Cracking a skill-specific interview, like one for Web Press Operations, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Web Press Operations Interview

Q 1. Describe your experience with different types of web presses (e.g., heatset, coldset).

My experience encompasses both heatset and coldset web presses, each with its unique characteristics and applications. Heatset web presses use heat to dry the ink, allowing for higher-quality printing and vibrant colors, often used for magazines and catalogs. I’ve worked extensively with Goss and MAN Roland heatset presses, mastering their intricate controls and maintenance procedures. Coldset presses, on the other hand, use lower temperatures and rely on absorption into the paper, making them ideal for newspapers and high-volume printing where speed is paramount. My experience with coldset presses includes working with Harris and Heidelberg models, where I honed my skills in managing high-speed production and minimizing waste. I’m comfortable troubleshooting issues specific to each technology, including ink drying problems in heatset and perfecting the paper moisture balance in coldset operations.

For example, in one instance, I successfully resolved a recurring web break issue on a Goss heatset press by identifying and replacing a worn dryer section roller. This required a detailed understanding of the press’s mechanical systems and the ability to isolate the problem through systematic diagnostics.

Q 2. Explain the process of makeready on a web press.

Makeready, the crucial setup phase before a print run, is a meticulous process. It involves several key steps: first, installing the printing plates onto the press cylinders. This is done with precision, ensuring accurate plate positioning and avoiding damage. Next, the ink and dampening systems are adjusted. This includes setting ink keys, determining the correct ink viscosity, and calibrating the fountain rollers to achieve the desired ink-water balance. Then, the paper path is carefully checked and adjusted, optimizing tension and ensuring smooth feed through the press. Finally, a series of test prints are run, used to fine-tune color registration, ink density, and overall print quality. We adjust settings, such as cut-off, impression, and side lay, based on the results of the test prints to produce a consistent and high-quality product. This iterative process requires a keen eye for detail and a solid understanding of the press’s functionality.

For example, when setting up a four-color job, I might use a color bar to fine-tune color registration, gradually adjusting the cylinder position until all four colors perfectly align.

Q 3. How do you troubleshoot common web press issues (e.g., web breaks, register problems)?

Troubleshooting web press issues demands a systematic approach. Web breaks, a common problem, can stem from various factors – paper wrinkles, improper tension, or even a faulty splice. My troubleshooting methodology involves systematically checking each component along the paper path, from the unwind reel to the delivery system. I inspect the paper for flaws, adjust tension controls, and examine the splice mechanism. Register problems, where colors misalign, often require adjustments to the cylinder positioning, ink keys, or even plate mounting. I use precision measuring tools and test prints to identify the source of misregistration and make the necessary corrections. This process requires a deep understanding of the press mechanics and the ability to interpret print results effectively.

For example, on a recent job, recurrent web breaks were traced to a poorly aligned web guide. A simple adjustment corrected the problem immediately, highlighting the importance of thorough inspection and attention to detail.

Q 4. What are the key quality control checks you perform during a press run?

Quality control is paramount throughout the press run. Key checks include verifying color accuracy against proof copies using spectrophotometer readings, ensuring consistent ink density across the entire print run, monitoring print register at regular intervals, inspecting for defects such as smudging, hickeys or print quality issues. Furthermore, I inspect paper for flaws and maintain consistent web tension. We also periodically check print dimensions for accuracy using standardized measuring tools. Documentation is crucial: I maintain detailed records of these checks, along with any adjustments made throughout the run, to ensure traceability and allow for continuous improvement. This meticulous approach ensures the final product meets the highest quality standards.

For instance, if ink density starts to fluctuate, I would investigate ink viscosity, fountain roller settings, and even potential ink contamination. Addressing such issues promptly prevents printing defects and ensures consistency.

Q 5. How familiar are you with different ink types and their application?

My experience includes working with a range of ink types, including UV, vegetable-based, and conventional oil-based inks. Each type demands a specific approach to application and handling. UV inks require specialized UV curing systems and necessitate careful consideration of ink viscosity and lamp intensity. Vegetable-based inks, environmentally friendly, sometimes need specific adjustments to achieve desired results. I understand the properties of each ink type and their effect on the press, including drying times and potential interactions with paper. I’m skilled in adjusting ink settings to achieve desired color saturation and density. Furthermore, I can effectively manage ink changes during a run, minimizing waste and maintaining color consistency throughout. Proper ink management is critical for both print quality and cost-effectiveness.

For instance, when switching from one ink color to another, I follow a standardized cleaning procedure to prevent contamination and maintain print quality.

Q 6. Describe your experience with color management and achieving accurate color reproduction.

Accurate color reproduction is crucial, and I’m proficient in color management techniques. This involves working closely with prepress to establish a robust color profile, utilizing spectrophotometers to measure color accurately, and employing software such as GMG ColorProof to ensure color consistency. I understand the importance of color calibration, maintaining consistent ink-water balance, and adjusting dot gain compensation to achieve the targeted colors. Furthermore, I have experience in troubleshooting color discrepancies, investigating potential causes such as ink variations, substrate differences, or improper color profiles. Addressing these issues requires a combination of technical expertise, problem-solving skills, and close collaboration with prepress and quality control personnel.

In a recent project involving a complex color design, I worked closely with the prepress team to fine-tune the color profiles, leading to accurate and consistent color reproduction throughout the entire print run.

Q 7. How do you maintain press safety standards and comply with regulations?

Press safety is my top priority. I adhere strictly to all relevant safety regulations, ensuring regular machine inspections, performing all maintenance according to manufacturer guidelines and wearing appropriate Personal Protective Equipment (PPE). Furthermore, I maintain a clean and organized work environment to minimize hazards. I participate in regular safety training and am knowledgeable about lockout/tagout procedures, emergency shutdown protocols, and fire safety measures. My emphasis on safe working practices extends to the entire team, promoting a culture of safety awareness and proactive hazard mitigation. I maintain detailed safety logs and actively contribute to the identification and elimination of potential risks.

For example, before performing any maintenance task on the press, I always follow the lockout/tagout procedure to prevent accidental injury.

Q 8. Explain your experience with pre-press procedures and their impact on press operations.

Pre-press procedures are the crucial steps taken before the actual printing process begins on the web press. They directly impact the quality, efficiency, and overall success of the press run. Think of it as meticulously preparing a recipe before starting to cook – any mistakes at this stage will affect the final outcome. My experience encompasses all aspects, from file preparation and trapping to proofing and platemaking.

File Preparation: This involves checking the artwork for color accuracy, resolution, and proper formatting (e.g., bleeds, margins). I’ve worked with various software like Adobe InDesign, Illustrator, and Photoshop, ensuring files are optimized for the press’s capabilities. For example, a low-resolution image will result in a blurry print.

Trapping: This crucial step prevents gaps between colors where they meet. I have experience with various trapping techniques, including spread and choke, tailored to the specific press and paper type. Improper trapping leads to unsightly gaps in the final product.

Proofing: This involves creating color-accurate proofs to ensure the final printed product matches the client’s expectations. I’ve utilized both soft and hard proofs, including color calibrated monitors and contract proofs, identifying discrepancies before going to press and saving time and resources.

Platemaking: I am proficient in creating and managing printing plates (CTP – Computer-to-Plate), ensuring accurate registration and consistent ink density. A poorly made plate can lead to misregistration or faded colors.

Essentially, a robust pre-press process minimizes errors on the press, reducing waste, downtime, and ultimately saving money while enhancing print quality.

Q 9. How do you manage waste and optimize efficiency during a press run?

Waste management and efficiency optimization are paramount in web press operations. They directly affect profitability and environmental responsibility. My approach is multifaceted, combining proactive strategies with real-time adjustments during the press run.

Minimizing Makeready Waste: I focus on reducing waste generated during the setup phase (makeready) by using advanced techniques like automated plate changing and precise ink and water settings. Experience with various web press systems has enabled me to refine makeready times significantly.

Monitoring and Adjusting: During the press run, I continuously monitor waste levels, ink consumption, and overall press performance using the press’s control system. Identifying and correcting issues early on is crucial in reducing waste. For instance, I might adjust the paper feed to minimize paper jams and waste.

Waste Recycling: I ensure all generated waste, including paper scraps and ink cartridges, is handled responsibly, following company and industry best practices for recycling and proper disposal. This minimizes our environmental impact.

Process Optimization: I actively participate in implementing lean manufacturing principles to streamline the workflow and identify areas for improvement. This includes analyzing production data to identify bottlenecks and implement corrective actions.

For instance, in a recent project, by optimizing paper feed settings and fine-tuning ink adjustments, we reduced waste by 15% during the press run, translating to significant cost savings.

Q 10. What is your experience with different paper types and their handling on a web press?

Experience with diverse paper types is critical for successful web press operation. Different papers have unique characteristics impacting printing quality, press speed, and overall efficiency. My expertise spans a wide range of paper weights, finishes, and compositions.

Paper Properties: I understand the impact of paper properties, such as grammage (weight), moisture content, and surface finish (coated, uncoated), on print quality. For example, a heavier paper requires adjustments to the press’s feeder and rollers. Coated papers demand different ink settings compared to uncoated ones.

Paper Handling: I’m proficient in setting up and adjusting the web press for various paper types, ensuring smooth paper flow and minimal jams. This involves adjusting parameters like web tension, paper guides, and roller pressure.

Problem Solving: I’ve effectively tackled challenges related to paper breaks, wrinkles, and misfeeds, identifying root causes and implementing corrective actions. Understanding the relationship between paper properties and press settings is key here.

I’ve worked with everything from lightweight newsprint to heavy-weight coated stock, adapting press settings for optimal results in each case. For example, I resolved a persistent paper jam issue on a high-speed press by carefully analyzing the paper’s moisture content and adjusting the rollers accordingly.

Q 11. Describe your experience with press automation and control systems.

Automation and control systems are essential for modern web press operations. They enhance efficiency, consistency, and overall productivity. My experience encompasses various automation levels, from basic to fully integrated systems.

Press Control Systems: I am proficient in operating and troubleshooting various press control systems, including those with sophisticated features like automatic register control, color control, and waste reduction algorithms. I have experience with both the older analog systems and the newer digital ones.

Automation Features: I understand and utilize automation features such as automatic plate changing, ink and water control, and automated cut-off adjustments. This experience minimizes manual intervention and increases efficiency.

Data Analysis: I utilize the data collected by the press control system for monitoring and optimizing performance, identifying potential issues, and ensuring quality control. For example, I use data to optimize ink and water settings to minimize waste and enhance consistency.

I’ve worked on presses with varying degrees of automation, from older presses requiring manual adjustments to highly automated systems that manage ink and register automatically. This diverse experience allows me to adapt to various press technologies.

Q 12. How do you handle press malfunctions and downtime?

Press malfunctions and downtime are inevitable. A methodical approach is crucial for minimizing their impact. My experience involves proactive prevention, prompt diagnosis, and efficient repair.

Troubleshooting: I possess a strong understanding of web press mechanics and electronics, enabling me to quickly diagnose and resolve a wide range of malfunctions. This includes identifying the cause of paper jams, ink problems, and mechanical failures.

Preventive Maintenance: A robust preventative maintenance program drastically reduces the likelihood of unexpected downtime. I follow strict maintenance schedules and perform regular inspections.

Prioritization: I prioritize repairs based on their impact on production. Critical issues are addressed immediately, while less urgent issues can be scheduled for later.

Communication: Effective communication with maintenance personnel and management is crucial during downtime, keeping everyone informed and working collaboratively to resolve the issue quickly.

For instance, I once successfully diagnosed and repaired a critical mechanical failure within an hour, minimizing downtime and preventing significant production losses by identifying a loose belt through systematic checks, rather than a more time-consuming approach.

Q 13. What is your experience with preventative maintenance procedures for web presses?

Preventative maintenance (PM) is the cornerstone of efficient and reliable web press operation. It involves scheduled inspections, cleaning, and repairs to prevent unexpected breakdowns and maximize uptime. My experience encompasses various PM procedures tailored to specific press models and operational conditions.

Scheduled Maintenance: I meticulously follow manufacturer-recommended PM schedules, ensuring timely lubrication, cleaning, and inspection of all critical components. This includes regular checks of rollers, gears, bearings, and other moving parts.

Inspection and Reporting: I perform thorough inspections, documenting findings and reporting any potential issues to the maintenance team. This proactive approach prevents small problems from escalating into major breakdowns.

Record Keeping: Maintaining accurate and detailed records of all PM activities is crucial for tracking maintenance history and identifying trends. This data helps in optimizing the PM schedule and predicting potential failures.

Continuous Improvement: I actively participate in evaluating and improving the PM program based on performance data and industry best practices. This ensures the program remains effective and adapted to evolving needs.

Through diligent PM, we reduced unscheduled downtime by 20% in the last year, improving productivity and reducing repair costs.

Q 14. Describe your experience working with different types of printing plates.

My experience includes working with a variety of printing plates, each with its unique properties and applications. The choice of plate type depends on factors such as the press type, printing method, and desired print quality.

Conventional Plates: I have experience with traditional metal plates, including those made using photopolymer and direct imaging techniques. These require careful handling and processing.

CTP Plates: I am proficient in using Computer-to-Plate (CTP) technology, where images are directly imaged onto plates using lasers. This eliminates the need for film and reduces processing time.

Plate Types: I understand the differences between various plate types, including their image resolution, durability, and ink acceptance characteristics. For example, thermal plates are suitable for shorter runs, while UV plates offer better durability for longer runs.

Plate Handling: I follow proper procedures for handling plates to prevent damage and ensure proper mounting on the press. This involves careful storage and cleaning techniques.

For example, recently, switching from conventional plates to a more durable CTP plate resulted in a significant reduction in plate damage and waste, boosting efficiency and lowering costs.

Q 15. How do you calculate press speeds and production estimates?

Calculating press speeds and production estimates involves several factors. It’s not just about the press’s maximum speed, but also the job’s specifics. Think of it like baking a cake – you need the right ingredients (job specs) and the right oven (press) to get the desired result (on-time delivery).

- Press Speed (impressions per hour or iph): This is the maximum number of sheets the press can print per hour. This is usually provided by the manufacturer or determined through testing.

- Number of colors: More colors mean more passes through the press, increasing the overall time. A four-color job will take longer than a one-color job.

- Sheet size: Larger sheets take longer to print, even at the same iph.

- Make-ready time: This is the time needed to set up the press for the job, including plate changes, ink adjustments, and testing. This can range from 30 minutes to several hours depending on the complexity of the job.

- Number of sheets per job: The total quantity needed is crucial.

- Downtime: Unexpected issues like jams or maintenance will impact overall production time. This often needs to be factored in as a percentage of total run time.

Example Calculation: Let’s say we have a job of 10,000 sheets, 4-color process printing on a press with a speed of 15,000 iph, using a standard sheet size. Make-ready time is estimated at 1 hour. Ignoring downtime for this simplified example:

Total printing time = (10,000 sheets / 15,000 iph) * 4 colors = 2.67 hours

Total estimated production time = 2.67 hours + 1 hour (make-ready) = 3.67 hours

In reality, you’d add a buffer for downtime and other unforeseen circumstances.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your understanding of different finishing processes (e.g., folding, cutting, binding).

Finishing processes are crucial for the final presentation and usability of printed materials. They transform a stack of printed sheets into a finished product. Think of it like adding the finishing touches to a beautifully baked cake; the presentation matters just as much as the taste!

- Folding: This involves using machines like folder-inserters to fold sheets into various formats like letter folds, Z-folds, or gate folds, depending on the design.

- Cutting: This is done using guillotines or other cutting equipment to trim sheets to the precise dimensions, ensuring clean edges and consistent sizing.

- Binding: This is how the printed sheets are assembled. Common methods include:

- Saddle Stitch: Sheets are folded and stapled through the center fold.

- Perfect Binding: Pages are glued together along the spine, creating a smooth edge.

- Wire-O Binding: Double-loop wire is used to create a durable, lay-flat binding.

- Case Binding: Used for hardcover books, involving a cover that is adhered to the text block.

The choice of finishing process depends heavily on the project’s requirements, the type of document (brochure, booklet, book), and the desired outcome.

Q 17. How do you interpret and follow press instructions and specifications?

Interpreting and following press instructions and specifications is fundamental to successful printing. Accuracy is paramount; even minor mistakes can lead to significant waste and delays. It’s like following a precise recipe – every step matters.

Press instructions usually come in the form of job tickets, which contain details such as:

- Job Name & Number: Unique identifier for tracking.

- Number of copies/sheets: Total quantity to be printed.

- Paper type and size: Crucial for press setup and ink selection.

- Ink specifications: Colors, percentages, and any special color requirements (Pantones).

- Finishing instructions: Folding, cutting, and binding specifics.

- Imposition scheme: How the pages are arranged on the sheet for efficient printing and folding.

I meticulously review these instructions, confirming all details with pre-press before starting the run. Any discrepancies are immediately flagged and corrected to prevent errors. I regularly check the printed output against the proofs to ensure color accuracy and registration (proper alignment of colors). Detailed logs are kept throughout the process for quality control and troubleshooting.

Q 18. Describe your experience working in a team environment within a pressroom.

My experience in a pressroom is all about teamwork. It’s a fast-paced, high-pressure environment where everyone’s role is interconnected. We’re like a well-oiled machine, each part essential to the smooth functioning of the whole.

I’ve worked closely with pre-press operators, ensuring smooth handoffs of jobs and resolving any pre-press issues that might impact the printing process. I collaborate with finishing personnel to ensure a seamless transition from printing to binding and cutting. Effective communication and problem-solving are critical, and I’ve often been involved in mentoring junior press operators, sharing my knowledge and experience to support team growth.

In one instance, we faced a significant deadline for a large-scale brochure printing job. Through proactive communication and collaboration, the pre-press, press, and finishing teams worked seamlessly to deliver the project ahead of schedule. This highlighted the importance of teamwork and effective communication in our dynamic environment.

Q 19. How do you handle pressure and meet tight deadlines?

The pressroom is a high-pressure environment, especially when facing tight deadlines. My approach is to remain calm and organized. Think of it like navigating a storm – you need a steady hand and a clear plan.

I prioritize tasks based on urgency and importance. I effectively utilize checklists to ensure that all necessary steps are followed. Proactive communication with my team and supervisors keeps everyone informed of the progress and any potential issues. Problem-solving is an integral part of my approach; I analyze situations quickly and efficiently to determine the best course of action. If unexpected issues arise, I leverage my experience and resources to find solutions and minimize delays.

For example, during a rush job, we encountered a paper jam that threatened to delay the whole project. By quickly diagnosing the problem and working collaboratively with my team, we resolved it within minutes, avoiding any significant disruption to the schedule.

Q 20. What is your familiarity with MIS (Management Information Systems) in a print environment?

Management Information Systems (MIS) are crucial in modern print environments. They provide the backbone for efficient job tracking, cost analysis, and overall workflow management. It’s like having a central nervous system for the entire print operation.

My familiarity with MIS includes using software to track job progress, from order entry to completion. This includes monitoring production metrics such as press speeds, downtime, and material usage. I’m proficient in generating reports from MIS data, providing valuable insights into production efficiency and identifying areas for improvement. I understand the importance of accurate data entry for effective cost accounting and inventory management. This allows for informed decision-making regarding pricing, resource allocation, and overall business strategy.

Q 21. Describe your experience with different types of print finishing equipment.

I have extensive experience with various types of print finishing equipment. This includes different types of folders (e.g., single, double, and multi-fold folders), cutters (e.g., guillotines, rotary cutters), and binding equipment (e.g., saddle stitchers, perfect binders, wire-O machines). I am familiar with both manual and automated systems, understanding the advantages and limitations of each. My experience extends to troubleshooting and basic maintenance of these machines, ensuring optimal performance and minimizing downtime.

For example, I’m experienced with Heidelberg and Muller Martini finishing equipment, known for their reliability and efficiency. I’m adept at setting up and operating these machines, ensuring accurate and efficient finishing for a wide range of print jobs. My knowledge encompasses the proper handling and maintenance of each system to ensure optimal performance and longevity.

Q 22. Explain your understanding of ink density and its relationship to print quality.

Ink density, in web press operations, refers to the concentration of ink on the printed substrate. It’s crucial for achieving the desired color and overall print quality. Think of it like painting a wall – too little paint (low ink density), and the color is weak and faded; too much paint (high ink density), and it’s muddy and uneven.

In printing, we measure ink density using a densitometer. This device measures the amount of light reflected by the printed area, giving us a numerical value representing the ink’s opacity. Target density values are determined by the print job’s specifications and the type of ink and paper being used. Deviations from these targets affect the vibrancy, contrast, and overall visual appeal of the printed product. For instance, if a logo needs to be a specific shade of red, precise ink density control ensures its consistent reproduction throughout the print run. Low ink density will result in a pale, weak red, while excessive density can make it appear dark and muddy, potentially compromising the logo’s clarity and brand recognition.

Q 23. How do you manage ink and paper inventory in a pressroom?

Managing ink and paper inventory in a pressroom requires a systematic approach involving careful planning, precise tracking, and proactive monitoring. We use a combination of software and manual checks. Our inventory management system tracks ink usage, predicts future needs based on past print jobs, and generates automated alerts when stock levels reach a pre-defined minimum.

For paper, we work closely with our suppliers, negotiating favorable terms and ensuring timely deliveries to avoid production delays. We maintain detailed records of paper specifications (grade, weight, size) to ensure compatibility with various print jobs. Regular stock checks are conducted to verify inventory against the system’s data and identify any discrepancies. Proper storage conditions are vital to maintain paper quality; this includes a climate-controlled environment to avoid moisture damage and protect against excessive humidity. We also regularly audit our inventory to identify any obsolete stock that needs to be appropriately managed.

Q 24. What are your preferred methods for documenting press setups and troubleshooting processes?

Detailed documentation is paramount in press operations. We utilize a combination of digital and physical methods. For press setups, we employ a digital press setup sheet, which includes specifications like ink settings, paper type, speed, and other relevant parameters for the job. This sheet is then updated with any adjustments made during the run. We maintain a secure digital archive of these sheets, accessible to all relevant personnel. Additionally, we use images or videos of the setup, capturing crucial settings like roller adjustments, and maintaining an image log on a network drive.

For troubleshooting, we maintain a detailed logbook documenting problems encountered, the steps taken to resolve them, and the outcome. This logbook also includes images or videos of problem areas, assisting in efficient diagnostics in case of recurrence. The use of standardized codes for faults ensures consistency in reporting across the team. For example, a code like `C-102` might represent a specific type of color register issue, allowing for quicker identification and resolution of the problem. A combination of these meticulous procedures helps in both preventing future issues and streamlining future troubleshooting.

Q 25. How do you ensure consistent print quality across large print runs?

Maintaining consistent print quality throughout extensive runs demands meticulous attention to detail and a multi-pronged approach. We start with thorough pre-press checks, ensuring the files are optimized for print and the color profiles are accurately set. Then, we carefully monitor the press during the run, paying close attention to parameters such as ink density, register, and moisture level. Regular color checks with a densitometer are carried out, compared to the pre-press targets, and adjustments made as needed.

Automated systems play a key role. Modern web presses have sophisticated sensors that constantly monitor these parameters and automatically make minor adjustments as needed, minimizing fluctuations in print quality. We also conduct regular maintenance on the press to prevent mechanical issues that might compromise consistency. Finally, regular operator training and adherence to standard operating procedures ensure the team is well-equipped to handle any challenges and maintain the high standards required for consistent print quality.

Q 26. Describe your experience with different types of web break detection systems.

My experience encompasses various web break detection systems, ranging from older, mechanical systems to the latest sophisticated sensor-based technologies. Older systems often relied on simple tension sensors and physical break detectors, which while reliable, sometimes caused delays due to their reaction time.

Modern systems are far more advanced. Many incorporate ultrasonic, optical, or capacitive sensors that detect web breaks almost instantly, minimizing downtime. Some even predict potential breaks before they occur, enabling proactive adjustments. For example, I’ve worked with systems that use non-contact sensors which detect changes in web tension and promptly halt the press before a break occurs, preventing waste and increasing efficiency. The choice of system depends on the type of press, the application, and the desired level of automation, but all are geared towards maximizing press uptime and minimizing waste.

Q 27. How familiar are you with the various components of a web press (e.g., rollers, dampening system)?

I possess extensive knowledge of web press components. Understanding these is critical for effective troubleshooting and efficient press operation. The roller system, including impression cylinders, chill rollers, and inking rollers, is fundamental. Proper roller setting and maintenance is crucial for consistent ink transfer and print quality. The dampening system, which controls the moisture level on the paper, significantly influences ink absorption and color reproduction. I am well-versed in different dampening systems, including conventional, alcohol-based, and water-based systems and their respective maintenance requirements.

Beyond rollers and the dampening system, I understand the function and interaction of other critical components like the feed system (managing paper flow), the impression cylinder (controlling the pressure between the plate and paper), the dryer system (drying the ink), and the delivery system (stacking the finished product). I also have familiarity with the complex control systems used to manage the precise and coordinated movements of all these components.

Q 28. Explain your process for verifying the accuracy of printed materials before delivery.

Verifying print accuracy before delivery is a rigorous multi-step process. It begins with a thorough visual inspection of the printed sheets, checking for defects like smears, misregisters, and color inconsistencies. We then use a densitometer to measure the ink density and compare it to the target values specified in the job ticket. We perform a precise register check on crucial elements like text and images to ensure perfect alignment. For critical jobs, we use a 100% inspection, meticulously checking every sheet for any imperfections.

Beyond visual and instrumental checks, we also perform a thorough quality control check using a standardized checklist. This checklist includes checks for print quality, dimensional accuracy, binding and finishing quality (if applicable), and adherence to the job specifications. Finally, we pull a selection of printed pieces and assemble a sample for client approval before the final delivery. This ensures client satisfaction and avoids costly reprints due to unforeseen issues, ensuring quality and accuracy throughout the entire process.

Key Topics to Learn for Your Web Press Operations Interview

- Understanding the Web Press Workflow: From pre-press preparation (file handling, imposition) to printing, finishing, and quality control. Consider the entire process and potential bottlenecks.

- Color Management and Calibration: Learn about color profiles (e.g., ICC profiles), color space conversions, and the practical application of maintaining consistent color throughout the printing process. Be prepared to discuss troubleshooting color discrepancies.

- Print Production Technologies: Familiarize yourself with different types of web presses (e.g., heatset, coldset), their capabilities, and limitations. Understand the differences in printing techniques and their suitability for various substrates.

- Quality Control and Troubleshooting: Discuss methods for identifying and resolving common printing issues (e.g., misregistration, color variations, ink problems). Show your understanding of quality metrics and how to maintain them.

- Press Maintenance and Safety: Demonstrate awareness of routine press maintenance procedures and safety protocols. This shows responsibility and a commitment to operational efficiency.

- Automation and Workflow Optimization: Discuss your experience with or knowledge of automated processes in web press operations and how these contribute to increased efficiency and reduced waste.

- Industry Best Practices and Standards: Research industry standards and best practices related to web press operations, demonstrating your commitment to professional excellence.

- Environmental Considerations: Discuss sustainable practices within web press operations, including waste reduction and responsible ink usage.

Next Steps

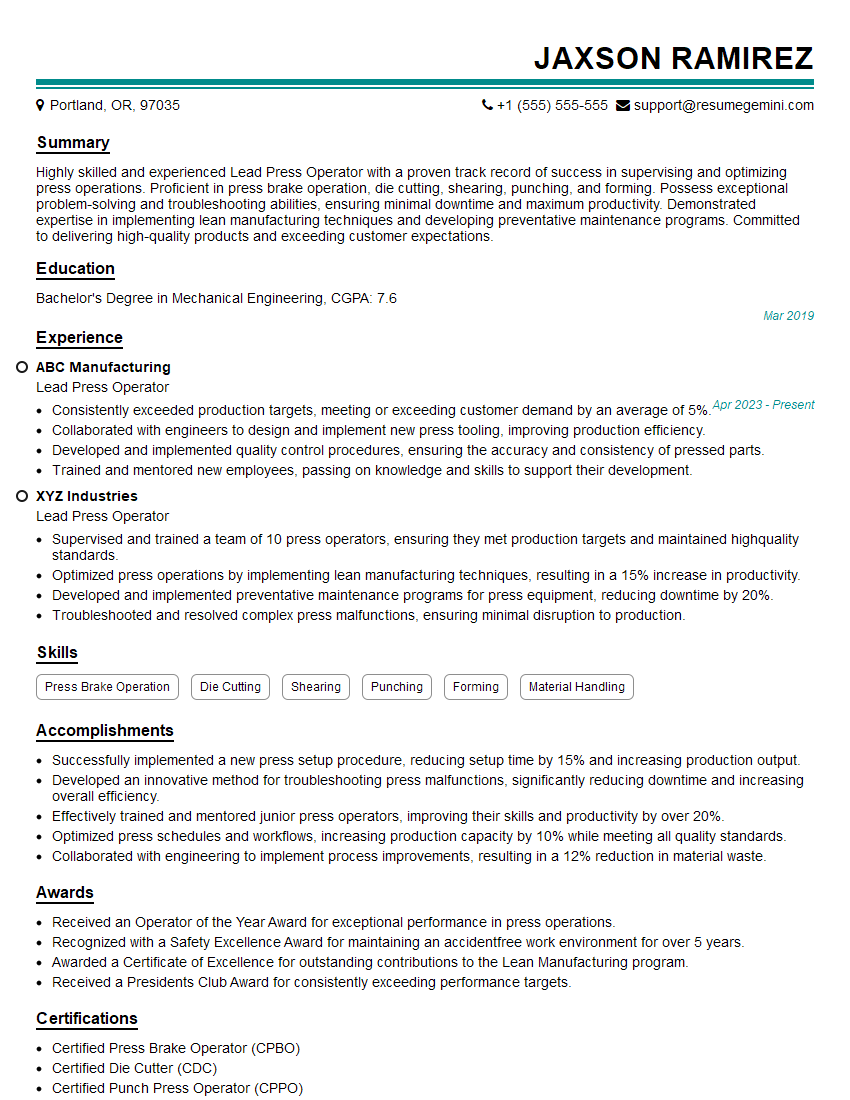

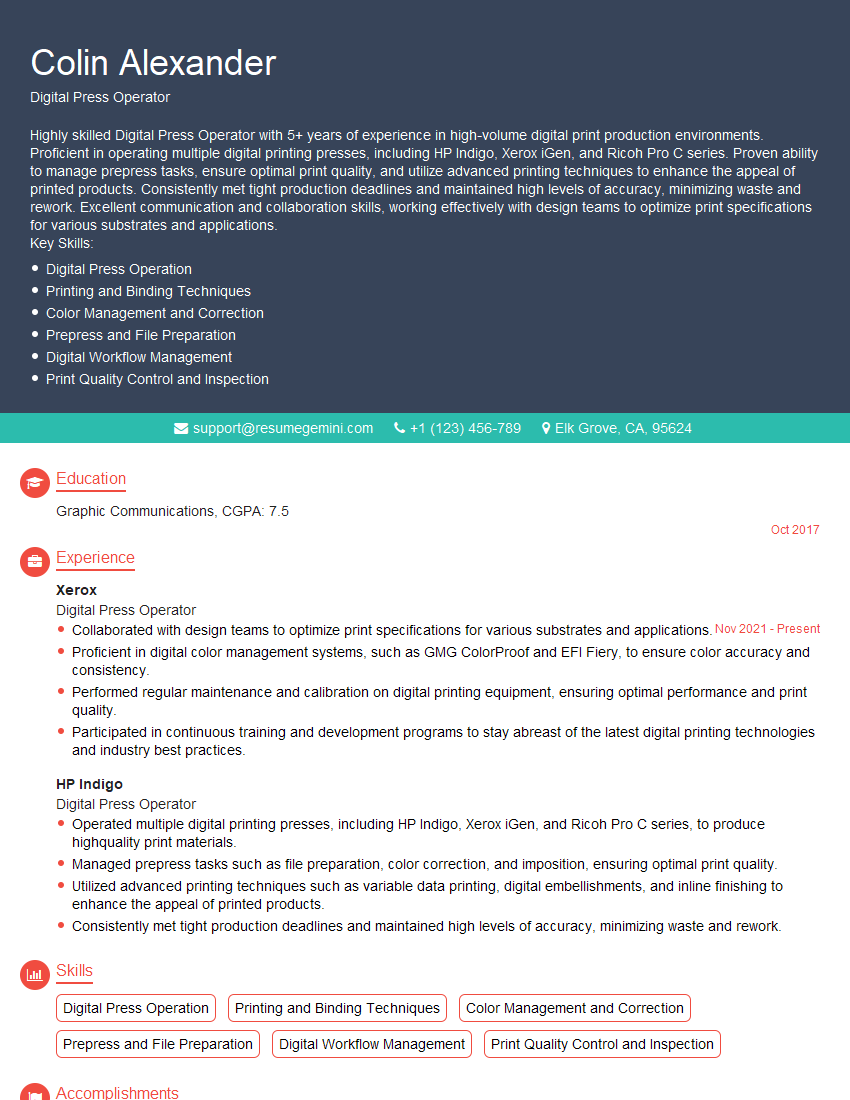

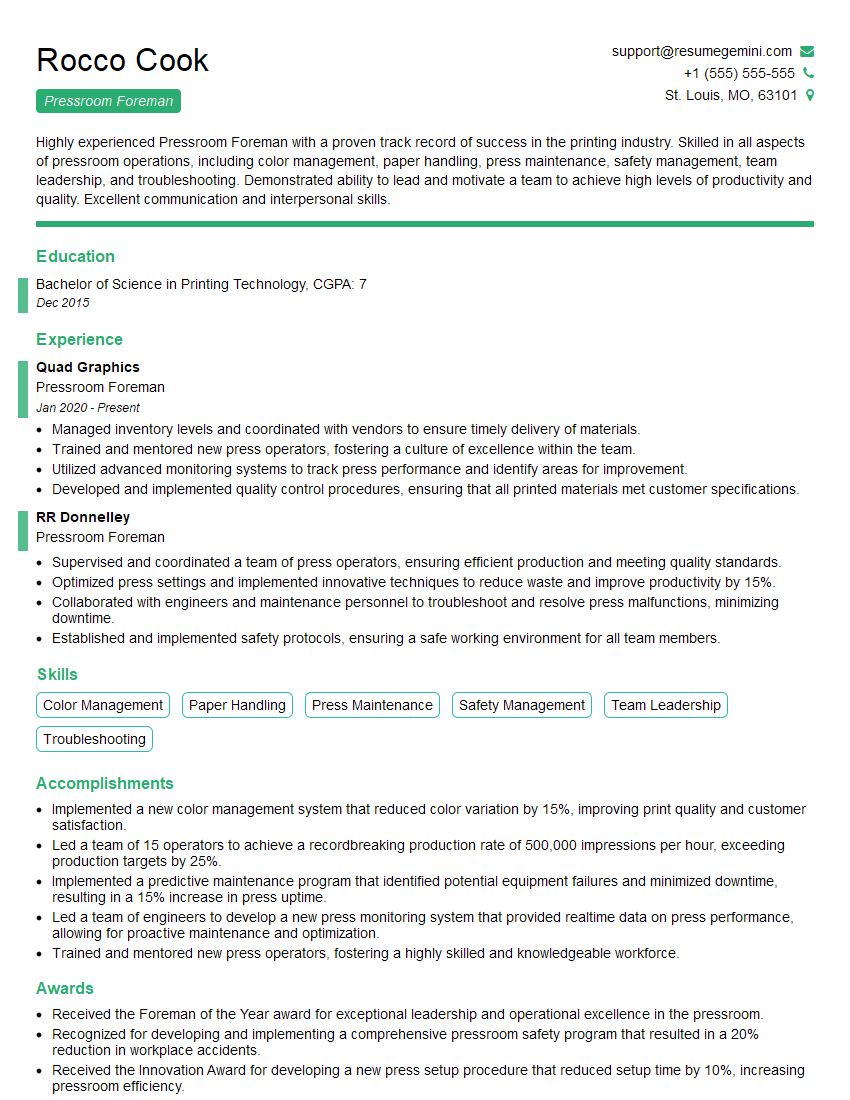

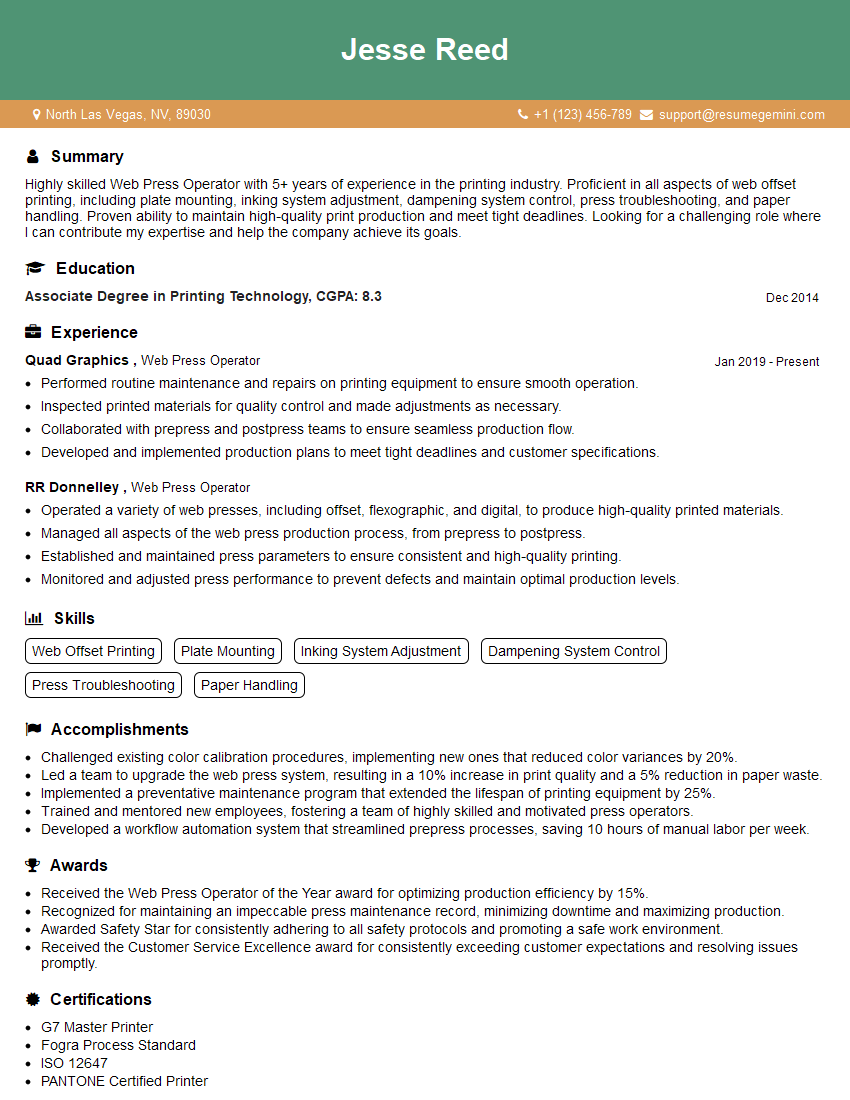

Mastering Web Press Operations opens doors to a rewarding career with opportunities for growth and specialization. A strong resume is crucial for showcasing your skills and experience to potential employers. Creating an ATS-friendly resume will significantly increase your chances of getting noticed. We recommend using ResumeGemini, a trusted resource for building professional resumes. ResumeGemini provides examples of resumes tailored to Web Press Operations to help you get started. This will allow you to present your qualifications effectively and increase your chances of landing your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good