Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Yard Management and Fleet Coordination interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Yard Management and Fleet Coordination Interview

Q 1. Describe your experience managing a yard’s daily operations.

Managing a yard’s daily operations involves orchestrating a complex ballet of activities to ensure efficient flow of goods and vehicles. It’s like conducting an orchestra, where each section – receiving, staging, dispatching, and maintenance – must play in harmony. My experience encompasses overseeing all aspects, from scheduling inbound and outbound shipments to coordinating gate operations and managing personnel. For example, at my previous role, I implemented a new yard management system (YMS) that reduced turnaround times by 15% by streamlining the gate process and improving communication between drivers and yard staff. This involved creating standardized operating procedures, optimizing gate assignments, and implementing a real-time tracking system for trailers.

Another key aspect is proactive problem-solving. Anticipating potential bottlenecks, such as peak delivery times, requires careful planning and resource allocation. For instance, during seasonal rushes, I’d strategically schedule extra personnel, optimize trailer positioning, and proactively communicate with clients to manage expectations. This proactive approach ensures smooth operations even under pressure.

Q 2. How do you optimize yard space utilization?

Optimizing yard space utilization is crucial for maximizing efficiency and minimizing costs. Think of it like a Tetris game – fitting as many pieces (trailers, containers) as possible into the available space while maintaining easy accessibility. My approach involves a multi-pronged strategy.

- Strategic Trailer Placement: Utilizing a combination of fixed and flexible space allocation to accommodate different trailer sizes and types. Prioritizing high-frequency access trailers in readily available spaces.

- YMS Integration: Implementing a Yard Management System (YMS) with advanced features such as space optimization algorithms, which allows real-time monitoring of available space and automatic assignment of locations based on trailer size, type, and pickup/delivery schedule.

- Regular Audits and Adjustments: Regularly reviewing yard layout and trailer placement to identify areas for improvement and make adjustments based on data-driven insights.

- Height Optimization: Utilizing stacking technology where appropriate, especially for standard-sized containers or pallets. Ensuring safe and stable stacking practices are followed strictly.

For instance, by implementing a YMS with space optimization algorithms, I was able to increase yard capacity by 10% at a previous company without increasing the physical size of the yard, resulting in significant cost savings.

Q 3. Explain your approach to managing driver schedules and assignments.

Managing driver schedules and assignments requires careful planning and real-time coordination. It’s about ensuring the right driver is at the right place at the right time with the right trailer. My approach starts with a strong understanding of driver availability, preferred routes, and specialized skills.

- Route Optimization: Utilizing route planning software to determine the most efficient delivery routes, minimizing travel time and fuel consumption. This involves considering factors such as traffic conditions, delivery windows, and driver preferences.

- Communication: Maintaining open and transparent communication channels with drivers through mobile apps or dispatch systems. Providing real-time updates on assignments, delays, and any relevant information.

- Fair Scheduling: Developing a fair and equitable scheduling system to ensure driver workload is distributed efficiently and fairly among the team. Consideration is given to driver experience, availability, and preferences when possible.

- Performance Monitoring: Tracking driver performance metrics, such as on-time delivery rates, to identify areas for improvement and provide constructive feedback.

In one case, I implemented a mobile app that allowed drivers to self-assign pick-up and delivery locations based on their availability and proximity, increasing efficiency and driver satisfaction significantly.

Q 4. How do you handle unexpected delays or equipment malfunctions in the yard?

Unexpected delays and equipment malfunctions are inevitable in yard operations. Having a well-defined contingency plan is crucial for minimizing disruption. My approach is based on proactive communication, resource allocation, and problem-solving.

- Immediate Response Team: Having a dedicated team ready to address equipment issues promptly. This might involve mechanics, maintenance personnel, or even external contractors depending on the severity.

- Real-time Communication: Utilizing a communication system to alert all stakeholders—drivers, dispatch, management—of delays and their potential impact. Transparency is key to mitigate frustrations.

- Contingency Planning: Having backup equipment and personnel available to mitigate delays. This might involve having spare trailers or arranging for alternative transportation if necessary.

- Root Cause Analysis: After resolving the issue, conducting a root cause analysis to understand what went wrong and implement preventive measures to avoid future occurrences.

For instance, during a recent ice storm that led to equipment failure, our pre-planned response, including communication protocols and backup equipment, allowed us to minimize disruptions by a significant degree, avoiding major delays and penalties.

Q 5. What metrics do you use to evaluate yard efficiency?

Evaluating yard efficiency involves tracking key metrics to identify areas for improvement and measure the success of implemented strategies. Key metrics I frequently use include:

- Throughput: The number of trailers processed per hour or day. This helps assess the overall efficiency of the yard’s operations.

- Turnaround Time: The time it takes for a trailer to enter and leave the yard. This metric directly reflects efficiency and reflects operational smoothness.

- On-Time Delivery Rate: The percentage of shipments delivered on time, demonstrating the effectiveness of scheduling and operational execution.

- Yard Utilization: The percentage of yard space actively used. This highlights efficient space management.

- Driver Dwell Time: The average time drivers spend in the yard waiting to pick up or drop off trailers. This pinpoints potential bottlenecks and areas needing streamlining.

- Safety Incidents: The number of safety incidents per unit of work or time period. Prioritizing a safe work environment is critical.

By regularly monitoring these metrics and analyzing trends, I can pinpoint bottlenecks and implement changes to improve overall yard efficiency.

Q 6. Describe your experience with yard safety protocols and procedures.

Yard safety is paramount. My experience encompasses developing and implementing comprehensive safety protocols and procedures to minimize risks and ensure a safe working environment for all personnel and visitors. This is not just a checklist but a core value.

- Safety Training: Providing regular safety training to all employees, covering topics such as forklift operation, hazard recognition, and emergency procedures. This is often refreshed to incorporate new regulations or lessons learned from incidents.

- Hazard Identification and Mitigation: Conducting regular safety inspections to identify and mitigate potential hazards, such as poorly lit areas, uneven surfaces, and potential trip hazards. This includes using checklists and documenting findings.

- Emergency Response Plan: Developing and regularly testing an emergency response plan, including procedures for handling accidents, fires, and other emergencies. This could involve drills and clear communication protocols.

- Personal Protective Equipment (PPE): Ensuring that all employees have access to and properly utilize necessary PPE, such as high-visibility vests, safety shoes, and hearing protection. This includes regular maintenance and replacements.

- Compliance: Maintaining compliance with all relevant safety regulations and industry best practices. This is ongoing and requires staying updated on the latest standards.

One example is the implementation of a ‘near-miss’ reporting system where employees could report potential hazards without fear of reprisal, fostering a culture of proactive safety and continuous improvement.

Q 7. How do you maintain accurate inventory tracking within the yard?

Maintaining accurate inventory tracking is essential for efficient yard operations and preventing costly errors. My approach utilizes a combination of technology and manual processes to ensure data integrity.

- YMS Integration: Leveraging a Yard Management System (YMS) with real-time inventory tracking capabilities. This provides a centralized database of all trailers, containers, and goods within the yard.

- Barcode/RFID Scanning: Using barcode or RFID scanning technology to track individual items and their location within the yard. This eliminates manual data entry and reduces errors.

- Regular Physical Inventory Checks: Conducting regular physical inventory checks to verify the accuracy of the YMS data. This helps to identify discrepancies and address any potential data entry issues.

- Data Reconciliation: Regularly reconciling inventory data with inbound and outbound shipments to ensure accuracy and consistency. This involves comparing data from various sources and identifying discrepancies.

- Automated Reporting: Using the YMS to generate reports on inventory levels, movement, and other key metrics. This provides valuable data for decision-making.

In my previous role, we implemented a real-time inventory tracking system that reduced inventory discrepancies by 80%, resulting in substantial cost savings and improved efficiency.

Q 8. Explain your process for managing inbound and outbound shipments.

Managing inbound and outbound shipments requires a systematic approach focusing on efficiency and accuracy. My process begins with meticulously tracking shipments from the moment they’re scheduled. This involves verifying arrival times, confirming carrier details, and allocating appropriate dock space. For inbound shipments, I prioritize unloading and verifying the goods against the manifest, ensuring no damage or discrepancies occur. Simultaneously, I coordinate with warehouse staff for storage and onward movement. Outbound shipments involve a similar process in reverse. We confirm orders, prepare the goods for shipment, schedule pickups, and provide drivers with all necessary documentation. The entire process is heavily reliant on robust communication with carriers, warehouse staff, and clients, usually facilitated through a Transportation Management System (TMS). This system allows for real-time tracking and updates, preventing delays and minimizing disruptions.

For example, imagine a rush order for perishable goods. My process would involve prioritizing the shipment, assigning it to the fastest available dock, and ensuring its immediate loading onto the designated carrier. Real-time tracking through the TMS would allow for monitoring every stage of its journey, ensuring timely delivery.

Q 9. How do you handle driver communication and dispatching?

Effective driver communication and dispatching are crucial for efficient fleet operations. I utilize a combination of technologies and strategies. A robust dispatching system, often integrated with our TMS, allows for efficient assignment of loads based on driver location, vehicle type, and delivery deadlines. I personally ensure clear and concise communication with drivers, providing them with detailed route information, delivery instructions, and any necessary updates throughout the day. This often involves utilizing two-way communication apps like mobile dispatching software that allows for real-time location tracking and messaging. Regular briefings, both individually and in group sessions, are vital for maintaining high communication levels and addressing any operational concerns.

For instance, if a road closure necessitates a route change, I promptly inform affected drivers via the dispatching app, providing them with alternative routes and estimated time of arrival adjustments. This proactive approach prevents delays and fosters trust between management and the drivers.

Q 10. What software or systems have you used for yard management?

Throughout my career, I’ve had the opportunity to work with several yard management systems (YMS) and transportation management systems (TMS). These systems are critical for optimizing yard operations. Some prominent examples include Manhattan Associates, Blue Yonder, and Oracle Transportation Management. These systems allow for real-time visibility into yard activities, enabling effective tracking of inbound and outbound shipments, managing equipment, and optimizing space utilization. I am also proficient in using various warehouse management systems (WMS) that seamlessly integrate with YMS and TMS to manage inventory and optimize warehouse operations. These integrated systems provide a holistic view of the entire supply chain, significantly improving efficiency and decision-making.

In a previous role, we utilized Manhattan Associates YMS, which greatly enhanced our yard operations by providing features such as gate management, appointment scheduling, and real-time tracking of trailers and containers within the yard. The system’s reporting capabilities helped us analyze operational bottlenecks and identify areas for improvement.

Q 11. Describe a time you had to resolve a conflict between drivers or dock workers.

In one instance, a conflict arose between two drivers over a preferred loading dock. Both claimed priority based on their delivery schedules. Instead of taking sides, I initiated a calm and structured discussion to understand the root cause of the conflict. I reviewed both drivers’ schedules and the overall yard utilization data using the YMS. It turned out that a minor error in the scheduling system had created the conflict. I explained the situation transparently to both drivers, highlighting the system error. To resolve it, I adjusted the loading schedule, giving priority to the time-sensitive delivery, whilst also ensuring the second driver did not experience an unreasonable delay. Post-resolution, I communicated the temporary schedule change to other relevant stakeholders and reported the system error to the IT team for rectification, preventing future occurrences of the same issue.

Q 12. How do you ensure compliance with all relevant regulations?

Ensuring regulatory compliance is paramount in yard management and fleet coordination. This involves staying updated on all relevant federal, state, and local regulations concerning transportation, safety, and environmental protection. We maintain a comprehensive compliance program, regularly reviewing and updating our policies and procedures to meet evolving regulations. Driver training programs focus heavily on safety regulations, including hours-of-service rules, proper loading techniques, and vehicle maintenance. We conduct regular audits to monitor compliance and identify areas for improvement. Furthermore, we maintain detailed records of vehicle maintenance, driver logs, and shipments to demonstrate our commitment to adherence to all relevant regulations. This is crucial for preventing penalties and maintaining a strong safety record.

For example, we meticulously track driver hours to ensure strict adherence to HOS regulations. Our software automatically flags any potential violations, allowing for proactive intervention to prevent breaches. This proactive approach minimizes the risk of fines and maintains the safety of our drivers and the public.

Q 13. How do you manage fuel consumption and vehicle maintenance costs?

Managing fuel consumption and vehicle maintenance costs requires a multi-pronged approach. We utilize telematics systems to monitor fuel efficiency, identifying drivers and vehicles with above-average consumption. This data helps in implementing driver training programs focusing on fuel-efficient driving techniques and regular vehicle maintenance. Preventive maintenance schedules are rigorously followed, reducing the risk of costly repairs and unexpected downtime. We also analyze vehicle usage patterns to optimize routes and avoid unnecessary idling. Fuel purchasing strategies, including negotiating favorable contracts with fuel providers, help minimize expenses. Regular reviews of maintenance costs and fuel consumption patterns provide insights for continuous improvement and cost reduction strategies.

For example, we implemented a driver reward program recognizing drivers who consistently maintain high fuel efficiency. This incentivized careful driving, leading to a significant reduction in overall fuel costs.

Q 14. What strategies do you employ to improve driver retention?

Improving driver retention is crucial for operational stability and cost control. We focus on creating a positive and supportive work environment. This involves fair compensation, benefits packages, and regular performance reviews. Open communication channels allow for addressing concerns and providing drivers with a voice. We invest in driver training and development, providing opportunities for advancement. Regular appreciation and recognition programs reinforce positive contributions. Furthermore, we seek to provide work-life balance through flexible scheduling where possible. By prioritizing the well-being of our drivers, we cultivate a loyal and productive workforce.

For instance, we introduced a mentorship program pairing experienced drivers with newer ones, creating a supportive team environment and encouraging knowledge sharing. This has significantly improved driver retention and boosted overall morale.

Q 15. Describe your experience with different types of yard equipment.

My experience encompasses a wide range of yard equipment, from the most common forklifts and reach stackers to specialized equipment like straddle carriers and top handlers. I’m familiar with both pneumatic and electric models, understanding the operational differences and maintenance requirements for each. For instance, I’ve overseen the efficient deployment of reach stackers in a high-volume container yard, optimizing their usage to minimize idle time and maximize throughput. With straddle carriers, I’ve been involved in planning their movements to ensure safe and efficient stacking and retrieval of containers. My experience also includes working with specialized equipment for handling oversized or hazardous materials, always prioritizing safety and regulatory compliance.

- Forklifts: Proficient in various types (counterbalance, reach, side-loader) and their application in different yard layouts.

- Reach Stackers: Experienced in optimizing stacking strategies for maximum space utilization and efficient retrieval.

- Straddle Carriers: Expertise in their safe operation and integration into yard management systems for real-time tracking.

- Top Handlers: Understanding of their limitations and suitability for specific container handling tasks.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you prioritize tasks in a high-pressure yard environment?

Prioritizing tasks in a high-pressure yard environment requires a structured approach. I utilize a system that combines urgency, importance, and resource availability. I employ a prioritization matrix that categorizes tasks based on their impact and deadline. For example, urgent and high-impact tasks, such as unloading perishable goods or resolving a critical blockage, take precedence. Less urgent but still important tasks, like routine maintenance or inventory updates, are scheduled strategically. This approach, coupled with real-time monitoring of yard activities, allows me to dynamically adjust priorities as needed. I also leverage communication to ensure all team members are aware of the current priorities and can contribute effectively. Think of it like a conductor of an orchestra; each instrument (task) has its importance and timing, and the conductor (me) ensures a harmonious and efficient operation.

Q 17. How do you track and analyze key performance indicators (KPIs)?

Tracking and analyzing KPIs is crucial for optimizing yard operations. Key metrics I focus on include dwell time (the time containers spend in the yard), truck turnaround time, equipment utilization, safety incidents, and inventory accuracy. I leverage yard management systems (YMS) to collect data automatically and generate reports. These reports allow me to identify bottlenecks and areas for improvement. For example, consistently high dwell time might indicate issues with gate operations or inefficient stacking. Low equipment utilization might suggest a need for better scheduling or staff training. By analyzing trends in these KPIs, I can proactively address problems and implement strategies to enhance efficiency and productivity. Data visualization tools are also used to easily communicate these findings to stakeholders.

Q 18. Explain your experience with route optimization and planning.

My experience with route optimization and planning involves utilizing various techniques to minimize travel time and distances for both inbound and outbound shipments. I’m proficient in using route planning software, considering factors like traffic patterns, road restrictions, and delivery windows. In one project, I implemented a new routing system that reduced delivery times by 15% by incorporating real-time traffic data and optimizing delivery sequences. This reduced fuel costs and improved driver satisfaction. Beyond software, I also consider the physical layout of the yard and the efficiency of material handling equipment when designing routes. For instance, I might reorganize storage areas to minimize travel distances between loading docks and storage locations. The goal is always to create a smooth, efficient flow of goods.

Q 19. How do you handle customer inquiries and complaints related to yard operations?

Handling customer inquiries and complaints requires a proactive and empathetic approach. I prioritize immediate acknowledgment of concerns and provide updates regularly. A clear communication channel – whether phone, email, or a dedicated portal – is essential. Thorough investigation of complaints is key, involving reviewing relevant documentation and possibly interviewing involved personnel. I aim to resolve issues quickly and fairly, offering solutions that satisfy both the customer and our operational needs. For example, if a customer complains about late delivery, I would investigate potential causes, such as traffic delays or internal processing issues, and provide a clear explanation and potential compensation if appropriate. Documentation of all inquiries and resolutions is crucial for future reference and continuous improvement.

Q 20. Describe your experience with different transportation modes (e.g., trucking, rail).

My experience extends to various transportation modes, including trucking, rail, and occasionally, barge transport. I understand the operational differences and logistical challenges associated with each mode. For trucking, I’m familiar with managing carrier relationships, negotiating rates, and tracking shipments. With rail, I’m experienced in coordinating with rail yards for timely loading and unloading of containers. This often involves careful planning to minimize delays and ensure smooth transitions between modes. I consider factors such as capacity limitations, transit times, and cost-effectiveness when selecting transportation modes. In one project, I successfully integrated rail transport into our supply chain, significantly reducing transportation costs and improving overall efficiency.

Q 21. How do you ensure the security of goods within the yard?

Ensuring the security of goods within the yard is paramount. My approach involves a multi-layered strategy, encompassing physical security measures, access control, and surveillance. This includes secured fencing, gate access systems with authorized personnel and vehicle identification, and comprehensive CCTV coverage. Regular security patrols and inspections are conducted to identify potential vulnerabilities. We also implement robust inventory management systems to track goods and minimize the risk of theft or loss. Additionally, employee training and background checks are crucial to maintain a secure environment. We regularly review and update our security protocols to adapt to evolving threats and best practices. The goal is to create a secure environment that protects the integrity of our client’s goods while maintaining efficient operations.

Q 22. What is your experience with warehouse management systems (WMS)?

My experience with Warehouse Management Systems (WMS) is extensive. I’ve worked with various systems, from legacy on-premise solutions to modern cloud-based platforms like Oracle WMS, SAP EWM, and Blue Yonder. My expertise extends beyond simply using these systems; I understand their underlying functionalities and how to integrate them effectively with other systems to optimize warehouse operations. This includes configuring the system for specific client needs, defining workflows, managing inventory accuracy, and generating insightful reports for improved decision-making. For instance, in a previous role, I implemented a new WMS that reduced our picking errors by 15% and improved order fulfillment speed by 20%. This was achieved by optimizing warehouse layout within the WMS, implementing directed putaway strategies, and leveraging advanced features like slotting optimization.

Furthermore, I understand the importance of data integrity and system maintenance. I’m proficient in data migration processes, ensuring seamless transitions between systems, and I regularly participate in system upgrades and training to maintain peak efficiency and leverage the latest functionalities.

Q 23. How do you manage driver hours of service (HOS) compliance?

Managing driver Hours of Service (HOS) compliance is critical for safety and legal adherence. My approach involves a multi-pronged strategy. Firstly, we utilize electronic logging devices (ELDs) integrated with our transportation management system (TMS) to automatically track driver hours. This data is constantly monitored for potential violations. Secondly, we have established clear procedures and training programs for drivers regarding HOS regulations. These programs emphasize the importance of compliance and provide practical guidance on managing their driving time effectively. Thirdly, we implement proactive measures like route optimization to minimize driving time and fatigue.

For example, we use predictive analytics to forecast potential HOS violations based on planned routes and driver schedules, allowing us to intervene proactively and adjust plans as needed. This ensures compliance, prevents costly fines, and promotes driver well-being. We also conduct regular audits and reviews of HOS data to identify trends and improve our compliance strategies over time.

Q 24. How do you integrate yard management with overall supply chain operations?

Yard management is intrinsically linked to overall supply chain operations. It’s the crucial link between inbound and outbound logistics, directly impacting on-time delivery, inventory control, and overall efficiency. Effective yard management ensures a smooth flow of goods, minimizes congestion, and reduces dwell time. I integrate yard management with the broader supply chain by employing a holistic approach that involves close collaboration between different departments: operations, transportation, warehousing, and customer service.

For example, real-time yard visibility through a yard management system (YMS) allows us to track trailers, containers, and other assets, providing accurate information to warehouse teams for timely order fulfillment. The system also facilitates efficient gate management, appointment scheduling, and optimized trailer placement, enhancing the overall supply chain efficiency. By integrating YMS with TMS, we achieve seamless communication between yard and transportation, optimizing truck routes and minimizing empty miles. This ensures better resource allocation and improved delivery times.

Q 25. Describe your experience with implementing new technologies or processes in yard operations.

I have extensive experience implementing new technologies and processes to improve yard operations. In one project, we implemented a Radio-Frequency Identification (RFID) system to track trailers and containers in real-time. This dramatically improved accuracy and speed of inventory management compared to manual tracking methods. The data collected from the RFID system was integrated with our YMS, providing a single source of truth for yard operations.

Another significant project involved the implementation of an advanced YMS with AI-powered optimization capabilities. This system significantly improved gate management, truck scheduling, and trailer positioning, reducing congestion and improving throughput. In both cases, successful implementation involved thorough planning, stakeholder communication, rigorous testing, and a phased rollout to minimize disruption and ensure user adoption. Key to success was training and ongoing support for the users. We also used a robust change management process and gathered feedback consistently for continual improvement.

Q 26. How do you handle inclement weather or other unforeseen circumstances?

Handling inclement weather and unforeseen circumstances requires a proactive and adaptable approach. Our contingency plans include real-time weather monitoring to anticipate potential disruptions. We adjust scheduling based on forecasts, prioritizing critical shipments and communicating delays to customers proactively. For example, during a severe snowstorm, we might prioritize the movement of perishable goods and re-route trucks to avoid hazardous road conditions. We also have alternative transportation plans in place and collaborate with our carriers to mitigate delays.

In addition to weather, unexpected events such as equipment breakdowns or accidents need immediate response. Our processes involve clear communication channels and well-defined emergency procedures. This ensures quick response times, minimizing disruptions and maintaining operational resilience. Regular safety drills and training sessions prepare our teams to handle various scenarios efficiently and safely.

Q 27. What is your experience with load planning and optimization?

Load planning and optimization are crucial for efficient and cost-effective transportation. My experience involves utilizing various techniques to maximize space utilization in trucks and containers, minimizing empty miles, and ensuring safe and secure transport. This includes using software tools that incorporate dimensions, weight, and fragility of goods to create efficient loading plans. We also consider factors like delivery routes and delivery windows to optimize the overall transportation plan.

For instance, we use algorithms that analyze historical data to predict demand and optimize delivery routes, leading to significant fuel savings and reduced transportation costs. In practice, this often involves collaborating with carriers to ensure proper loading practices and using technology like route optimization software that considers traffic, road closures, and other dynamic factors. A successful load plan reduces empty space, increases efficiency, and ultimately lowers operational costs.

Q 28. How do you proactively identify and mitigate potential risks in yard operations?

Proactive risk mitigation is paramount in yard operations. My approach involves identifying potential hazards and implementing measures to prevent incidents before they occur. This involves regular safety audits, thorough equipment inspections, and robust training programs for all personnel. We use risk assessment methodologies to identify potential issues, such as traffic congestion, security breaches, or accidents, and develop mitigation strategies.

For example, we might implement security measures such as CCTV monitoring, access control systems, and regular security patrols to deter theft and unauthorized access. Similarly, we employ clear signage, speed limits, and designated traffic lanes to prevent accidents and ensure smooth traffic flow within the yard. We also analyze data from our YMS and other systems to identify potential bottlenecks or areas for improvement, enabling us to take preventative action and minimize the risk of operational disruptions.

Key Topics to Learn for Yard Management and Fleet Coordination Interview

- Yard Optimization Strategies: Understanding and applying techniques to maximize space utilization, minimize congestion, and improve efficiency within the yard.

- Fleet Scheduling and Routing: Developing efficient schedules and routes for vehicles, considering factors like delivery windows, driver availability, and traffic conditions. Practical application includes experience with route optimization software and proficiency in managing delivery exceptions.

- Inventory Management and Tracking: Implementing systems for tracking inventory within the yard, ensuring accurate counts, and managing stock levels effectively. This includes understanding first-in, first-out (FIFO) principles and the use of relevant technologies like barcode scanners or RFID.

- Safety and Compliance Procedures: Deep understanding of relevant health and safety regulations, implementing and enforcing best practices to maintain a safe working environment, and ensuring adherence to all company policies.

- Communication and Coordination: Effective communication with drivers, dispatchers, warehouse staff, and clients to ensure seamless operations and efficient problem-solving. This includes experience with various communication tools and conflict resolution techniques.

- Technological Proficiency: Familiarity with yard management systems (YMS), transportation management systems (TMS), and other relevant software applications used in fleet coordination. Demonstrate understanding of data analysis and reporting capabilities within these systems.

- Problem-Solving and Decision-Making: Ability to identify and resolve logistical challenges in real-time, adapting strategies to unforeseen circumstances and making informed decisions under pressure.

Next Steps

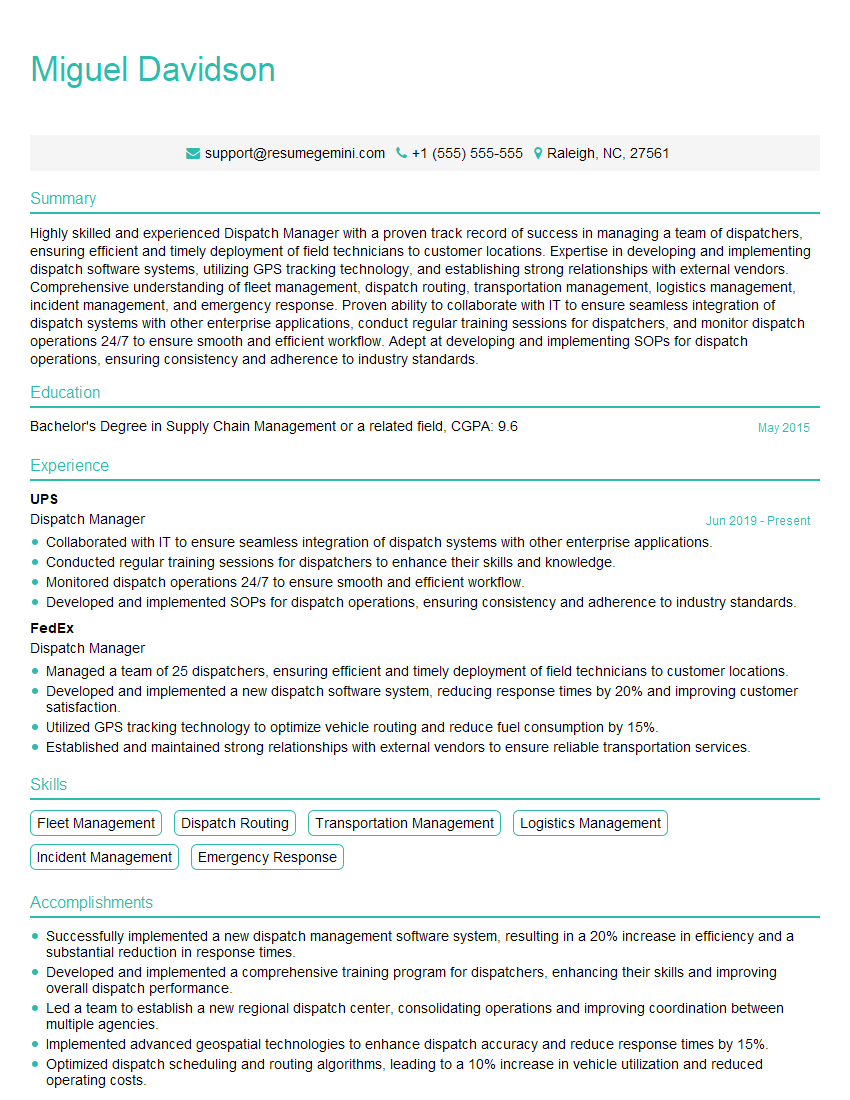

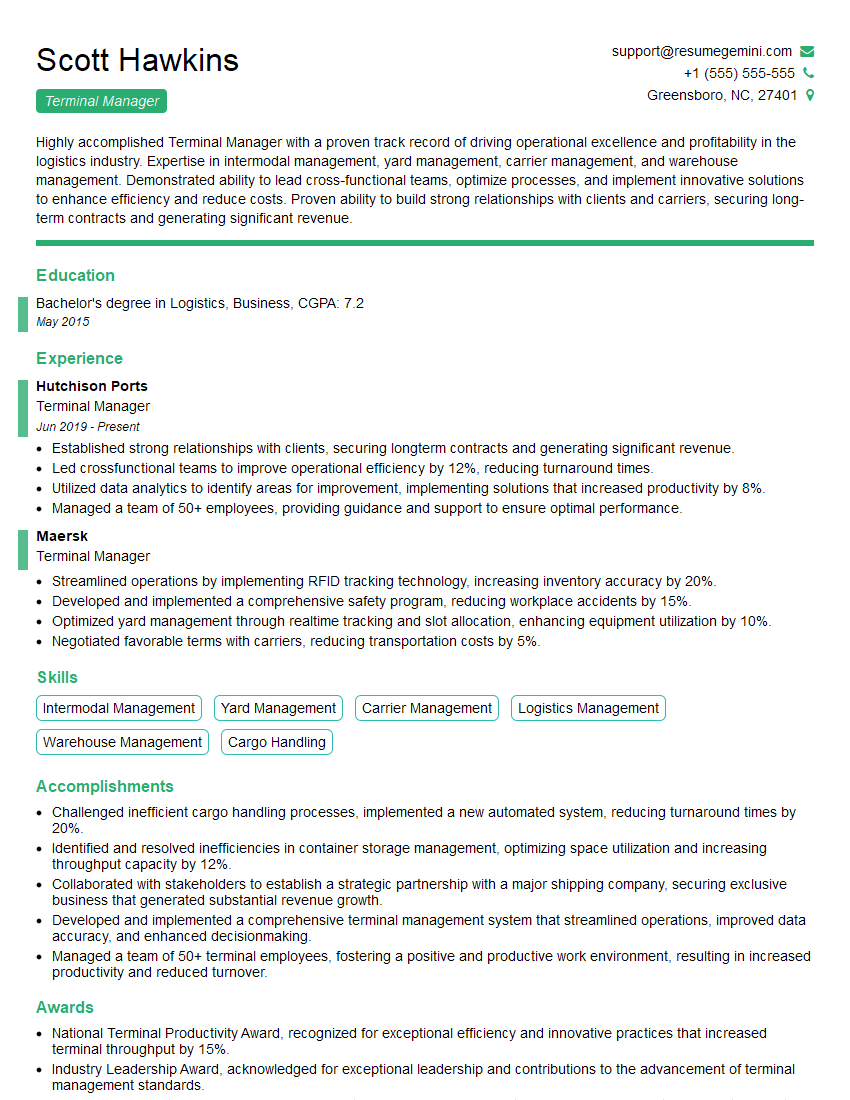

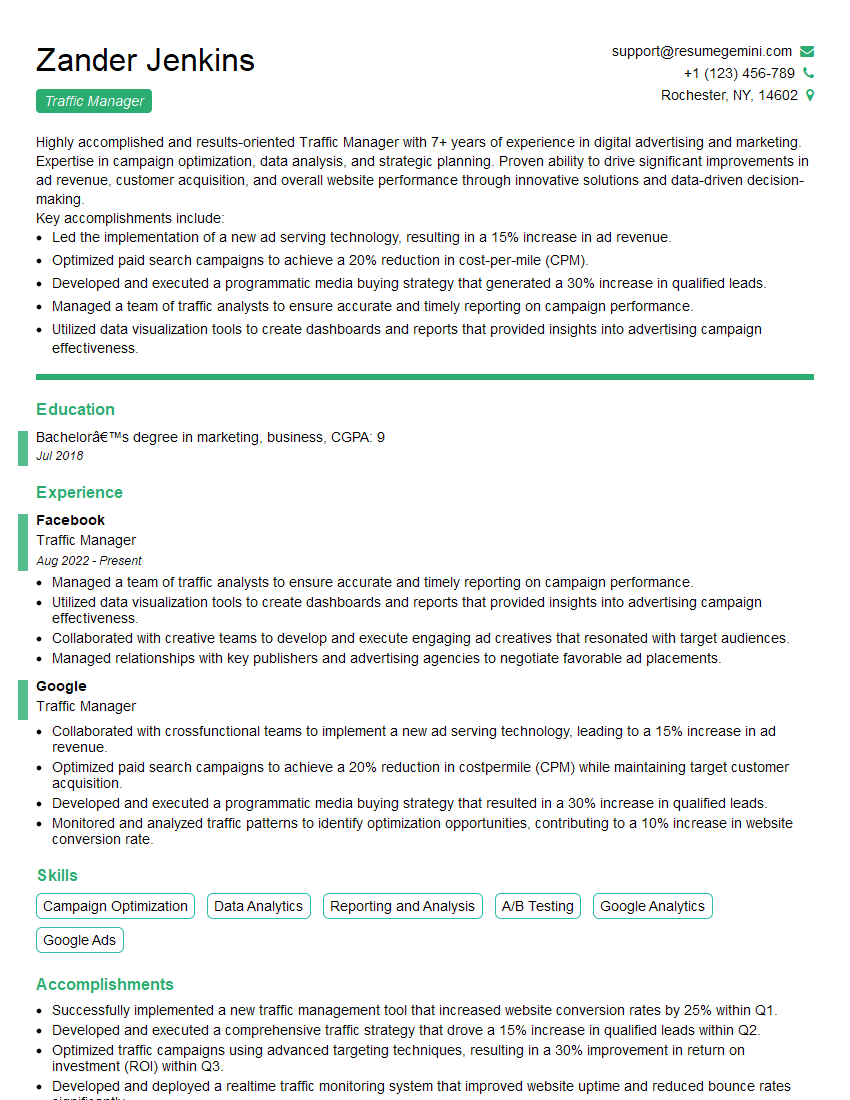

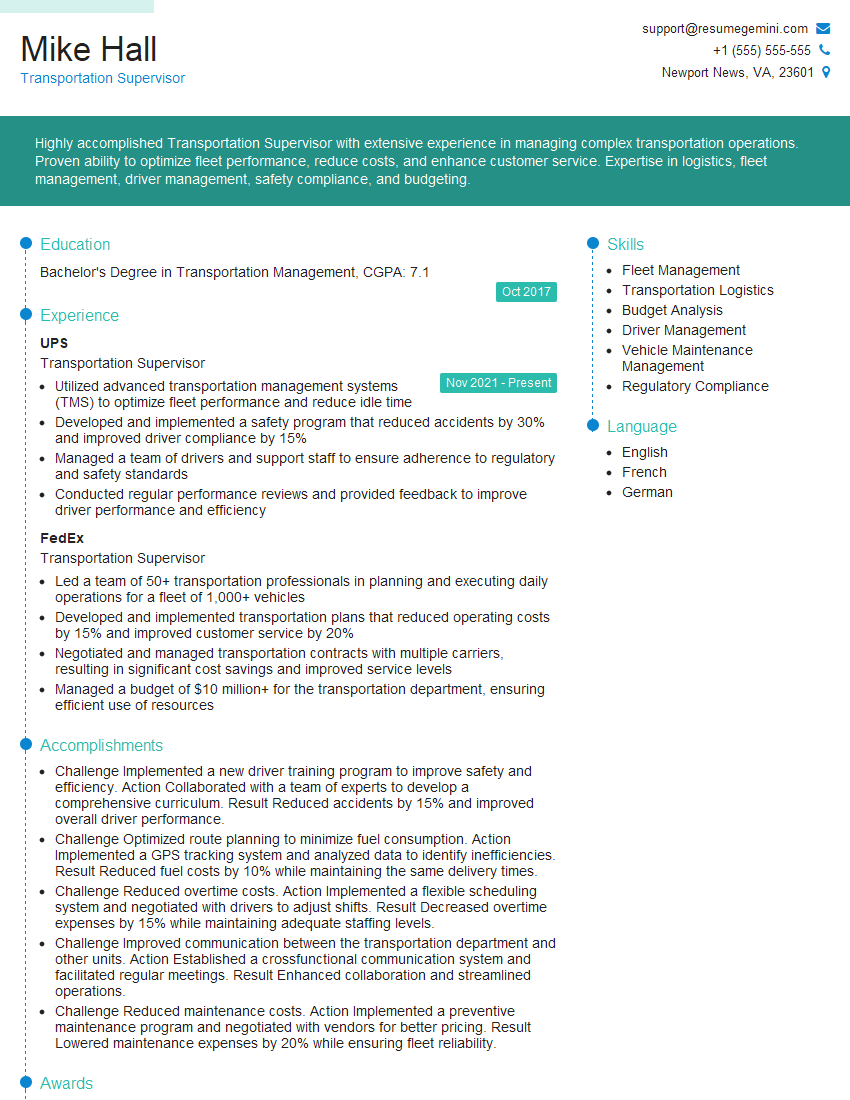

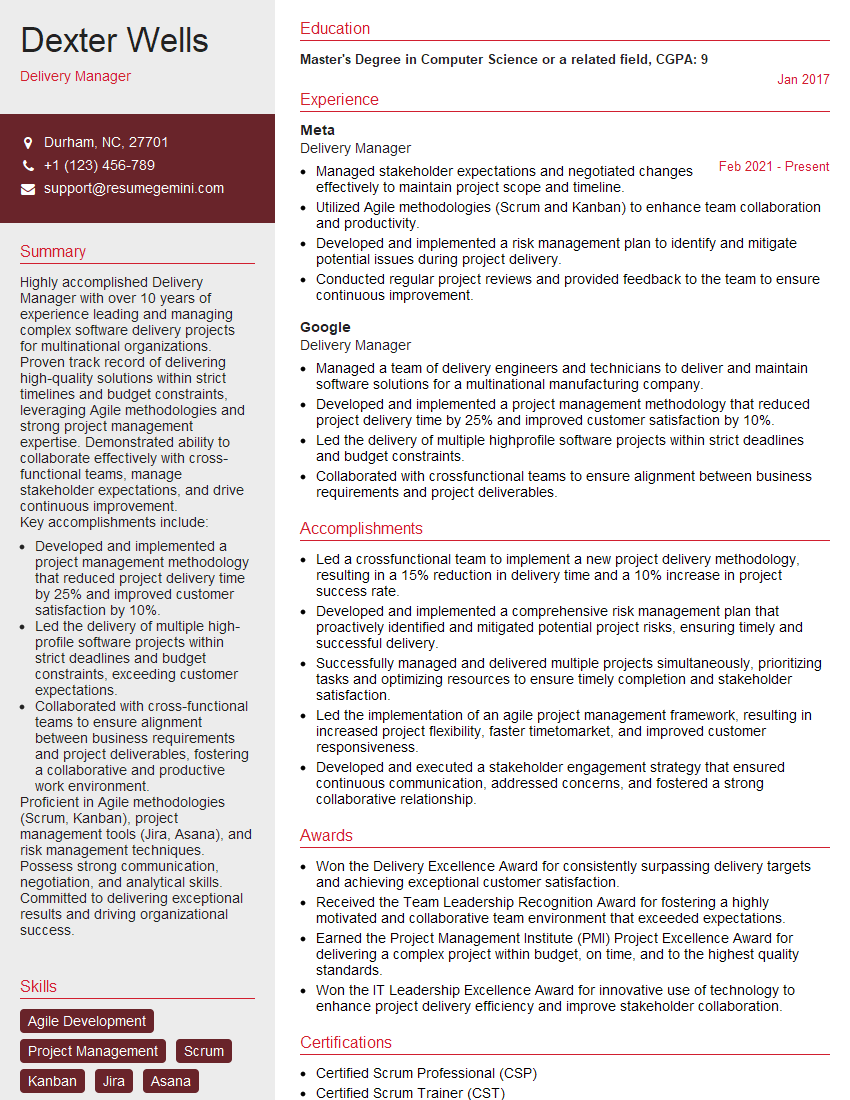

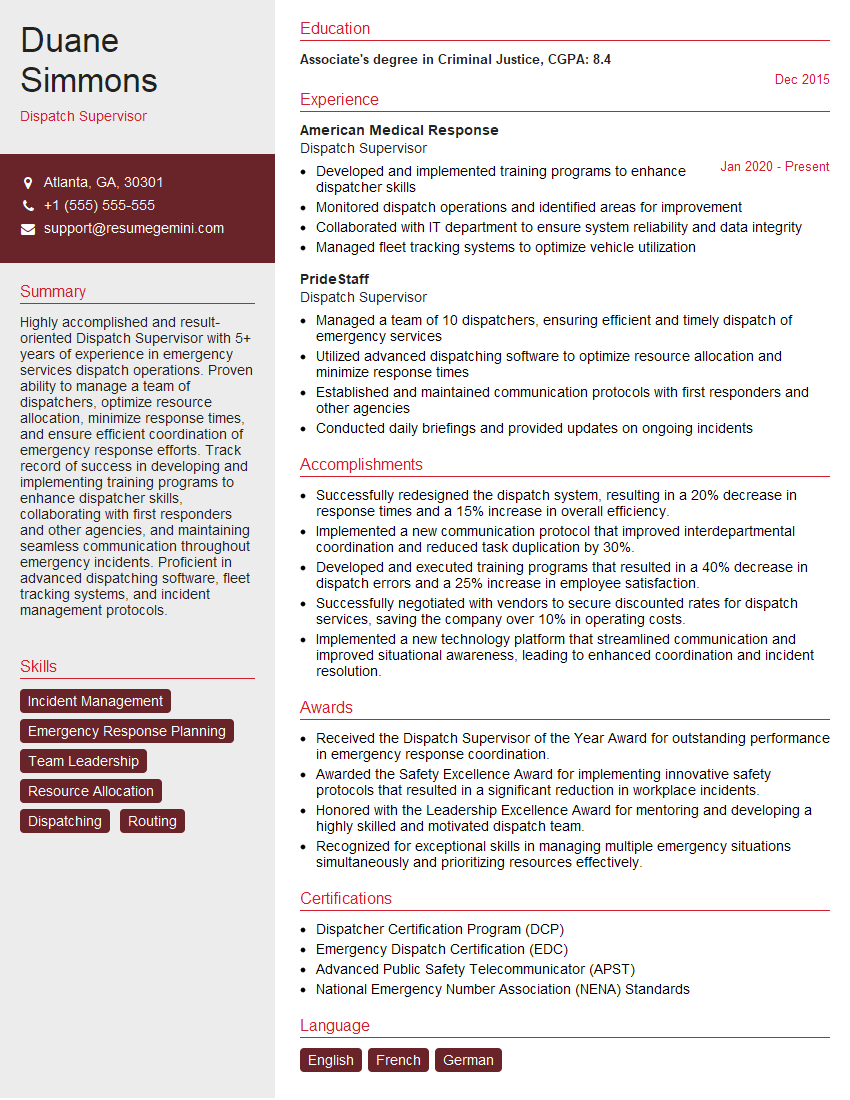

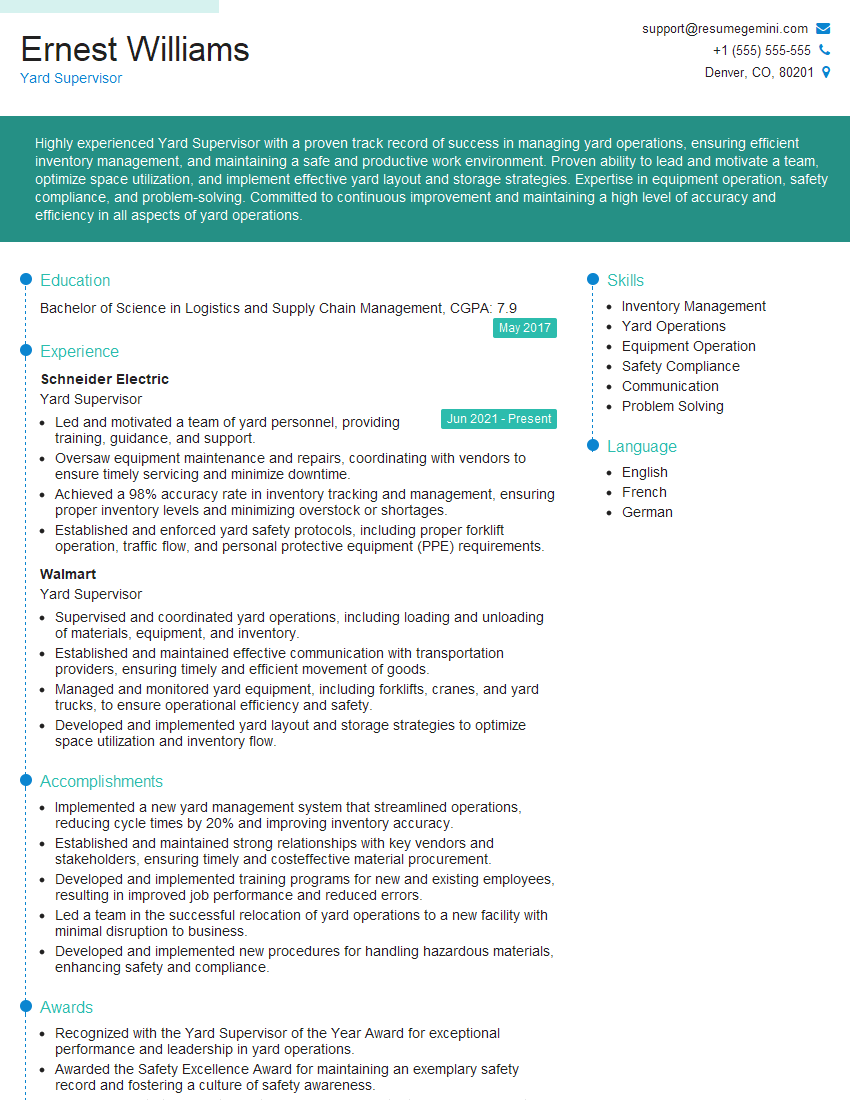

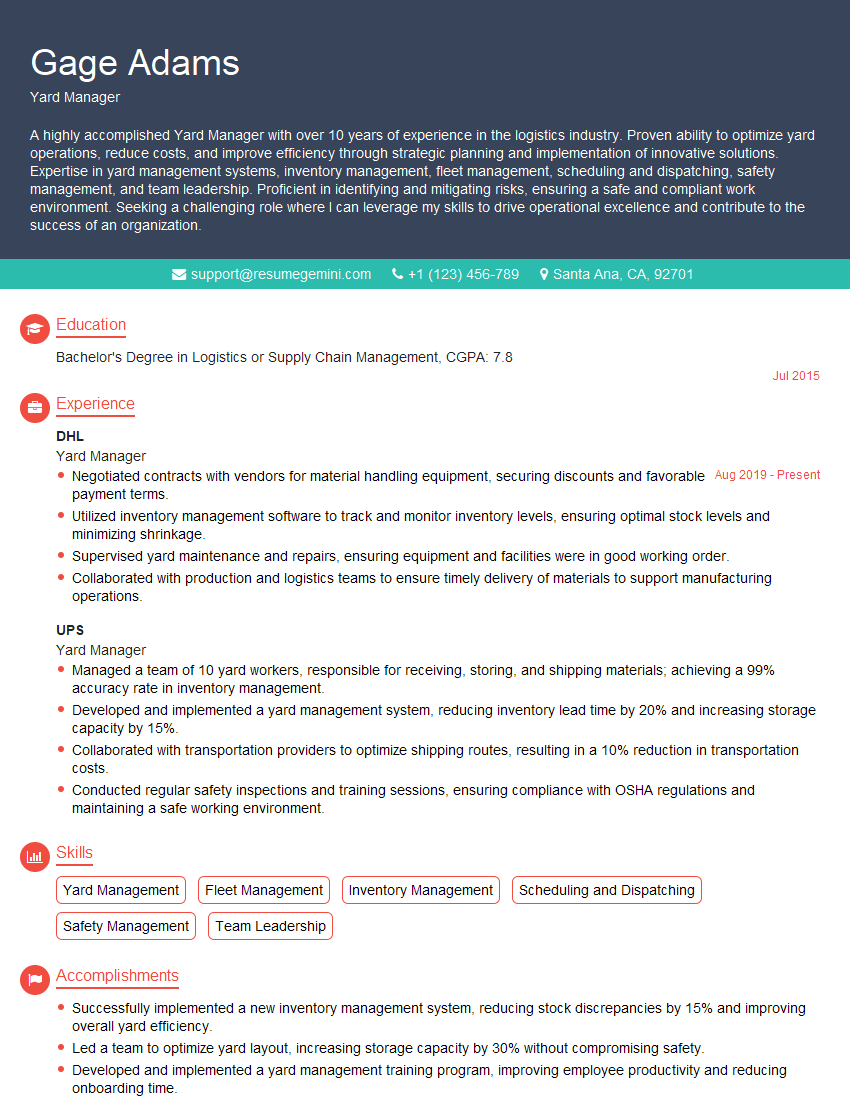

Mastering Yard Management and Fleet Coordination opens doors to rewarding careers with excellent growth potential in logistics, supply chain, and transportation industries. To stand out, a strong and ATS-friendly resume is crucial. This is where ResumeGemini can help. ResumeGemini offers a trusted platform to build a professional resume that showcases your skills and experience effectively. We provide examples of resumes tailored to Yard Management and Fleet Coordination to guide you through the process. Invest time in crafting a compelling resume to maximize your job prospects.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good