Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Workplace Hygiene and Sanitation interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Workplace Hygiene and Sanitation Interview

Q 1. Explain your understanding of the Hazard Analysis and Critical Control Points (HACCP) system.

HACCP, or Hazard Analysis and Critical Control Points, is a preventative system for ensuring food safety. Instead of simply reacting to contamination, HACCP proactively identifies potential hazards at every stage of food production, processing, and serving, and then puts controls in place to prevent or eliminate those hazards. Think of it like a detailed roadmap to food safety, preventing problems before they arise.

It involves seven principles:

- Conduct a hazard analysis: Identify potential biological, chemical, and physical hazards that could contaminate food.

- Determine critical control points (CCPs): Identify steps in the process where hazards can be prevented, eliminated, or reduced to safe levels. These are crucial points that require strict monitoring.

- Establish critical limits: Set measurable criteria for each CCP to ensure it’s under control. For example, a CCP might be cooking temperature, and the critical limit could be 165°F (74°C).

- Establish monitoring procedures: Regularly monitor CCPs to ensure critical limits are met. This might involve using thermometers, visual inspections, or other methods.

- Establish corrective actions: Define actions to take if a CCP deviates from its critical limits. This could involve discarding contaminated food, retraining staff, or adjusting equipment settings.

- Establish verification procedures: Regularly verify that the HACCP plan is working effectively. This could involve auditing the process, reviewing records, or conducting environmental monitoring.

- Establish record-keeping and documentation procedures: Maintain detailed records of all HACCP activities. This is essential for traceability and accountability.

For example, in a restaurant, a CCP could be the handwashing station. The critical limit would be proper handwashing techniques and frequency. Monitoring would involve observing staff handwashing practices. Corrective action would include retraining employees on proper handwashing if deficiencies are observed.

Q 2. Describe your experience with developing and implementing hygiene and sanitation protocols.

In my previous role at a large-scale catering company, I was instrumental in developing and implementing comprehensive hygiene and sanitation protocols. This involved a multi-faceted approach, starting with a thorough risk assessment of the entire food handling process. We identified high-risk areas like food preparation, storage, and serving, and tailored protocols accordingly. We developed detailed Standard Operating Procedures (SOPs) with step-by-step instructions, using visual aids and checklists to ensure consistent application. These SOPs covered everything from personal hygiene practices (handwashing, uniform standards) to equipment sanitation, cleaning schedules, and waste disposal. I also implemented a robust training program for all staff, incorporating practical demonstrations and regular refresher courses to maintain proficiency. Regular audits and inspections were carried out to ensure compliance, with corrective actions promptly implemented where necessary. The effectiveness of our protocols was demonstrably successful, resulting in a significant reduction in foodborne illness incidents and improved overall workplace hygiene.

Q 3. What are the key differences between cleaning, sanitizing, and disinfecting?

Cleaning, sanitizing, and disinfecting are all crucial aspects of hygiene, but they have distinct roles:

- Cleaning removes visible soil, food residue, and other contaminants from surfaces. Think of it as the first step – getting rid of the obvious dirt.

- Sanitizing reduces the number of microorganisms on a surface to a safe level. It doesn’t necessarily kill all microbes, but brings the level down to an acceptable range. This is usually achieved through heat or chemical sanitizers.

- Disinfecting kills or inactivates most microorganisms on a surface. This is typically done with chemical disinfectants, and it’s used in situations where a higher level of microbial reduction is required, such as after a spill of potentially harmful substances.

Imagine cleaning a kitchen counter: First, you’d clean it with soap and water to remove food scraps. Then you might sanitize it with a chemical sanitizer to further reduce bacteria. If someone spilled raw meat juice on the counter, you’d likely disinfect it after cleaning to kill any potentially harmful pathogens.

Q 4. How would you address a suspected outbreak of foodborne illness in a workplace?

Responding to a suspected foodborne illness outbreak requires immediate and decisive action. The first step is to initiate an internal investigation, interviewing affected individuals to identify common food items consumed and possible points of contamination. Simultaneously, we would isolate any potentially contaminated food products and suspend use of suspect equipment. We’d immediately contact the relevant health authorities (e.g., public health department) to report the incident and cooperate fully with their investigation. A thorough environmental sampling would be conducted to test food, surfaces, and equipment for pathogens. This includes collecting samples from suspected points of contamination, such as refrigerators, cutting boards, and preparation areas. We would implement enhanced cleaning and disinfection procedures, focusing on identified high-risk areas. Depending on the findings of the investigation, we might need to recall potentially contaminated products or implement more rigorous food safety practices. Employee retraining on hygiene and food handling may also be required. Detailed records of the outbreak, investigation, and corrective actions would be meticulously documented.

Q 5. What are the common sources of workplace contamination and how can they be controlled?

Workplace contamination can stem from various sources:

- Foodborne pathogens: Bacteria, viruses, and parasites can contaminate food through improper handling, inadequate cooking, cross-contamination, and insufficient refrigeration.

- Poor personal hygiene: Unwashed hands, coughing or sneezing near food, and inadequate clothing can introduce pathogens to the food handling environment.

- Contaminated equipment and surfaces: Dirty cutting boards, utensils, and work surfaces can harbor microorganisms and facilitate cross-contamination.

- Pests: Rodents, insects, and birds can contaminate food and surfaces with pathogens and their droppings.

- Improper waste disposal: Incorrect storage and disposal of waste can attract pests and create breeding grounds for microorganisms.

Control measures include:

- Strict hygiene protocols: Implementing and enforcing thorough handwashing procedures, proper clothing, and employee training on food safety.

- Regular cleaning and sanitizing: Establishing and adhering to regular cleaning and sanitizing schedules for equipment and work surfaces.

- Pest control: Implementing a robust pest control program to prevent pest infestation.

- Proper food storage: Maintaining appropriate temperatures and using proper storage containers to prevent food spoilage and cross-contamination.

- Effective waste management: Properly storing and disposing of waste to avoid attracting pests and promoting microbial growth.

Q 6. Describe your experience with various cleaning and disinfection agents and their appropriate applications.

My experience encompasses a wide range of cleaning and disinfection agents, including quaternary ammonium compounds (quats), chlorine-based disinfectants, iodine-based sanitizers, and peracetic acid. The choice of agent depends heavily on the specific application and the type of microorganism being targeted. Quats are commonly used for general sanitizing of food contact surfaces; they are relatively non-corrosive and effective against a range of bacteria. Chlorine-based disinfectants are powerful but can be corrosive and require careful handling. Iodine-based sanitizers are often used in food processing, offering broad-spectrum antimicrobial activity. Peracetic acid is a potent disinfectant effective against a wider range of microorganisms including spores, often used in more demanding settings. Crucially, proper dilution and contact time are paramount to ensure efficacy and prevent damage to surfaces. I always adhere to manufacturer’s instructions for use and safety precautions when handling these chemicals. Safety Data Sheets (SDS) are consulted to understand potential hazards and appropriate handling procedures, and Personal Protective Equipment (PPE) like gloves and eye protection is used as required.

Q 7. How do you ensure compliance with relevant health and safety regulations?

Ensuring compliance with health and safety regulations is paramount. This begins with a thorough understanding of relevant legislation, such as the FDA Food Code in the US, or equivalent regulations in other jurisdictions. We maintain up-to-date knowledge of these regulations through continuous professional development and engagement with regulatory bodies. A comprehensive hygiene program, including documented SOPs, training records, and audit trails, forms the core of our compliance strategy. Regular internal audits and inspections ensure that our protocols are consistently followed. We actively seek external audits and inspections, treating these as opportunities for improvement rather than mere compliance exercises. Corrective actions are swiftly implemented in response to any identified non-compliance issues. Documentation is meticulously maintained, providing a clear and auditable record of our activities and demonstrating our commitment to meeting the highest hygiene and safety standards.

Q 8. Explain your understanding of personal protective equipment (PPE) and its importance in hygiene and sanitation.

Personal Protective Equipment (PPE) refers to the barriers and safeguards used to protect individuals from exposure to hazardous substances or situations in the workplace. In hygiene and sanitation, PPE is crucial for preventing the spread of pathogens and protecting workers from potential harm. Its importance lies in minimizing risk of infection, injury, and contamination.

- Examples of PPE relevant to hygiene and sanitation: Gloves (nitrile, latex, etc.), gowns or aprons, eye protection (goggles, face shields), respirators (N95 masks, etc.), and footwear (boots, closed-toe shoes).

- Importance: Imagine cleaning a biohazard spill without gloves; the risk of infection is significantly high. Similarly, without eye protection, splashes of cleaning agents could cause serious eye damage. PPE provides a critical layer of protection, minimizing these risks.

- Selection of PPE: The type of PPE required depends on the specific task. For example, cleaning a toilet requires different PPE than handling a blood spill. Proper risk assessments must precede PPE selection to guarantee effective protection.

Q 9. How would you train employees on proper hygiene and sanitation practices?

Training employees on proper hygiene and sanitation practices is a multifaceted process requiring a blend of theory and practical application. A comprehensive program should include:

- Initial Training: This involves a detailed explanation of hygiene principles, sanitation procedures, the importance of handwashing, and correct use of PPE. Interactive sessions, videos, and demonstrations are effective.

- Hands-on Practice: Practical training is crucial; employees should be guided through the correct methods of cleaning and disinfecting different surfaces and equipment. Role-playing scenarios can simulate real-world situations.

- Regular Refresher Training: Hygiene and sanitation protocols evolve; regular refresher training ensures employees stay updated on best practices and new technologies. This might involve short quizzes or updated training modules.

- Feedback and Evaluation: Continuous feedback helps identify areas needing improvement. Regular evaluations, including observations and practical assessments, ensure the effectiveness of the training.

- Documentation: Maintaining comprehensive training records demonstrates compliance and facilitates tracking employee progress.

For example, I’d use a combination of presentations, videos showing correct handwashing techniques, and supervised practice sessions cleaning a mock-up restroom. Post-training quizzes and observation during actual work would assess knowledge retention and skill proficiency.

Q 10. How do you monitor and evaluate the effectiveness of hygiene and sanitation programs?

Monitoring and evaluating hygiene and sanitation programs involves a multi-pronged approach to ensure effectiveness and identify areas for improvement. This includes:

- Regular Inspections: Scheduled inspections of work areas are essential to assess cleanliness, identify potential hazards, and ensure compliance with established protocols. Checklists and scoring systems can streamline this process.

- Environmental Monitoring: Swab testing of surfaces can reveal the presence of microbial contamination, providing objective data on cleaning effectiveness. This data helps target areas requiring additional attention.

- Data Analysis: Tracking key performance indicators (KPIs), such as the frequency of reported infections or the number of non-compliances, provides insights into the program’s impact. Trends in data can highlight areas for improvement or indicate the need for modified protocols.

- Employee Feedback: Gathering feedback from employees through surveys or interviews helps identify challenges and areas where additional support or training may be needed. Anonymous feedback mechanisms are crucial for honesty.

- Audits: Internal or external audits provide an independent assessment of the program’s effectiveness against established standards and regulations.

For instance, I’d use a combination of regular visual inspections, monthly swab testing of high-touch surfaces, and an annual comprehensive audit to ensure our program maintains high standards.

Q 11. Describe your experience with waste management and disposal protocols.

Waste management and disposal protocols are paramount in maintaining hygiene and sanitation. My experience encompasses proper segregation of waste streams, adhering to relevant regulations, and ensuring safe disposal. This includes:

- Segregation: Different types of waste (e.g., general waste, recyclable materials, biohazardous waste, sharps) require specific handling and disposal methods. Proper labeling and segregation are critical.

- Biohazardous Waste: Biohazardous waste, such as blood or contaminated materials, needs careful handling and disposal according to stringent regulations. This often includes using leak-proof containers, autoclaving (sterilizing under high pressure and temperature), and specialized waste disposal services.

- Sharps Management: Sharps disposal requires puncture-resistant containers and specialized handling procedures to prevent injuries. Proper training is vital for personnel handling sharps.

- Record Keeping: Maintaining accurate records of waste generation, disposal methods, and waste transporter information is essential for compliance and traceability.

For example, in a healthcare setting, I’ve overseen the implementation of a color-coded waste management system, ensuring proper segregation and disposal of all waste types, strictly following all relevant safety and regulatory requirements.

Q 12. What are your methods for preventing cross-contamination?

Preventing cross-contamination—the transfer of pathogens from one surface or item to another—is vital for maintaining hygiene. My methods include:

- Proper Cleaning and Disinfection: Cleaning removes visible dirt and debris, while disinfection eliminates pathogens. Following a systematic cleaning process, from least to most contaminated areas, is key.

- Dedicated Equipment: Using color-coded cleaning equipment for different areas (e.g., restrooms, food preparation areas) prevents accidental cross-contamination.

- Hand Hygiene: Frequent and thorough handwashing is perhaps the single most effective method for preventing cross-contamination. Hand sanitizers can be used as a supplementary measure.

- Proper Storage of Cleaning Supplies: Storing cleaning supplies in designated areas, away from food preparation areas, helps prevent accidental contamination.

- Protective Clothing: Using appropriate PPE (gloves, gowns) minimizes the risk of transferring pathogens from contaminated surfaces to clean ones.

Imagine a kitchen: Using separate cutting boards for raw meat and vegetables prevents cross-contamination that could lead to foodborne illnesses. This same principle applies across many settings.

Q 13. Explain your knowledge of different types of disinfectants and their effectiveness against various pathogens.

Various disinfectants possess different properties and effectiveness against various pathogens. The choice of disinfectant depends on the target pathogen and the surface being disinfected.

- Types of Disinfectants: Common types include alcohol-based solutions (e.g., isopropyl alcohol), chlorine-based solutions (bleach), quaternary ammonium compounds (quats), and hydrogen peroxide. Each has its strengths and weaknesses.

- Effectiveness: Alcohol is effective against many bacteria and viruses, but not spores. Chlorine bleach is a broad-spectrum disinfectant, effective against a wide range of pathogens, including spores, but can be corrosive to some surfaces. Quats are effective against many bacteria, but less so against viruses and spores. Hydrogen peroxide is effective against a broad spectrum of microorganisms and is less corrosive.

- Factors affecting effectiveness: Contact time (how long the disinfectant remains on the surface), concentration, temperature, and the presence of organic matter all influence the effectiveness of a disinfectant.

- Labeling and Instructions: Always follow the manufacturer’s instructions on dilution and application. Using a disinfectant incorrectly can reduce its effectiveness or damage the surface.

For example, alcohol-based hand sanitizer is effective for everyday use against common bacteria and viruses, but for a surface contaminated with Clostridium difficile spores, a sporicidal disinfectant like chlorine bleach would be more appropriate. However, always consider material compatibility before selecting a disinfectant.

Q 14. How would you handle a situation involving a biohazard spill?

Handling a biohazard spill requires immediate action and strict adherence to established protocols to prevent exposure and contamination.

- Immediate Actions: The first step is to restrict access to the spill area, preventing further contamination. This involves evacuating personnel from the immediate vicinity.

- PPE: Don appropriate PPE, including gloves, gowns, eye protection, and a respirator, depending on the nature of the biohazard.

- Containment: Contain the spill using absorbent materials (e.g., spill kits) to prevent spread. Avoid splashing or aerosolization.

- Cleaning and Disinfection: Use an appropriate disinfectant, following manufacturer’s instructions, to decontaminate the affected area. This typically involves repeated cleaning and disinfection cycles.

- Disposal: Dispose of all contaminated materials (including PPE) according to established protocols for biohazardous waste.

- Documentation: Maintain a detailed record of the incident, including the type of biohazard, the steps taken, and the personnel involved.

- Post-Exposure Follow-up: Ensure appropriate medical evaluation and follow-up for any personnel potentially exposed to the biohazard.

For example, a blood spill would require immediate containment using absorbent pads, followed by disinfection with a suitable disinfectant, such as a 10% bleach solution, proper disposal of contaminated materials, and a thorough post-exposure assessment for those who may have been exposed.

Q 15. How do you ensure the proper maintenance and calibration of sanitation equipment?

Proper maintenance and calibration of sanitation equipment is crucial for ensuring effectiveness and preventing cross-contamination. Think of it like regularly servicing your car – neglecting it leads to breakdowns and poor performance. My approach involves a multi-pronged strategy.

Preventive Maintenance Schedules: I establish detailed schedules for routine cleaning, lubrication, and component checks based on manufacturer recommendations and equipment usage. This includes documenting each maintenance activity.

Calibration Procedures: For equipment like automated floor scrubbers or dishwashers that require precise measurements (e.g., chemical dispensing, water temperature), I implement regular calibration checks using certified instruments. Any deviations from set standards are documented and rectified immediately. For example, a discrepancy in chemical dispensing could lead to ineffective cleaning or damage to surfaces.

Staff Training: Thorough training is paramount. Staff are educated on proper equipment operation, cleaning procedures, and the importance of reporting any malfunctions promptly. We use hands-on training and checklists to ensure understanding. This prevents misuse and extends the lifespan of the equipment.

Record Keeping: Meticulous record-keeping is essential. We maintain detailed logs of all maintenance activities, calibrations, repairs, and any issues encountered. This allows for trend analysis, predictive maintenance, and compliance auditing.

For instance, in a previous role, I implemented a preventative maintenance program that reduced equipment downtime by 15% and extended the lifespan of our industrial dishwashers by two years.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with pest control strategies and implementation?

Effective pest control is not just about eliminating pests; it’s about preventing infestations. My experience encompasses integrated pest management (IPM) strategies, a holistic approach that minimizes pesticide use while maximizing effectiveness. It’s about proactively managing the environment to prevent problems rather than just reacting to them.

Identification & Monitoring: Accurate pest identification is the first step. I’d use traps and visual inspections to determine the type and extent of the infestation. Monitoring enables early detection, preventing larger-scale problems.

Sanitation & Exclusion: This is the cornerstone of IPM. We focus on eliminating food sources, water sources, and harborages. This involves regular cleaning, sealing cracks and crevices, and proper waste disposal. Think of it like denying a burglar access to your house.

Targeted Treatments: Only when necessary, we’d use targeted pest control methods. This might involve bait stations, traps, or, as a last resort, professional pest control services. We always prioritize environmentally friendly and safe solutions.

Documentation & Reporting: Detailed records of pest activity, treatments, and inspections are maintained to track effectiveness and compliance. This is crucial for audits and demonstrating proactive pest management.

In a previous food processing facility, I implemented an IPM program that reduced pest-related incidents by 80% within a year, significantly improving product safety and reducing the risk of costly shutdowns.

Q 17. Describe your experience in auditing hygiene practices.

My experience in auditing hygiene practices involves conducting thorough assessments to identify strengths, weaknesses, and areas needing improvement. I utilize a systematic approach that includes both document review and on-site observations. This is not just about finding fault, it’s about identifying opportunities for improvement.

Review of Documentation: I start by reviewing relevant documents such as cleaning schedules, training records, pest control reports, and equipment maintenance logs. Inconsistencies or gaps in documentation are flagged for investigation.

On-site Observation: Direct observation of hygiene practices is crucial. This involves observing staff performing their tasks, assessing the cleanliness of work areas, and checking equipment functionality. I use checklists to ensure consistency and thoroughness.

Interviews: Interviews with staff at all levels help to understand their perspectives on hygiene practices, identify any challenges, and gauge their training effectiveness.

Gap Analysis: Based on the documentation review, observations, and interviews, I perform a gap analysis comparing current practices against relevant standards (GMP, OSHA, etc.). This allows for prioritization of improvement efforts.

Report & Recommendations: A comprehensive report summarizing the findings, including areas of compliance and non-compliance, along with specific recommendations for improvement is developed and presented. This report acts as a roadmap for corrective action.

I’ve conducted numerous audits across various sectors, consistently identifying critical control points and facilitating the development of effective corrective actions. For instance, in a recent audit of a healthcare facility, I identified a critical gap in hand hygiene practices and developed a comprehensive training program that significantly improved compliance rates.

Q 18. What are the key performance indicators (KPIs) you would use to measure the success of a hygiene program?

Key Performance Indicators (KPIs) are essential for measuring the effectiveness of a hygiene program and demonstrating its value. These KPIs must be measurable, achievable, relevant, and time-bound (SMART). My typical KPIs include:

Infection rates (Healthcare): Tracking the number of infections helps measure the effectiveness of infection control measures.

Environmental contamination levels: Regular swab testing to detect microbial contamination on surfaces provides quantifiable data.

Pest incidents: Monitoring the number and types of pest sightings shows the effectiveness of pest control measures.

Compliance rates: Tracking staff adherence to hygiene protocols, such as handwashing or glove usage, helps assess training effectiveness.

Equipment downtime: Monitoring equipment malfunctions helps to assess the effectiveness of maintenance programs.

Employee training scores: Assessing employee understanding of hygiene procedures.

Audit scores: Monitoring compliance with relevant standards and guidelines.

Customer complaints: Monitoring complaints related to hygiene issues.

The choice of KPIs will depend on the specific context and objectives of the hygiene program. Regular review and adjustment of KPIs are necessary to ensure their continued relevance and usefulness.

Q 19. How familiar are you with relevant industry standards and guidelines (e.g., GMP, OSHA)?

I am very familiar with relevant industry standards and guidelines such as Good Manufacturing Practices (GMP), Occupational Safety and Health Administration (OSHA) regulations, and others relevant to specific sectors (e.g., HACCP for food safety). Understanding these guidelines is crucial for establishing effective and compliant hygiene programs. They provide a framework for best practices and help ensure worker safety and product quality. I regularly review updates to these standards to remain current with best practices and regulatory changes.

For example, my knowledge of GMP principles allows me to create cleaning validation programs that ensure the effectiveness of our sanitation procedures and meet regulatory requirements. Similarly, my understanding of OSHA regulations ensures that safety measures are in place to protect employees from hazards associated with cleaning chemicals and equipment.

Q 20. Describe your problem-solving skills related to hygiene and sanitation challenges.

Effective problem-solving in hygiene and sanitation requires a systematic approach. I typically use a structured methodology, similar to the scientific method, to tackle challenges:

Problem Definition: Clearly defining the problem is the first step. What specifically is going wrong? What are the symptoms and potential root causes?

Data Collection: Gathering relevant data through observation, interviews, and document review is critical for understanding the scope and nature of the problem.

Analysis: Analyzing the collected data to identify potential root causes is essential. This might involve using tools like fishbone diagrams or 5 Whys.

Solution Development: Based on the analysis, develop potential solutions. This usually involves brainstorming and considering multiple options.

Implementation: Select the most appropriate solution and implement it. This often involves pilot testing before full-scale rollout.

Evaluation: Evaluate the effectiveness of the solution through monitoring and data collection. Did it solve the problem? Are there any unintended consequences?

For example, when dealing with recurring bacterial contamination in a food processing plant, I utilized a root cause analysis to determine that inadequate employee training on cleaning procedures was the primary issue. I then developed and implemented a comprehensive training program that addressed this gap and significantly reduced contamination levels.

Q 21. How would you handle a conflict with an employee regarding hygiene protocols?

Handling conflicts regarding hygiene protocols requires a calm, professional, and constructive approach. My strategy focuses on understanding the employee’s perspective while ensuring compliance with established procedures.

Private Conversation: I would initiate a private conversation with the employee to understand their concerns and perspective. Active listening is crucial here. Why are they not following the protocols?

Clarification & Education: I would clearly explain the importance of the hygiene protocol, emphasizing its role in safety, quality, and compliance. Any misunderstandings or ambiguities would be addressed.

Collaborative Problem-Solving: Where possible, I would work collaboratively with the employee to identify solutions that address their concerns while upholding the hygiene standards. Perhaps there are practical challenges that need to be addressed.

Documentation & Follow-up: The conversation, any agreed-upon solutions, and the follow-up actions would be documented. Further follow-up would be scheduled to monitor compliance and address any ongoing issues.

Progressive Discipline (if necessary): If the non-compliance persists despite attempts to address the issues collaboratively, then progressive disciplinary measures would be implemented in accordance with company policies. This should be a last resort.

My goal is always to foster a positive and collaborative work environment where hygiene protocols are understood and followed. Constructive feedback and support are more effective in the long run than punitive measures.

Q 22. How do you prioritize hygiene tasks in a fast-paced environment?

Prioritizing hygiene tasks in a fast-paced environment requires a strategic approach combining urgency and efficiency. Think of it like a triage system in a hospital – addressing the most critical needs first.

- High-Risk Areas First: Identify high-traffic areas (entrances, restrooms, break rooms) and areas with potential for high contamination (food preparation areas, medical equipment). These get prioritized for cleaning and disinfection.

- Frequency Based on Use: High-use areas need more frequent cleaning than low-use areas. Restrooms, for example, might require cleaning every few hours, while a rarely used storage room may only need weekly attention.

- Time Blocking and Scheduling: Implementing a cleaning schedule with specific time blocks allocated for different tasks ensures consistency. This schedule needs to be flexible to accommodate unexpected spills or messes, but having a baseline plan is crucial.

- Teamwork and Communication: Clear communication within the cleaning team is essential. Using checklists, task assignments, and real-time updates helps ensure all areas are addressed efficiently. A well-trained team can anticipate needs and adapt to changing priorities.

- Data-Driven Decisions: Tracking cleaning frequency, areas cleaned, and identified contamination helps refine the prioritization process over time. This data-driven approach enables continuous improvement.

For example, in a busy hospital, cleaning and disinfecting patient rooms and surgical areas would take top priority over cleaning less frequently used administrative offices.

Q 23. What are the different types of hand hygiene techniques and when should each be used?

Hand hygiene is fundamental to infection control. Different techniques are needed depending on the level of contamination.

- Handwashing with Soap and Water: This is the gold standard for most situations. It’s effective at removing visible soil, transient bacteria, and viruses. It should be performed for at least 20 seconds, covering all surfaces of the hands and fingers.

- Alcohol-Based Hand Rub (ABHR): ABHRs are quicker and more convenient than handwashing, making them ideal when soap and water aren’t readily available. They are highly effective against many bacteria and viruses, but less so against certain types of spores or heavily soiled hands. Always check the alcohol concentration – at least 60% is generally recommended.

- Surgical Hand Scrub: Used before surgical procedures, this involves a more rigorous cleansing process, often with an antimicrobial agent, to reduce the bacterial count on the hands to a minimum. It usually involves scrubbing for a longer duration and using a specific technique.

When to use each technique: Use handwashing when hands are visibly soiled or after handling contaminated materials. Use ABHR when hands are not visibly soiled and you are in a setting where handwashing is inconvenient (e.g., during patient rounds in a hospital). Surgical hand scrubs are reserved exclusively for surgical procedures and other sterile procedures.

Q 24. Describe your experience with implementing a color-coded cleaning system.

Implementing a color-coded cleaning system significantly improves hygiene standards and helps avoid cross-contamination. Imagine a hospital – a simple color-coded system can easily distinguish mops and cloths used in bathrooms from those used in patient rooms.

In my previous role, we implemented a system using four colors: Red (restrooms), Green (general areas), Yellow (food preparation), and Blue (patient care). Each color was assigned specific cleaning tools (mops, buckets, cloths) and designated areas. This included clearly labeled storage areas for each color-coded set to prevent mixing. We provided training to the cleaning staff on the proper use of the system and the importance of avoiding cross-contamination. We also regularly audited compliance with the system. The results were impressive – we saw a significant reduction in reported infections, particularly in high-risk areas.

The key to success is comprehensive training, readily available resources (e.g., clearly labeled tools and storage areas), and consistent monitoring. The system should be simple to understand and implement, so it can be easily adopted and maintained. Regular audits help maintain standards and identify any areas for improvement.

Q 25. How do you stay updated on the latest advancements in hygiene and sanitation technologies?

Staying updated is critical in this field. New technologies and best practices are constantly emerging. I employ several strategies:

- Professional Organizations: Active membership in organizations like the Association for Professionals in Infection Control and Epidemiology (APIC) provides access to journals, conferences, and webinars featuring the latest research and advancements.

- Industry Publications: I regularly read peer-reviewed journals, industry magazines, and online resources to stay abreast of new technologies, regulations, and best practices. Examples include publications like the Journal of Infection Prevention.

- Conferences and Workshops: Attending industry conferences and workshops offers opportunities to learn from experts, network with peers, and see demonstrations of new technologies.

- Online Courses and Webinars: Many reputable organizations offer online courses and webinars on various aspects of hygiene and sanitation. These provide a convenient and accessible way to stay updated.

- Regulatory Updates: Staying informed about changes in regulations and standards (e.g., OSHA guidelines) is crucial to ensuring compliance and maintaining best practices.

Continuous learning is essential to adapting to the ever-changing landscape of hygiene and sanitation.

Q 26. What is your experience with using hygiene monitoring devices (e.g., ATP meters)?

ATP meters are invaluable tools for verifying the effectiveness of cleaning and disinfection procedures. ATP (adenosine triphosphate) is present in all living organisms, so measuring ATP levels provides an indication of the amount of organic matter remaining on a surface after cleaning. Think of it like a quick ‘contamination check’.

My experience involves using ATP meters to assess cleanliness in various settings, including food processing facilities, hospitals, and healthcare facilities. The process typically involves swabbing a surface, inserting the swab into the meter, and obtaining a relative light unit (RLU) reading. A lower RLU value indicates a cleaner surface. We use the data obtained from ATP meters to identify areas needing improvement and to track the effectiveness of our cleaning protocols over time. This data-driven approach allows for continuous improvement and ensures that cleaning processes are effective.

It’s important to remember that ATP meters are a supplementary tool. They don’t replace visual inspection and proper cleaning techniques. However, they provide objective data that can be used to validate cleaning processes and ensure compliance with hygiene standards.

Q 27. Explain your understanding of the importance of proper ventilation in maintaining workplace hygiene.

Proper ventilation plays a vital role in maintaining workplace hygiene by controlling the spread of airborne contaminants and reducing the buildup of moisture and odors. Imagine a poorly ventilated kitchen – the smells and airborne particles quickly accumulate, creating an unpleasant and potentially unhealthy environment.

Effective ventilation systems remove dust, pollutants, moisture, and odors, improving air quality and minimizing the risk of infection. They also help to prevent the growth of mold and mildew, which can cause respiratory problems and other health issues. The type of ventilation system required depends on the specific workplace and the types of contaminants present. This could range from simple exhaust fans to complex HVAC systems with filtration and air circulation controls. Regular maintenance and filter changes are critical to ensure the ventilation system operates effectively.

In a healthcare setting, proper ventilation is crucial to preventing the spread of airborne pathogens. In industrial settings, it helps to control the spread of dust and other particulate matter. Regardless of the workplace type, adequate ventilation is a cornerstone of a healthy and productive work environment.

Key Topics to Learn for Workplace Hygiene and Sanitation Interview

- Infection Prevention and Control: Understanding the chain of infection, standard precautions, and the use of personal protective equipment (PPE).

- Cleaning and Disinfection Procedures: Practical application of cleaning and disinfecting protocols for various surfaces and equipment; knowledge of different disinfectants and their appropriate use.

- Waste Management: Safe handling, segregation, and disposal of different types of waste (e.g., infectious, hazardous, general waste) according to regulations.

- Food Safety and Hygiene: Principles of food safety, including temperature control, proper food storage, and prevention of cross-contamination.

- Pest Control: Strategies for preventing and controlling pest infestations, including identification of common pests and appropriate treatment methods.

- Hand Hygiene: The importance of proper handwashing techniques and the use of hand sanitizers.

- Regulatory Compliance: Familiarity with relevant health and safety regulations and standards related to workplace hygiene and sanitation.

- Risk Assessment and Mitigation: Identifying potential hygiene and sanitation risks in the workplace and developing strategies to mitigate them.

- Training and Education: Developing and delivering training programs on workplace hygiene and sanitation to employees.

- Auditing and Monitoring: Conducting regular audits and inspections to ensure compliance with hygiene and sanitation standards.

Next Steps

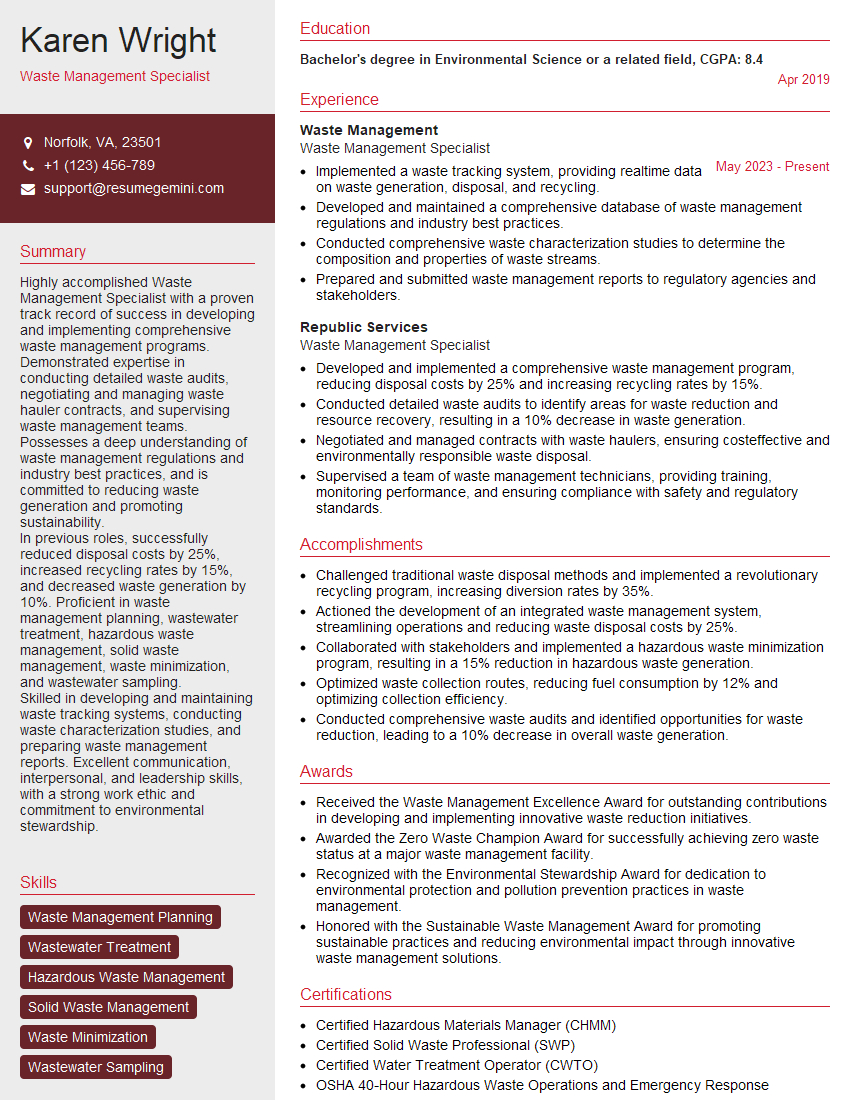

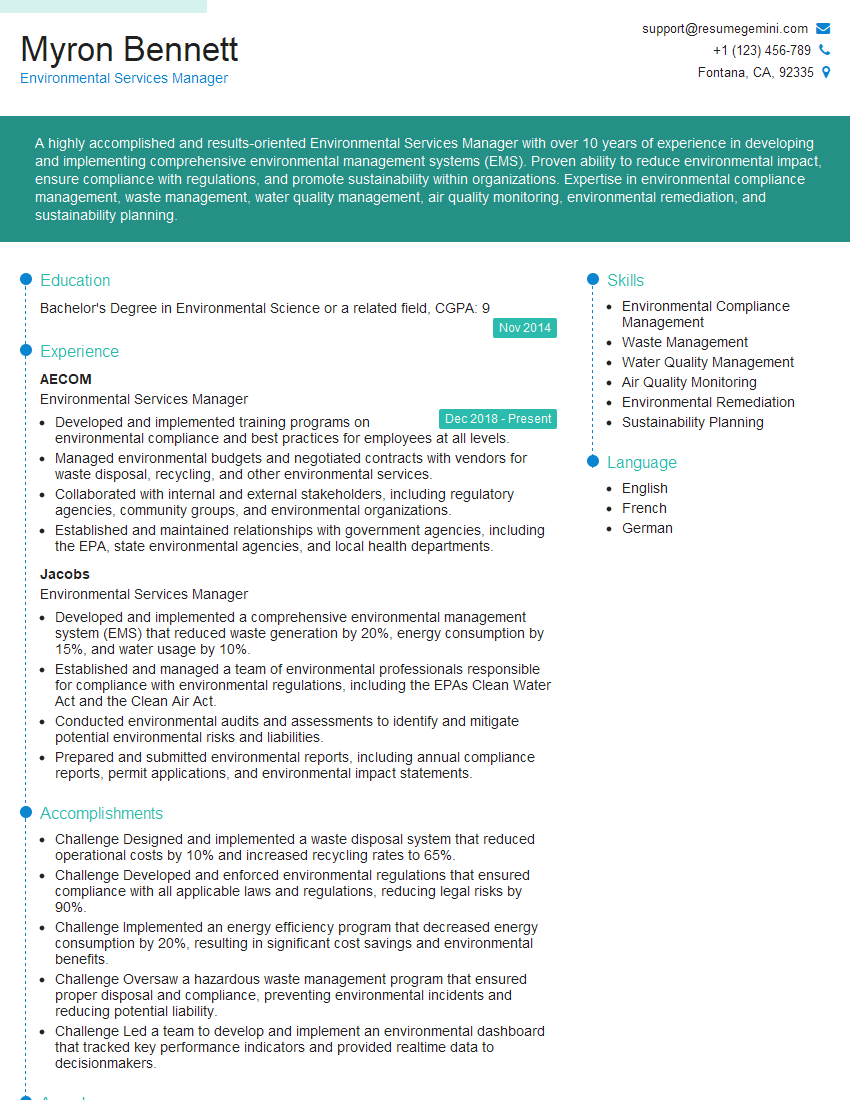

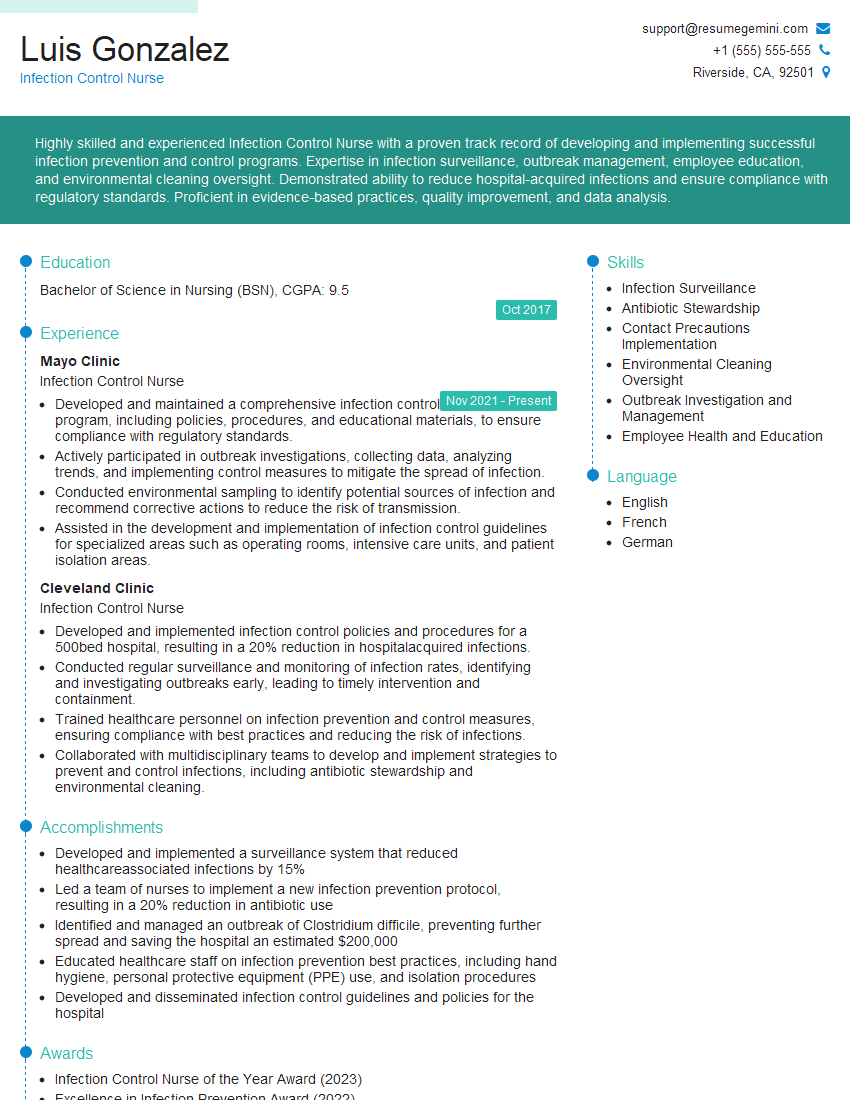

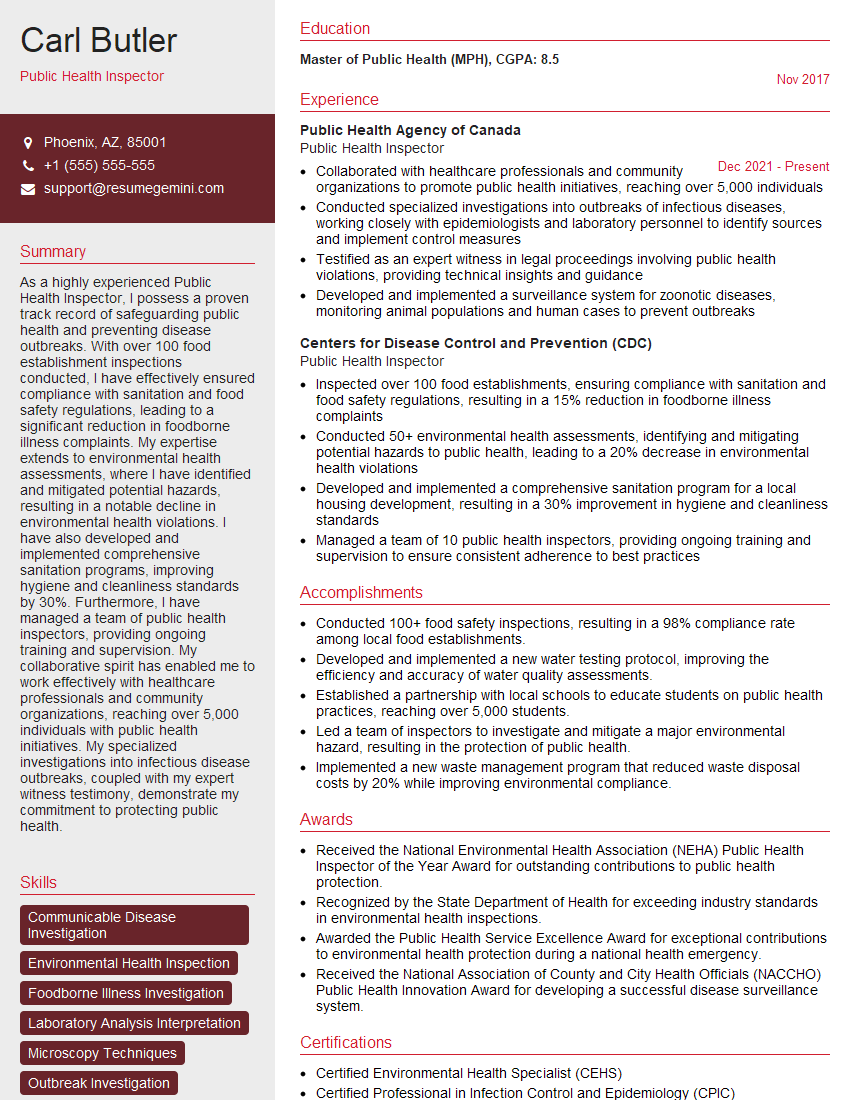

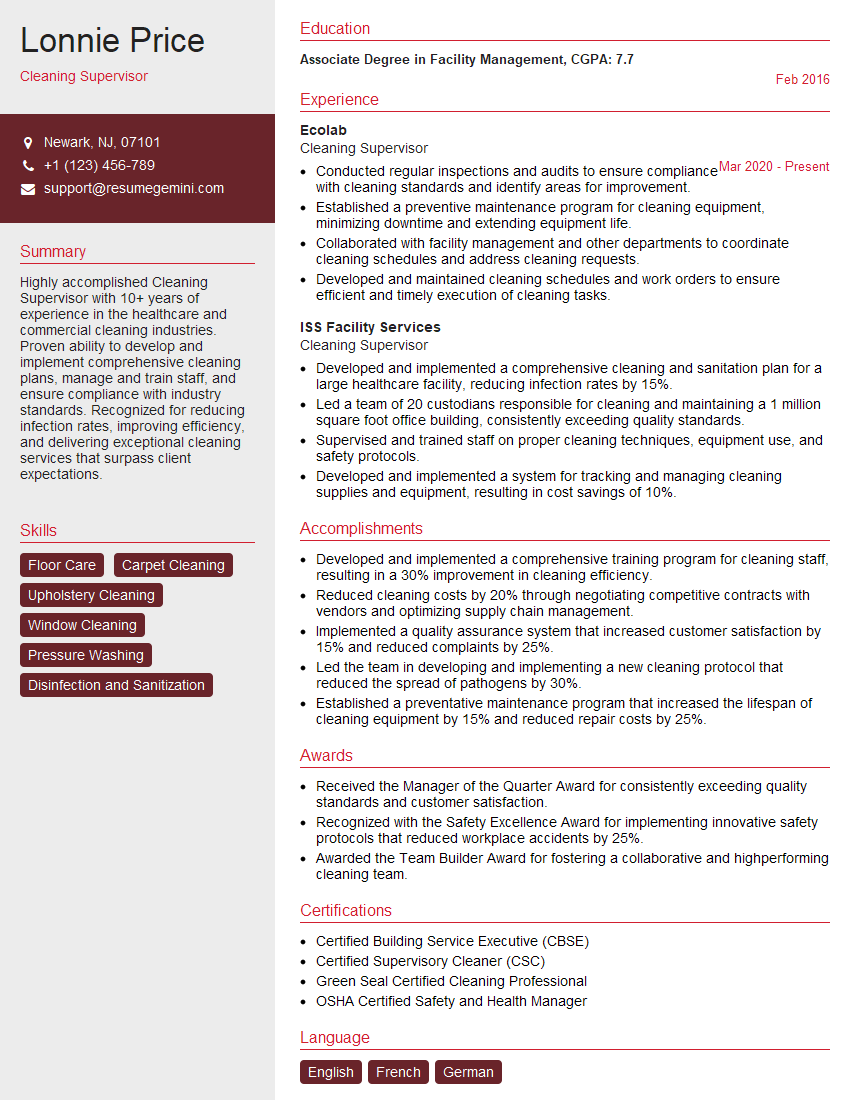

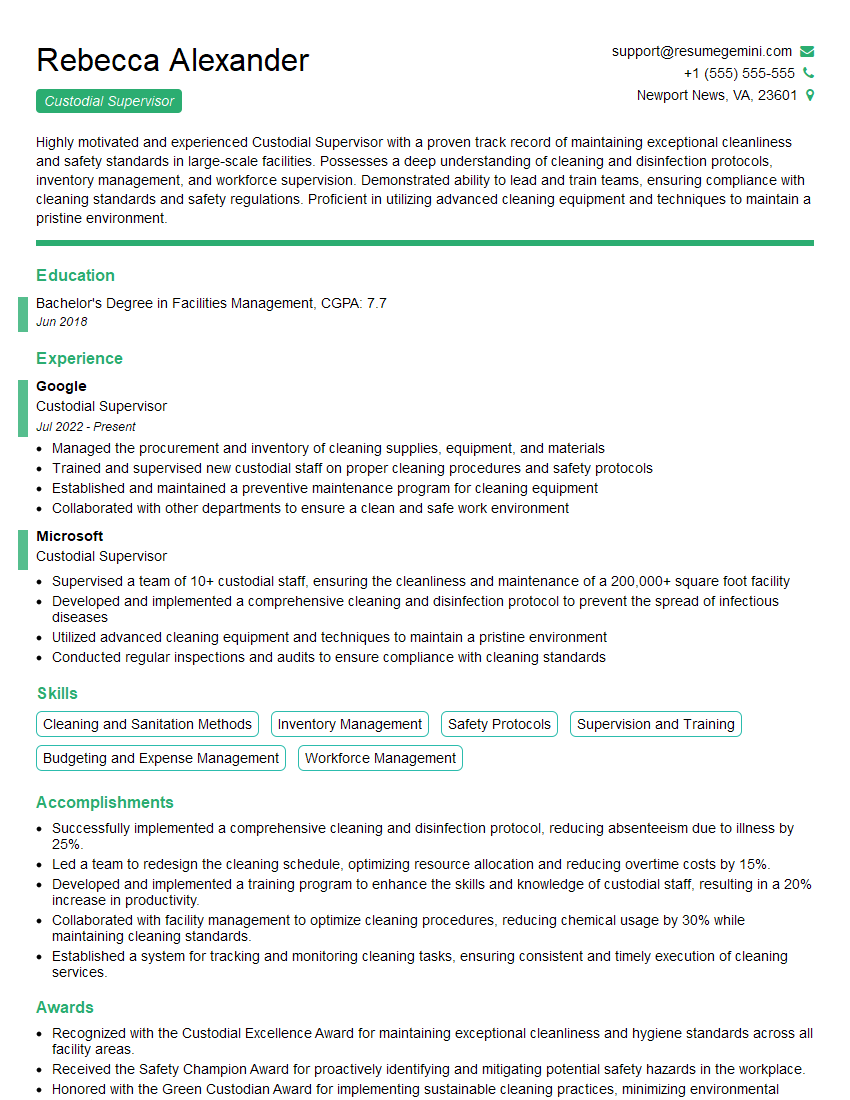

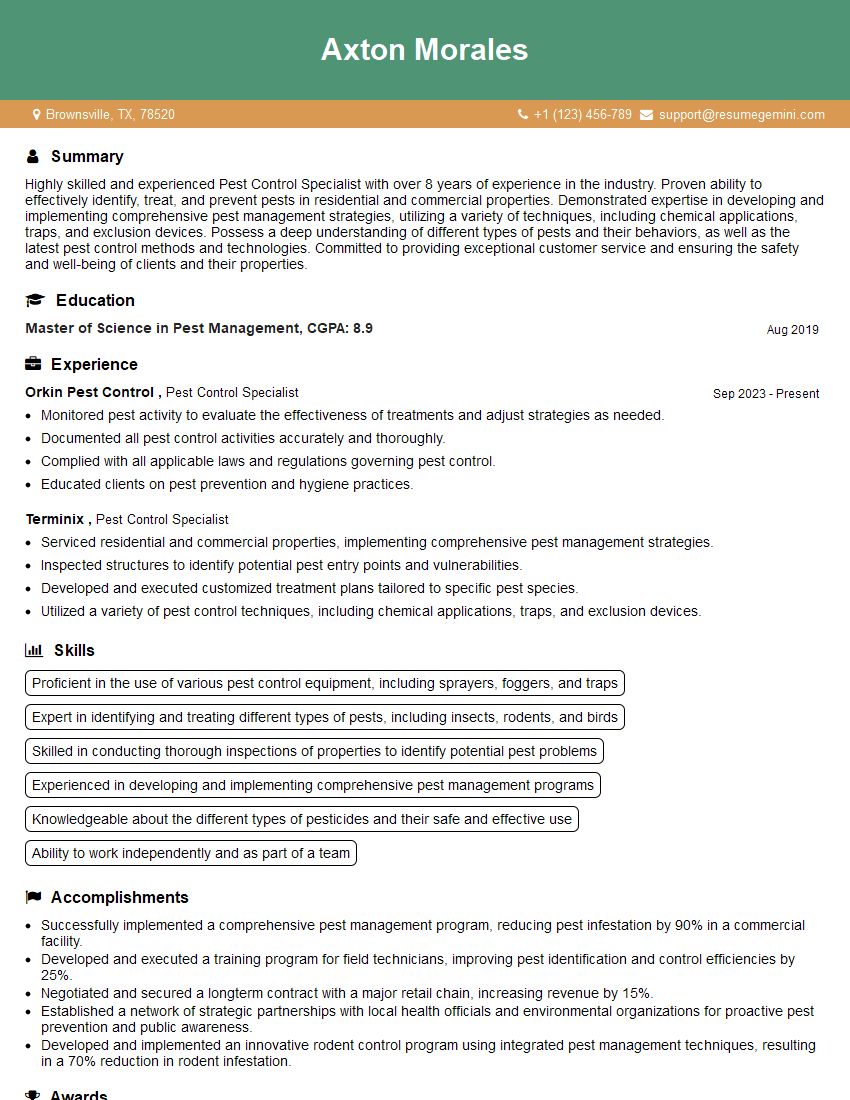

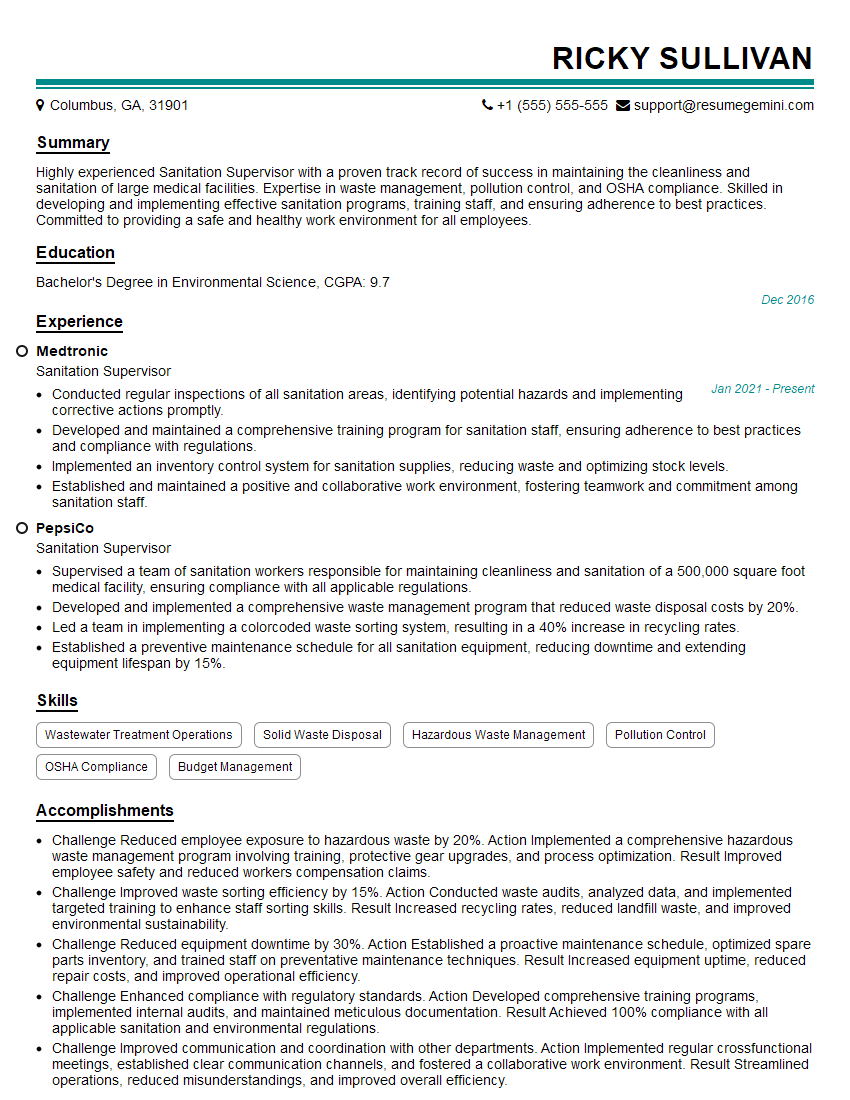

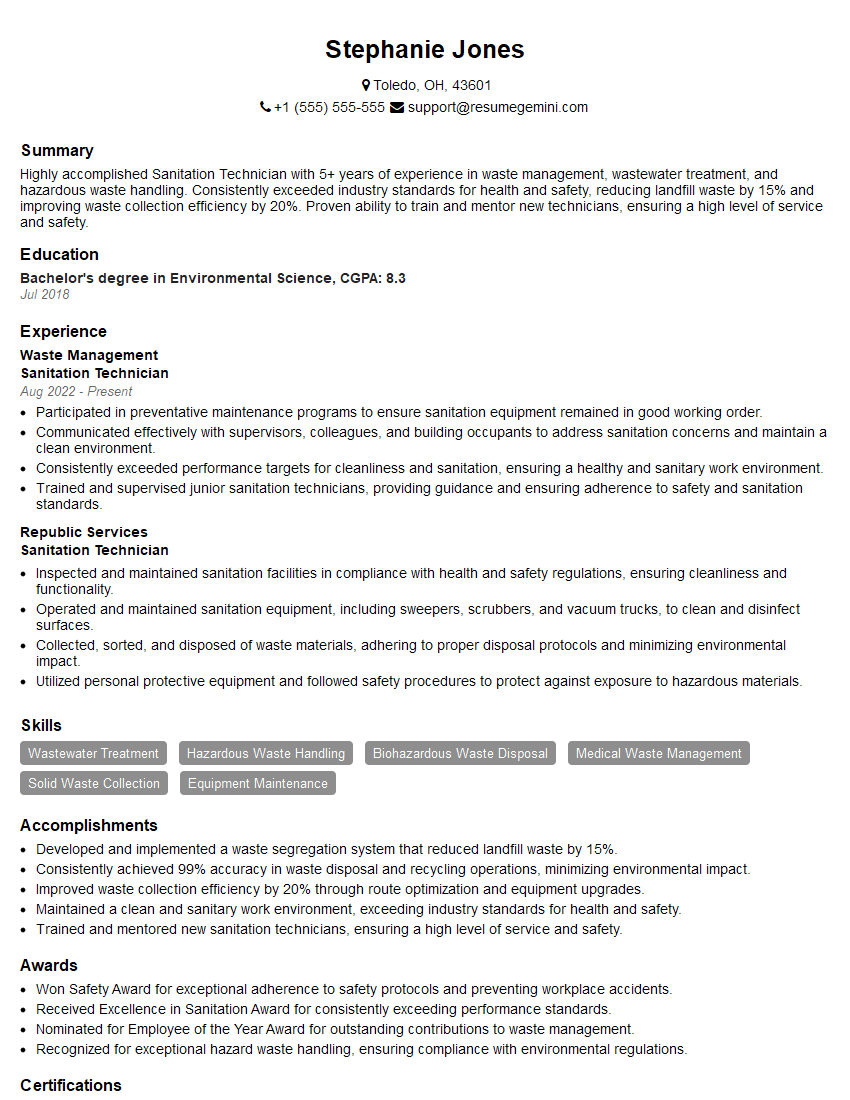

Mastering Workplace Hygiene and Sanitation opens doors to a rewarding career with excellent growth potential in diverse sectors. Proficiency in these areas demonstrates a commitment to safety and a proactive approach to health, highly valued by employers. To significantly boost your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. We strongly encourage you to leverage ResumeGemini, a trusted resource, to build a professional and impactful resume. ResumeGemini provides examples of resumes tailored to the Workplace Hygiene and Sanitation field, guiding you in showcasing your qualifications in the best possible light.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).