Unlock your full potential by mastering the most common Weaving and Knitting Technologies interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Weaving and Knitting Technologies Interview

Q 1. Explain the difference between warp and weft yarns in weaving.

In weaving, the warp and weft yarns are the two fundamental components that create the fabric structure. Think of it like building a wall: the warp yarns are the vertical, strong foundational elements, while the weft yarns are the horizontal ones that interlace with the warp to create the fabric’s body.

- Warp yarns: These are the lengthwise yarns that are stretched tightly on the loom before weaving begins. They provide the structural integrity of the fabric, setting the overall width and length. Imagine them as the strong supporting beams of a building.

- Weft yarns: These are the crosswise yarns that are interwoven through the warp yarns. They are inserted using a shuttle or other mechanism and determine the fabric’s texture, color, and pattern. Think of them as the bricks filling in the spaces between the supporting beams.

A simple analogy is a basket: the warp is the vertical framework, and the weft is the weaving in and out that creates the container. The relationship between warp and weft dictates the fabric’s properties like strength, drape, and texture.

Q 2. Describe different weaving structures (plain, twill, satin).

Weaving structures are defined by how the warp and weft yarns interlace. Three basic structures are plain weave, twill weave, and satin weave. Each offers distinct visual and textural characteristics.

- Plain weave: This is the simplest weave structure. Each weft yarn passes over one warp yarn and under the next, creating a straightforward, balanced structure. It’s durable and versatile, commonly found in cotton sheets and simple fabrics. Think of a checkerboard pattern – that’s essentially what a plain weave looks like on a microscopic level.

- Twill weave: In twill weaves, the weft yarns pass over and under several warp yarns in a diagonal pattern. This creates a distinctive diagonal line across the fabric. The angle of this diagonal, and the number of yarns passed over or under, can vary considerably, creating different textures and designs. Denim is a classic example of twill weave, its characteristic diagonal lines visible to the naked eye.

- Satin weave: Satin weaves feature a long float, meaning the weft or warp yarn goes over several yarns before interlacing. This creates a smooth, lustrous surface with a noticeable sheen. Because of the long floats, satin weaves tend to be less durable than plain or twill weaves, but they are valued for their beautiful drape and luxurious feel. Silk charmeuse is a typical example of satin weave.

These basic structures can be combined and modified to create an almost infinite variety of fabric textures and designs. Understanding these foundations is key to designing and analyzing woven fabrics.

Q 3. What are the common types of knitting machines?

Knitting machines vary significantly, but can be broadly categorized by their needle type and operational mechanism. Common types include:

- Circular knitting machines: These machines produce tubular fabric (like socks or sleeves) by knitting in a circular pattern. They’re highly efficient for producing large quantities of seamless garments.

- Flat knitting machines: These machines knit flat fabric pieces, which are then seamed together as needed. They offer greater design flexibility than circular machines, allowing for more intricate patterns.

- Single-bed knitting machines: These simpler machines use one set of needles to create a single layer of fabric. They’re relatively easy to operate and maintain.

- Double-bed knitting machines: These more advanced machines use two sets of needles, allowing for the creation of complex structures and patterns, including double-layered fabrics.

- Intarsia machines: These machines work with different colored yarns to produce detailed patterns and designs within the fabric.

The choice of machine depends on factors like production scale, desired fabric structure, and complexity of the design. A small-scale operation might use a single-bed flat knitting machine, while a large textile company would likely employ highly automated circular knitting machines.

Q 4. Explain the difference between weft knitting and warp knitting.

Weft knitting and warp knitting are two fundamental methods for creating knitted fabrics. They differ significantly in their yarn arrangement and resulting fabric properties.

- Weft knitting: In weft knitting, a single yarn is looped and interlocked in a horizontal direction. Think of knitting by hand – you create loops across the width of the fabric. The fabric is formed one row at a time, with each row interlocked with the previous one. This process produces fabrics that tend to unravel easily if a stitch is broken (like a dropped stitch).

- Warp knitting: In warp knitting, multiple yarns are fed into the machine and looped simultaneously in a vertical direction. Multiple yarns are looped at the same time. This process produces a fabric that is much more stable, and less prone to laddering or unraveling. Warp knitted fabrics are often more durable and have a better dimensional stability.

A simple way to visualize this is to think of weft knitting like building a wall brick by brick, whereas warp knitting is like weaving multiple threads together simultaneously to create a fabric. Warp knitting is typically used for underwear, while weft knitting is commonly used for sweaters.

Q 5. Describe various knitting stitches (stockinette, garter, rib).

Knitting stitches are the fundamental building blocks of knitted fabrics. They are created by manipulating the loops of yarn. Here are three common stitches:

- Stockinette stitch: This is the most basic stitch, created by alternating knit (K) and purl (P) rows. The right side has a smooth, neat surface while the wrong side has a bumpy texture. Think of a plain sweater – the smooth side is often stockinette stitch.

- Garter stitch: This stitch is created by knitting every row (K). It produces a simple, reversible fabric with a ridged texture. It’s often used for blankets and scarves due to its simplicity and warmth.

- Rib stitch: This stitch is formed by repeating a pattern of knit and purl stitches within a row, often in a 1×1 (K1, P1) or 2×2 (K2, P2) pattern. This creates a stretchy, textured fabric with vertical ribs. Rib stitches are commonly found in cuffs, neckbands and waistbands for their elasticity.

These are just a few examples, and many other stitches are created by combining and varying these basic elements to create complex textures and patterns.

Q 6. How do you troubleshoot a jammed weaving loom?

Troubleshooting a jammed weaving loom requires a systematic approach. Safety first: always turn off the power before attempting any repairs.

- Identify the problem: Carefully examine the loom to pinpoint the exact location of the jam. Is it a broken thread, a tangled yarn, or a mechanical issue?

- Remove the obstruction: Carefully untangle any knotted or broken threads. Use appropriate tools to carefully remove any physical obstacles without damaging the loom.

- Check for broken parts: Inspect the loom for broken parts, such as a damaged shuttle, reed, or heddle. If necessary, replace the broken part.

- Re-thread the loom: If necessary, carefully re-thread the loom, ensuring that all the threads are properly placed in the heddles and reed.

- Check the tension: Ensure that the warp threads are properly tensioned. Incorrect tension can lead to jams and breakage.

- Test the loom: After resolving the issue, run the loom slowly to check if the jam has been completely resolved.

If the problem persists after these steps, it’s best to consult a loom repair technician or refer to the loom’s manual.

Q 7. How do you identify and resolve common knitting machine faults?

Troubleshooting knitting machine faults requires a combination of knowledge and systematic investigation. Always disconnect the power before attempting any repairs.

- Identify the symptom: Note the specific problem—dropped stitches, uneven tension, skipped stitches, noise, or the machine won’t turn on.

- Inspect the needles: Examine the needles for bent, broken, or misaligned needles. Replace or repair as needed. Even a slightly bent needle can cause significant problems.

- Check the yarn supply: Make sure the yarn is feeding correctly, that there are no knots or tangles, and that the tension is appropriate.

- Examine the carriage or cam system: For malfunctioning parts such as the carriage, assess the timing and movement of all components. A slight misalignment can cause major problems.

- Check for broken parts: Look for any broken components, such as the yarn guide, tensioner or other parts.

- Test the machine: Run the machine slowly after making any repairs or adjustments. If the problem persists, consult the manual or a repair specialist.

Regular maintenance, including cleaning and lubrication, can significantly reduce the likelihood of machine faults. Remember, safety is paramount – always refer to the manufacturer’s instructions and seek professional help if necessary.

Q 8. Explain the concept of yarn count and its significance.

Yarn count, also known as yarn number or yarn size, refers to the fineness or thickness of a yarn. It’s a crucial parameter in textile manufacturing because it directly impacts the fabric’s properties like drape, weight, and strength. There are several systems for expressing yarn count, the most common being the English system (denier), the metric system (tex), and the direct system (number of hanks per unit weight).

For example, a higher yarn count (e.g., 60s cotton) indicates finer, thinner yarns, resulting in a lighter, more delicate fabric, whereas a lower yarn count (e.g., 10s cotton) signifies thicker yarns producing heavier, more robust fabrics. The choice of yarn count is determined by the end-use of the fabric; fine yarns are used for lingerie or dress shirts, while heavier yarns might be suitable for denim or towels.

Understanding yarn count is essential for predicting the fabric’s characteristics and ensuring consistent quality throughout the production process. It allows manufacturers to accurately estimate material costs, optimize machine settings, and meet customer specifications.

Q 9. What are the different types of yarn used in weaving and knitting?

The variety of yarns used in weaving and knitting is vast, categorized by fiber type, structure, and twist. Some common types include:

- Natural Fibers: Cotton, wool, silk, linen – each offering unique properties such as softness (cotton), warmth (wool), luster (silk), and strength (linen).

- Synthetic Fibers: Polyester, nylon, acrylic, rayon – these offer advantages like durability, wrinkle resistance, and cost-effectiveness, often blended with natural fibers for improved performance.

- Blends: Combinations of natural and synthetic fibers – blending allows manufacturers to tailor fabric properties, for example, combining cotton’s softness with polyester’s durability to create a durable, comfortable shirt fabric.

- Specialty Yarns: These include yarns with special effects like slub yarns (irregular thickness), bouclé yarns (looped structure), and metallic yarns (incorporating metallic threads).

The selection of yarn depends on factors such as the intended application of the fabric, the desired aesthetic, and the budget. For instance, a high-quality wool yarn would be chosen for a luxury sweater, whereas a cost-effective polyester yarn might be preferred for a mass-produced garment.

Q 10. Describe different fabric finishes and their applications.

Fabric finishes are processes applied to fabrics to modify their properties, improving their appearance, feel, and performance. Examples include:

- Bleaching: Removes natural colors, creating a bright white base.

- Dyeing: Adds color using various methods like vat dyeing or reactive dyeing.

- Printing: Applies designs to fabric using techniques like screen printing or digital printing.

- Calendering: Uses rollers to impart smoothness, gloss, or texture.

- Mercerization: Treats cotton fabric to improve its luster, strength, and dye affinity.

- Water Repellent Finishes: Apply coatings to make fabrics water-resistant.

- Flame Retardant Finishes: Enhance safety by making fabrics less flammable.

The application of a specific finish depends on the end-use of the fabric. For example, a water-repellent finish is essential for outerwear fabrics, while a soft hand feel is crucial for garments against the skin. Careful selection and application of finishes are crucial for achieving desired fabric characteristics.

Q 11. How do you ensure quality control in weaving and knitting processes?

Quality control in weaving and knitting involves continuous monitoring and inspection at every stage, from raw material selection to final product inspection. Key aspects include:

- Raw Material Inspection: Checking yarn quality for consistency in count, strength, and color.

- Process Monitoring: Regularly monitoring machine settings, tension, and weft insertion to prevent defects.

- In-Process Inspection: Regularly inspecting fabric during production to identify and correct any defects early on.

- Final Inspection: Thoroughly inspecting the finished fabric for flaws like holes, broken ends, and unevenness.

- Statistical Process Control (SPC): Using statistical methods to monitor process parameters and identify trends.

Implementing a robust quality control system ensures consistent fabric quality, reduces waste, and maintains customer satisfaction. Regular training of personnel and use of advanced inspection tools are critical for effective quality control.

Q 12. Explain the importance of fabric testing in textile manufacturing.

Fabric testing is essential in textile manufacturing to ensure that the fabric meets the required quality standards and performance specifications. Testing provides objective data on crucial properties, enabling manufacturers to improve processes, ensure consistency, and satisfy customer requirements.

Common tests include:

- Tensile Strength: Measures the fabric’s resistance to tearing and breaking.

- Abrasion Resistance: Assesses the fabric’s ability to withstand rubbing and wear.

- Colorfastness: Evaluates the fabric’s resistance to color fading due to washing, light, or rubbing.

- Shrinkage: Determines the fabric’s tendency to shrink after washing.

- Wrinkle Resistance: Measures the fabric’s resistance to creasing.

Testing results help manufacturers identify potential problems early in the production process, allowing for timely adjustments to ensure the final product meets the desired standards. This minimizes waste, reduces customer complaints, and enhances brand reputation.

Q 13. What are the common fabric defects in weaving and knitting?

Common fabric defects in weaving and knitting can be broadly categorized into:

- Weaving Defects: Broken ends, missed ends, slubs, holes, mispicks, slack ends, shading.

- Knitting Defects: Dropped stitches, ladders, holes, missed courses, floats, fabric distortions.

These defects can result from various factors such as machine malfunction, incorrect yarn tension, poor operator skill, or raw material inconsistencies. Early detection and correction of these defects are crucial to minimize waste and maintain product quality. Thorough quality control practices and well-maintained machinery are essential in minimizing the occurrence of fabric defects.

Q 14. Describe your experience with different types of textile machinery.

Throughout my career, I’ve gained extensive experience with a wide range of textile machinery, including:

- Weaving Machines: I’ve worked with various types of weaving machines, from traditional shuttle looms to modern air-jet and rapier looms. My experience encompasses setting up, operating, and troubleshooting these machines, ensuring optimal performance and fabric quality.

- Knitting Machines: I possess hands-on experience with both weft knitting machines (circular and flat bed) and warp knitting machines (raschel and tricot). This includes expertise in different knitting techniques and stitch structures, allowing me to create diverse fabric types.

- Finishing Machinery: I’m familiar with various finishing machines including calenders, stenters, and dyeing and bleaching equipment. This knowledge extends to understanding the parameters and effects of different finishing processes on fabric properties.

My experience extends beyond mere operation; I understand the mechanics and automation aspects of these machines, enabling me to contribute to optimizing production processes and improving overall efficiency. I’m adept at diagnosing and resolving machine malfunctions, minimizing downtime, and ensuring smooth production flow.

Q 15. How familiar are you with CAD software for textile design?

I’m highly proficient in using CAD software for textile design. My experience encompasses several industry-standard programs, including but not limited to Lectra, Optitex, and Adobe Illustrator. These tools are crucial for creating intricate designs, simulating weaving and knitting processes, and generating precise technical specifications for production. For example, using Lectra’s Modaris, I can develop complex 3D garment simulations to visualize drape and fit before actual production, significantly reducing prototyping costs and time. I’m also comfortable with creating repeat patterns and exploring various weave structures virtually before committing to the physical process. My proficiency extends to exporting files in various formats for seamless integration into the manufacturing workflow.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your understanding of the textile supply chain.

The textile supply chain is a complex network involving numerous stages, from raw material sourcing to the final product reaching the consumer. It typically begins with fiber production (e.g., cotton farming, wool shearing), followed by fiber processing (cleaning, spinning into yarn). Then comes the yarn manufacturing, which might include dyeing and other treatments. Next is the fabric manufacturing stage, where yarns are woven or knitted into fabrics. This is often followed by fabric finishing (e.g., dyeing, printing, washing), and then garment manufacturing (cutting, sewing, embellishment). Finally, distribution, marketing, and retail complete the chain. I have a thorough understanding of each stage and its associated challenges, allowing me to anticipate potential bottlenecks and optimize processes for efficient production.

Q 17. How do you manage production timelines and deadlines?

Managing production timelines and deadlines requires meticulous planning and proactive monitoring. I utilize project management tools to create detailed Gantt charts, breaking down large projects into smaller, manageable tasks with clearly defined responsibilities and deadlines. Regular progress meetings with the team allow for early identification of potential delays and prompt corrective action. I also employ critical path analysis to pinpoint crucial stages needing close attention. For instance, if a shipment of dye is delayed, I can immediately assess its impact on the overall schedule and explore alternative solutions, such as using a substitute dye or adjusting the production sequence to minimize downtime. This proactive approach ensures projects are completed on time and within budget.

Q 18. How do you handle conflict resolution within a team?

Conflict resolution is an essential skill in a collaborative environment. My approach is to foster open communication and encourage team members to express their concerns freely. I strive to create a safe space where differing opinions are valued and constructive criticism is welcomed. When conflict arises, I facilitate discussions to identify the root cause, focusing on the issue at hand rather than personalities. I help team members understand each other’s perspectives and work towards a mutually agreeable solution. If necessary, I mediate the discussion, ensuring a fair and equitable outcome. The goal is always to strengthen team cohesion and improve overall productivity.

Q 19. Describe your experience working with different types of fibers (cotton, wool, silk, synthetic).

I have extensive experience working with a wide range of fibers, including cotton, wool, silk, and various synthetics like polyester, nylon, and acrylic. My experience spans various aspects of their processing, from yarn construction to fabric manufacturing. For example, I understand the nuances of spinning cotton for fine fabrics versus heavier, durable ones. I am familiar with the challenges of handling wool’s natural crimp and elasticity, understanding how to achieve optimal results in knitting or weaving. The delicate nature of silk requires specific processing techniques to prevent damage, which I have mastered through years of hands-on experience. Similarly, I’m well-versed in the properties of synthetic fibers and how they behave under different conditions, enabling me to select appropriate blends and processes for different applications.

Q 20. How do different fiber properties affect fabric drape and texture?

Fiber properties significantly influence fabric drape and texture. For example, the length and fineness of fibers affect the smoothness and luster of the resulting fabric. Long staple fibers, like Egyptian cotton, tend to create smoother, more luxurious fabrics than short staple fibers. The fiber’s crimp (natural waviness) contributes to the fabric’s elasticity and drape. Wool, with its high crimp, produces fabrics with excellent drape and resilience. Fiber strength dictates the durability and resistance to wrinkling. Strong fibers like nylon create wrinkle-resistant fabrics, while weaker fibers like linen often create softer but more easily creased fabrics. Finally, fiber cross-section affects the feel and texture; round fibers feel smoother than irregular ones. Understanding these properties is essential in choosing the right fiber for a desired fabric outcome.

Q 21. Explain your experience with different dyeing and finishing techniques.

My experience with dyeing and finishing techniques is comprehensive. I’m familiar with various dyeing methods, including vat dyeing (for deep, durable colors), reactive dyeing (for bright, vibrant colors on cellulose fibers), and acid dyeing (for wool and silk). I also have experience with printing techniques like screen printing, rotary printing, and digital printing. Finishing techniques I’m proficient in include washing, mercerization (for increased luster and strength in cotton), calendaring (for smoothing and compacting fabrics), and heat-setting (for stabilizing synthetic fibers). I have practical knowledge of how different techniques can alter the hand-feel, drape, and durability of fabrics. For example, mercerizing cotton increases its luster and dye uptake, resulting in a brighter, more vibrant color and improved texture. This depth of knowledge allows me to select the most suitable treatments for any given project.

Q 22. Describe your knowledge of different types of weaving looms (e.g., rapier, air-jet).

Weaving looms are the heart of fabric creation, each type offering unique advantages. Let’s explore some key varieties:

- Rapier Looms: These use grippers (rapiers) to carry the weft yarn across the warp yarns. They’re versatile and can handle various yarn types and fabric structures. Think of the rapiers as nimble fingers carrying the yarn across the threads. The speed and precision of these ‘fingers’ determine the loom’s efficiency and the fabric’s quality. I’ve personally worked extensively with Sulzer rapier looms, known for their high-speed capabilities and adaptability to different fabric weights.

- Air-Jet Looms: Instead of grippers, these use high-pressure air jets to propel the weft yarn across the warp. Air-jet looms are renowned for their high speed and efficiency, particularly in producing lightweight fabrics. Imagine compressed air as a powerful wind, swiftly carrying the weft across the warp. This method is particularly effective for delicate yarns that might be damaged by mechanical grippers. My experience includes troubleshooting and optimizing Picanol air-jet looms, focusing on minimizing yarn breakage and maximizing production output.

- Other Loom Types: While rapier and air-jet looms are prominent, there are others like projectile looms (using a small projectile to carry the weft), water-jet looms (using water jets), and the more traditional shuttle looms (using a shuttle to carry the weft). Each has its specific applications and limitations, determined by factors such as yarn type, fabric structure, and production volume.

The choice of loom depends entirely on the desired fabric characteristics and production requirements. Factors such as yarn count, fabric width, fabric structure, and production speed all influence the selection process.

Q 23. Explain your understanding of different knitting machine technologies (e.g., circular, flat).

Knitting machine technology offers two primary configurations: circular and flat knitting.

- Circular Knitting Machines: These produce tubular fabrics, ideal for socks, sweaters, and seamless garments. Imagine a circular knitting machine as a highly efficient knitting carousel. Needles arranged in a circle create seamless tubes. The diameter of the circle determines the width of the fabric produced. Variations within circular knitting include single-jersey, double-jersey, and rib structures, offering a wide range of fabric properties.

- Flat Knitting Machines: These create flat fabric pieces. Flat knitting machines are versatile and can produce a vast array of intricate patterns and textures. These machines work like a sophisticated typewriter, producing rows of stitches across a flat surface. They’re often used for garments requiring complex designs and often utilize technologies like intarsia and jacquard for pattern integration. I have significant experience programming and maintaining both single-bed and double-bed flat knitting machines, ensuring seamless production runs and high-quality outputs.

The choice between circular and flat knitting machines hinges on the desired fabric type and the garment’s construction. Factors like stitch density, pattern complexity, and production volume dictate the selection. For example, a large-scale production of simple socks would optimally utilize circular knitting machines, while a small-scale production of complex sweaters might favor flat knitting machines.

Q 24. How do you maintain and repair textile machinery?

Maintaining and repairing textile machinery requires a blend of preventative maintenance, regular inspections, and prompt troubleshooting. It’s a multi-step process:

- Preventative Maintenance: This involves regular cleaning, lubrication, and adjustments to prevent breakdowns. Think of it as regular checkups at the doctor; it helps catch minor issues before they become major problems. This includes scheduled oil changes, cleaning of lint traps, and inspection of moving parts.

- Regular Inspections: Daily visual checks for loose parts, frayed belts, or unusual noises are critical. These inspections help identify potential problems early on, preventing catastrophic failures. I’ve developed detailed inspection checklists specific to each machine type.

- Troubleshooting: When problems arise, a systematic approach is essential. This typically involves tracing the issue back to its source, using diagnostic tools and technical manuals. I’m proficient in diagnosing mechanical, electrical, and electronic issues. For instance, I recently resolved a yarn breakage issue on a rapier loom by adjusting the rapier speed and tension.

- Parts Replacement: Occasionally, parts need to be replaced. This requires sourcing appropriate replacement parts and having the skills to install them correctly. I have established relationships with reliable suppliers to ensure timely procurement of quality parts.

Effective maintenance practices significantly minimize downtime and extend the lifespan of the machinery, contributing significantly to a profitable and efficient operation. My experience has taught me the importance of meticulous record-keeping, enabling effective tracking of maintenance schedules and facilitating quick problem resolution.

Q 25. Explain your experience with automated textile production systems.

My experience with automated textile production systems is extensive. I’ve worked with fully automated systems integrating various machines through computerized control systems. These systems encompass aspects such as:

- Automated Material Handling: Automated systems for feeding raw materials and transporting finished goods are crucial for efficiency. This minimizes manual handling and reduces the chances of human error.

- Computerized Control Systems: Sophisticated software controls the entire process, adjusting parameters, monitoring performance, and making real-time adjustments. I’m familiar with PLC (Programmable Logic Controller) programming and SCADA (Supervisory Control and Data Acquisition) systems, critical components in automated textile production.

- Data Acquisition and Analysis: Automated systems provide a wealth of data on production efficiency, quality parameters, and machine performance. Analysis of this data helps optimize the processes and minimize waste.

Working with automated systems has significantly increased my understanding of efficient production and has helped to implement strategies for streamlined operations and improved quality. For example, in a previous role, I helped integrate a new automated fabric inspection system which improved quality control and reduced waste by 15%.

Q 26. What are the safety procedures you follow while operating textile machinery?

Safety is paramount when working with textile machinery. My safety procedures are stringent and encompass:

- Lockout/Tagout Procedures: Before any maintenance or repair, machinery must be completely shut down and locked out to prevent accidental starting. This is a non-negotiable practice.

- Personal Protective Equipment (PPE): This includes the appropriate clothing, eye protection, and hearing protection to protect against potential hazards. Specific PPE depends on the tasks being performed.

- Machine Guards: Ensuring all machine guards are in place and functioning correctly prevents accidental contact with moving parts. Regular inspection of guards is crucial.

- Emergency Stop Buttons: Knowing the location and function of emergency stop buttons is essential for all personnel. Regular training reinforces this.

- Regular Safety Training: Consistent training on safe operating procedures and hazard awareness is critical for all employees. This includes refresher training and updates on new safety regulations.

I strictly adhere to all safety protocols and actively promote a safety-conscious work environment. A safe work environment is not just a matter of compliance; it’s a fundamental aspect of ethical and responsible manufacturing.

Q 27. How do you calculate the production efficiency of weaving and knitting processes?

Calculating the production efficiency of weaving and knitting processes involves several key metrics:

- Production Rate: This is usually measured in meters of fabric produced per hour (for weaving) or pieces produced per hour (for knitting). Factors influencing this include machine speed, yarn quality, and machine efficiency.

- Machine Uptime: This represents the percentage of time the machine is actually producing fabric, excluding downtime due to maintenance, repairs, or breakdowns. High uptime is crucial for efficiency.

- Fabric Quality: The percentage of acceptable fabric produced compared to the total production. High-quality output directly impacts efficiency because defective fabric needs to be reworked or discarded.

- Waste Rate: This refers to the percentage of yarn or fabric wasted during the production process. Minimizing waste significantly improves efficiency.

The overall production efficiency can be calculated using various formulas, depending on the specific context. For example, a simplified efficiency calculation could be:

Efficiency (%) = (Production Rate x Machine Uptime x Fabric Quality) / (Nominal Production Rate) * 100where ‘Nominal Production Rate’ is the theoretically maximum production rate of the machine under ideal conditions.

Regular monitoring of these metrics provides insights into areas for improvement, helping to maximize production output while minimizing waste and downtime. This allows for informed decision-making on potential process improvements.

Q 28. Describe your experience with implementing quality improvement initiatives.

Implementing quality improvement initiatives requires a structured approach. My experience has centered around the principles of Lean Manufacturing and Six Sigma methodologies:

- Value Stream Mapping: This technique helps identify areas of waste and inefficiency within the production process. By visually mapping the entire process, bottlenecks and areas for improvement become clearly apparent. I’ve used this to optimize yarn handling and reduce waste in weaving processes.

- 5S Methodology: This focuses on workplace organization: Sort, Set in Order, Shine, Standardize, and Sustain. This improves workflow, reduces errors, and enhances safety. Implementing 5S in a weaving mill significantly improved machine accessibility and reduced downtime.

- Statistical Process Control (SPC): SPC uses statistical methods to monitor and control variations in the production process. This helps identify and address issues before they escalate into major problems. I’ve utilized SPC to minimize fabric defects in both weaving and knitting operations.

- Root Cause Analysis (RCA): When defects or problems arise, RCA is used to identify the underlying causes, not just the symptoms. This is crucial for implementing effective solutions and preventing recurrence. A recent RCA investigation led to the identification and correction of a machine vibration issue that was causing consistent yarn breakage.

Through the application of these methodologies, I’ve consistently achieved improvements in quality, reduced defects, and increased overall production efficiency. I believe that continuous improvement is not just a goal; it’s a fundamental principle of successful manufacturing.

Key Topics to Learn for Weaving and Knitting Technologies Interview

- Yarn Properties and Selection: Understanding fiber types (natural and synthetic), yarn structures (spun, filament), and their impact on fabric properties. Practical application: Choosing the right yarn for a specific fabric and end-use.

- Weaving Principles: Mastering warp and weft systems, different weave structures (plain, twill, satin), and their influence on fabric characteristics (drape, strength, texture). Practical application: Troubleshooting weaving defects and optimizing loom settings.

- Knitting Principles: Understanding knit structures (weft, warp, and double knits), stitch types, and their effect on fabric properties (stretch, stability, drape). Practical application: Designing knitwear patterns and selecting appropriate knitting machines.

- Textile Machinery: Familiarity with different types of weaving and knitting machines (e.g., shuttle looms, air-jet looms, circular knitting machines), their functionalities, and maintenance. Practical application: Operating and troubleshooting machinery in a production environment.

- Fabric Finishing: Understanding various finishing processes (e.g., dyeing, printing, coating) and their impact on fabric hand, durability, and performance. Practical application: Selecting appropriate finishing techniques for different fabrics and end-uses.

- Quality Control and Testing: Knowledge of textile testing methods (e.g., tensile strength, abrasion resistance, colorfastness) and quality control procedures. Practical application: Ensuring consistent product quality and meeting industry standards.

- Computer-Aided Design (CAD) in Textiles: Understanding the role of CAD software in textile design and manufacturing. Practical application: Creating virtual fabric samples and optimizing production processes.

- Sustainability and Eco-Friendly Practices: Awareness of sustainable textile production methods and environmentally friendly materials. Practical application: Incorporating sustainable practices into the design and manufacturing process.

Next Steps

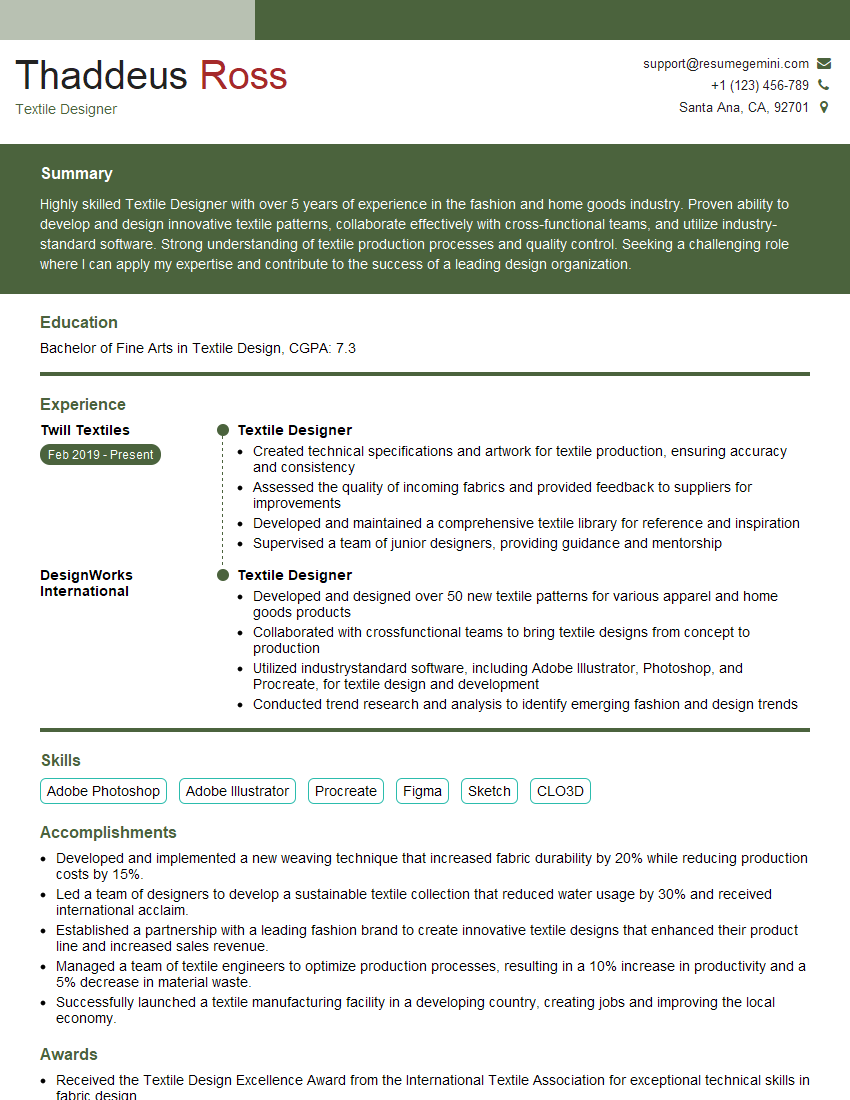

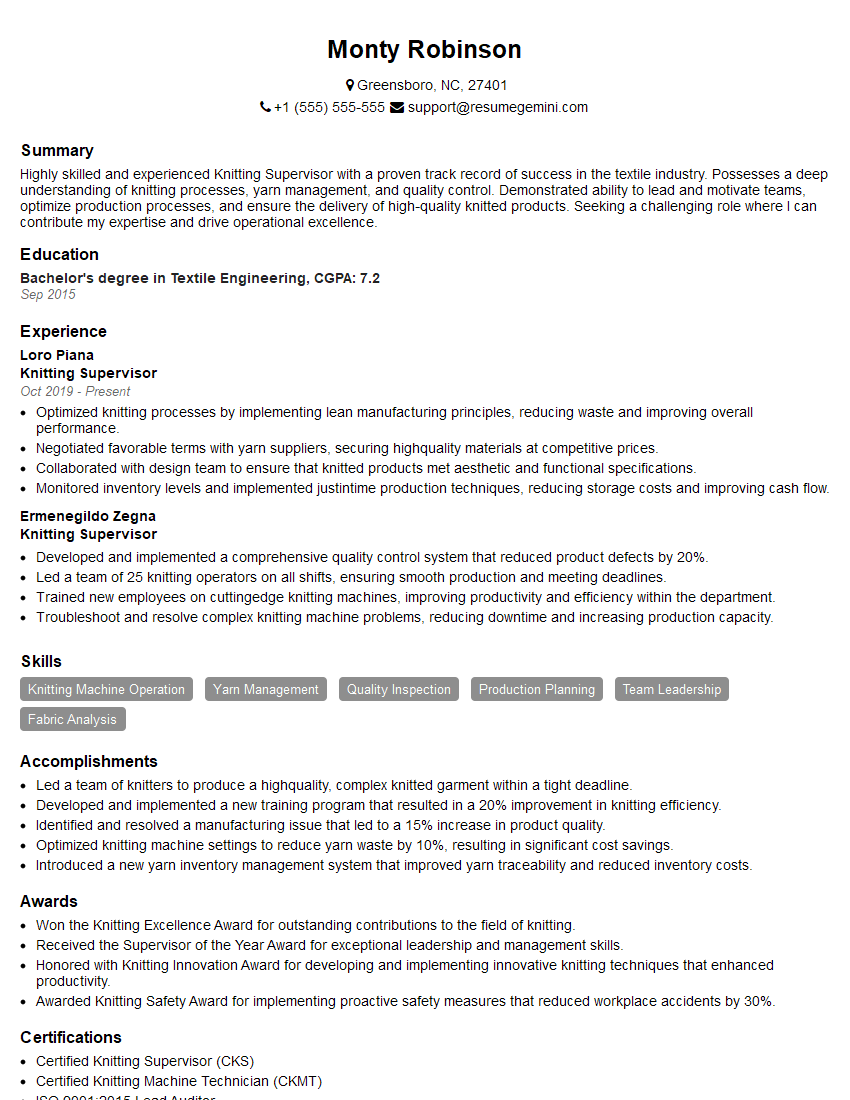

Mastering Weaving and Knitting Technologies opens doors to exciting career opportunities in the textile industry, offering diverse roles in design, manufacturing, quality control, and research and development. To maximize your job prospects, crafting a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and effective resume that highlights your skills and experience. They offer examples of resumes tailored to Weaving and Knitting Technologies to guide you through the process. Invest time in creating a compelling resume – it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good