Unlock your full potential by mastering the most common Yarn Production Knowledge interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Yarn Production Knowledge Interview

Q 1. Explain the different types of yarn spinning systems.

Yarn spinning systems are broadly categorized into two main types: short staple spinning and long staple spinning. Short staple spinning deals with fibers like cotton, wool, and synthetic fibers that are relatively short. Long staple spinning uses longer fibers such as silk, linen, or some specialized synthetic fibers.

- Short Staple Spinning Systems: These involve several processes to transform short fibers into a continuous yarn. The most common systems include:

- Ring Spinning: This is a classic and widely used method, known for its versatility and ability to produce high-quality yarns. It involves twisting fibers together using a rotating ring and traveler.

- Rotor Spinning: A high-speed process that produces relatively thick, hairy yarns quickly and cost-effectively. It utilizes a rotating rotor to create the yarn.

- Air-Jet Spinning: This system uses compressed air to twist and compact the fibers, leading to finer and stronger yarns compared to rotor spinning.

- Open-End Spinning (OE): Similar to air-jet spinning, it uses air to create the yarn. Often used for cheaper yarns.

- Long Staple Spinning Systems: These systems are more suited for longer fibers and tend to produce smoother, higher-quality yarns. Examples include:

- Worsted Spinning: Emphasizes parallel fiber alignment, resulting in a smoother, stronger yarn. Often used for high-quality woolen garments.

The choice of spinning system depends on fiber type, desired yarn properties (strength, fineness, evenness), and cost considerations.

Q 2. Describe the process of yarn twisting.

Yarn twisting is the process of combining and interlacing fibers to create a continuous strand. It’s crucial for yarn strength and stability. Think of it like braiding hair – the individual strands are weaker than the combined braid. The process involves feeding several fibers (or slivers) to a twisting mechanism. The twist imparts strength, cohesion, and prevents the fibers from separating. The twist is measured in turns per inch (tpi) or turns per meter (tpm). Higher twists generally result in stronger, smoother yarns, but can also make the yarn less flexible.

Different twisting mechanisms are used, depending on the spinning system. Ring spinning uses a rotating traveler to twist the fibers; rotor spinning uses the centrifugal force of a rotor; and air-jet spinning uses jets of air to impart the twist. The amount of twist is carefully controlled to achieve the desired yarn properties. Too little twist leads to weak, easily unraveling yarn, while too much can make the yarn stiff and brittle.

Q 3. What are the key quality parameters for yarn?

Key quality parameters for yarn are crucial for ensuring the final fabric meets quality standards. These parameters can be broadly grouped into:

- Strength: Measured as tensile strength (the force needed to break the yarn), it’s a critical indicator of durability. A weaker yarn will lead to a weaker fabric.

- Evenness: Refers to the uniformity of the yarn’s thickness along its length. Unevenness leads to visible flaws and inconsistencies in the fabric.

- Hairiness: The amount of protruding fibers from the yarn surface. High hairiness can impact the fabric’s smoothness and appearance.

- Count/Fineness: Indicates the yarn’s thickness – finer yarns have a higher count (e.g., 80s cotton is finer than 40s cotton). This influences fabric drape and softness.

- Twist: The number of turns per inch or meter, significantly impacting yarn strength and structure.

- Elongation: The ability of the yarn to stretch before breaking. High elongation implies elasticity and gives the fabric better drapability and resilience.

These parameters are measured using specialized instruments and tests, like the Uster Tester, which is a widely used system in the industry for yarn quality assessment.

Q 4. How do you identify and troubleshoot common yarn defects?

Identifying and troubleshooting yarn defects requires a systematic approach. Visual inspection is the first step, followed by detailed analysis using specialized testing equipment. Common yarn defects include:

- Thick places/Thin places: Uneven yarn thickness, often due to problems in the fiber preparation or spinning process.

- Slubs: Localized thickenings caused by fiber clumps.

- Neps: Small entangled fiber clusters.

- Broken ends: Yarn breaks during the spinning process.

- Hairiness: Excessive fiber protruding from the yarn.

Troubleshooting involves pinpointing the source of the defect within the spinning process. For example, thick places might originate from uneven fiber feeding, while slubs could indicate problems in the carding or combing stages. Careful examination of the yarn and investigation of the machine settings and maintenance records are essential for effective troubleshooting.

Q 5. Explain the importance of yarn count and its measurement.

Yarn count, also known as yarn number or yarn fineness, represents the thickness of the yarn. It’s crucial because it directly affects the fabric’s properties like weight, drape, and texture. There are different systems for measuring yarn count, including:

- Direct System: The count is the number of units of length (e.g., yards, meters) per unit of weight (e.g., pound, kilogram).

- Indirect System: The count is the number of units of weight per unit of length.

For example, a yarn with a count of 40s (in the direct system) means there are 40 hanks (840 yards) weighing one pound. Higher counts indicate finer yarns (e.g., 60s is finer than 40s). The correct interpretation of yarn count is essential for selecting the appropriate yarn for a particular fabric type and ensuring consistent fabric quality. An incorrect yarn count can lead to significant issues in the downstream processes like weaving and knitting.

Q 6. What are the different types of fibers used in yarn production?

A wide variety of fibers are used in yarn production, each with unique properties affecting the final yarn characteristics:

- Natural Fibers:

- Cotton: A staple fiber, widely used for its softness, absorbency, and breathability.

- Wool: A staple fiber, known for its warmth, elasticity, and moisture-wicking properties.

- Silk: A long fiber, renowned for its luxurious feel, smoothness, and luster.

- Linen: A long fiber, strong, absorbent, and known for its crispness and drape.

- Synthetic Fibers:

- Polyester: A strong, durable, and wrinkle-resistant fiber, widely used in blends.

- Nylon: Extremely strong and resilient, often used for hosiery and outdoor wear.

- Acrylic: A soft, warm, and relatively inexpensive fiber, often used as a wool substitute.

- Rayon: A semi-synthetic fiber, soft, and drapes well.

Blending different fibers is common to achieve specific properties in the yarn. For example, combining cotton with polyester can create a more durable and wrinkle-resistant fabric.

Q 7. Describe the role of lubricants in yarn production.

Lubricants play a vital role in yarn production by reducing friction between fibers and machinery. This is especially important in high-speed spinning processes. Lubricants:

- Reduce fiber breakage: By minimizing friction, they prevent fibers from breaking during twisting and winding.

- Improve yarn evenness: They help prevent fiber slippage and ensure a consistent yarn diameter.

- Enhance machine efficiency: Less friction means smoother operation and reduced wear on machinery.

- Improve spinning performance: They assist in preventing the build-up of static electricity, which can cause problems during the spinning process.

Lubricants are carefully selected based on fiber type and spinning system. The choice involves considering their viscosity, compatibility with fibers, and environmental impact. Incorrect lubrication can lead to increased fiber breakage, uneven yarn, machine downtime, and lower yarn quality. Regular lubrication is critical for maintaining efficient and high-quality yarn production.

Q 8. How do you maintain optimal machine efficiency in yarn production?

Maintaining optimal machine efficiency in yarn production is crucial for profitability and minimizing waste. It’s a multi-faceted approach focusing on preventative maintenance, operator training, and process optimization.

- Preventative Maintenance: Regular scheduled maintenance, including cleaning, lubrication, and part replacements, significantly reduces downtime caused by unexpected breakdowns. Think of it like servicing your car – regular checks prevent major issues down the line. We implement a comprehensive PM schedule, tracking machine performance metrics to identify potential problems before they arise.

- Operator Training: Skilled operators are essential. Proper training on machine operation, troubleshooting, and quality control ensures machines are run efficiently and correctly. We regularly conduct training sessions focusing on best practices and new technologies.

- Process Optimization: Analyzing production data to identify bottlenecks and inefficiencies is key. This may involve adjusting machine settings, improving material handling, or implementing lean manufacturing principles. For example, we recently implemented a new software system that provides real-time machine performance data, allowing us to immediately address any deviations from optimal parameters.

- Spare Parts Management: Having readily available spare parts minimizes downtime during repairs. We maintain a well-stocked inventory of crucial components, enabling quick replacements and minimizing production interruptions.

By combining these strategies, we achieve maximum machine uptime, reduce production costs, and maintain consistent yarn quality.

Q 9. Explain the process of yarn winding and its importance.

Yarn winding is the process of transferring yarn from a supply package (like a bobbin or cone) onto a larger package, typically a cone or a spool. This is a critical step because it prepares the yarn for subsequent processes like weaving or knitting.

The importance of yarn winding lies in:

- Package Formation: Winding creates a uniform and manageable package of yarn that is suitable for downstream processes. A poorly wound package can lead to yarn breaks and production inefficiencies.

- Yarn Protection: Proper winding minimizes yarn damage and ensures its integrity. This is particularly important for delicate yarns.

- Consistent Tension Control: Maintaining consistent tension during winding is crucial for preventing yarn breakage and ensuring uniform yarn package density. Uneven tension can lead to weak points in the yarn, affecting the final product’s quality.

- Efficient Processing: Well-wound packages facilitate smooth and efficient processing in later stages of textile manufacturing.

Different types of winding machines exist, each offering unique capabilities to meet specific yarn types and package requirements. For instance, precision winding machines are used for high-quality yarns requiring superior package density and uniformity.

Q 10. What are the different types of yarn packages?

Yarn packages come in a variety of shapes and sizes, each serving a specific purpose in the textile manufacturing process. The choice of package depends on the type of yarn, the subsequent process, and the desired properties of the final product.

- Cones: These are widely used for their ability to hold a large quantity of yarn and provide excellent unwinding characteristics. They are ideal for weaving and knitting.

- Bobbins: These cylindrical packages are commonly used in spinning and winding processes. They are generally smaller than cones and suitable for finer yarns.

- Cheese Packages: These have a characteristic layered structure, providing a large yarn capacity and good unwinding performance.

- Spools: These are simple cylindrical packages, often used for smaller yarn quantities or specialized applications.

- Packages for specific needs: There are also specialized packages designed for specific needs like high-speed weaving or particular yarn types like those with slub or novelty effects.

Choosing the right yarn package is crucial for ensuring efficient downstream processing and maintaining yarn quality.

Q 11. Describe the role of quality control in yarn production.

Quality control (QC) in yarn production is a systematic process designed to ensure that the yarn meets predetermined specifications and standards. It involves continuous monitoring and testing at various stages of the production process to identify and rectify any defects or inconsistencies.

The role of QC includes:

- Raw Material Inspection: Ensuring the quality of raw materials (fibers) before they enter the production process.

- In-Process Monitoring: Regular checks throughout the production process to identify potential problems early.

- Finished Yarn Testing: Thorough testing of the finished yarn to ensure it meets the required specifications for strength, evenness, and other parameters.

- Defect Analysis: Identifying the root causes of defects to prevent their recurrence.

- Data Recording and Analysis: Maintaining detailed records of QC tests and using data analysis to identify trends and areas for improvement.

A robust QC system ensures consistent yarn quality, reduces waste, and ultimately enhances customer satisfaction. Without it, defects could lead to costly rework and dissatisfied customers.

Q 12. How do you ensure consistent yarn quality throughout the production process?

Ensuring consistent yarn quality is a continuous effort, requiring attention to detail at every stage of the production process. It’s achieved through a combination of strategies:

- Precise Machine Settings: Maintaining optimal machine settings for each step of yarn production (spinning, winding, etc.) is crucial. Regular calibration and adjustments are essential.

- Consistent Raw Material Quality: Using high-quality, consistent raw materials minimizes variations in yarn properties.

- Effective Process Control: Implementing appropriate process controls to monitor parameters such as twist, tension, and speed throughout the production line. This often involves automated monitoring and control systems.

- Regular Maintenance: Preventative maintenance of machinery prevents unexpected breakdowns and ensures consistent performance.

- Operator Training: Well-trained operators are crucial for maintaining consistent process parameters and identifying potential issues.

- Statistical Process Control (SPC): Using statistical methods to monitor and control the production process, allowing for early detection of variations and corrective action.

By meticulously following these steps, we can reduce variations in yarn quality and ensure consistent performance across all batches.

Q 13. Explain the concept of yarn strength and its testing methods.

Yarn strength refers to the yarn’s resistance to breakage under tension. It’s a critical quality characteristic that significantly affects the final product’s performance. A strong yarn is essential for durable fabrics and garments.

Testing methods for yarn strength include:

- Single-strand strength testing: This method involves testing the breaking strength of individual yarn strands using a tensile tester. The result is usually expressed in grams per tex (g/tex) or centiNewtons per tex (cN/tex).

- Bundle strength testing: This method involves testing the breaking strength of a bundle of yarn strands, providing an indication of the overall strength and uniformity of the yarn.

These tests provide crucial data for evaluating yarn quality and identifying potential weaknesses. They help us optimize the spinning process, improve yarn consistency, and ensure that the yarn meets the requirements for the intended application. For example, if yarn strength consistently falls below the specified standard, we investigate the cause – this could be issues with the raw materials, machine settings, or even environmental factors.

Q 14. What are the common causes of yarn breakage?

Yarn breakage is a significant issue in yarn production, leading to production downtime, reduced efficiency, and increased costs. Several factors can contribute to yarn breakage:

- Fiber defects: Short fibers, neps (small entangled fiber clusters), or other fiber imperfections can weaken the yarn and make it prone to breakage.

- Insufficient twist: Inadequate twist in the yarn reduces its strength and makes it less resistant to breakage.

- Excessive twist: Conversely, excessive twist can also weaken the yarn and lead to breakage. It can create internal stresses within the yarn structure.

- Machine problems: Malfunctioning machinery, such as damaged rollers or guides, can cause uneven tension and contribute to yarn breakage.

- Environmental factors: High humidity or temperature fluctuations can affect yarn properties and increase the likelihood of breakage.

- Poor winding practices: Incorrect winding procedures can create weak points in the yarn package, leading to breakage during unwinding.

Identifying and addressing the root causes of yarn breakage through careful monitoring, process adjustments, and preventative maintenance is critical for maintaining efficient and high-quality yarn production.

Q 15. How do you address variations in fiber length during yarn production?

Addressing variations in fiber length is crucial for producing consistent yarn quality. Fiber length directly impacts yarn strength, evenness, and overall appearance. We use several methods to manage this:

Blending: Combining fibers of different lengths to achieve a target mean fiber length and a desired fiber length distribution. This is like mixing different types of flour to get the perfect texture for baking – a blend of long and short fibers provides strength and softness.

Sorting: Pre-spinning processes might involve sorting fibers by length using techniques like air classification or mechanical separation. This ensures that fibers within a particular batch are more uniform.

Spinning System Selection: Different spinning systems are better suited to handle varying fiber lengths. For example, ring spinning is more tolerant of longer fibers, while rotor spinning is more adaptable to shorter fibers. Choosing the right system is key to optimizing yarn quality given the available fiber.

Careful Fiber Selection: From the outset, selecting fibers with consistent length distributions minimizes problems downstream. Knowing your fiber source and its characteristics is essential for proactive quality control.

Regular monitoring of fiber length distribution throughout the process using instruments like a fiber length sorter ensures that deviations are identified and corrected promptly. This proactive approach minimizes waste and maintains consistent yarn quality.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with different types of yarn testing equipment.

My experience encompasses a wide range of yarn testing equipment, including:

Uster Tester: This is an industry standard for assessing yarn evenness, strength, imperfections (neps, slubs), and other critical quality parameters. I’m proficient in interpreting the Uster reports to identify areas for improvement in the spinning process.

Yarn Tensile Strength Tester: This instrument measures the breaking strength and elongation of the yarn, providing crucial insights into its durability and performance.

Hairiness Tester: Measures the amount of protruding fibers, which impacts the yarn’s feel and appearance.

Evenness Tester: This evaluates the uniformity of the yarn’s linear density, helping to identify variations that might lead to weak points or inconsistencies in the fabric.

Microscope: A crucial tool for visual inspection of yarn imperfections at a microscopic level.

I’m familiar with both manual and automated testing methods and understand the importance of proper calibration and maintenance to ensure accurate and reliable results. I’ve utilized this equipment to troubleshoot production issues, optimize spinning parameters, and ensure that the final product meets the required quality standards.

Q 17. Explain the importance of maintaining proper humidity and temperature in a yarn production facility.

Maintaining proper humidity and temperature is paramount in yarn production because these factors directly impact fiber properties and yarn quality. Fluctuations can lead to:

Fiber breakage: Low humidity can make fibers brittle and prone to breaking, resulting in yarn defects and reduced strength.

Static electricity: Low humidity increases static electricity, causing fibers to cling together, leading to uneven yarn and processing difficulties.

Dimensional instability: Changes in humidity and temperature can affect the yarn’s dimensions, leading to problems in subsequent processes like weaving or knitting.

Yarn quality variations: Inconsistent conditions result in inconsistent yarn properties.

Therefore, we use environmental control systems – humidifiers, dehumidifiers, and air conditioning – to maintain a stable and optimal environment, typically with a relative humidity around 65% and a temperature range of 20-24°C. Regular monitoring and adjustment are essential to ensure consistency and prevent quality issues. Imagine trying to build a sandcastle on a windy beach – the fluctuating conditions make it impossible to build anything substantial; similarly, uncontrolled temperature and humidity render a consistent yarn product almost impossible to achieve.

Q 18. How do you manage waste and reduce material loss in yarn production?

Waste management and material loss reduction are critical for both environmental responsibility and economic viability in yarn production. We implement several strategies:

Optimized Spinning Parameters: Fine-tuning machine settings like twist, speed, and tension minimizes breakage and reduces waste generated during spinning.

Regular Machine Maintenance: Preventative maintenance ensures optimal machine performance, minimizing downtime and yarn defects.

Efficient Cleaning and Recycling: We have implemented systems for efficient cleaning of machines and recycling of waste fibers. This reduces landfill waste and recovers valuable materials.

Process Optimization: Continuous improvement projects focus on identifying and eliminating sources of waste throughout the production process, from fiber preparation to yarn packaging.

Waste Audits: Regularly analyzing waste streams helps identify areas for improvement and measure the success of waste reduction efforts.

By focusing on these areas, we can significantly reduce waste, improve efficiency, and reduce the environmental footprint of yarn production, contributing to a more sustainable manufacturing process.

Q 19. Describe your experience with yarn production planning and scheduling.

My experience in yarn production planning and scheduling includes:

Demand Forecasting: Analyzing historical sales data, market trends, and customer orders to accurately forecast yarn demand.

Production Planning: Developing detailed production schedules that balance capacity constraints, material availability, and customer delivery deadlines.

Inventory Management: Maintaining optimal levels of raw materials and finished goods to meet demand while minimizing storage costs and obsolescence.

Capacity Planning: Assessing current production capacity and making recommendations for expansion or upgrades to meet future demand.

ERP Systems: Proficient in using Enterprise Resource Planning (ERP) software to manage and track production schedules, inventory levels, and other key metrics.

I’ve successfully implemented just-in-time (JIT) inventory strategies in previous roles, minimizing storage costs while ensuring prompt delivery to customers. I use various scheduling techniques like Kanban and Lean Manufacturing principles to optimize workflow and improve efficiency.

Q 20. How do you improve efficiency and productivity in yarn production?

Improving efficiency and productivity in yarn production requires a multi-faceted approach:

Automation: Implementing automation technologies such as automatic doffing systems, robotic handling, and automated quality control systems can significantly improve efficiency and reduce labor costs.

Lean Manufacturing Principles: Adopting lean methodologies like Kaizen (continuous improvement) and 5S (sort, set in order, shine, standardize, sustain) helps to eliminate waste and optimize workflows.

Preventative Maintenance: Regular maintenance reduces downtime and improves machine efficiency.

Employee Training and Development: Investing in employee training improves skills and boosts productivity. A well-trained workforce is more efficient and capable of identifying and resolving production bottlenecks.

Data Analytics: Utilizing data analytics tools to monitor key performance indicators (KPIs) such as production output, waste rates, and machine downtime helps identify areas for improvement.

For example, in a previous role, by implementing a lean manufacturing initiative we were able to reduce production lead times by 15% and decrease waste by 10%, demonstrating the tangible benefits of focusing on efficiency improvements.

Q 21. What are the safety protocols you follow in a yarn production environment?

Safety is paramount in a yarn production environment. Our safety protocols include:

Personal Protective Equipment (PPE): Mandatory use of PPE such as safety glasses, hearing protection, and gloves to protect workers from potential hazards.

Lockout/Tagout Procedures: Strict adherence to lockout/tagout procedures to prevent accidental machine starts during maintenance or repairs.

Machine Guarding: Ensuring all machines are properly guarded to prevent accidental contact with moving parts.

Regular Safety Training: Providing regular safety training to all employees on hazard identification, risk assessment, and emergency procedures.

Emergency Response Plan: A well-defined emergency response plan is in place to handle incidents such as fires, spills, or injuries.

Ergonomic Workplace Design: The workplace is designed to minimize ergonomic risks and promote worker comfort and well-being.

We conduct regular safety audits and inspections to identify and address potential hazards promptly. A safe working environment is not just a legal requirement, it’s crucial for maintaining a productive and healthy workforce.

Q 22. Explain your experience with different types of yarn production machinery.

My experience encompasses a wide range of yarn production machinery, from the initial stages of fiber preparation to the final yarn packaging. I’ve worked extensively with various types of carding machines, like roller carding machines and needle looms, for fiber opening and cleaning. My expertise extends to different spinning systems, including ring spinning, which is the most common method, and the more advanced technologies like rotor spinning and air-jet spinning. Each system has its strengths and weaknesses in terms of yarn quality, production speed, and cost-effectiveness. For example, ring spinning produces a high-quality, strong yarn, but it’s slower and more expensive than rotor spinning. I’m also familiar with winding, twisting, and doubling machines, along with modern automation systems that monitor and control these processes for optimal efficiency and consistency.

Furthermore, I have practical experience with modern quality control instruments such as evenness testers and strength testers which play a vital role in ensuring high-quality yarn production. This hands-on experience allows me to troubleshoot issues effectively and optimize machine settings for improved performance.

Q 23. Describe your experience with lean manufacturing principles in yarn production.

Lean manufacturing principles are central to my approach to yarn production. I’ve implemented several lean methodologies, including 5S (Sort, Set in Order, Shine, Standardize, Sustain) to improve workplace organization and efficiency. This has resulted in reduced waste and improved safety. I’ve also actively participated in Kaizen events, focusing on continuous improvement through small, incremental changes. For example, one Kaizen project involved optimizing the layout of our spinning machines to reduce transportation time and improve workflow. This resulted in a measurable increase in output and reduction in machine downtime. I understand the importance of value stream mapping to identify bottlenecks and waste in the production process and have used this technique effectively to improve overall efficiency.

Beyond these methods, I’m proficient in applying principles of Total Quality Management (TQM), focusing on preventing defects rather than simply detecting them after production. This includes close monitoring of raw materials, consistent machine maintenance, and operator training to maintain consistent standards throughout the process. The use of statistical process control (SPC) charts is integral to identifying deviations from these standards in a timely fashion.

Q 24. How do you handle unexpected production issues and downtime?

Unexpected production issues and downtime are inevitable in yarn production. My approach involves a structured problem-solving methodology. First, I focus on quickly identifying the root cause of the problem. This often involves a thorough examination of the machine, raw materials, and the overall process. I utilize diagnostic tools and collaborate with maintenance staff to pinpoint the issue accurately. Once identified, I implement a quick fix to minimize downtime, while simultaneously initiating a longer-term solution to prevent future occurrences.

For example, if a machine malfunction occurs, I would immediately initiate a safety shutdown, assess the situation and based on severity either perform minor repairs or notify the maintenance team. While repairs are underway, I would work to redirect production to other available machines or temporarily adjust production plans to minimize impact on overall schedules. After the issue is resolved, a thorough post-mortem analysis is conducted to understand the root cause and implement preventative measures, possibly involving adjustments to maintenance schedules or operator training.

Q 25. Explain your experience with data analysis and reporting in yarn production.

Data analysis and reporting are crucial for continuous improvement in yarn production. I’m proficient in using various data analysis tools and techniques to monitor key performance indicators (KPIs). This includes analyzing data related to production output, machine efficiency, yarn quality, waste, and energy consumption. I use statistical software and spreadsheets to generate reports and visualize data trends to identify areas for improvement.

For example, by analyzing data on yarn breakage rates, I was able to pinpoint a specific machine setting that was contributing to excessive breakages. By adjusting this setting, we significantly reduced breakages and improved overall productivity. I also use data analysis to predict potential issues before they occur, enabling proactive maintenance and minimizing disruptions. This predictive capability stems from understanding historical data trends and applying appropriate statistical modeling techniques. My reports are designed to be clear, concise, and actionable, providing management with the information they need to make informed decisions.

Q 26. How familiar are you with different yarn numbering systems (e.g., English, Metric)?

I’m very familiar with different yarn numbering systems, including the English system (indirect system) and the Metric system (direct system). The English system expresses yarn count as the number of hanks (840 yards) per pound, while the Metric system expresses it as the number of meters per kilogram. Understanding both is vital for accurate communication with suppliers, customers, and within the production process itself.

Converting between systems is a critical skill. For example, a yarn with an English count of 20s is equivalent to a specific metric count. I use conversion formulas and reference tables to ensure consistent measurement and prevent errors related to misinterpretations. This understanding also allows me to analyze data correctly, regardless of the system used for recording.

Q 27. Describe your experience with implementing process improvements in yarn production.

I have extensive experience implementing process improvements in yarn production, focusing on efficiency, quality, and cost reduction. My approach typically involves a systematic process: starting with identifying areas needing improvement through data analysis and observation, followed by brainstorming potential solutions, evaluating these solutions based on cost-benefit analysis and feasibility. Implementation involves careful planning and monitoring of progress and finally, documenting the results and sharing best practices across the team.

For example, I successfully implemented a new yarn winding technique that reduced yarn waste by 15% and improved winding speed by 10%. This involved researching new winding technologies, training staff on the new technique, and closely monitoring the results to ensure the improvements were sustained. Another example involves implementing a preventative maintenance program which drastically improved uptime and reduced machine repair costs.

Q 28. How do you ensure compliance with industry standards and regulations in yarn production?

Compliance with industry standards and regulations is paramount in yarn production. I’m familiar with relevant safety standards, environmental regulations (such as waste disposal guidelines), and quality control standards (e.g., ISO 9001). I ensure compliance by meticulously documenting all processes, maintaining detailed records of raw materials, and regularly conducting quality checks throughout the production process.

For instance, I ensure proper disposal of wastewater and other industrial waste according to environmental regulations, working closely with our environmental compliance officer. Regular audits and inspections are crucial, and I actively participate in these to identify any non-compliance issues and implement corrective actions promptly. Operator training on safety protocols is a cornerstone of compliance, emphasizing the importance of safe handling of machinery and materials. This commitment to compliance not only safeguards the environment and employees, but also protects the company’s reputation and ensures long-term sustainability.

Key Topics to Learn for Yarn Production Knowledge Interview

- Fiber Properties & Selection: Understanding different fiber types (cotton, wool, synthetics), their properties (strength, length, fineness), and how these impact yarn quality and suitability for various applications.

- Yarn Manufacturing Processes: Familiarize yourself with spinning systems (ring spinning, rotor spinning, air-jet spinning), their advantages and disadvantages, and the resulting yarn characteristics. Consider the practical aspects of each process, including machine maintenance and troubleshooting.

- Yarn Quality Control: Learn about the various testing methods used to assess yarn quality (tensile strength, evenness, imperfections). Understand how these tests inform production decisions and contribute to maintaining consistent quality standards.

- Yarn Structure & Properties: Grasp the relationship between yarn twist, count, and the resulting yarn properties (strength, elasticity, drape). Be prepared to discuss how these factors influence the final fabric characteristics.

- Raw Material Handling & Management: Understand best practices for storing and handling raw materials to maintain quality and prevent waste. Explore the impact of storage conditions on fiber properties and subsequent yarn production.

- Production Planning & Optimization: Learn about techniques for optimizing yarn production processes, including minimizing waste, improving efficiency, and managing production schedules. Consider the role of lean manufacturing principles.

- Troubleshooting & Problem Solving: Develop your ability to identify and address common problems encountered during yarn production, such as yarn breakage, inconsistencies in quality, and machine malfunctions.

- Health and Safety Regulations: Be aware of the relevant health and safety regulations and best practices associated with yarn production, including machine safety and handling of raw materials.

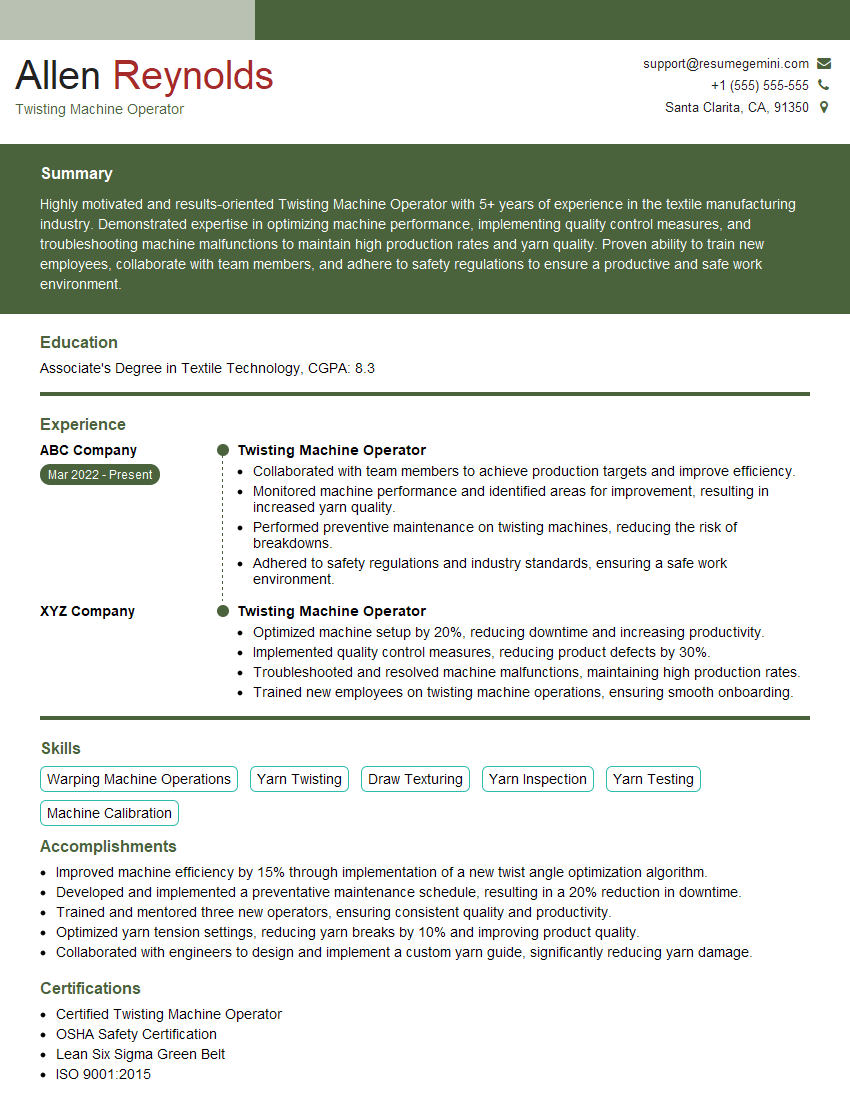

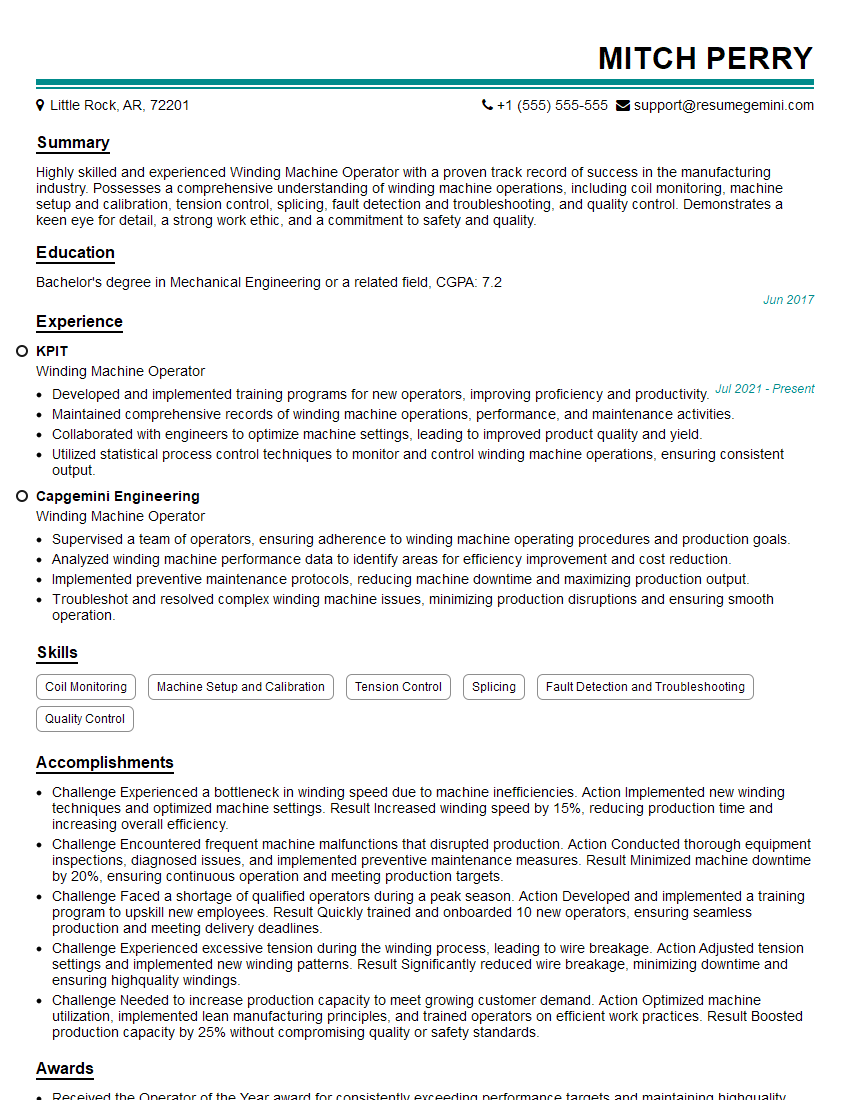

Next Steps

Mastering Yarn Production Knowledge is crucial for career advancement in the textile industry, opening doors to more senior roles and higher earning potential. A well-crafted resume is your first impression on potential employers. Creating an ATS-friendly resume is vital to ensure your application is seen by recruiters. ResumeGemini is a trusted resource that can help you build a professional, impactful resume that stands out from the competition. They offer examples of resumes tailored to Yarn Production Knowledge to help you get started. Invest time in building a strong resume; it’s a key step towards securing your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good