The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Wool Industry Knowledge interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Wool Industry Knowledge Interview

Q 1. Explain the different types of wool fibers and their properties.

Wool fibers are classified based on several factors, primarily the breed of sheep and the fiber’s characteristics. Here are some key types:

- Merino Wool: Known for its fine diameter, softness, and crimp (the natural waviness of the fiber). It’s highly prized for its luxurious feel and drape, commonly used in high-end apparel.

- Rambouillet Wool: Similar to Merino but often slightly coarser, offering good strength and resilience. It’s versatile and used in a range of applications.

- Corriedale Wool: A medium-fine wool, offering a balance of softness and strength. It’s often used in blends, adding durability without compromising comfort.

- Crossbred Wool: A blend of different wool breeds, offering a variety of properties depending on the breeds used. It’s a cost-effective option with varying levels of softness and strength.

- Carpet Wool: A coarser, stronger wool type primarily used for carpets and rugs. It’s less expensive than finer wools but still offers excellent durability.

The properties of wool fibers, like softness, strength, crimp, and elasticity, directly impact the final product’s quality and performance. For instance, finer wools (like Merino) produce softer, more luxurious fabrics, while coarser wools (like carpet wool) are better suited for durable items that need to withstand wear and tear.

Q 2. Describe the wool scouring process and its importance.

Wool scouring is a crucial process in wool processing where the raw fleece is cleaned to remove impurities like grease (lanolin), dirt, and vegetable matter. This is done using a series of washes with hot water, detergents, and sometimes solvents.

The importance of scouring lies in:

- Improving Fiber Quality: Scouring removes impurities, making the fibers cleaner, brighter, and more pliable for subsequent processing.

- Enabling Dyeing and Finishing: Clean fibers absorb dyes more evenly, resulting in consistent and vibrant colors. Scouring also prepares the fibers for other finishing processes.

- Increasing Fiber Strength: The removal of lanolin can actually improve the fiber’s strength. While lanolin protects the fiber in the fleece, it can hinder strength in later stages of processing.

- Reducing Waste and Improving Efficiency: Scouring is critical to remove material that would reduce the overall yield of fiber.

Think of it like washing your clothes before you wear them – scouring prepares the wool fibers for the next stage of their journey from fleece to fabric, guaranteeing a superior end product.

Q 3. What are the key factors affecting wool fiber quality?

Several factors influence wool fiber quality. These can be broadly categorized as:

- Breed of Sheep: Different sheep breeds produce fibers with varying diameters, lengths, crimp, and strength. Merino sheep, for instance, are renowned for their fine and soft wool.

- Climate and Pasture Conditions: The sheep’s diet and environmental conditions significantly impact fiber quality. Adequate nutrition leads to healthier sheep and better quality wool.

- Farming Practices: Proper sheep management, including shearing techniques and handling, minimizes fiber damage and maintains quality.

- Fiber Characteristics: These include fiber diameter (fineness), length (staple length), strength, crimp, and color. Finer fibers generally produce softer fabrics, longer fibers lead to less pilling, and stronger fibers result in more durable fabrics.

- Contamination Levels: The presence of dirt, vegetable matter, and other contaminants significantly affects the quality of wool fibers.

For example, a Merino sheep raised in harsh, dry conditions might produce shorter, coarser wool compared to a Merino sheep raised in ideal conditions with ample nutrition. This highlights the interconnectedness of all these factors in determining the final quality of the wool fiber.

Q 4. How is wool graded and what are the grading systems used?

Wool is graded based on various fiber characteristics, mainly fiber diameter (fineness), length (staple length), strength, and cleanliness. Several grading systems exist, varying by country and organization. Common aspects include:

- Micron Count: Measures the fiber diameter in microns (micrometers), with finer fibers having a lower micron count and representing higher quality. A lower micron count usually means softer, more luxurious wool.

- Staple Length: Refers to the length of individual wool fibers. Longer staple lengths generally indicate higher quality and stronger yarns.

- Strength: Measures the fiber’s resistance to breakage. Stronger fibers produce more durable fabrics.

- Cleanliness: Assesses the amount of vegetable matter and other impurities present in the wool. Higher cleanliness ratings mean better quality.

- Yield: This describes the percentage of clean wool after scouring, indicating the efficiency of the processing.

Grading systems often use numerical scales or descriptive terms (e.g., fine, medium, coarse) to categorize the wool. These systems are essential for determining price and suitability for specific applications. For example, finer wool with a low micron count commands a higher price than coarser wool due to its superior quality and luxurious feel.

Q 5. Explain the different types of wool yarn and their applications.

Wool yarns are categorized based on several factors, including fiber type, spinning method, and intended use:

- Worsted Yarn: Produced from long, parallel fibers, resulting in a smooth, strong, and even yarn. Commonly used in tailored garments and high-quality clothing.

- Woollen Yarn: Made from shorter, more tangled fibers, resulting in a softer, more textured yarn. This type is often used in sweaters, blankets, and other more casual apparel.

- Novelty Yarn: Features unique textures and patterns due to special spinning techniques or the inclusion of other fibers. Examples include slub yarns, bouclé yarns, and tweed yarns.

- Combed Top Yarn: A premium yarn spun from combed top fibers, known for their smoothness, evenness, and strength.

The choice of yarn depends on the desired fabric characteristics and end-use. Worsted yarns are ideal for structured garments, whereas woollen yarns provide a cozy, informal feel. Novelty yarns add visual interest, and combed top yarns are used when superior quality is required.

Q 6. Describe the process of weaving wool fabric.

Weaving wool fabric involves interlacing warp yarns (running lengthwise) and weft yarns (running across the width) on a loom. The process can be summarized as follows:

- Warping: Preparing the warp yarns by winding them onto a large beam.

- Drawing-in: Threading the warp yarns through the heddles (vertical frames) and reed (a comb-like structure) on the loom.

- Shedding: Raising and lowering the heddles to separate the warp yarns, creating a space for the weft yarn to pass through.

- Picking: Inserting the weft yarn across the shed (the opening created by the shedder) using a shuttle or other mechanism.

- Beating-up: Pressing the newly inserted weft yarn against the previously woven fabric using the reed.

- Taking-up: Winding the woven fabric onto a cloth beam as it is produced.

Different weaving techniques (plain weave, twill weave, satin weave, etc.) create various fabric textures and patterns. The type of yarn and weave chosen determine the fabric’s final characteristics like drape, durability, and texture. For example, a tightly woven wool fabric will be more durable and less likely to pill than a loosely woven one.

Q 7. What are the common defects found in wool fabrics?

Several defects can occur during wool fabric production, impacting its quality and appearance. Some common defects include:

- Pilling: Formation of small balls of fiber on the fabric surface, usually due to friction.

- Shrinkage: Reduction in fabric dimensions after washing, caused by felting or relaxation shrinkage.

- Weaving Defects: Issues like broken ends, missed picks, holes, and slubs (thick or thin areas in the yarn).

- Dyeing Defects: Uneven color, color bleeding, or poor colorfastness.

- Fiber Defects: Weak fibers, neps (small knots of tangled fibers), and impurities.

These defects can be minimized through careful control of the production process, including the selection of high-quality raw materials, proper processing techniques, and quality control measures. For example, using pre-shrunk yarns or employing specific finishes can reduce shrinkage issues. Detecting and addressing defects early in the production process can save time and resources and improve the overall quality of the finished product.

Q 8. How is wool dyed and finished?

Wool dyeing and finishing is a multi-stage process that transforms raw wool into a finished textile. It begins with scouring, where the wool is cleaned to remove lanolin (natural oil) and dirt. Then comes dyeing, where the fibers absorb color. There are various dyeing methods, including:

- Acid dyeing: Uses acid dyes that bind well to wool fibers, creating vibrant colors.

- Mordant dyeing: A chemical (mordant) is used to help the dye bind more effectively, producing durable color.

- Vat dyeing: Insoluble dyes are reduced to a soluble form, allowing them to penetrate the fibers, and then re-oxidized to become permanent.

After dyeing, the wool undergoes finishing processes to enhance its properties. These include:

- Carbonizing: Removes vegetable matter from wool.

- Fulling/Milling: A process of felting the wool, making it thicker and denser.

- Setting: Using heat and pressure to fix the shape and dimensions of the fabric.

- Pressing: Smooths out wrinkles and gives the fabric a finished appearance.

For example, a high-end wool suit fabric might undergo acid dyeing for bright, consistent color, followed by fulling to create a dense, luxurious drape, and pressing for a crisp finish. The specific processes depend on the desired final product and its intended use.

Q 9. Explain the concept of wool shrinkage and its control.

Wool shrinkage refers to the reduction in size of a wool garment after washing. It’s caused by the unique structure of wool fibers – they are covered with scales that interlock when agitated with water and heat. This causes the fibers to felt together, resulting in shrinkage. The degree of shrinkage depends on factors like fiber type, yarn construction, and washing conditions.

Controlling wool shrinkage involves several techniques:

- Pre-shrinking: Treating the fabric with heat and moisture to cause controlled shrinkage before garment production. This is common with high-quality woolen items.

- Superwash treatment: Applying a resin coating to the fibers that reduces their tendency to felt. This allows for machine washing without significant shrinkage. It’s frequently used for machine-washable wool garments.

- Careful washing: Washing wool garments in cold water with a gentle detergent and air-drying them flat prevents excess shrinkage.

Imagine trying to fit a wool sweater after washing it without considering shrinkage—it might be too small! Superwash treatments address this issue, providing a convenient solution for consumers. Pre-shrinking eliminates shrinkage by managing it in the early stages of the manufacturing process.

Q 10. What are the environmental impacts of wool production?

Wool production, while offering a renewable fiber source, has environmental impacts. These include:

- Greenhouse gas emissions: Sheep farming contributes to methane emissions from livestock digestion.

- Land degradation: Overgrazing can lead to soil erosion and desertification.

- Water pollution: Wastewater from wool processing plants can contain chemicals that pollute waterways.

- Pesticide use: Chemicals used to control parasites on sheep can have negative impacts on ecosystems.

- Biodiversity loss: Intensive sheep farming can lead to habitat loss and reduced biodiversity.

For instance, a farm with a high sheep density might contribute significantly to methane emissions and soil erosion. The use of certain dyes and chemicals in processing also presents water pollution risks. These concerns highlight the need for sustainable practices in the wool industry.

Q 11. Describe the sustainable practices in the wool industry.

Sustainable practices in the wool industry aim to minimize its environmental footprint and ensure ethical treatment of animals. These include:

- Regenerative agriculture: Farming practices that improve soil health and carbon sequestration, reducing the negative impact of grazing.

- Reduced chemical use: Minimizing the use of pesticides and fertilizers in sheep farming and opting for natural dyes and finishing agents in processing.

- Water conservation: Implementing water-efficient practices in sheep farming and wool processing.

- Waste reduction and recycling: Recycling wool scraps and developing closed-loop systems to minimize waste.

- Animal welfare: Ensuring ethical treatment of sheep throughout their life cycle, including access to pasture, adequate veterinary care and humane shearing practices.

- Traceability and transparency: Tracking wool from farm to finished product to ensure sustainable practices are implemented throughout the supply chain.

Certifications like Responsible Wool Standard (RWS) provide frameworks to verify these practices. Consumers increasingly seek out sustainably produced wool, driving the industry towards greater environmental and social responsibility.

Q 12. What are the different types of wool blends used in textiles?

Wool blends combine wool with other fibers to enhance its properties or reduce costs. Common blends include:

- Wool/Polyester: Polyester adds durability, wrinkle resistance, and reduces cost. Commonly used in outerwear and suits.

- Wool/Silk: Silk adds luxurious drape and softness, creating high-end fabrics.

- Wool/Cotton: Cotton adds breathability and absorbency, often used in summer clothing.

- Wool/Cashmere: Cashmere, a luxurious fiber from goats, adds incredible softness and warmth. Used in high-end sweaters and scarves.

- Wool/Acrylic: Acrylic is a synthetic fiber that reduces cost and improves washability. Often used in budget-friendly knitwear.

The proportions of each fiber in the blend affect the final fabric’s properties. A high wool content generally indicates better quality and performance, but blending allows manufacturers to create fabrics with a wide range of characteristics to meet different needs and price points.

Q 13. How do you assess the quality of raw wool?

Assessing raw wool quality involves evaluating several characteristics:

- Fiber diameter: Finer fibers (measured in microns) produce softer, more luxurious yarns. A micron measurement is crucial for determining the quality grade.

- Fiber length: Longer fibers yield stronger, less prone-to-pilling yarns.

- Fiber strength: Stronger fibers produce durable fabrics.

- Cleanliness: The amount of vegetable matter and impurities affects the quality and ease of processing.

- Color: The natural color of the wool can impact the dyeing process and the final product’s appearance.

- Crimp: The waviness of the fibers; more crimp means better elasticity and insulation.

Experts use instruments like a micron gauge and optical sorters to assess these characteristics. Visual inspection and tactile assessment also play a crucial role. The grading system varies across different countries and markets but broadly speaking the finer and longer the fiber, the higher the quality and cost.

Q 14. What are the challenges in managing wool supply chains?

Managing wool supply chains presents several challenges:

- Traceability: Tracking wool from farm to finished product can be difficult, especially with complex supply chains.

- Fluctuations in supply: Wool production can be affected by weather conditions and animal health, causing price volatility.

- Ethical sourcing: Ensuring the wool comes from farms that practice animal welfare and environmental sustainability.

- Demand variability: Consumer demand fluctuates, creating challenges for inventory management and forecasting.

- Logistics and transportation: Transporting wool can be expensive and environmentally impactful. Bulk transportation is usually most efficient but adds to its environmental impact.

- Data management: Tracking and managing large amounts of data related to wool production and sales can be challenging.

Blockchain technology and other digital tools are being explored to improve traceability and transparency, making the supply chain more efficient and sustainable. Effective collaboration between all stakeholders (farmers, processors, manufacturers, and retailers) is crucial for overcoming these challenges.

Q 15. Explain the role of quality control in wool manufacturing.

Quality control in wool manufacturing is paramount, ensuring the final product meets the required standards of quality, consistency, and customer expectations. It’s a multifaceted process that starts from the fleece itself and continues throughout every stage of production.

- Raw Material Assessment: This involves meticulous inspection of the raw fleece for factors like fiber length, diameter, strength, cleanliness (absence of vegetable matter), and color. Variations in these characteristics directly impact the final fabric’s properties.

- Processing Control: Throughout scouring (cleaning), carding (aligning fibers), spinning (creating yarn), and weaving or knitting (fabric creation), regular quality checks are performed. This might involve testing yarn strength, evenness, and the fabric’s density and drape.

- Finished Fabric Inspection: The final fabric undergoes thorough inspection for defects such as holes, inconsistencies in color or texture, and shrinkage issues. This often involves visual inspection, but also sophisticated testing for properties like shrinkage resistance, pilling resistance, and water resistance.

- Statistical Process Control (SPC): Modern wool mills utilize SPC techniques to monitor and manage variations in the manufacturing process. Data on various parameters are collected and analyzed to identify trends and prevent defects.

For instance, if a significant portion of the yarn is found to be weaker than the standard, the process parameters need adjustment. This might involve tweaking the spinning machine settings or re-evaluating the quality of the raw material.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you identify different wool fiber types under a microscope?

Identifying different wool fiber types under a microscope relies on observing several key characteristics. The magnification needed is typically quite high (40x or higher).

- Fiber Diameter: Different wool breeds have distinct fiber diameters. Fine wools like Merino have very thin fibers, while coarser wools like Lincoln have much thicker ones. Measurement using a calibrated eyepiece micrometer is crucial.

- Scale Structure: Wool fibers are covered in overlapping scales, giving them their characteristic crimp. The size and arrangement of these scales vary between breeds. Merino wool often displays fine, dense scales, while coarser wools show larger, more loosely arranged ones.

- Medullation: Some wool fibers have a central core called a medulla. The presence, size, and distribution of the medulla can be indicative of the wool type. Many fine wools lack a medulla, while some coarser wools have prominent ones.

- Fiber Length and Crimp: Although not directly microscopic characteristics, the length and crimp of fibers are visible and provide additional clues. Longer fibers generally contribute to strength and resilience.

For example, comparing a sample of Merino wool with that of a coarser breed like Bluefaced Leicester under a microscope would reveal significant differences in fiber diameter and scale structure. The Merino would display finer fibers with densely packed scales, while the Leicester would show thicker fibers with larger, more sparsely distributed scales.

Q 17. Discuss the use of technology in wool processing.

Technology has revolutionized wool processing, enhancing efficiency, precision, and product quality. Automation and data-driven insights are becoming increasingly critical.

- Automated Sorting and Grading: Sophisticated optical sorting systems utilize image analysis to quickly and accurately classify wool fibers based on their color, diameter, and length, optimizing the use of raw material.

- Precision Spinning: Advanced spinning machines can produce yarns with improved consistency and higher strength, leading to superior fabric quality. Data monitoring systems enable real-time adjustments to spinning parameters.

- Computer-Aided Design (CAD) in Fabric Design: CAD software allows designers to create complex and intricate fabric patterns digitally, enabling rapid prototyping and minimizing waste.

- Fiber Testing Equipment: Automated testing instruments perform precise measurements of fiber properties like diameter, length, strength, and elasticity, facilitating more consistent quality control.

- Supply Chain Management Software: Streamlined tracking of wool from farm to finished product ensures transparency and enhances traceability.

For instance, automated optical sorters can effectively remove vegetable matter and other impurities from the fleece, significantly reducing the labor involved and improving the final product quality. Similarly, precision spinning systems allow the production of finer and more consistent yarns, directly enhancing the quality and value of the resulting fabrics.

Q 18. What are the trends and future prospects of the wool industry?

The wool industry faces both challenges and opportunities. Sustainability, innovation, and technological advancements will shape its future.

- Sustainable Practices: Increasing consumer demand for environmentally friendly products is pushing the industry towards more sustainable farming and processing techniques. This includes reducing water and energy consumption and minimizing waste.

- Innovation in Fiber Processing: Research and development in new technologies are yielding innovations in fiber treatment and fabric production, leading to improved performance characteristics, like water resistance and wrinkle resistance.

- Focus on Performance and Functionality: The market is seeing increasing demand for performance fabrics with specialized functionalities, such as moisture-wicking or antimicrobial properties. This necessitates further innovation in wool processing techniques.

- Brand Storytelling and Traceability: Consumers are increasingly interested in knowing the origin and production journey of their products. Traceability initiatives and responsible brand storytelling are becoming crucial for consumer trust and market success.

- Competition from Synthetics: The wool industry faces ongoing competition from synthetic fibers, necessitating a continuous effort to highlight wool’s unique properties, sustainability aspects, and overall value proposition.

For example, the development of biodegradable wool-based packaging solutions is a testament to the industry’s commitment to sustainability. The integration of technology to enhance the moisture-wicking property of wool in sportswear showcases innovation to meet consumer demand.

Q 19. Describe the different finishing treatments applied to wool fabrics.

Wool fabrics undergo various finishing treatments to enhance their properties and aesthetic appeal. These treatments are crucial for achieving the desired drape, feel, and performance characteristics.

- Scouring: Removes impurities like grease and dirt from the raw wool.

- Carbonizing: Removes vegetable matter from the wool.

- Dyeing: Imparts color to the fabric, using various methods like solution dyeing, piece dyeing, or yarn dyeing.

- Finishing: This broad category includes numerous treatments:

- Pressing and Calendering: Improves smoothness and drape.

- Shrink-proofing: Reduces the fabric’s tendency to shrink after washing.

- Water-repellent treatments: Make the fabric resistant to water.

- Anti-pilling treatments: Reduces the formation of pills or bobbles on the surface.

- Softening treatments: Enhance the fabric’s softness and handle.

- Flame-retardant treatments: Improve fire safety.

For instance, a wool suit fabric might undergo scouring, dyeing, pressing, and anti-pilling treatments to ensure it’s wrinkle-resistant, retains its shape, and looks smooth after repeated wear and washing.

Q 20. What are the health and safety considerations in wool handling?

Health and safety considerations in wool handling are crucial throughout the entire process, from shearing to manufacturing. Exposure to certain substances and working conditions can pose risks.

- Respiratory Hazards: Wool dust can cause respiratory problems, including allergic reactions and asthma. Adequate ventilation, respiratory protection (e.g., masks), and regular health checks are essential.

- Skin Irritation: Contact with wool fibers can cause skin irritation and dermatitis in some individuals. Protective clothing and regular hand washing are important preventative measures.

- Noise Pollution: Some wool processing machinery can generate significant noise levels. Hearing protection and noise reduction measures are crucial.

- Chemical Hazards: Exposure to chemicals used in dyeing, finishing, and cleaning processes can pose health risks. Appropriate safety protocols, personal protective equipment (PPE), and regular monitoring are vital.

- Ergonomic Hazards: Repetitive movements and awkward postures during tasks like shearing and sorting can cause musculoskeletal disorders. Ergonomic assessments and workplace modifications can help mitigate risks.

For example, implementing a thorough respiratory protection program in a wool spinning mill can drastically reduce the incidence of respiratory issues among workers. Similarly, providing appropriate protective gloves and regular skin checks can help minimize the risk of dermatitis.

Q 21. How do you determine the appropriate fiber count for a wool fabric?

Determining the appropriate fiber count for a wool fabric depends on the intended end-use and desired properties. Fiber count, expressed as the number of yarns per inch (both warp and weft), significantly influences the fabric’s characteristics.

- Fabric Weight and Drape: Higher fiber counts generally result in denser, heavier fabrics with a better drape and potentially higher durability.

- Warmth and Insulation: Denser fabrics (higher fiber count) provide better insulation and warmth.

- Softness and Handle: The fiber count influences the fabric’s softness and feel. Extremely high counts can sometimes result in a stiffer, less soft handle.

- Cost: Higher fiber counts often translate to higher fabric costs due to the increased amount of yarn required.

The process involves considering the desired properties and making a trade-off between quality, performance, and cost. A lightweight wool summer suit might have a lower fiber count compared to a heavy winter coat, where warmth and durability are paramount. Experience and data from past projects play a critical role in making informed decisions about fiber count.

For example, a fine wool sweater intended for casual wear might have a fiber count of 18-20 warp and weft, offering a balance of softness, warmth, and durability. In contrast, a heavy wool overcoat designed for maximum warmth might have a higher count of 24-28 to achieve increased density.

Q 22. Explain the importance of yarn twist in wool fabrics.

Yarn twist is crucial in wool fabrics because it directly impacts the final product’s properties. Think of it like twisting individual strands of rope to create a stronger, more durable whole. The amount of twist, or turns per inch (TPI), determines the fabric’s strength, drape, and texture.

Higher twist results in a firmer, stronger fabric with less stretch and better durability. This is ideal for applications like outerwear or upholstery where resilience is paramount. Imagine a tightly twisted wool yarn used in a rugged winter coat – it will resist wear and tear effectively.

Lower twist produces softer, drapier fabrics with more elasticity. This is preferred for garments where comfort and a luxurious feel are prioritized, such as sweaters or scarves. Think of a loosely twisted yarn creating a soft, flowing knit.

The type of twist (S-twist or Z-twist) also influences the fabric’s final appearance and handling. The choice of twist is a critical decision made during yarn manufacturing, heavily impacting the end product’s quality and market appeal.

Q 23. How do you address customer complaints about wool product quality?

Addressing customer complaints about wool product quality is paramount for maintaining customer trust and brand reputation. My approach is systematic and prioritizes understanding the issue before providing a resolution.

- Active Listening: I start by carefully listening to the customer’s complaint, allowing them to fully explain their experience. This helps identify the core problem – is it a manufacturing defect, incorrect care instructions, or simply unmet expectations?

- Investigation: I then investigate the complaint, checking the product’s specifications against the customer’s description. If there’s a visible defect, I document it with photographs. If the issue involves shrinkage or pilling, I might require more details about care practices.

- Solution-Oriented Approach: My aim is to find a fair and efficient solution. This might involve a refund, replacement, or repair, depending on the nature and severity of the issue. For example, if a sweater has a manufacturing flaw, a replacement would be appropriate. If the problem is due to improper care, I’d offer guidance on proper wool care.

- Follow-Up: After resolving the issue, I follow up with the customer to ensure their satisfaction and address any lingering concerns. This builds trust and strengthens the customer relationship.

This process ensures that each complaint is treated individually and fairly, reinforcing a commitment to quality and customer service.

Q 24. Describe the role of traceability in the wool supply chain.

Traceability in the wool supply chain is essential for ensuring ethical sourcing, product quality, and consumer trust. It’s like having a detailed ‘family tree’ for every batch of wool, allowing us to track its journey from farm to finished product.

Traceability involves recording and documenting every stage of the wool’s journey, from the sheep’s identification (often through electronic tags) to shearing, processing, manufacturing, and retail. This detailed record allows us to:

- Verify Origin and Authenticity: Confirm the wool’s origin and ensure it meets specific quality standards. For instance, we can verify that ‘Merino wool from Australia’ truly originates from Australia.

- Improve Sustainability: Monitor farming practices, ensuring they are environmentally responsible and ethical. This includes checking for animal welfare standards and sustainable land management practices.

- Enhance Quality Control: Quickly identify the source of any quality issues, allowing for prompt corrective actions. If a batch of wool shows inconsistencies, traceability helps pinpoint the stage where the problem occurred.

- Build Consumer Confidence: Provide transparent and reliable information to consumers about the product’s origins and production methods, increasing trust and brand loyalty.

Blockchain technology is increasingly used to enhance traceability, providing a secure and tamper-proof record of the wool’s journey.

Q 25. What are the key performance indicators (KPIs) for wool production?

Key Performance Indicators (KPIs) for wool production are essential for measuring efficiency, profitability, and sustainability. They provide valuable insights for continuous improvement.

- Yield: The amount of clean wool obtained per sheep, measured in kilograms. A higher yield indicates efficient shearing and processing.

- Fiber Diameter: The average thickness of the wool fibers, measured in microns. This directly affects the wool’s softness, strength, and suitability for different applications. Finer fibers generally command higher prices.

- Fiber Length: The average length of the wool fibers. Longer fibers are usually stronger and more suitable for high-quality yarns.

- Clean Wool Percentage: The proportion of clean wool after scouring (removing impurities), indicating the efficiency of the processing. A higher percentage reflects less waste.

- Production Cost per Kilogram: The cost of producing one kilogram of clean wool, including shearing, processing, and transportation. Lower costs improve profitability.

- Sustainability Metrics: Indicators of environmental impact, such as water usage, carbon footprint, and land management practices.

Tracking these KPIs allows producers to identify areas for optimization, improving efficiency, and reducing costs, while also enhancing sustainability.

Q 26. Explain the difference between merino and cashmere wool.

Merino and cashmere are both luxurious wool fibers, but they differ significantly in their source, properties, and price.

- Source: Merino wool comes from Merino sheep, a breed known for its fine, soft fleece. Cashmere comes from the soft undercoat of cashmere goats.

- Fiber Diameter: Merino wool fibers are generally finer than cashmere, ranging from 15 to 24 microns, while cashmere is usually between 14 and 19 microns (although some can be finer). This difference affects the softness and warmth of the resulting fabrics.

- Softness and Warmth: Both are exceptionally soft, but cashmere is often considered even softer and more luxurious due to its finer fibers and unique structure. Cashmere also offers superior warmth-to-weight ratio.

- Durability: Merino wool is known for its durability and resilience, whereas cashmere is more delicate and requires more careful handling.

- Price: Cashmere is significantly more expensive than Merino wool due to its rarity, the smaller amount of fiber obtained from each goat, and its higher processing costs.

The choice between Merino and cashmere depends on the desired balance of softness, warmth, durability, and price. Merino is a versatile option for various garments, while cashmere is often reserved for luxury apparel.

Q 27. Describe the process of blending different types of wool.

Blending different types of wool is a common practice used to achieve specific properties in the final fabric. It’s like mixing different ingredients in a recipe to create a unique flavor profile.

The process typically involves combining different wool fibers (e.g., Merino, coarser wools, recycled wool) during the carding and combing stages of yarn production. This ensures that the fibers are thoroughly mixed, creating a uniform blend. The proportions of each wool type are determined by the desired characteristics of the final fabric:

- Improving Softness: Adding finer wools like Merino to coarser wools will improve softness.

- Enhancing Strength: Blending strong, long-fiber wools with shorter, softer fibers improves the yarn’s overall strength and durability.

- Reducing Cost: Mixing more expensive, high-quality wools with less expensive wools can create a cost-effective fabric with acceptable quality.

- Modifying Texture: Blending wools with different textures can create interesting effects in the final fabric.

Careful selection of wool types and proportions is crucial to achieve the desired balance of properties. Sophisticated blending techniques can create fabrics with unique characteristics that are superior to using a single type of wool alone.

Q 28. How would you handle a situation where wool fiber quality is inconsistent?

Inconsistency in wool fiber quality is a serious issue that can negatively impact the final product and the brand’s reputation. My approach to handling this situation involves a multi-stage process:

- Identify the Source: The first step is to pinpoint the stage where the inconsistency occurred – was it during shearing, processing, or storage? Detailed traceability records are essential here.

- Analyze the Inconsistency: Determine the nature of the inconsistency. Is it related to fiber diameter, length, color, or other properties? Laboratory testing might be needed to quantify the variations.

- Isolate Affected Batches: Once the source and nature of the inconsistency are understood, it’s important to isolate the affected batches of wool to prevent them from contaminating other materials.

- Implement Corrective Actions: Depending on the severity of the inconsistency and the stage where it occurred, corrective actions might include:

- Adjusting processing parameters (e.g., carding, combing)

- Reclaiming or re-processing affected batches

- Discarding severely affected materials

- Implement Preventative Measures: To avoid future inconsistencies, review all processes involved in wool handling and processing, focusing on identifying and eliminating potential sources of variation. This might include improvements in quality control procedures or adjustments to storage conditions.

- Monitor and Evaluate: Regularly monitor wool fiber quality throughout the production process to detect and address any new inconsistencies promptly.

This systematic approach ensures that the issue is addressed effectively, minimizing its impact on the final product and preventing future occurrences.

Key Topics to Learn for Your Wool Industry Knowledge Interview

- Fiber Properties: Understanding wool fiber characteristics (fineness, length, strength, crimp, elasticity), their impact on yarn quality, and different wool types (Merino, Shetland, etc.). Practical application: Analyzing fiber samples to assess suitability for specific end-products.

- Wool Production: Familiarize yourself with sheep breeds, shearing practices, wool grading and classing, and the supply chain from farm to factory. Practical application: Evaluating the efficiency and sustainability of different production methods.

- Yarn Manufacturing: Learn about spinning processes (worsted, woolen), yarn counts, and the relationship between yarn structure and fabric properties. Practical application: Troubleshooting issues in yarn production or suggesting improvements to existing processes.

- Fabric Production: Gain knowledge of weaving, knitting, and non-woven fabric production methods, and how they affect the final fabric’s performance and characteristics. Practical application: Selecting appropriate fabric structures for different garments or applications.

- Finishing and Dyeing: Understand the various finishing processes (scouring, carbonizing, felting) and dyeing techniques used to enhance wool fabrics’ properties and appearance. Practical application: Assessing the environmental impact of different finishing treatments.

- Quality Control and Testing: Learn about standard testing methods used to assess wool fiber and fabric quality (e.g., fiber diameter measurement, strength testing, colorfastness testing). Practical application: Implementing quality control measures to ensure consistent product quality.

- Sustainability and Ethical Sourcing: Understand the environmental and ethical considerations within the wool industry, including responsible sheep farming, water usage, and waste management. Practical application: Identifying and implementing sustainable practices within a wool production or manufacturing environment.

Next Steps

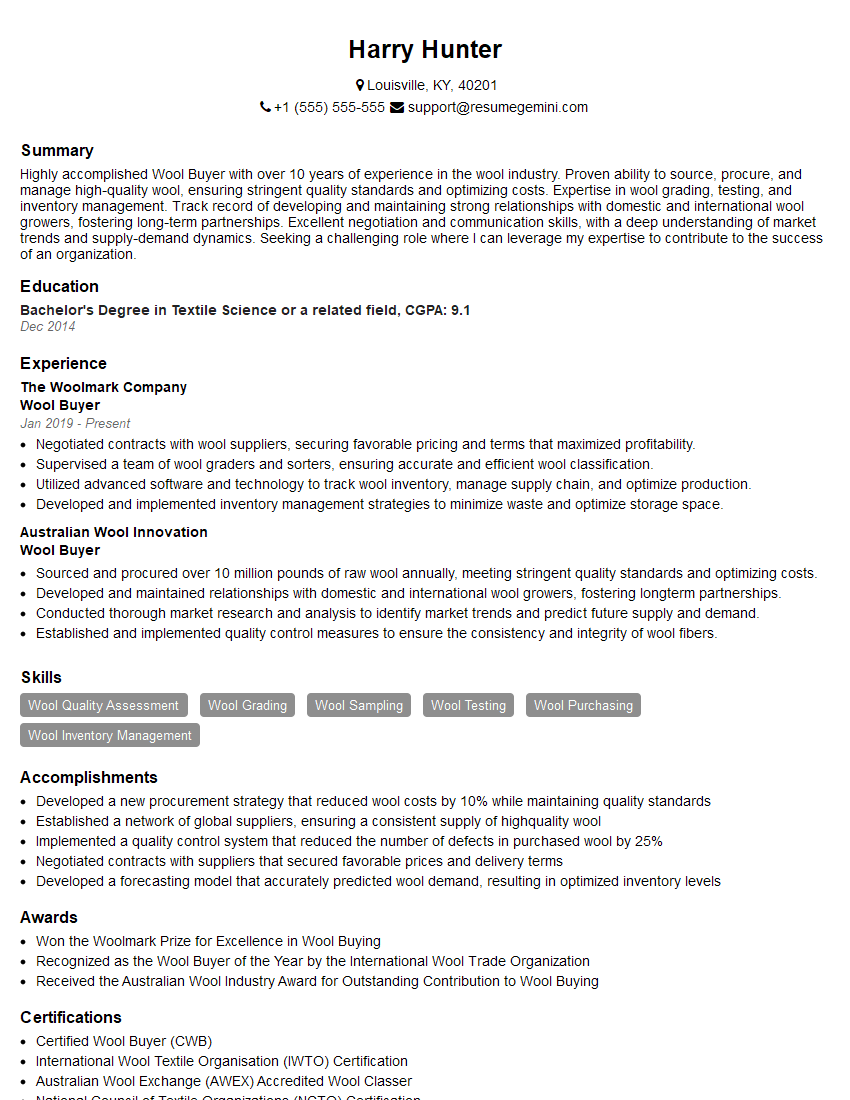

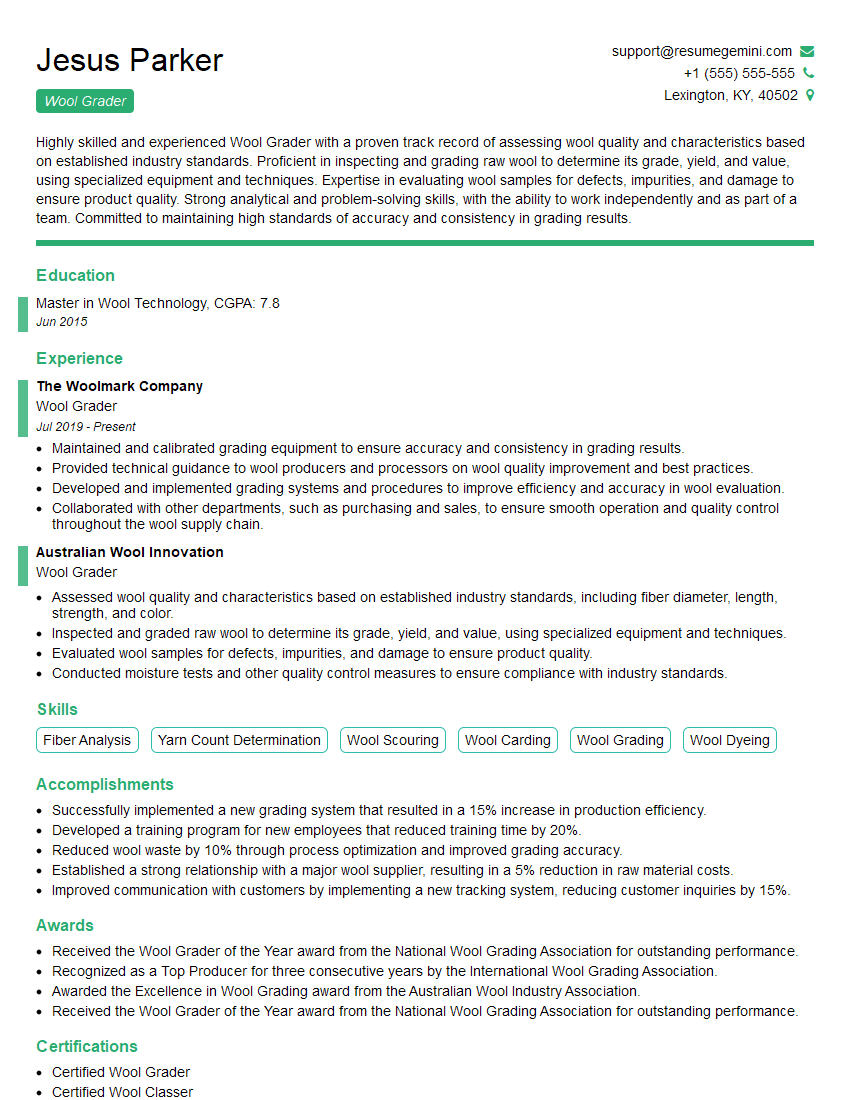

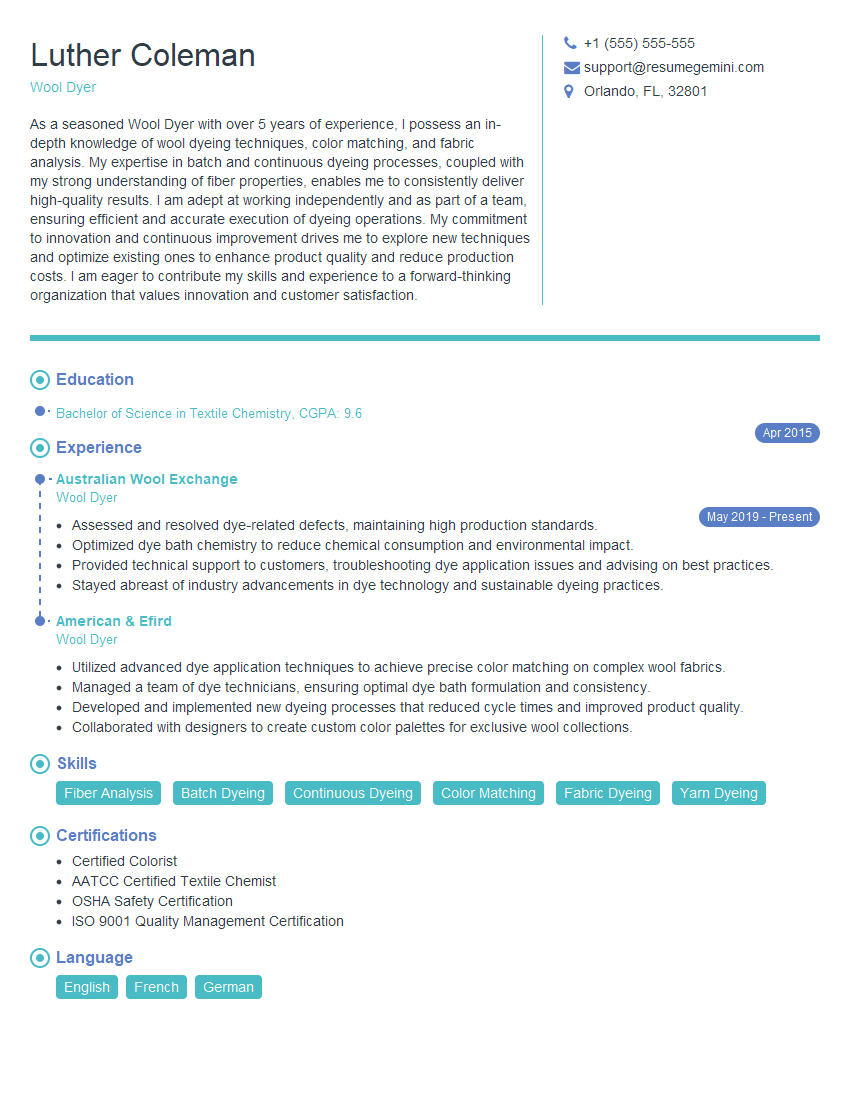

Mastering wool industry knowledge is crucial for career advancement, opening doors to specialized roles and higher earning potential. A strong understanding of these topics will significantly improve your interview performance and demonstrate your commitment to the industry. To maximize your job prospects, creating a compelling and ATS-friendly resume is paramount. ResumeGemini is a trusted resource to help you build a professional and effective resume tailored to the wool industry. We offer examples of resumes specifically designed to showcase wool industry knowledge, helping you present your skills and experience in the best possible light. Take the next step towards your dream career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good