Cracking a skill-specific interview, like one for Wildland Firefighting Equipment, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Wildland Firefighting Equipment Interview

Q 1. Describe the different types of pumps used in wildland firefighting.

Wildland firefighting relies on various pumps, each suited to different needs. The most common are positive displacement pumps and centrifugal pumps.

Positive Displacement Pumps: These pumps move a fixed volume of water with each stroke. Think of them like a piston pushing water. They excel at handling high pressures and thick slurries, often used in portable pumps for initial attack or in larger engines for supplying water to longer hoses. Examples include piston pumps and diaphragm pumps. Diaphragm pumps are particularly useful because they are less prone to damage from debris.

Centrifugal Pumps: These pumps use spinning impellers to create a centrifugal force, pushing water outwards. They are generally better suited for high-volume, lower-pressure applications. You’ll often find these as the main pumps in larger water tenders or stationary pump systems at water sources. Their efficiency drops significantly if they try to pump against too much resistance, so proper hose layout is crucial.

Choosing the right pump depends on the water source, the distance water needs to travel, and the required pressure. A small, positive displacement pump might be perfect for a remote handline, while a powerful centrifugal pump is essential for a large-scale firefight.

Q 2. Explain the maintenance schedule for a wildfire engine.

A wildfire engine’s maintenance is crucial for safety and operational readiness. It involves a multi-faceted approach, including daily, weekly, monthly, and annual checks.

Daily: Check fluid levels (water, oil, coolant), tire pressure, hose connections, and the pump’s operation. Ensure all lights and warning devices are functional. This is a quick visual inspection, aiming to catch minor issues before they escalate.

Weekly: More thorough checks include inspecting the engine compartment for leaks, cleaning debris, and lubricating moving parts as specified in the engine’s manual. This is where you’d address any minor issues found during daily checks.

Monthly: Perform a more comprehensive inspection of the entire engine, checking the battery, belts, hoses for wear, and the functionality of all equipment, such as the communication system and the pump priming system.

Annually: This requires professional servicing. It includes a complete engine overhaul, replacing fluids, inspecting and replacing worn parts, and testing all safety systems. This is essential for ensuring the engine is in top condition for the next fire season.

Proper documentation of all maintenance is essential for tracking repairs, ensuring compliance with regulations, and providing a clear record for future maintenance needs. Think of it as a medical record for your engine – vital for its long-term health.

Q 3. What are the safety procedures for operating a chainsaw in wildland firefighting?

Chainsaw safety in wildland firefighting is paramount. It’s a dangerous tool, but with proper procedures, risks can be significantly reduced.

Pre-use Inspection: Always inspect the chainsaw before use, ensuring the chain is sharp, properly tensioned, and the safety features (chain brake, etc.) are functional. A dull chain increases the risk of kickback.

Personal Protective Equipment (PPE): This is non-negotiable. Always wear appropriate PPE, including chaps, helmet with face shield, gloves, and hearing protection. Chaps are designed to protect your legs from a potentially deadly kickback.

Proper Technique: Use the correct felling techniques, taking into account tree lean, wind direction, and potential hazards. Never cut above shoulder height unless using specialized equipment and techniques. Proper technique minimizes the risk of kickback and injury.

Environmental Awareness: Be acutely aware of your surroundings. Look for potential hazards like unstable terrain, other firefighters, or nearby structures that could be damaged by falling trees.

Refueling Safety: Refuel the chainsaw in a safe location, away from heat sources and other potential ignition hazards. Never refuel a hot chainsaw.

Emergency Procedures: Have a plan for emergencies. Know where the nearest medical facilities are located and have clear communication protocols with your team.

Regular training and practice are key to developing safe and efficient chainsaw operation techniques. A well-trained firefighter can confidently and safely use this important tool.

Q 4. How do you identify and address common problems with water pumps?

Troubleshooting water pumps involves systematic checks. Let’s explore some common problems and solutions.

No Water Flow: Check the water source – is there enough water? Are there any obstructions in the intake line (leaves, debris)? Is the pump primed correctly? If using a positive displacement pump, ensure the valve is open and the pump is operating correctly. Often a simple visual inspection reveals the issue.

Low Water Pressure: A clogged strainer or suction line can restrict water flow. Examine the hose connections for leaks or kinks. A partially clogged impeller in a centrifugal pump could also be the culprit. Cleaning or replacing the filter/strainer usually resolves this. Kinks must be carefully removed.

Pump Overheating: This suggests insufficient lubrication or a problem with the pump’s cooling system. Check oil levels and ensure that the pump’s cooling vents are not blocked. A malfunctioning cooling system should be addressed by a mechanic.

Pump Cavitation: This happens when there’s a partial vacuum in the pump, leading to reduced performance and damage. This often indicates a problem with suction – check for leaks in the intake line and ensure sufficient water supply. Repairing leaks and ensuring a positive water source will eliminate this.

Addressing these issues requires careful observation and understanding of the pump’s mechanism. If the problem persists after basic troubleshooting, professional help is necessary.

Q 5. Describe the proper use and maintenance of a fire shelter.

A fire shelter is a personal protective device providing last-resort protection from extreme heat and flames. Proper use and maintenance are critical to its effectiveness.

Proper Use: It’s a last resort. Deploy it only when escape routes are impossible. Find a relatively level spot, clear of burnable debris. Deploy it according to manufacturer instructions, ensuring it’s completely unfolded and sealed.

Maintenance: Regularly inspect the shelter for tears, burns, or other damage. Check the seams, zippers, and reflective material. Clean it carefully after each use to remove dirt and debris. Avoid storing it in direct sunlight or extreme temperatures.

Training: Proper deployment and use require thorough training. Practicing deploying the shelter in controlled settings is vital.

The fire shelter is a lifeline, but it’s only effective if properly maintained and used only as a last resort. Training and regular inspection are non-negotiable for safety.

Q 6. What are the limitations and capabilities of various types of hand tools used in wildland firefighting?

Hand tools are indispensable in wildland firefighting. Each tool has specific capabilities and limitations.

Shovels: Excellent for digging fire lines, but they are limited by their size and the physical effort required. They’re great for smaller fires or creating hand lines but impractical for large-scale firebreaks.

Pulaskis: Combine a hoe and an axe, allowing for both digging and chopping. They are versatile and efficient for clearing brush and creating fire lines. They’re ideal for creating lines in more challenging terrain than shovels allow.

McLeods: These are primarily rakes, with a short axe or pick on one side. They are useful for clearing light brush and creating fire lines, but they lack the power of an axe or pulaski for heavier work. They’re good for finishing fire lines.

Axes: Great for felling trees and clearing heavier brush, but they are less effective for creating fire lines than a pulaski. They are important for clearing obstacles and creating defensible space.

Selecting the right tool depends on the terrain, fuel type, and the task at hand. Having a range of hand tools allows firefighters to adapt to varying situations effectively.

Q 7. Explain the importance of regular inspections for wildland firefighting equipment.

Regular inspections of wildland firefighting equipment are not just recommended – they’re essential for safety and operational effectiveness. Think of it like regular checkups at the doctor’s; preventative maintenance is far better than reactive repair.

Safety: Malfunctioning equipment can lead to serious injury or death. Regular inspections identify potential hazards before they become critical problems. A simple hose leak today can become a catastrophic failure tomorrow.

Effectiveness: Well-maintained equipment operates at peak performance, allowing firefighters to work more efficiently and effectively. A well-maintained pump delivers water more effectively than one that needs repair.

Cost-Effectiveness: Addressing small issues during an inspection is far cheaper and less time-consuming than dealing with major repairs. A small leak repaired early can prevent extensive damage later.

Legal Compliance: Many jurisdictions mandate regular inspections for safety compliance. Documentation ensures that everything is up to code and that everyone is safe.

A proactive approach to equipment maintenance enhances safety, improves performance, and is crucial for responsible wildland firefighting operations.

Q 8. How do you determine the appropriate Personal Protective Equipment (PPE) for different wildland firefighting scenarios?

Selecting the right Personal Protective Equipment (PPE) for wildland firefighting is crucial for safety. It depends entirely on the specific scenario, considering factors like fuel type, terrain, weather conditions, and the intensity of the fire.

For example, fighting a fast-moving crown fire in steep terrain demands a different level of protection than mopping up a slow-burning ground fire in flat, open land.

- High-risk scenarios (e.g., fast-moving crown fires, steep terrain): Require full PPE including a wildland fire helmet with face shield, Nomex® clothing (jacket and pants), gloves (leather or nomex), sturdy fire-resistant boots with steel toes, eye protection, and a communication device.

- Moderate-risk scenarios (e.g., controlled burns, mop-up operations): May allow for slightly less protective gear, perhaps substituting a hard hat for a wildland fire helmet if the risk of falling debris is low. However, Nomex® clothing and protective boots remain essential.

- Low-risk scenarios (e.g., initial attack on a small fire): While still requiring eye protection and sturdy work boots, Nomex® clothing might be optional depending on the specific conditions and risk assessment.

Remember, the overriding principle is to prioritize safety. Always err on the side of caution when selecting PPE. A thorough risk assessment, conducted before each deployment, is vital for making informed decisions about appropriate equipment.

Q 9. Describe the process for fueling a wildland fire engine safely.

Fueling a wildland fire engine safely is a critical procedure that necessitates strict adherence to established protocols. A single spark can have devastating consequences.

- Engine Shutdown: Before commencing fueling, always ensure the engine is completely shut off and the ignition key is removed.

- Area Clearance: Clear a safe perimeter around the engine. Remove any flammable materials like dry grass or brush, and ensure adequate ventilation to prevent the buildup of potentially explosive fuel vapors.

- Grounding: Use a static grounding wire to connect the fuel nozzle to the engine’s chassis to prevent static electricity buildup. Static discharge can ignite fuel vapors.

- No Smoking: Absolutely no smoking within the vicinity of the fueling operation.

- Slow and Steady: Fuel the tank slowly and avoid overfilling. Overfilling can lead to spills and increase the risk of ignition.

- Spill Cleanup: Immediately clean up any fuel spills using absorbent materials. Never attempt to start the engine if a spill has occurred.

- Post-Fueling Check: After fueling, carefully inspect the area for any fuel leaks or spills before restarting the engine.

Remember, safety is paramount. A well-executed fueling procedure significantly reduces the chances of accidents. Regular training and adherence to standardized procedures are crucial for maintaining safety standards.

Q 10. What are the signs of malfunction in a fire hose and how do you address them?

Identifying and addressing fire hose malfunctions is crucial for effective firefighting and the safety of personnel. Regular inspection is key.

- Kinks and Bends: Kinks restrict water flow and can cause hose bursts under high pressure. Straighten the hose immediately.

- Leaks: Small leaks can escalate rapidly. Identify the leak’s source. Small punctures can often be temporarily repaired with hose clamps and sealant, but larger damage necessitates replacement.

- Abrasions and Cuts: Damage to the hose’s outer layer reduces its durability and increases the risk of bursting. Protect the damaged area with a wrap or repair kit, and consider replacing the hose if the damage is extensive.

- Cracks or Weakening: Inspect for cracks or general weakening, especially at couplings and bends. These are signs of wear and tear and warrant a repair or hose replacement to prevent catastrophic failure.

- Coupling Issues: Loose or damaged couplings can result in significant water loss and require immediate attention. Check that couplings are securely fastened and undamaged.

Addressing hose malfunctions promptly prevents accidents and ensures firefighting operations are effective. Remember that a damaged hose is not just inefficient but also a serious safety hazard. Regular hose maintenance is critical for keeping them in good working order.

Q 11. Explain the difference between various types of fire retardant and their applications.

Different fire retardants are designed for specific applications, each possessing unique properties that affect its effectiveness and environmental impact.

- Water: The most common and versatile retardant, effective for cooling and suppressing fires, especially on initial attacks and mop-up operations. However, it’s less effective on extremely dry fuels.

- Phosphate-based retardants: These create a coating on fuel that reduces flammability. They’re effective on various fuels but can have environmental concerns, particularly with water sources. Different formulations exist with varying levels of environmental impact.

- Polymer-based retardants: These form a gel-like layer, effective for clinging to steep slopes and suppressing re-ignition. They have less environmental impact compared to phosphate-based retardants but can be more expensive.

- Ammonium-based retardants: These are commonly used in aerial applications, creating a barrier against fire advancement. They are effective but some have environmental concerns regarding water quality.

The choice of retardant depends on the specific characteristics of the fire and its surroundings. Factors such as fire behavior, fuel type, topography, and environmental sensitivity all play crucial roles in selecting the appropriate retardant. Environmental impact assessments are critical in responsible wildland firefighting.

Q 12. How do you maintain and repair a pulaski or McLeod?

Maintaining and repairing a Pulaski or McLeod axe is essential for their effectiveness and safety. Regular maintenance extends their lifespan and improves performance.

- Sharpening: Sharpen both the axe head and the adze frequently, using a file or grinder. A sharp tool is safer and more effective.

- Handle Check: Regularly inspect the handle for cracks or looseness. Replace a damaged handle immediately.

- Head Tightening: Ensure the axe head is securely attached to the handle. If it’s loose, tighten it using a wedge or similar method.

- Cleaning: After each use, clean the tools thoroughly to remove dirt and debris. This prevents rust and corrosion.

- Rust Prevention: Apply a light coating of oil or other rust preventative to protect the metal parts.

- Storage: Store the tools in a dry place to prevent rust and damage.

Proper maintenance increases the lifespan of these invaluable tools and makes the work of wildland firefighters safer and more efficient. A dull tool is dangerous and ineffective – take pride in maintaining your tools.

Q 13. Describe the procedures for cleaning and storing firefighting equipment after use.

Cleaning and storing firefighting equipment properly after use is vital for maintaining its effectiveness and safety. Neglecting this can lead to equipment damage, reduced lifespan, and safety hazards.

- Cleaning: After each use, hose down all equipment, removing dirt, debris, and any remaining retardant. Use appropriate cleaning agents as needed, but always ensure they are compatible with the equipment materials.

- Drying: Allow equipment to thoroughly dry before storing. Moisture can lead to rust and corrosion, especially with metal components.

- Inspection: Inspect the equipment for any damage or wear and tear. Address any issues promptly.

- Repair/Replacement: Repair or replace any damaged components. Using damaged equipment is unsafe and inefficient.

- Storage: Store equipment in a designated, clean, dry, and secure location. Protect it from the elements and potential damage.

- Organization: Organize equipment logically for efficient retrieval during emergencies.

Proper cleaning and storage practices not only ensure the longevity of expensive equipment but also contributes to the safety and readiness of the firefighting team. A well-maintained and organized equipment cache is crucial for efficient response and safety.

Q 14. What are the common causes of equipment failure in wildland firefighting and how can they be prevented?

Equipment failure in wildland firefighting can have severe consequences. Understanding common causes and implementing preventative measures is paramount.

- Lack of Maintenance: Neglecting regular maintenance, including cleaning, inspection, and repair, is a major contributor to equipment failure.

- Improper Use: Operating equipment beyond its designed capabilities or using it incorrectly can lead to damage and failure.

- Environmental Factors: Extreme heat, dust, and moisture can damage equipment over time. Proper storage and protection are necessary.

- Wear and Tear: Consistent use naturally leads to wear and tear. Regular inspection and timely replacement of worn parts are crucial.

- Improper Storage: Storing equipment improperly, exposing it to the elements or allowing it to become contaminated, shortens its lifespan and increases failure risk.

Preventing equipment failure involves a proactive approach. This includes implementing regular maintenance schedules, providing thorough training to personnel on proper equipment use and care, selecting appropriate equipment for specific tasks, and creating a culture that prioritizes safety and maintenance. Remember that preventing equipment failure is far more cost-effective and safer than dealing with its consequences.

Q 15. How do you communicate equipment malfunctions or damage to your supervisor?

Reporting equipment malfunctions or damage is crucial for safety and operational efficiency. My process begins with immediate notification to my immediate supervisor using the established communication channels, typically radio or satellite phone, depending on the situation and location. This initial report includes the nature of the malfunction or damage, the specific piece of equipment affected (e.g., ‘Engine 3, water pump malfunction’), and the location. Then, I follow up with a written report, usually through a standardized incident report form, detailing the circumstances leading to the malfunction, the extent of the damage, and any actions taken to mitigate the issue. For example, if a chainsaw malfunctions, I’d report the specific issue (e.g., ‘Chain broke due to hitting a rock’), the chain’s condition and the location before attempting any temporary repairs. This ensures a thorough record is kept for maintenance, repairs, and safety investigations.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with GPS and mapping technology in wildland firefighting.

GPS and mapping technology are indispensable in wildland firefighting. My experience includes using handheld GPS units for navigation in rugged terrain, especially when deploying to remote locations or establishing fire lines. We use mapping software integrated with the GPS to track fire perimeters, identify hot spots, and strategize resource allocation. I’m proficient in using GIS (Geographic Information Systems) software to analyze terrain data, vegetation type, and weather patterns, assisting in developing suppression strategies and predicting fire behavior. During the Biscuit Fire, for instance, we used real-time GPS tracking to coordinate multiple crews across a vast, changing landscape, enabling effective communication and resource deployment. This technology significantly improved our situational awareness and tactical response.

Q 17. What are the different types of communication systems used in wildland firefighting and their limitations?

Wildland firefighting utilizes various communication systems, each with its limitations. We primarily rely on VHF (Very High Frequency) radios for short-range communication within a fire crew or incident command team. However, VHF signals can be blocked by terrain, limiting their range and effectiveness in mountainous areas. Satellite phones offer broader range, crucial in remote areas where VHF is unreliable, but they are susceptible to interference and may have limited bandwidth. Two-way radios, while practical, also have a limited range depending on factors like weather, terrain, and radio power. We also often use text messaging through satellite phones or dedicated communication devices for relaying non-urgent information or for reporting incidents. A reliable communication strategy is imperative; knowing the limitations of each system and having backups is vital in high-stress emergencies.

Q 18. How do you perform a pre-operational check on a wildfire engine?

A pre-operational check on a wildfire engine is a critical safety procedure. It involves a systematic inspection of all major components. This starts with a visual inspection of the engine’s exterior, checking for any damage or leaks. Next, I check fluid levels (water, oil, fuel) and ensure they are within acceptable ranges. I then inspect the tires, checking for proper inflation and any signs of wear or damage. The braking system is thoroughly checked, both manually and by testing the brakes. I also test the lights, sirens, and communication systems. This also includes verifying the functionality of the pump, hoses, nozzles, and other equipment mounted on the engine. Finally, I review the equipment’s load capacity and weight distribution to ensure safe operation. Every check is meticulously documented to maintain a record of the engine’s condition and to ensure that all safety standards are met. Skipping this step would be irresponsible and potentially dangerous.

Q 19. Describe your experience with different types of fire shelters and their deployment.

I have experience with Nomex and fire-resistant shelters. Nomex shelters are lightweight, individually deployed shelters designed to provide temporary protection from radiant heat and flames in the event of an escape from an advancing fire. Deployment involves quickly and correctly unfolding and positioning the shelter; this is often practiced extensively through drills. I’ve also used larger, more complex shelters designed for multiple personnel in extreme situations. These are deployed collaboratively and require specific team procedures. Regular training on deployment procedures is non-negotiable; the lives of those using these shelters depend upon it. It’s not simply a matter of knowing how to deploy; it’s about understanding the limitations of each shelter, appropriate environmental factors for deployment, and reacting quickly and calmly under immense pressure.

Q 20. Explain the importance of regular training on wildland firefighting equipment.

Regular training on wildland firefighting equipment is paramount for safety and effectiveness. Equipment evolves, and training keeps firefighters up-to-date on the latest advancements in technology and safety procedures. Furthermore, repetitive training helps develop muscle memory and quick reactions, essential during emergency situations. Training involves hands-on practice with each piece of equipment, covering both normal operation and emergency procedures. It also includes familiarization with maintenance schedules, problem-solving scenarios, and safety protocols. For example, regular training on chainsaw operation ensures that we understand maintenance routines and safety protocols, preventing accidents and maximizing safety. Lack of training increases risks and reduces operational efficiency; it’s a critical element of our job.

Q 21. How do you adapt equipment usage to different terrain conditions?

Adapting equipment use to different terrain conditions is critical for both efficiency and safety. On steep slopes, we utilize specialized equipment and techniques to prevent equipment damage and injury. For example, we might use smaller, lighter chainsaws in difficult terrain to reduce operator fatigue and prevent accidents. We might also adjust our hose lays and pump placement for optimal water delivery and avoid potential hazards like erosion or unstable ground. In areas with heavy undergrowth, specialized tools designed to clear brush are necessary. In rocky areas, we would utilize equipment suited for harder surfaces, protecting it and extending its life. Each terrain requires a risk assessment, a selection of the most appropriate equipment, and mindful and safe operating procedures. This flexibility and preparedness are crucial for effective and safe wildfire suppression.

Q 22. What are the environmental considerations when using firefighting equipment?

Environmental considerations in wildland firefighting are paramount. We must minimize the impact of our equipment and operations on the already stressed ecosystem. This includes soil erosion from heavy equipment, water contamination from firefighting foam (though many departments are transitioning to more environmentally friendly options), and air pollution from engine exhaust and smoke.

- Soil Erosion: We use techniques like establishing firebreaks strategically, avoiding unnecessary vehicle traffic, and employing erosion control measures after the fire is contained. For example, we might use straw wattles or seed the burned area to prevent soil loss.

- Water Contamination: Minimizing the use of foam is crucial. When it’s absolutely necessary, we carefully select environmentally safer foams and ensure proper disposal of contaminated water. This often involves containment booms and specialized cleanup crews.

- Air Pollution: We strive to use cleaner-burning engines and implement strategies to reduce smoke emissions. This includes prescribed burning techniques that minimize smoke production and the use of smoke dispersal modelling to predict and mitigate the impacts of smoke plumes.

Every decision made in the field needs to weigh the immediate firefighting needs against the long-term environmental consequences. It’s a constant balancing act.

Q 23. Explain the safety protocols when working with hazardous materials related to firefighting.

Safety protocols for hazardous materials in firefighting are extremely strict. We adhere to a rigorous system of training, personal protective equipment (PPE), and emergency response plans.

- Training: All personnel receive extensive training on identifying, handling, and mitigating hazards like fuels (e.g. propane tanks), chemicals, and potentially contaminated water. This includes HAZMAT (Hazardous Materials) awareness and response training.

- PPE: Appropriate PPE is essential, including self-contained breathing apparatus (SCBA), protective suits, gloves, and eye protection depending on the hazard encountered. We are very particular about checking our gear before each incident.

- Emergency Response: Clear communication and well-rehearsed emergency response plans are crucial. This includes established evacuation procedures, decontamination protocols, and access to emergency medical services.

- Decontamination: After exposure to hazardous materials, decontamination is critical. We follow established procedures, which may involve washing down equipment and personnel, and using specialized cleaning agents.

Imagine a scenario where we encounter a chemical spill during a wildfire. Our first step would be to secure the area, notifying emergency responders and initiating decontamination procedures for affected personnel and equipment.

Q 24. How do you manage equipment inventory and logistics in a wildfire incident?

Managing equipment inventory and logistics in a wildfire incident is a complex, dynamic process. It requires careful planning, real-time tracking, and efficient communication.

- Pre-Incident Planning: This involves cataloging all available equipment, including its location, condition, and maintenance status. We also determine storage locations, transportation routes, and pre-position equipment in strategic locations.

- Real-time Tracking: During an incident, we use GPS tracking systems and radio communication to monitor the location and status of equipment. This allows us to quickly deploy needed resources.

- Efficient Deployment: We prioritize equipment deployment based on the needs of different fire crews and changing fire conditions. This often involves staging areas and designated supply points.

- Maintenance and Repair: A dedicated team manages equipment maintenance and repairs on-site. This might include minor repairs by field mechanics or the transport of severely damaged equipment to a repair facility.

Think of it as a constantly shifting puzzle. We need to adapt to the changing fire situation and make sure the right tools are in the right place at the right time, all while maintaining equipment readiness.

Q 25. What is your experience with different types of aerial firefighting equipment?

My experience encompasses a range of aerial firefighting equipment.

- Air Tankers: I’ve worked with various air tankers, from smaller single-engine air tankers (SEATs) to large air tankers capable of carrying thousands of gallons of retardant. I understand their capabilities, limitations, and the crucial coordination with ground crews.

- Helicopters: My experience includes working with both light and heavy helicopters. Helicopters are versatile, used for water drops, slinging equipment, and personnel transport. I’m familiar with the different types of helicopter-based water buckets and the challenges of operating in difficult terrain.

- Rotor-Wing Aircraft: I’ve witnessed the effectiveness of using helicopters for precise water drops in inaccessible areas and for supporting ground crews with critical supplies. This is often crucial in areas where other resources are unavailable.

Understanding the performance characteristics of different aircraft is critical for effective incident management. For example, the choice between a helicopter and an air tanker often depends on the fire’s location, size, and the type of terrain.

Q 26. Describe the process for reporting and documenting equipment maintenance.

Equipment maintenance reporting and documentation are critical for safety and accountability. We use a comprehensive system to track maintenance activities.

- Preventative Maintenance: Regular preventative maintenance schedules are established for each piece of equipment. These schedules are based on manufacturer’s recommendations and our own experience.

- Maintenance Logs: Detailed maintenance logs record all inspections, repairs, and servicing. These logs include dates, descriptions of work performed, and the signatures of personnel involved.

- Software Systems: We often utilize computerized maintenance management systems (CMMS) that track equipment inventory, maintenance schedules, and repair history. This provides a centralized database for managing the entire fleet.

- Repair Orders: For more significant repairs, we generate repair orders, documenting the problem, the work performed, and the associated costs. This helps track expenditures and improve efficiency.

This meticulous record-keeping is vital. It not only ensures equipment reliability but also allows for analysis to predict potential failures and prevent costly downtime. Proper documentation can also be crucial for insurance claims and legal purposes.

Q 27. How do you troubleshoot and repair common problems with power saws?

Troubleshooting and repairing power saws is a common task in wildland firefighting. My experience allows me to diagnose and fix a range of issues.

- Starting Problems: This could be due to a variety of reasons, such as a clogged air filter, a faulty spark plug, or low fuel. I would systematically check each component to identify the cause.

- Chain Problems: A dull or damaged chain can significantly reduce cutting efficiency and pose a safety hazard. Sharpening, replacing, or adjusting the chain tension is often necessary.

- Engine Issues: Problems like engine stalling or overheating can point to problems with the carburetor, fuel system, or cooling system. I would carefully inspect these systems, often involving adjustments or repairs.

- Safety Concerns: Before any repair work, I ensure the saw is properly shut off and the chain brake is engaged to prevent accidental injuries.

For example, if a saw is stalling, I would first check the fuel and air filter. If the problem persists, I’d move to check the spark plug and carburetor. A methodical approach is key to safe and efficient repair.

Q 28. What is your experience with specialized equipment for managing prescribed burns?

My experience with specialized equipment for prescribed burns includes a variety of tools designed for controlled ignition and monitoring.

- Drip Torches: These are used for creating fire lines and controlling the spread of the burn. I’m experienced in their safe and effective use, considering weather conditions and fuel types.

- Helitorches: For larger burns, helitorches are employed for more efficient ignition. I understand the coordination needed between the helicopter crew and ground personnel to ensure safe operations.

- Ignition Devices: Various ignition devices, including fusees and other controlled ignition systems, are used depending on the specific burn plan. Knowing how to select the appropriate device for the circumstances is critical.

- Monitoring Equipment: We utilize various monitoring tools, such as weather stations and infrared cameras, to track the burn’s progress and mitigate any risks. Proper monitoring is vital for ensuring the burn stays within its planned boundaries.

Prescribed burns require careful planning and execution. The choice of equipment depends heavily on the size and location of the burn, as well as weather conditions and the type of vegetation being treated.

Key Topics to Learn for Wildland Firefighting Equipment Interview

- Personal Protective Equipment (PPE): Understanding the types, uses, and limitations of various PPE, including fire-resistant clothing, helmets, eye protection, and respiratory equipment. Consider the importance of proper fit and maintenance.

- Hand Tools & Equipment: Familiarize yourself with the operation and maintenance of tools like shovels, pulaskis, axes, and McLeod tools. Be prepared to discuss their application in different fire situations and terrain.

- Water Delivery Systems: Gain a thorough understanding of different water delivery systems used in wildland firefighting, including pumps, hoses, and water tenders. Discuss the challenges of water supply in remote areas.

- Engine and Equipment Maintenance: Discuss preventative maintenance procedures, troubleshooting common issues, and safety protocols related to engine and equipment operation. Highlight your experience with inspection and repair.

- Specialized Equipment: Research specialized equipment such as drip torches, fire shelters, and communication systems. Understand their purpose, proper use, and safety considerations.

- Safety Procedures and Regulations: Demonstrate your knowledge of safety regulations and protocols related to wildland firefighting equipment, including pre-operational checks, and emergency procedures.

- Fuel Behavior and Fire Suppression Strategies: Relate your knowledge of wildland fire behavior to the selection and use of appropriate firefighting equipment. Explain how equipment choices influence fire suppression strategies.

Next Steps

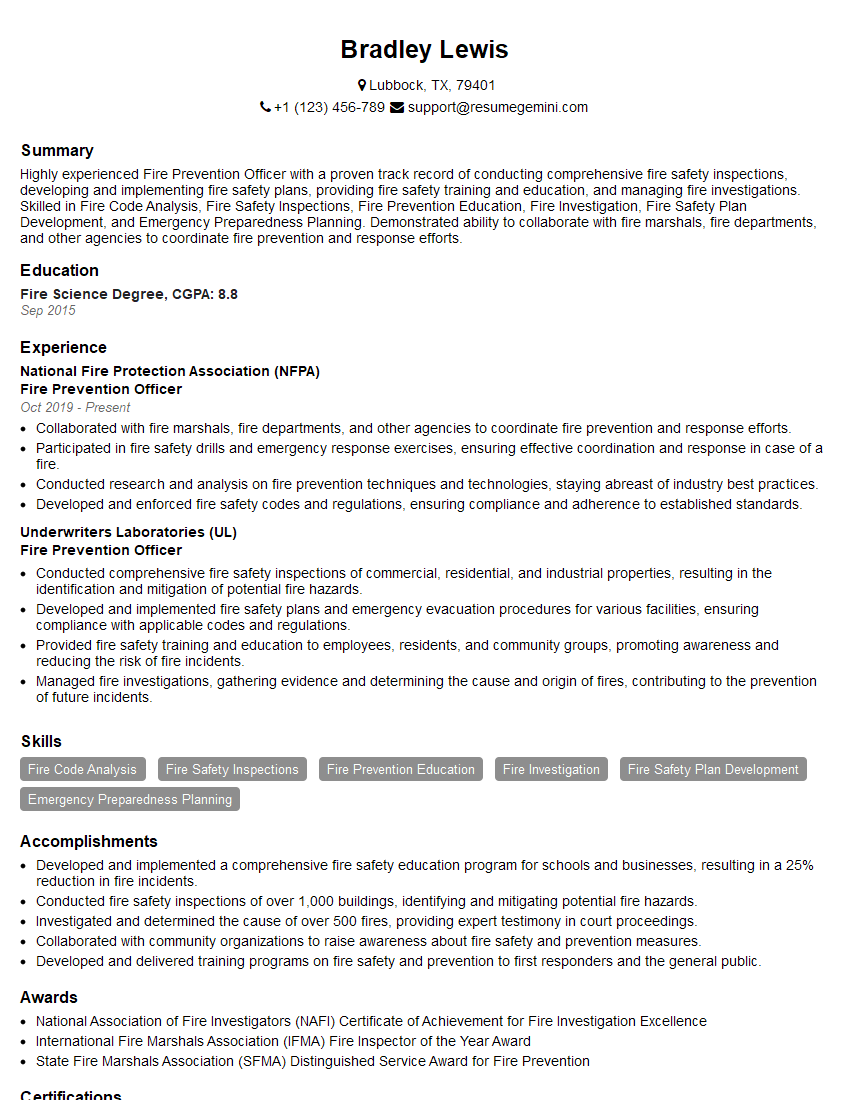

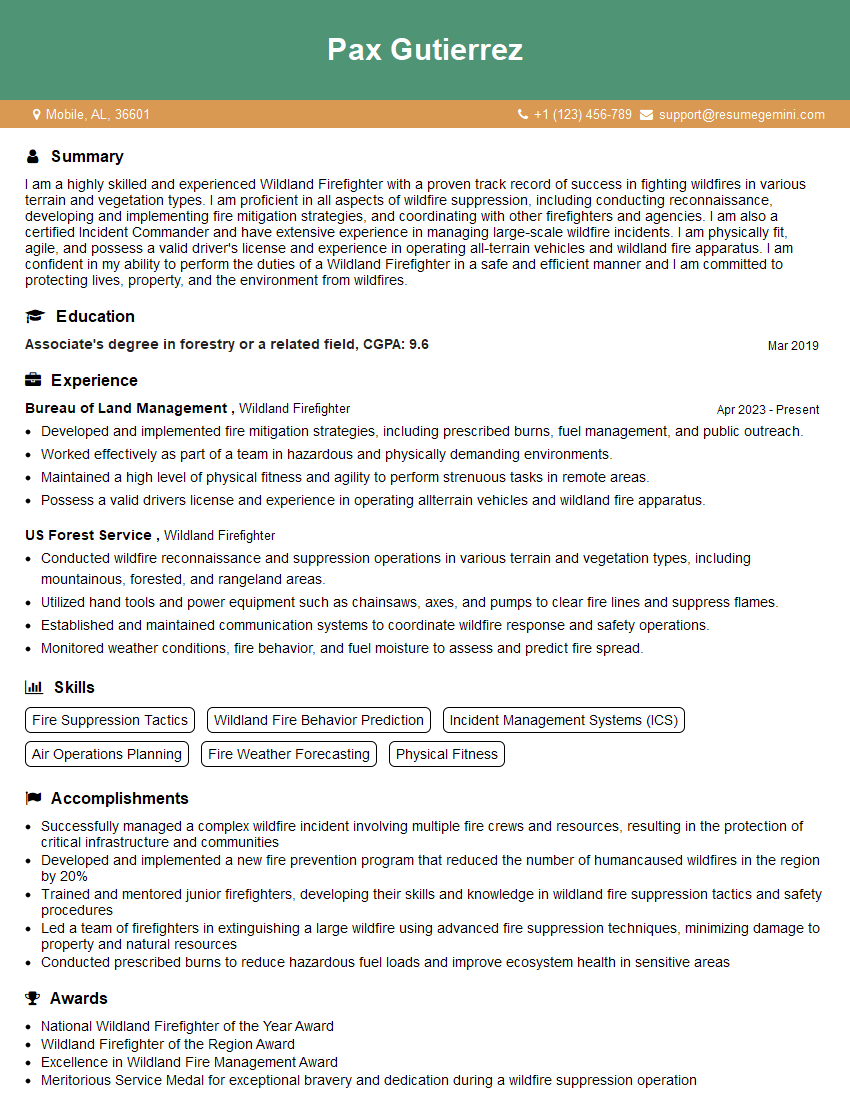

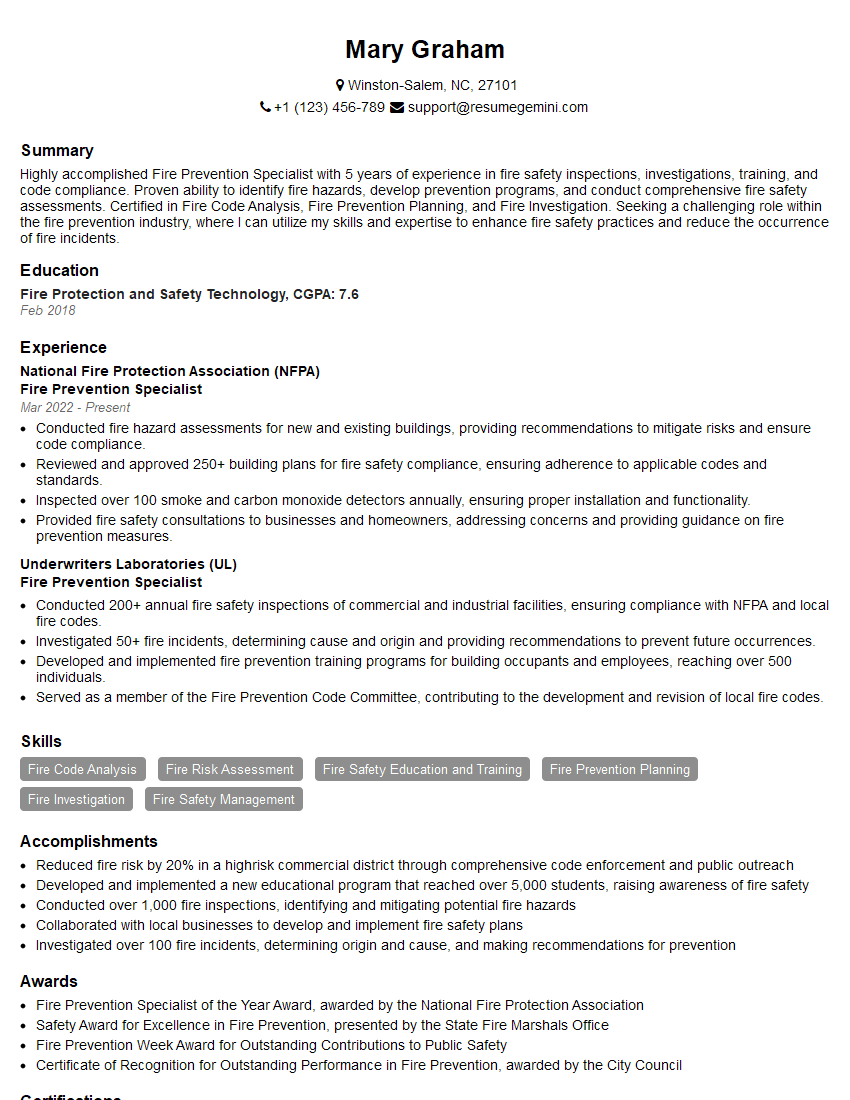

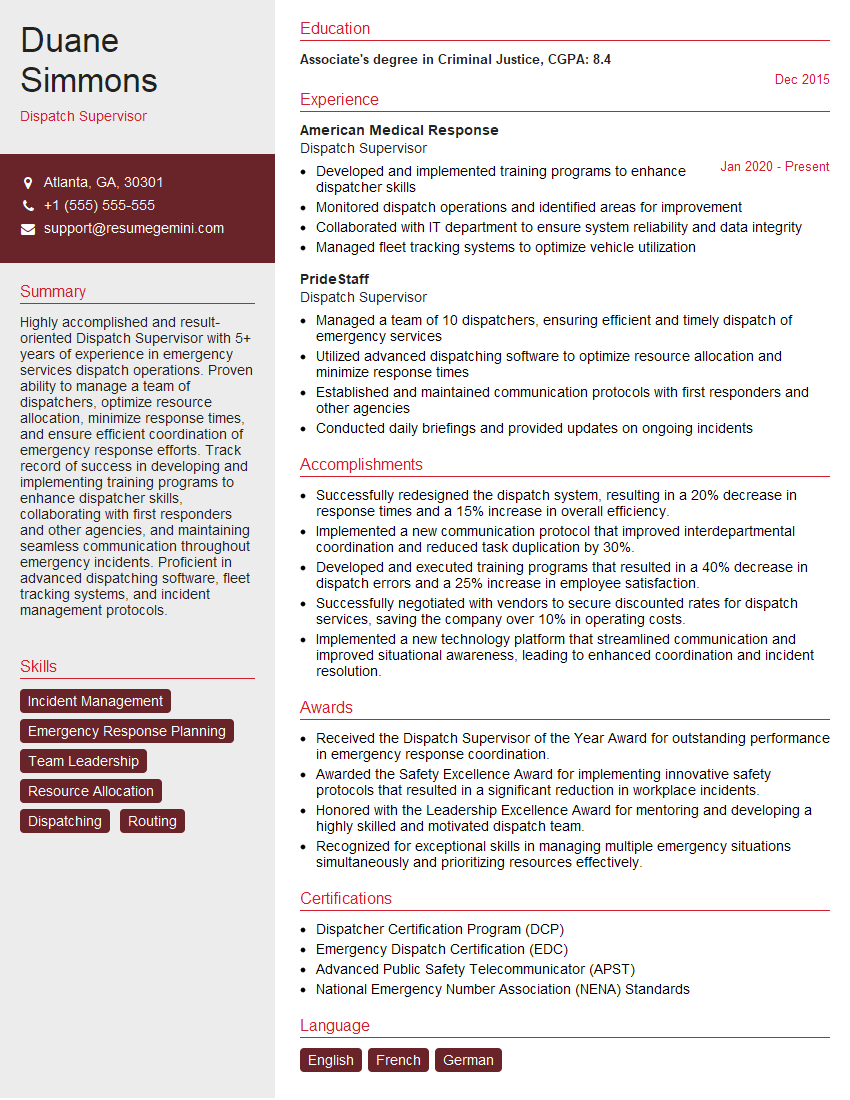

Mastering wildland firefighting equipment is crucial for career advancement in this challenging and rewarding field. A strong understanding of equipment, its capabilities, and limitations will set you apart from other candidates and demonstrate your commitment to safety and efficiency. To maximize your job prospects, creating an ATS-friendly resume is essential. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your skills and experience effectively. Examples of resumes tailored to the Wildland Firefighting Equipment field are available to help guide your resume creation process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good