Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential World-class manufacturing interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in World-class manufacturing Interview

Q 1. Describe your experience implementing Lean Manufacturing principles.

Lean Manufacturing focuses on eliminating waste and maximizing value. In my previous role at Acme Manufacturing, we implemented Lean principles across the assembly line. This involved a comprehensive Value Stream Mapping exercise to identify bottlenecks and non-value-added activities. We then used Kaizen events – short, focused improvement projects – to tackle these issues. For example, one Kaizen event focused on optimizing the movement of parts between workstations. By implementing a simple kanban system and rearranging the layout, we reduced lead time by 20% and improved efficiency significantly. We also trained all employees in Lean principles, empowering them to identify and eliminate waste in their daily tasks. The result was a 15% increase in overall productivity within six months.

Another key aspect was the introduction of 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain). This improved workplace organization, reducing search time and improving safety. We didn’t just implement these methodologies; we fostered a culture of continuous improvement, ensuring Lean thinking became ingrained in the company’s DNA.

Q 2. Explain the DMAIC methodology in Six Sigma.

DMAIC is a data-driven, problem-solving methodology used in Six Sigma. It stands for Define, Measure, Analyze, Improve, and Control. It’s a structured approach to tackling process improvements, ensuring a systematic and measurable impact.

- Define: Clearly define the problem, its impact, and the project goals. This involves establishing a clear project charter and defining critical to quality (CTQ) characteristics.

- Measure: Gather data to quantify the current process performance. This might involve collecting data on defects, cycle times, and customer satisfaction. Control charts and other statistical tools are utilized.

- Analyze: Analyze the collected data to identify root causes of the problem. Tools like Pareto charts, fishbone diagrams, and process capability analysis are employed to pinpoint the key factors influencing the process.

- Improve: Develop and implement solutions to address the root causes. This might include process redesign, technology upgrades, or training initiatives.

- Control: Monitor the improved process to ensure the gains are sustained. This involves establishing control charts and implementing procedures to prevent the problem from recurring. Regular monitoring and adjustments are essential.

For instance, at Beta Technologies, we used DMAIC to reduce the defect rate in a specific welding process. Through careful data analysis, we identified faulty equipment as the root cause. Replacing the equipment led to a significant reduction in defects, demonstrating the effectiveness of the DMAIC methodology.

Q 3. How would you address a production bottleneck?

Addressing a production bottleneck requires a systematic approach. Firstly, I’d use data to pinpoint the exact bottleneck. This might involve analyzing cycle times, machine utilization, and work-in-process (WIP) inventory at various stages of the production process. Once identified, I’d explore several solutions:

- Increase capacity: This could involve adding more equipment, upgrading existing equipment, or implementing automation. The cost-effectiveness of each option needs careful evaluation.

- Improve efficiency: Analyzing the workflow at the bottleneck point might reveal inefficiencies. Lean tools like Value Stream Mapping can highlight areas for improvement. This could involve process simplification, operator training, or better material handling.

- Redistribute workload: If possible, some of the workload from the bottleneck area could be shifted to other, less congested areas. This might involve re-sequencing tasks or adjusting the production schedule.

- Improve material flow: Sometimes, bottlenecks are caused by delays in material supply. Improving inventory management, optimizing material handling, or implementing Just-in-Time (JIT) inventory systems could help.

For example, in a previous project, a bottleneck was caused by a single, slow machine. We analyzed its performance and found that regular maintenance was lacking. Implementing a preventive maintenance schedule dramatically improved the machine’s uptime, resolving the bottleneck without significant capital investment.

Q 4. What are the key performance indicators (KPIs) you would monitor in a manufacturing environment?

The key performance indicators (KPIs) I would monitor in a manufacturing environment are:

- Overall Equipment Effectiveness (OEE): Measures the effectiveness of equipment in producing good parts. A low OEE indicates potential issues with equipment performance or downtime.

- Throughput: The rate at which finished goods are produced. A low throughput suggests bottlenecks or process inefficiencies.

- Lead Time: The time it takes to produce a product from start to finish. Reducing lead time is crucial for faster order fulfillment and improved customer satisfaction.

- Defect Rate: The percentage of defective products produced. A high defect rate indicates quality problems that require attention.

- Inventory Turnover: Measures the efficiency of inventory management. High inventory turnover suggests effective inventory control.

- Cost per Unit: Tracks the cost of producing each unit. Reducing cost per unit enhances profitability.

- Safety Incidents: Tracking the number of safety incidents helps prioritize safety improvement initiatives.

- On-Time Delivery: Measures the percentage of orders delivered on time, which is crucial for customer satisfaction.

These KPIs provide a holistic view of manufacturing performance and help identify areas needing improvement.

Q 5. Describe your experience with Total Productive Maintenance (TPM).

Total Productive Maintenance (TPM) is a proactive approach to equipment maintenance that involves all employees. My experience with TPM includes its implementation at Gamma Industries. We started by establishing a structured maintenance program, involving both planned and preventative maintenance. This included training operators to perform basic maintenance tasks, empowering them to identify potential problems early on. We also created cross-functional teams responsible for specific equipment, fostering a sense of ownership and accountability.

Regular equipment inspections became a standard practice. We transitioned from a reactive, breakdown-based maintenance system to a proactive, preventative one. This reduced downtime significantly, leading to increased productivity and improved product quality. A key success factor was the strong emphasis on employee involvement and training. The increased employee engagement in equipment maintenance fostered a culture of ownership and continuous improvement.

Q 6. How would you improve the efficiency of a specific manufacturing process?

Improving the efficiency of a specific manufacturing process requires a structured approach. First, I’d clearly define the process and its current performance metrics. I’d then use tools like Value Stream Mapping to visualize the process and identify areas of waste. Waste can take many forms, including excess inventory, unnecessary transportation, waiting times, overproduction, and defects.

Once the waste areas are identified, we can implement solutions tailored to each type of waste. For example, we might eliminate unnecessary steps in the process, implement automation to reduce manual labor, improve material flow to reduce waiting times, or implement quality control measures to reduce defects.

After implementing improvements, I’d carefully monitor the process to measure the effectiveness of the changes. Data analysis will be essential to demonstrate the impact of the implemented changes and identify further areas for improvement. Continuous improvement is vital in optimizing manufacturing processes. In one case, streamlining the layout of a workstation and implementing a standardized work procedure reduced cycle time by 25%.

Q 7. What is your experience with Value Stream Mapping?

Value Stream Mapping is a lean manufacturing tool used to visualize the flow of materials and information in a process. It helps identify waste and bottlenecks, paving the way for process improvements. I have extensive experience using Value Stream Mapping to analyze and improve various manufacturing processes.

The process usually involves mapping the current state of the process, identifying value-added and non-value-added steps, calculating lead times and inventory levels, and then creating a future state map that depicts the improved process. The future state map outlines the proposed changes and their expected impact on lead time, inventory, and overall efficiency. For example, at Delta Corp, using Value Stream Mapping revealed a significant bottleneck in the packaging process. We used this map to justify investment in new packaging equipment. The results significantly reduced the lead time and improved throughput.

Value Stream Mapping isn’t just about creating a diagram; it’s a collaborative process involving individuals from different departments. The collective brainstorming sessions during the mapping exercise often lead to innovative solutions that might not have been identified otherwise. The visual representation provided by the map facilitates easier understanding and agreement on improvement initiatives.

Q 8. Explain the 5S methodology and its application in manufacturing.

5S is a methodology designed to organize the workplace for efficiency and effectiveness. It’s an acronym for five Japanese words: Seiri (Sort), Seiton (Set in Order), Seisō (Shine), Seiketsu (Standardize), and Shitsuke (Sustain). It’s more than just tidiness; it’s a systematic approach to eliminating waste and improving workplace safety.

- Seiri (Sort): This involves identifying and removing unnecessary items from the workspace. Think of it like decluttering your desk – only keep what you need for your daily tasks. For example, in a manufacturing setting, this could involve removing obsolete tools, excess inventory, or broken equipment.

- Seiton (Set in Order): This step focuses on organizing the remaining items for easy access and efficient workflow. Everything should have a designated place, and that place should be clearly marked. Imagine a well-organized toolbox – each tool has its own spot, making it quick and easy to find what you need.

- Seisō (Shine): This involves cleaning the workspace and keeping it clean. This isn’t just about superficial cleaning; it’s about proactively identifying and addressing potential problems. For example, regularly cleaning machinery can prevent breakdowns and ensure optimal performance.

- Seiketsu (Standardize): This involves establishing standardized procedures for maintaining the 5S practices. This ensures consistency and prevents a return to disorder. For example, creating visual aids or checklists to maintain cleanliness and organization.

- Shitsuke (Sustain): This is the most crucial step, focusing on maintaining the improvements made through the previous four steps. It requires consistent effort and commitment from everyone involved. This can involve regular audits, employee training, and continuous improvement initiatives.

In manufacturing, implementing 5S can lead to reduced waste, improved safety, increased efficiency, and better quality control. A clean, organized workspace allows for easier identification of defects and potential problems, leading to quicker resolutions.

Q 9. How would you handle a significant quality control issue?

Handling a significant quality control issue requires a structured and systematic approach. My strategy involves the following steps:

- Immediate Containment: The first priority is to stop the production of defective items and prevent further issues. This might involve isolating the affected batch, halting the production line, or implementing temporary corrective measures.

- Root Cause Analysis: A thorough investigation is crucial to determine the root cause of the problem. Tools like Fishbone diagrams (Ishikawa diagrams), Pareto charts, and 5 Whys can help identify contributing factors. I would involve cross-functional teams, including production, quality control, and engineering.

- Corrective Actions: Based on the root cause analysis, effective corrective actions must be implemented. This might involve machine adjustments, operator retraining, material changes, or process improvements. These actions should be documented and verified.

- Preventive Actions: To prevent recurrence, preventive measures should be implemented. This could include implementing stricter quality checks, updating procedures, or investing in new technology. The goal is to build a robust system to prevent similar problems.

- Documentation and Review: The entire process, from the initial identification of the issue to the implementation of preventive measures, should be thoroughly documented. Regular reviews should be conducted to ensure the effectiveness of the corrective and preventive actions.

For example, during my time at [Previous Company Name], we experienced a significant increase in defective products due to a faulty component. By systematically following these steps, we identified the faulty supplier, implemented stricter incoming inspection procedures, and ultimately resolved the issue.

Q 10. What experience do you have with Kaizen events?

Kaizen events, also known as Kaizen workshops or blitz events, are focused improvement activities involving a cross-functional team working intensely for a short period (typically a few days) to solve a specific problem or improve a process. I’ve participated in numerous Kaizen events throughout my career, focusing on various aspects of manufacturing, from reducing machine downtime to streamlining production flows.

In one particular event at [Previous Company Name], we focused on reducing setup time for a key production line. Through brainstorming, data analysis, and hands-on problem-solving, we identified bottlenecks and implemented several improvements, including a new tool organization system and streamlined changeover procedures. The event resulted in a 30% reduction in setup time, significantly increasing overall production efficiency.

My role in these events usually involves leading the team, facilitating discussions, guiding the problem-solving process, and ensuring that the agreed-upon improvements are implemented and sustained. I’m adept at utilizing various lean tools and techniques, such as value stream mapping, to pinpoint areas for improvement.

Q 11. How do you measure and improve Overall Equipment Effectiveness (OEE)?

Overall Equipment Effectiveness (OEE) is a key performance indicator (KPI) that measures the effectiveness of a manufacturing process. It’s calculated by multiplying three factors: Availability, Performance, and Quality.

- Availability: Represents the time the equipment is available for production, considering planned and unplanned downtime.

Availability = (Total Planned Production Time - Downtime) / Total Planned Production Time - Performance: Measures the speed at which the equipment operates compared to its designed speed.

Performance = Actual Production Rate / Ideal Production Rate - Quality: Reflects the percentage of good products produced compared to the total number produced.

Quality = (Total Good Products / Total Products) * 100%

OEE is calculated by multiplying these three factors: OEE = Availability * Performance * Quality. An OEE of 100% signifies perfect production efficiency, which is rarely achieved.

Improving OEE involves focusing on each of its three components. To improve Availability, we can implement predictive maintenance, reduce equipment breakdowns, and optimize scheduling. To enhance Performance, we might focus on operator training, reducing cycle times, and optimizing machine parameters. Finally, to improve Quality, we can implement stricter quality control measures, improve process stability, and reduce defects.

Regular monitoring of OEE allows us to track progress, identify bottlenecks, and implement targeted improvements. Data-driven decision-making is critical for sustained OEE improvement.

Q 12. Describe your experience with Kanban systems.

Kanban is a visual system for managing workflow, typically used in just-in-time (JIT) manufacturing environments. It uses cards or other visual signals to indicate the need for materials or parts. My experience with Kanban systems spans several years, involving implementation, optimization, and troubleshooting.

In one project at [Previous Company Name], we implemented a Kanban system to manage the flow of materials in our assembly line. This involved defining the workflow, setting appropriate Kanban card limits (to control work-in-progress), and establishing clear communication channels between different stages of the production process. The implementation led to a significant reduction in inventory levels, improved lead times, and increased overall efficiency. We used a combination of physical Kanban cards and a digital Kanban board to track progress and manage the workflow.

The success of a Kanban system relies heavily on clear communication, well-defined roles, and continuous monitoring. I’m skilled in adapting Kanban principles to different contexts and optimizing the system based on real-time data analysis.

Q 13. How would you implement a new manufacturing technology or process?

Implementing new manufacturing technology or processes requires a structured approach, emphasizing careful planning and execution. My approach typically involves the following stages:

- Needs Assessment: Clearly define the business need for the new technology or process. What problems are we trying to solve? What are the expected benefits (e.g., increased efficiency, improved quality, cost reduction)?

- Technology Selection: Research and evaluate different technologies or processes. Consider factors such as cost, capability, integration with existing systems, and long-term maintenance requirements. Thorough due diligence is critical at this stage.

- Pilot Implementation: Implement the new technology or process on a small scale first, allowing for testing and refinement before full-scale rollout. This minimizes risk and allows for adjustments based on real-world results.

- Training and Support: Provide comprehensive training to employees on the new technology or process. Ongoing support and troubleshooting are essential during the initial phases of implementation.

- Monitoring and Evaluation: Continuously monitor the performance of the new technology or process. Collect data to measure the impact on key performance indicators (KPIs) and make adjustments as needed. Regular reviews are vital to ensure sustained improvement.

- Continuous Improvement: Once the new technology or process is fully implemented, continue to seek ways to optimize its performance. Embrace continuous improvement methodologies like Kaizen to identify and address any remaining inefficiencies.

For instance, when implementing a new automated assembly system, we would start with a pilot run on a limited product line, closely monitor its performance, train operators, and address any issues before deploying it across the entire factory.

Q 14. Explain your understanding of Statistical Process Control (SPC).

Statistical Process Control (SPC) is a method used to monitor and control processes by statistically analyzing data. It involves using control charts to track process variables over time, identifying trends, and detecting deviations from expected behavior. The goal is to ensure that the process remains within specified limits, minimizing variability and preventing defects.

Control charts typically plot data points over time, showing the central tendency (mean) and the variability (standard deviation). Control limits are established based on historical data, indicating the expected range of variation. Points outside these limits suggest a process shift, requiring investigation and corrective action.

Different types of control charts are used depending on the type of data being analyzed. For example, X-bar and R charts are used for continuous data (like weight or length), while p-charts are used for attribute data (like the percentage of defective items).

By using SPC, manufacturers can identify potential problems early, before they lead to significant quality issues or production losses. It is a powerful tool for proactively managing variation and improving process stability. In my experience, the effective implementation of SPC significantly reduces defects and streamlines the production process. The key is in interpreting the control charts correctly and responding appropriately to signals of process instability.

Q 15. How do you prioritize competing projects in a manufacturing setting?

Prioritizing competing projects in a manufacturing setting requires a structured approach that balances urgency, importance, and resource availability. I typically use a prioritization matrix, often a variation of the Eisenhower Matrix (Urgent/Important), combined with a weighted scoring system.

First, I define clear criteria for each project, such as projected ROI, strategic alignment with business goals, customer demand, and risk mitigation. Then, each project is scored against these criteria. For example, a project with high ROI, strategic importance, and high customer demand would receive a higher score than one with lower scores across these criteria. The Eisenhower Matrix helps categorize projects as:

- Urgent and Important: These are tackled immediately. Think of a critical machine breakdown halting production.

- Important but Not Urgent: These are scheduled for future execution. An example is implementing a new lean manufacturing process to improve efficiency.

- Urgent but Not Important: These are delegated or outsourced. This could involve addressing a minor supplier issue impacting a non-critical product line.

- Neither Urgent nor Important: These are eliminated or deferred.

Finally, resource allocation is determined based on the prioritized projects, considering capacity constraints and team expertise. Regular monitoring and adjustments are essential to adapt to changing circumstances.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with root cause analysis techniques?

Root cause analysis (RCA) is crucial for preventing recurring problems. I have extensive experience with several techniques, including the 5 Whys, fishbone diagrams (Ishikawa diagrams), and fault tree analysis. The 5 Whys involves repeatedly asking ‘why’ to drill down to the root cause. For instance, if a machine keeps malfunctioning, we might ask:

- Why did the machine malfunction? (Answer: Worn-out bearing)

- Why was the bearing worn out? (Answer: Lack of regular lubrication)

- Why wasn’t it lubricated? (Answer: Maintenance schedule wasn’t followed)

- Why wasn’t the schedule followed? (Answer: Inadequate training for maintenance staff)

- Why was the training inadequate? (Answer: Lack of dedicated training budget)

The fishbone diagram helps visualize potential causes categorized by factors like manpower, machinery, materials, and methods. Fault tree analysis is more complex and useful for critical systems, tracing potential failures back to their origins. Choosing the right technique depends on the complexity of the problem. Regardless of the method, effective RCA requires a collaborative team effort, thorough data collection, and unbiased investigation.

Q 17. Describe your experience with capacity planning.

Capacity planning ensures sufficient resources are available to meet production demands. My experience includes using various techniques, from simple spreadsheet models to sophisticated software solutions. A key aspect is forecasting future demand, often using historical data, market trends, and sales projections. Then, we analyze current production capacity, identifying bottlenecks and inefficiencies. This involves assessing the capabilities of machines, workforce skills, and available space.

For example, if demand for a product is projected to increase by 30%, we need to determine whether our existing equipment and personnel can handle it. If not, options include investing in new equipment, optimizing existing processes (like implementing automation), or outsourcing part of the production. Regular capacity reviews and adjustments are crucial to adapt to fluctuating demand and prevent capacity shortages or overcapacity, both of which impact profitability.

Q 18. How do you manage inventory levels to optimize costs and production?

Managing inventory levels requires striking a balance between ensuring sufficient stock to meet demand and minimizing storage costs, obsolescence, and capital tied up in inventory. I utilize various inventory management techniques, including:

- Just-in-Time (JIT) inventory: This minimizes inventory by receiving materials only when needed. It requires a highly efficient and reliable supply chain.

- Economic Order Quantity (EOQ): This model calculates the optimal order quantity that minimizes total inventory costs (ordering costs and holding costs).

- ABC analysis: This classifies inventory items based on their value and consumption rate, allowing for focused management of high-value items.

Implementing an effective inventory management system requires robust forecasting, real-time tracking of inventory levels, and close collaboration with suppliers. Regular inventory audits and adjustments help ensure accuracy and identify potential issues. For example, using barcodes and RFID technology for accurate tracking and managing slow-moving items by implementing promotional strategies or finding alternative uses.

Q 19. How do you ensure compliance with safety regulations in a manufacturing plant?

Ensuring compliance with safety regulations is paramount in manufacturing. My approach is proactive, focusing on prevention rather than reaction. This begins with a thorough understanding of all relevant regulations (OSHA, local, etc.) and implementing a comprehensive safety management system. This involves:

- Regular safety training for all employees: covering hazard identification, safe operating procedures, and emergency response.

- Regular safety inspections and audits: identifying potential hazards and ensuring compliance with safety standards.

- Implementing safety protocols and procedures: covering machine guarding, lockout/tagout procedures, personal protective equipment (PPE) use, and emergency response plans.

- Investigating and reporting all accidents and incidents: identifying root causes and implementing corrective actions to prevent recurrence.

- Promoting a strong safety culture: where safety is a shared responsibility and employees are empowered to report hazards without fear of retribution.

Beyond compliance, fostering a culture of safety leads to a more productive and engaged workforce, reducing accidents and improving overall efficiency.

Q 20. What is your experience with supply chain management and optimization?

Supply chain management is crucial for ensuring the timely and cost-effective delivery of materials and products. My experience includes optimizing various aspects of the supply chain, from supplier selection and relationship management to logistics and inventory control. I utilize various techniques to improve efficiency and reduce costs, such as:

- Supplier relationship management (SRM): Building strong relationships with key suppliers to ensure quality, reliability, and cost-effectiveness.

- Demand forecasting and planning: Accurately predicting demand to optimize production and inventory levels.

- Logistics optimization: Improving transportation efficiency and reducing lead times.

- Risk management: Identifying and mitigating potential disruptions to the supply chain.

For instance, implementing a vendor-managed inventory (VMI) system, where suppliers manage our inventory levels, can significantly reduce storage costs and improve responsiveness to demand fluctuations. Leveraging technology such as ERP systems and supply chain visibility tools provides real-time insights and improved decision-making. Continuous monitoring and improvement are key to maintaining a resilient and efficient supply chain.

Q 21. How do you build and motivate a high-performing manufacturing team?

Building a high-performing manufacturing team requires a multifaceted approach focusing on recruitment, training, motivation, and collaboration. I begin by assembling a team with diverse skills and experience. Then, I invest in comprehensive training programs, ensuring employees have the necessary skills and knowledge to perform their tasks effectively. This goes beyond technical training and includes teamwork, problem-solving, and communication skills.

Motivation comes from creating a positive and supportive work environment where employees feel valued and respected. This involves:

- Clear communication and expectations: Ensuring everyone understands their roles and responsibilities.

- Providing opportunities for growth and development: Supporting career advancement and professional development.

- Recognizing and rewarding achievements: Celebrating successes, both individually and as a team.

- Empowering employees: Giving them autonomy and responsibility in their work.

- Promoting teamwork and collaboration: Fostering a culture of mutual respect and support.

Regular team meetings, feedback sessions, and opportunities for open communication are crucial for maintaining a high-performing and engaged team. Creating a shared sense of purpose, where team members understand the importance of their work and its contribution to the overall success of the company, enhances motivation and productivity.

Q 22. Describe your experience with project management methodologies in a manufacturing environment.

My experience with project management methodologies in manufacturing centers around Agile and Lean principles, complemented by traditional project management approaches like PRINCE2. In a fast-paced manufacturing environment, rigidity is the enemy of efficiency. Agile’s iterative approach, with its emphasis on frequent feedback and adaptation, allows for quicker responses to changing market demands and unforeseen production issues. I’ve successfully utilized Scrum frameworks to manage complex projects, involving cross-functional teams responsible for everything from new product introduction to equipment upgrades. For example, in my previous role, we used Agile to implement a new automated assembly line. The iterative nature allowed us to address unexpected integration challenges quickly and keep the project on schedule, ultimately resulting in a 15% increase in production efficiency.

Lean methodologies, particularly Kanban, have been instrumental in optimizing workflow and minimizing waste. By visualizing the workflow and limiting work in progress, we could pinpoint bottlenecks and improve throughput. For instance, by implementing a Kanban system for the procurement of raw materials, we reduced lead times by 20%. While Agile and Lean provide the dynamic framework, the structure of PRINCE2 ensures that larger projects maintain a clear scope, defined deliverables, and rigorous risk management processes.

Q 23. How would you implement a new quality management system?

Implementing a new quality management system (QMS) requires a phased approach, ensuring buy-in from all levels of the organization. I would begin with a thorough gap analysis to assess the current state and identify areas for improvement against a chosen standard, such as ISO 9001. This involves reviewing existing processes, documentation, and performance data. The next step is to establish a project team with representation from across the organization to ensure that all relevant perspectives are considered and team members are invested in the success of the project. This team will lead the design, development, and implementation phases.

The implementation involves designing new processes, documenting procedures, training personnel, and deploying the QMS. Crucial elements include establishing robust quality control checks at each stage of production, implementing corrective and preventive actions (CAPA) procedures to address non-conformances, and developing key performance indicators (KPIs) to monitor the effectiveness of the system. Regular audits and management reviews are vital to ensure continuous improvement. For example, in one project I used a phased rollout, starting with a pilot program in a specific department to test the system’s effectiveness before a full-scale deployment across the entire factory. This allowed us to identify and resolve any issues early on.

Q 24. What is your experience with cost reduction initiatives in manufacturing?

My experience with cost reduction initiatives focuses on a holistic approach that combines process optimization, waste elimination, and strategic sourcing. I don’t believe in short-term, cost-cutting measures that compromise quality or long-term sustainability. Instead, I look for opportunities for continuous improvement. For example, in one project, we conducted a detailed value stream mapping exercise to identify non-value-added activities in our production process. This led to the elimination of redundant steps and improved process flow, resulting in a 10% reduction in manufacturing costs.

Another key area is strategic sourcing. By leveraging our purchasing power and negotiating better deals with suppliers, we were able to reduce the cost of raw materials significantly. Implementing a lean manufacturing philosophy helps to minimise waste. This includes addressing inventory management through techniques like Just-in-Time (JIT) delivery and 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain) to improve workplace efficiency. Data analysis plays a vital role in tracking the effectiveness of cost reduction initiatives and identifying areas requiring further attention.

Q 25. How do you handle conflict resolution within a manufacturing team?

Conflict resolution within a manufacturing team requires a proactive and collaborative approach. My strategy is based on open communication, active listening, and a focus on finding mutually beneficial solutions. I begin by creating a safe space for team members to express their concerns and perspectives without fear of judgment. Active listening is crucial to understand the root cause of the conflict, often going beyond the surface-level issues.

Once the issues are understood, I facilitate a collaborative discussion to identify potential solutions. I encourage team members to brainstorm solutions together, fostering a sense of shared ownership in the resolution process. If necessary, I may use mediation techniques to help facilitate communication and guide the team towards a consensus. Documentation of the conflict and the agreed-upon resolution is crucial for preventing future recurrences. For example, in a situation involving conflicting priorities between two teams, I facilitated a joint planning session where the teams collaboratively prioritized tasks based on overall project goals, resulting in a collaborative and efficient workflow.

Q 26. Explain your experience with data analysis and reporting in manufacturing.

My experience with data analysis and reporting in manufacturing is extensive. I utilize various statistical methods and data visualization tools to monitor key performance indicators (KPIs), identify trends, and inform decision-making. I am proficient in using statistical software packages such as Minitab and R to analyze data from various sources, including production data, quality control data, and maintenance data. Data visualization tools like Tableau and Power BI are used to create dashboards that provide real-time insights into the performance of manufacturing operations.

For example, I used statistical process control (SPC) techniques to analyze production data and identify potential sources of variation in a manufacturing process. This led to the implementation of corrective actions that improved product quality and reduced scrap rates. Data analysis also plays a vital role in optimizing production schedules, predicting equipment failures, and identifying areas for improvement in overall manufacturing efficiency. Regular reports, delivered to management and relevant stakeholders, keep everyone informed on key metrics and highlight areas of success and challenge.

Q 27. How do you stay current with advancements in World-Class Manufacturing practices?

Staying current with advancements in World-Class Manufacturing practices is an ongoing process that requires a multifaceted approach. I actively participate in professional organizations like the Society of Manufacturing Engineers (SME) and attend industry conferences and workshops to learn about the latest technologies and best practices. I also subscribe to industry publications and follow thought leaders in the field through online platforms and professional networking groups.

Continuous learning is key, and I regularly engage in online courses and training programs offered by reputable institutions. Benchmarking against high-performing manufacturing organizations provides valuable insights into their strategies and approaches. This involves studying case studies, attending industry events, and participating in peer-to-peer learning initiatives. Staying abreast of technological advancements, particularly in areas like automation, robotics, and data analytics, is vital for maintaining a competitive edge in the manufacturing landscape.

Q 28. Describe a time you had to make a difficult decision impacting manufacturing operations.

One of the most challenging decisions I had to make involved a significant equipment failure during a critical production run. The equipment was essential for producing a key component for a major customer, and the failure threatened to disrupt the entire supply chain and lead to significant financial penalties for missed deadlines. The initial assessment suggested a major repair, taking several weeks, or a costly replacement.

After carefully weighing the options, assessing the risks involved, and considering the potential impact on customer relationships, I decided to expedite the procurement of a replacement machine, even though it was a more expensive solution in the short term. While this decision meant a significant immediate financial outlay, it averted the far greater costs associated with delayed delivery, reputational damage, and potential loss of the customer. The swift action minimized the downtime and avoided severe financial and customer-related repercussions. This experience reinforced the importance of considering the long-term consequences when faced with difficult decisions.

Key Topics to Learn for World-class Manufacturing Interview

- Lean Manufacturing Principles: Understanding and applying concepts like Kaizen, Value Stream Mapping, 5S, and Kanban to optimize processes and eliminate waste. Consider practical applications in your own experience or projects.

- Total Quality Management (TQM): Discuss the implementation of TQM methodologies, including Six Sigma, statistical process control (SPC), and continuous improvement initiatives. Think about how you’ve contributed to quality improvement in past roles.

- Supply Chain Management (SCM) in WCM: Explore the integration of efficient SCM strategies within a World-class manufacturing environment. This includes aspects like supplier relationships, inventory management, and logistics optimization.

- Advanced Manufacturing Technologies: Familiarize yourself with the role of automation, robotics, and digital technologies (e.g., IoT, AI) in modern WCM environments. Be ready to discuss the benefits and challenges of their implementation.

- Performance Measurement and Metrics: Understand key performance indicators (KPIs) used in WCM, such as Overall Equipment Effectiveness (OEE), cycle time, and defect rates. Be prepared to discuss how these metrics drive improvement.

- Problem-solving Methodologies: Demonstrate your proficiency in structured problem-solving techniques like root cause analysis (e.g., 5 Whys, Fishbone diagrams) and corrective action plans. Prepare examples from your experience where you’ve successfully solved manufacturing problems.

- Safety and Ergonomics in WCM: Discuss the importance of workplace safety and ergonomic principles in achieving a World-class manufacturing environment. Highlight your understanding of relevant safety regulations and best practices.

Next Steps

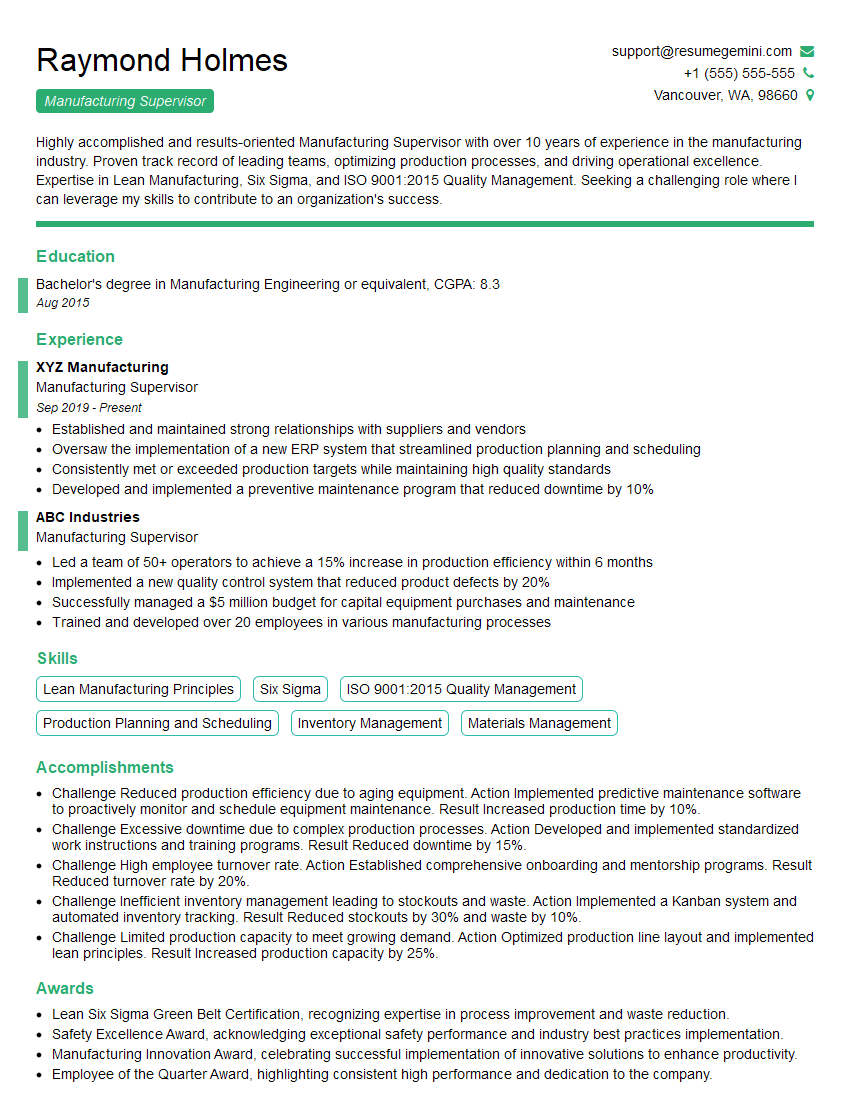

Mastering World-class manufacturing principles significantly enhances your career prospects in this highly competitive field. It demonstrates a commitment to efficiency, quality, and continuous improvement – qualities highly valued by employers. To significantly increase your chances of landing your dream role, focus on creating an ATS-friendly resume that showcases your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume that stands out from the competition. Examples of resumes tailored to World-class manufacturing are available to further assist you in crafting a compelling application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good