non-compliance can result in significant penalties, reputational damage, and importantly, endanger public health. Our team is dedicated to maintaining meticulous records, conducting regular testing, and continuously upgrading our infrastructure to comply with all applicable regulations.

Q 25. Describe your experience working with different types of pumps used in water distribution.

My experience encompasses a variety of pumps utilized in water distribution systems, each with its own strengths and weaknesses. These include:

- Centrifugal Pumps: These are the workhorses of most water distribution systems, known for their high flow rates and relatively efficient operation over a wide range of conditions. We use variable frequency drives (VFDs) to control their speed and optimize energy efficiency.

- Positive Displacement Pumps: These pumps are better suited for high-pressure, low-flow applications. They are useful for boosting pressure in localized areas or for handling highly viscous fluids. We’ve used these in specific applications to address localized pressure deficiencies.

- Submersible Pumps: Primarily used for water intake from wells or reservoirs, these pumps are efficient and require less space. Their submersion reduces noise and vibration.

- Vertical Turbine Pumps: These are often used for deep wells, offering high head capabilities. We’ve incorporated these in locations with significant elevation changes to ensure adequate pressure.

I’m proficient in pump selection, installation, operation, and maintenance, considering factors such as flow rate, head, efficiency, and life cycle costs. For example, I recently led a project to replace aging centrifugal pumps with more efficient models equipped with VFDs, resulting in significant energy savings and reduced operational costs.

Q 26. How do you manage and control water pressure fluctuations within a distribution network?

Managing and controlling water pressure fluctuations requires a multifaceted approach. Uncontrolled pressure variations can lead to pipe bursts, water hammer, and reduced water quality. Imagine a rollercoaster – we want a smooth, controlled ride, not a jerky, unpredictable one.

- Pressure Reducing Valves (PRVs): These valves automatically regulate pressure within specific zones of the distribution network. They are crucial for maintaining consistent pressure in areas with varying elevation or demand.

- Pressure Relief Valves (PRVs): These valves protect pipes from over-pressurization by automatically releasing excess water. These are essential safety measures.

- Storage Tanks: Strategically located storage tanks act as buffers, absorbing fluctuations in demand and ensuring a stable pressure supply. They’re crucial to prevent immediate pressure spikes.

- SCADA Systems: Supervisory Control and Data Acquisition (SCADA) systems provide real-time monitoring and control of the entire distribution network, enabling operators to respond promptly to pressure variations. We use data analytics from the SCADA system to anticipate and proactively manage pressure fluctuations.

- Hydraulic Modeling: We use advanced hydraulic modeling software to simulate the system’s behavior under various conditions, aiding in the design and optimization of pressure control strategies.

A comprehensive approach that integrates these technologies and strategies is essential to effectively manage pressure fluctuations and ensure a reliable and high-quality water supply.

Q 27. Explain the importance of regular system inspections and preventative maintenance.

Regular system inspections and preventative maintenance are fundamental to ensuring the longevity, efficiency, and safety of a water distribution system. It’s like regularly servicing your car – it prevents major problems down the road.

- Leak Detection: Regular leak detection surveys, using acoustic sensors or other techniques, are critical to identify and repair leaks promptly, minimizing water loss and preventing further damage. We employ a combination of methods, depending on the system’s specifics.

- Pipe Inspection: Regular inspections can identify corrosion, damage, or other issues that might compromise the integrity of the pipes. We use CCTV cameras and other non-invasive inspection methods to thoroughly assess pipe condition.

- Valve and Hydrant Maintenance: Regular testing and maintenance of valves and hydrants ensure their proper operation during emergencies or scheduled maintenance events. We have a strict schedule of this preventive maintenance.

- Pump Maintenance: Regular maintenance of pumps, including lubrication, bearing inspections, and seal replacements, extends their lifespan and prevents failures. This also contributes to energy efficiency.

- Water Quality Monitoring: Consistent water quality testing ensures the water remains safe and meets regulatory requirements.

By adhering to a preventative maintenance schedule, we can identify and rectify problems before they escalate into major disruptions or pose risks to public health. This proactive approach ultimately results in significant cost savings and improved system reliability.

Q 28. How do you troubleshoot and resolve issues related to air entrapment in water distribution pipelines?

Air entrapment in water distribution pipelines is a common problem that can reduce system efficiency, cause noise, and even lead to pipe damage. Think of it like a bubble in a straw – it disrupts the flow.

- Air Release Valves (ARVs): These valves are strategically installed at high points in the pipeline to allow trapped air to escape. Proper placement and maintenance of ARVs are crucial.

- Vacuum Breakers: These devices prevent air from entering the system through the creation of a vacuum. They are commonly installed at pump suction lines and other vulnerable points.

- Flushing: Targeted flushing of specific sections of the pipeline can help remove trapped air. Careful planning is crucial to avoid disrupting service.

- Hydraulic Modeling: Modeling can identify areas prone to air entrapment, informing the optimal placement of ARVs or other mitigation strategies.

- Proper Pipeline Design: Careful planning during the design phase can help minimize air entrapment by incorporating features like proper slopes and minimizing high points in the pipeline.

Troubleshooting air entrapment often involves a combination of these techniques. For example, if we detect noise in a particular section of the pipeline, we’d first inspect the associated ARV, then consider flushing or even investigate if the initial pipeline design needs reassessment for that specific area. Our approach is systematic, focusing on data-driven solutions.

Key Topics to Learn for Water Distribution System Troubleshooting Interview

- Hydraulics and Fluid Mechanics: Understanding pressure, flow, and head loss in pipe networks; applying principles of Bernoulli’s equation and Darcy-Weisbach equation to analyze system performance.

- Pipe Network Analysis: Utilizing software (e.g., EPANET) to model water distribution systems, simulate scenarios, and identify potential problems; interpreting network diagrams and analyzing pressure profiles.

- Water Quality Considerations: Identifying potential sources of contamination (e.g., cross-connections, leaks); understanding disinfection techniques and water quality parameters; troubleshooting issues related to taste, odor, and turbidity.

- Pumping Systems: Understanding pump curves and operating characteristics; troubleshooting pump failures and inefficiencies; optimizing pump scheduling for energy efficiency.

- Leak Detection and Repair: Utilizing various leak detection methods (e.g., acoustic listening, pressure monitoring); understanding different pipe materials and repair techniques; performing leak location and repair procedures.

- SCADA and Data Acquisition: Interpreting data from SCADA systems to monitor system performance; identifying anomalies and trends; using data analysis to diagnose problems and optimize operations.

- Valve Operation and Maintenance: Understanding different types of valves and their functions; troubleshooting valve malfunctions; developing valve maintenance schedules.

- Regulatory Compliance: Understanding relevant water quality regulations and safety standards; ensuring compliance with local and national regulations.

- Troubleshooting Methodologies: Applying systematic problem-solving approaches, including root cause analysis and fault tree analysis, to effectively diagnose and resolve water distribution system issues.

- Emergency Response Planning: Understanding emergency procedures for water main breaks, contamination events, and other critical situations; developing and implementing emergency response plans.

Next Steps

Mastering Water Distribution System Troubleshooting is crucial for career advancement in the water industry, opening doors to leadership roles and specialized positions. A strong resume is your key to unlocking these opportunities. Make sure your resume is ATS-friendly to maximize its visibility to potential employers. To help you create a compelling and effective resume, consider using ResumeGemini. ResumeGemini offers a streamlined approach to resume building and provides examples tailored to various roles, including Water Distribution System Troubleshooting, to help you present your skills and experience in the best possible light.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good