Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Computer-Aided Design (CAD) and Modeling interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Computer-Aided Design (CAD) and Modeling Interview

Q 1. What CAD software are you proficient in?

I’m proficient in several leading CAD software packages. My expertise primarily lies in Autodesk Inventor, SolidWorks, and AutoCAD. I’ve also worked with Fusion 360 and CATIA on various projects, allowing me to adapt to different software environments and project needs. My proficiency extends beyond basic functionality; I’m adept at leveraging advanced features like simulation tools, rendering, and data management within each platform.

Q 2. Explain your experience with 2D and 3D modeling.

My experience encompasses both 2D and 3D modeling, understanding that each serves a distinct purpose. 2D modeling, primarily using AutoCAD, is crucial for creating detailed technical drawings, schematics, and plans. I frequently use it for things like creating floor plans, generating detailed manufacturing drawings with dimensions and tolerances, and preparing documentation for fabrication. 3D modeling, using primarily Inventor and SolidWorks, allows for the creation of realistic digital representations of physical objects. This is invaluable for design exploration, virtual prototyping, and advanced analysis like stress testing and fluid dynamics simulations. For example, I used SolidWorks to design a complex injection-molded plastic part, iteratively refining the design based on simulated stress analysis, before finally generating manufacturing drawings in AutoCAD.

Q 3. Describe your process for creating a detailed CAD drawing.

Creating a detailed CAD drawing involves a structured, iterative process. It starts with a thorough understanding of the design requirements and specifications. Then, I typically follow these steps:

- Conceptualization and Sketching: I begin by sketching the design, either digitally or traditionally, to establish basic geometry and functionality.

- 3D Modeling: Using my preferred software (often Inventor or SolidWorks), I create the 3D model, paying close attention to dimensions, tolerances, and material properties. This stage involves feature-based modeling, utilizing tools like extrudes, revolves, and sweeps to build the design.

- Constraints and Relationships: I diligently apply constraints and relationships to ensure that the model behaves as expected and maintains dimensional accuracy as it’s modified. Parametric modeling is crucial at this stage.

- Assembly (if applicable): If the design involves multiple parts, I create an assembly, meticulously defining the relationships between components to simulate real-world functionality.

- Detailed Drawings: Once the 3D model is finalized, I generate 2D drawings that incorporate views, sections, dimensions, tolerances, material specifications, and other necessary annotations. This phase often leverages the automated drawing creation features within the CAD software.

- Review and Iteration: Finally, I conduct a thorough review, checking for errors, inconsistencies, and potential design flaws before releasing the final drawings.

For instance, in a recent project involving a robotic arm, I started with a basic kinematic sketch, progressed to a 3D model of each component, assembled them virtually, conducted motion simulation, and finally produced detailed manufacturing drawings for each part. This iterative process ensured the design was both functional and manufacturable.

Q 4. How do you handle revisions and updates in CAD projects?

Managing revisions and updates is crucial. I leverage version control systems built into most CAD software, such as Autodesk Vault or SolidWorks PDM. This allows tracking changes, reverting to previous versions if necessary, and managing multiple iterations of a design. A clear revision numbering system is also employed to ensure everyone works with the latest approved version. I always meticulously document each revision, noting the date, author, and the nature of the changes. Collaboration tools integrated within the CAD software also help in managing revisions collaboratively, allowing for feedback and review cycles before finalizing changes.

Q 5. What are your preferred CAD modeling techniques?

My preferred CAD modeling techniques depend on the project’s complexity and requirements. I frequently use feature-based modeling for its efficiency and ease of modification. However, I also utilize direct modeling for quick prototyping and design exploration, especially when dealing with complex organic shapes. When dealing with intricate assemblies, I prefer top-down assembly modeling, building the assembly first and then detailing the individual components.

Q 6. Explain your experience with parametric modeling.

Parametric modeling is a cornerstone of my CAD workflow. It allows defining design elements using parameters and equations, creating models that automatically update when parameters change. This is incredibly valuable for design exploration and optimization. For instance, I might parameterize the dimensions of a bracket to easily test different sizes and configurations, ensuring the design meets strength requirements while minimizing material use. This iterative process significantly reduces design time and minimizes errors.

Q 7. How do you manage large and complex CAD assemblies?

Managing large and complex assemblies necessitates a structured approach. I utilize techniques such as:

- Component organization: Grouping components logically into sub-assemblies to simplify management.

- Lightweight components: Employing techniques to reduce the file size of individual components without sacrificing detail.

- Component simplification: Using simplified representations of components in less critical areas of the assembly to improve performance.

- Assembly constraints: Using constraints effectively to ensure proper assembly functionality and maintain design intent.

- Data management: Leveraging CAD data management tools to manage files efficiently and track versions.

Q 8. Describe your approach to troubleshooting CAD issues.

My approach to troubleshooting CAD issues is systematic and methodical. I start by clearly defining the problem. Is it a geometric error, a rendering issue, a file corruption, or a software glitch? Then, I utilize a process of elimination, checking the simplest solutions first. For example, I might check for simple mistakes like incorrect units or constraints before diving into more complex issues.

I often employ the following steps:

- Reproduce the error: I try to consistently replicate the problem to understand its trigger.

- Isolate the source: If the issue is in a large assembly, I’ll try to isolate the problematic component or part.

- Check constraints and parameters: Many issues stem from poorly defined or conflicting constraints. Reviewing these is usually my next step.

- Review the history: If version control is in place, reviewing past versions can pinpoint when the issue first appeared.

- Consult documentation and online resources: The software documentation and online forums are invaluable resources.

- Seek help: If I’m unable to resolve the issue independently, I don’t hesitate to reach out to colleagues or the software’s support team.

For example, I once encountered a model that wouldn’t render correctly. After systematically checking the model’s geometry and constraints, I discovered a hidden, overlapping surface causing the rendering engine to crash. Removing the offending geometry solved the problem.

Q 9. How do you ensure accuracy and precision in your CAD models?

Ensuring accuracy and precision in CAD models is paramount. I use a multi-pronged approach:

- Precise units and tolerances: Defining clear units (e.g., millimeters, inches) and appropriate tolerances from the outset prevents accumulation of errors.

- Geometric constraints: I liberally use geometric constraints (distance, angle, parallelism, perpendicularity) to maintain relationships between elements, preventing dimensional drift.

- Regular model checks: Frequent model checks using built-in analysis tools (e.g., interference detection, mass properties calculation) identify potential issues early.

- Parametric modeling: Utilizing parametric modeling allows for easy modification and updates while maintaining design intent and dimensional consistency.

- Reference models: When appropriate, I utilize reference models or imported data to ensure compatibility and accuracy.

- Detailed documentation: Maintaining detailed documentation, including design specifications, tolerance tables, and material properties, is crucial for accuracy and future reference.

Imagine designing a complex engine component. Using parametric modeling and constraints ensures that if I adjust the piston diameter, all related dimensions – connecting rod length, cylinder bore – update automatically, maintaining the design intent and preventing errors.

Q 10. What are the limitations of different CAD software packages?

Different CAD software packages have strengths and weaknesses. For instance, SolidWorks excels in mechanical design with its intuitive interface and robust simulation capabilities, but might lack specialized tools found in other software for specific industries like architecture or civil engineering. AutoCAD, while versatile, might require more manual input for complex designs compared to more parametric options.

Here are some common limitations:

- Software-specific file formats: Data transfer between different packages can sometimes be problematic, necessitating translators or file conversions that might result in data loss.

- Licensing costs: High licensing fees can be a significant barrier, especially for smaller firms.

- Learning curve: Each package has its own learning curve; mastering advanced features often requires extensive training.

- Hardware requirements: Complex models demand high-performance computers, which can represent a substantial investment.

- Industry-specific features: Some packages are specialized towards particular industries; their features might not be suitable for other contexts.

For example, while Revit excels in Building Information Modeling (BIM), its capabilities for detailed mechanical component design may be less comprehensive than SolidWorks.

Q 11. Explain your experience with CAD data management and version control.

Effective CAD data management and version control are critical for successful projects. I’ve extensively used platforms like PDM (Product Data Management) systems and cloud-based solutions such as Autodesk Vault and SharePoint. These systems allow multiple users to work simultaneously on the same project without overwriting each other’s work and maintain a complete history of revisions.

My workflow involves:

- Check-in/Check-out: I always check out files before working on them and check them back in with clear descriptions of changes.

- Version numbering: Utilizing consistent version numbering ensures traceability and easy identification of specific revisions.

- Regular backups: I maintain regular backups of project files both locally and on the cloud, protecting against data loss.

- File naming conventions: I adhere to strict file naming conventions for organization and efficient retrieval.

- Metadata management: Populating files with relevant metadata (e.g., author, date, description) enhances searchability and accessibility.

In a past project, utilizing a PDM system prevented a costly error. A team member accidentally deleted a critical component from the main assembly. Because of our version control, we quickly restored the component from a previous version, minimizing project downtime.

Q 12. How do you collaborate with other team members using CAD software?

Collaboration is crucial in CAD. I utilize various methods depending on the project and team size. We employ tools such as shared network folders, cloud-based storage, and dedicated CAD collaboration platforms.

Effective collaboration strategies include:

- Clear communication: We use frequent meetings and communication channels (e.g., email, instant messaging) to discuss design decisions, progress, and potential issues.

- Centralized data repository: Using a central repository (e.g., PDM system, cloud storage) ensures everyone works on the most up-to-date files.

- Version control: Strict version control prevents conflicts and ensures everyone works on the same revision.

- Model review sessions: Regular model review sessions allow for constructive feedback and early detection of potential errors.

- Work breakdown structure: Dividing the project into smaller, manageable tasks enables parallel work and efficient collaboration.

For instance, in a recent project, our team used a cloud-based CAD collaboration platform. This enabled us to work simultaneously on different parts of a complex assembly, while ensuring that everyone had access to the latest version of the model, significantly speeding up the design process.

Q 13. Describe your experience with CAD rendering and visualization.

CAD rendering and visualization are essential for communicating design intent and evaluating the aesthetics of a product. I’m experienced in using various rendering software and techniques.

My experience includes:

- Software proficiency: I’m proficient in software like Keyshot, V-Ray, and the rendering capabilities within CAD packages themselves.

- Material selection: I meticulously select appropriate materials to realistically represent the final product.

- Lighting techniques: I understand and apply lighting techniques to enhance the visual impact of the renderings.

- Post-processing: I use post-processing techniques to refine the renderings and improve their overall quality.

- Animation: I have experience in creating animations to showcase the functionality or movement of a design.

For instance, in a project designing a new smartphone, I created high-quality renderings showcasing the device from different angles, highlighting its sleek design and features, aiding in the marketing and sales efforts.

Q 14. How do you create and manage CAD layers and blocks?

CAD layers and blocks are fundamental for organizing and managing complex models. Layers allow for grouping and controlling the visibility of different elements, simplifying the design process. Blocks are reusable components that can be inserted multiple times, maintaining consistency and saving time.

My approach includes:

- Logical layer organization: I use a logical naming convention for layers (e.g., “Exterior Walls”, “Interior Partitions”, “Mechanical Systems”), making it easy to navigate the model.

- Block creation: I create blocks for frequently used components (e.g., doors, windows, electrical outlets), ensuring consistency across the design.

- Attributes: I use attributes within blocks to parameterize elements (e.g., changing the size of a door without modifying the block geometry).

- Layer states: I utilize layer states to quickly switch between different views of the model, for example, showing only the structural elements or just the electrical systems.

- External references: I use external references (xrefs) to incorporate designs from other files into the current project.

For example, designing a building, I would create separate layers for structural elements, MEP (Mechanical, Electrical, Plumbing) systems, and architectural finishes. Reusing blocks for windows and doors maintains design consistency and speeds up the modeling process.

Q 15. How do you handle different file formats in CAD?

Handling different CAD file formats is crucial for collaboration and data exchange. Different software packages use proprietary formats (like .dwg for AutoCAD, .prt for Creo Parametric), and industry standards exist (like STEP, IGES). My approach involves a multi-pronged strategy:

- Understanding file compatibility: Before starting a project, I identify the required file formats and the software my team and collaborators will use. This prevents issues later on. For example, if we’re collaborating with a firm using SolidWorks, ensuring we can export to .sldprt or import from it is paramount.

- Using CAD software with robust import/export capabilities: Most modern CAD packages offer excellent import/export functionality. I leverage features like ‘translate’ or ‘import’ functions to handle various formats. For example, Autodesk Inventor handles a wide range of file types, minimizing conversion problems.

- Employing neutral file formats: When possible, I work with neutral formats like STEP (.stp) or IGES (.igs). These formats ensure better interoperability across different CAD systems, reducing data loss and errors. Think of them as a ‘universal language’ for CAD data.

- Troubleshooting and data repair: Sometimes, files become corrupted or contain errors during transfer or conversion. I use specialized tools or the built-in repair functionalities of CAD software to resolve these issues. I also practice meticulous file management and version control to prevent such scenarios.

In short, proactive planning, using versatile software, and a knowledge of neutral file formats are key to efficiently managing diverse CAD file formats.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are your strategies for optimizing CAD file sizes?

Optimizing CAD file sizes is critical for faster processing, smoother collaboration, and efficient data management. My approach involves several strategies:

- Simplifying geometry: I avoid unnecessary details and focus on creating models with the appropriate level of complexity. Think of it like sculpting – remove excess material to reveal the essential form. Complex curves and surfaces, for example, often require more data storage and computation. Removing unnecessary features like very fine details can drastically reduce the file size.

- Using appropriate modeling techniques: I utilize techniques like feature-based modeling (parametric modeling) to reduce redundant data. In feature-based modeling, models are built from features, not just geometry, saving significant space. The software stores relationships rather than complete geometry descriptions.

- Employing lower resolution meshes for visual representation: If high-resolution models are not needed for analysis, using lower resolution meshes for visual display can save significant space, especially in models with complex surfaces. High resolution is crucial for detailed analysis, but not always for visual renders.

- Data compression: Some CAD software supports data compression techniques to reduce file sizes. I use these features where appropriate, balancing compression level with any potential loss of data integrity.

- Purging unnecessary data: I regularly purge unnecessary data within the CAD model, such as unused layers, blocks, or materials. Think of it as digital house cleaning—removing unnecessary files or data. Regular purging keeps files tidy and small.

The optimal approach often requires a balance between model fidelity and file size. Each project requires careful consideration of these elements, prioritizing file size reduction without compromising necessary design data.

Q 17. Describe your experience with CAD printing and plotting.

My experience encompasses the entire CAD printing and plotting workflow, from model preparation to output management. I’ve worked with various 3D printing technologies (FDM, SLA, SLS) and different plotting devices (large-format printers, plotters).

- Model preparation: This crucial step involves checking model geometry for errors (e.g., non-manifold geometry, intersecting surfaces) that can hinder printing. I also optimize the model for the chosen printing method, ensuring appropriate wall thicknesses, supports, and orientation for successful printing.

- Choosing the right printer/plotter and settings: Different printers have various capabilities. I select the printer based on material properties, print resolution, and budget. I also configure the printer settings (layer height, infill density, print speed) for optimal results. Similarly, plotter settings, including paper size and resolution, are carefully adjusted for high-quality 2D drawings.

- File export and conversion: I export files in the format required by the chosen printer or plotter (e.g., STL for 3D printing, PDF for plotting). This often involves converting files between different formats and carefully checking the output before proceeding.

- Troubleshooting and quality control: Unexpected issues (e.g., print failures, inaccurate dimensions) sometimes occur. I troubleshoot these issues by carefully reviewing the process, model, and printer settings to identify and resolve the root cause. I also perform thorough quality checks of both prints and plots.

A recent project involved printing a complex prototype using SLA printing. I spent time preparing the model for support structures and orientation, resulting in a successful and precise print. This is a testament to the importance of thorough planning and meticulous execution.

Q 18. How do you ensure your CAD models meet industry standards?

Ensuring CAD models meet industry standards is critical for product safety, functionality, and regulatory compliance. My approach is guided by several key principles:

- Understanding relevant standards: Every industry has specific standards (e.g., ASME Y14.5 for dimensioning and tolerancing in mechanical engineering, ISO standards for various industries). I thoroughly research and understand the applicable standards for each project.

- Implementing standards in the design process: I integrate these standards into my design workflow from the initial stages. This includes using standardized parts, applying appropriate tolerances, and adhering to specific dimensioning practices.

- Using CAD software features: Modern CAD software includes features to help enforce standards (e.g., dimensioning tools that adhere to ASME Y14.5). I leverage these features to maintain consistency and accuracy.

- Formal documentation and reviews: I document all design decisions and ensure that the design complies with relevant standards. Design reviews with colleagues provide an additional layer of quality control. A checklist can be created to ensure all requirements are met.

- Testing and validation: Where applicable, simulations and testing are performed to verify the design meets its performance requirements and complies with standards.

For example, in a recent automotive project, adherence to specific safety standards for crash simulation was paramount. I meticulously ensured the model complied with all requirements throughout the design and validation processes. This process is vital, not only for product quality but also to mitigate potential liability issues.

Q 19. Explain your experience with CAD analysis and simulation.

CAD analysis and simulation are integral to my design process. My experience spans various simulation types, including:

- Finite Element Analysis (FEA): I use FEA to assess stress, strain, and deformation in components and assemblies under various loads and conditions. This helps optimize designs for strength, stiffness, and durability. For example, I’ve used FEA to analyze the stress distribution in a complex engine component to identify potential failure points.

- Computational Fluid Dynamics (CFD): CFD enables the simulation of fluid flow and heat transfer. I’ve employed CFD to analyze airflow around aerodynamic components or optimize cooling systems in electronic devices.

- Motion simulation (kinematics and dynamics): This helps verify the functionality of moving parts and mechanisms in assemblies, identifying potential interference or other kinematic problems. For example, I’ve used motion simulation to analyze the movement of a robotic arm to ensure proper operation and avoid collisions.

My workflow typically involves:

- Model preparation: Ensuring the CAD model is appropriate for the chosen simulation type, including mesh generation for FEA and CFD.

- Defining simulation parameters: Specifying material properties, boundary conditions, and load cases relevant to the analysis.

- Running the simulation: Utilizing appropriate simulation software to perform the analysis.

- Interpreting and reporting results: Analyzing simulation results, drawing conclusions, and documenting findings to guide design iterations.

The results of these analyses have been instrumental in improving designs, reducing material usage, and enhancing product performance.

Q 20. How do you stay up-to-date with the latest CAD technologies?

Staying current in the rapidly evolving field of CAD requires a multifaceted approach:

- Continuous learning: I regularly attend webinars, workshops, and online courses offered by software vendors and industry organizations. Many platforms offer both introductory and advanced training to stay on top of updates.

- Industry publications and journals: I subscribe to and read industry publications and journals to stay informed on the latest advancements and best practices.

- Online resources and communities: I actively participate in online forums and communities dedicated to CAD software and engineering. Engaging in these discussions fosters continuous learning and exposes me to new ideas and techniques.

- Software updates and new features: I regularly update my CAD software to access new features and functionality. Many software vendors offer release notes and tutorials detailing these updates.

- Networking and collaboration: Attending industry conferences and networking with other professionals is a valuable way to learn about new technologies and approaches. Discussions with colleagues are a great source of insight and knowledge sharing.

This commitment to lifelong learning ensures I remain at the forefront of CAD technology, applying the latest techniques to enhance my projects.

Q 21. What are some common challenges you’ve faced in CAD projects?

Throughout my career, I’ve encountered several common challenges in CAD projects:

- Data management and organization: Managing large datasets, maintaining version control, and preventing data loss can be complex, particularly in large collaborative projects. Employing robust file management systems and version control is crucial to combat this.

- Software compatibility and interoperability: Ensuring compatibility between different CAD software and file formats can be challenging. Using neutral file formats and choosing software with strong import/export features is helpful.

- Geometric complexity and modeling errors: Creating and managing complex geometric models can be difficult, leading to errors and inconsistencies. Using appropriate modeling techniques and regular quality checks can mitigate this.

- Balancing design intent with computational constraints: Developing highly detailed models may not always be feasible or necessary, especially when considering simulation times. Careful consideration of design intent and computational capacity is crucial.

- Meeting deadlines and managing resources: Balancing project deadlines, resource availability, and ensuring quality can be challenging. Effective project planning and resource allocation are paramount.

For instance, a recent project involved a complex assembly. We faced challenges in managing the data and ensuring compatibility with our collaborators. By implementing a clear data management plan and utilizing neutral file formats, we successfully overcame these obstacles and completed the project on time and within budget.

Q 22. Describe your experience with creating and using CAD templates.

CAD templates are pre-designed files containing standardized settings, parts, and annotations, acting as blueprints for new projects. My experience involves creating templates for everything from simple 2D drawings to complex 3D assemblies. For example, I developed a template for our company’s standard valve design, pre-populating it with common components like flanges, stems, and bodies, reducing design time by 50%. Another project involved creating a series of templates for architectural drawings, each customized to different building codes and company standards. These templates ensured consistency in project deliverables and simplified the workflow significantly. Key aspects of creating effective templates include defining standard layers, annotation styles, and units, as well as creating reusable blocks of common elements. Effective management of these templates, including version control and regular updates, is also crucial for maintaining accuracy and efficiency.

Q 23. How do you create detailed sections and elevations in CAD?

Creating detailed sections and elevations in CAD requires precision and a strong understanding of orthographic projection. I start by selecting the appropriate view and using the section tool to ‘cut’ through the model. The software then automatically generates a view showing the internal structure. Crucially, this isn’t a passive process. I carefully select section planes to clearly illustrate critical features. For instance, when designing a building, I’d use multiple sections to highlight structural elements, plumbing, and electrical systems. In addition to generating the sections, I then add dimensions, annotations, and other details required by the specific project or standards. Elevations, showing the vertical faces of the design, are often created similarly, sometimes by using dedicated elevation tools or by manually projecting details from the 3D model. Throughout the process, visual clarity and compliance with industry drawing standards are paramount.

Q 24. Explain your experience with surface modeling and solid modeling.

Surface and solid modeling are fundamental CAD techniques. Solid modeling creates a complete 3D representation of an object, defining its volume and mass properties. This is essential for tasks such as finite element analysis (FEA) and creating manufacturing drawings. Think of designing a complex engine component – solid modeling allows precise calculation of stresses and strains. Surface modeling, conversely, focuses on creating the outer shape of an object, defining its surfaces without explicitly defining its internal structure. This is frequently used for aesthetic design or freeform shaping. Consider car body design – surface modeling excels at creating smooth, elegant curves. My experience includes extensive use of both techniques, often combining them in a single project. For example, I might use surface modeling to create the initial aesthetic form of a product, then convert this to a solid model for engineering analysis and manufacturing.

Q 25. How do you use constraints and relationships in CAD modeling?

Constraints and relationships are the backbone of parametric modeling, a powerful technique for creating adaptable and easily modifiable designs. Constraints define geometric relationships between elements (e.g., parallelism, perpendicularity, tangency, distance). Relationships define how changes to one element affect others. For example, imagine designing a box. By applying constraints, I can ensure that all sides are equal, the corners are right angles, and the top and bottom faces are parallel. Modifying one side automatically updates all others, maintaining the design’s integrity. This is far superior to manually adjusting each element separately. My experience involves using these tools extensively to create robust, flexible models that respond efficiently to design changes, ultimately increasing productivity and reducing errors. Using constraints allows for efficient design iterations and easier modifications when parameters change.

Q 26. What are your skills in creating and using custom CAD tools?

Creating custom CAD tools significantly enhances efficiency. I’m proficient in using macro languages (e.g., VBA, AutoLISP) to automate repetitive tasks and develop specialized tools. One example is a macro I wrote to automatically generate detailed assembly drawings for a series of similar products, drastically reducing the manual effort required. Another project involved developing a custom tool to perform complex geometric calculations, automating a process that previously required manual calculations and significantly reduced the potential for errors. This demonstrates my ability to not only use existing CAD functionalities but also extend them to meet specific project needs, streamlining workflows and increasing overall productivity. My approach always prioritizes code clarity, maintainability, and robust error handling to ensure long-term usability.

Q 27. Describe your experience with creating detailed technical drawings.

Creating detailed technical drawings involves more than just generating images; it’s about communicating precise engineering information. My experience includes creating drawings conforming to industry standards (e.g., ANSI, ISO) and company specifications. This involves meticulous attention to detail, accurate dimensions, clear annotations, and a logical layout. For example, I’ve created detailed assembly drawings, part drawings, and schematics for complex machinery, ensuring that every dimension, tolerance, and material specification is accurately represented. These drawings have to be easily understood by manufacturers, inspectors, and other engineers. Effective communication through clear visual representation and appropriate annotation is paramount in this process. I also use various drawing styles (e.g., isometric, orthographic) appropriately, selecting the best for the specific purpose.

Q 28. How do you integrate CAD models with other engineering software?

Integrating CAD models with other engineering software is crucial for a complete design process. I have extensive experience integrating CAD models with FEA software for stress analysis, CFD software for fluid flow simulation, and CAM software for manufacturing process planning. This usually involves exporting the CAD model in a suitable neutral format (e.g., STEP, IGES) to ensure compatibility. For example, I’ve exported CAD models of turbine blades to FEA software to assess their performance under stress. The results informed design iterations to improve blade strength and durability. Similarly, I’ve integrated CAD models of piping systems with CFD software to optimize fluid flow. This iterative process using multiple software packages is vital for creating optimal and robust designs. Understanding data exchange formats and the limitations of each software package is crucial for smooth integration.

Key Topics to Learn for Computer-Aided Design (CAD) and Modeling Interview

- Fundamentals of CAD Software: Understand the interface, basic commands (drawing, editing, modifying), and file management within at least one major CAD software package (e.g., AutoCAD, SolidWorks, Revit). Be prepared to discuss your experience level and proficiency.

- 2D and 3D Modeling Techniques: Demonstrate knowledge of creating 2D drawings and 3D models, including wireframes, surfaces, and solids. Be ready to discuss different modeling techniques and their applications (e.g., extrusion, revolution, sweeping).

- Geometric Dimensioning and Tolerancing (GD&T): Explain your understanding of GD&T principles and how they ensure precision in manufacturing. Be prepared to interpret and apply GD&T symbols on drawings.

- Design for Manufacturing (DFM): Discuss how design choices impact manufacturing processes, costs, and feasibility. Be able to explain your considerations when designing for specific manufacturing methods (e.g., casting, machining, 3D printing).

- Computer-Aided Manufacturing (CAM): While not strictly CAD, a basic understanding of how CAD models translate into manufacturing instructions (CAM) is beneficial. Discuss your knowledge of CNC machining or other manufacturing processes.

- Data Management and Collaboration: Explain your experience with managing CAD files, version control, and collaborating with teams on design projects using cloud-based platforms or other collaborative tools.

- Problem-solving and Design Thinking: Be prepared to discuss your approach to solving design challenges, from initial concept to final product. Highlight your ability to troubleshoot issues and iterate on designs.

- Specific Software Expertise: Deepen your knowledge of the CAD software(s) most relevant to the job description. Practice advanced features and demonstrate your ability to tackle complex modeling tasks.

Next Steps

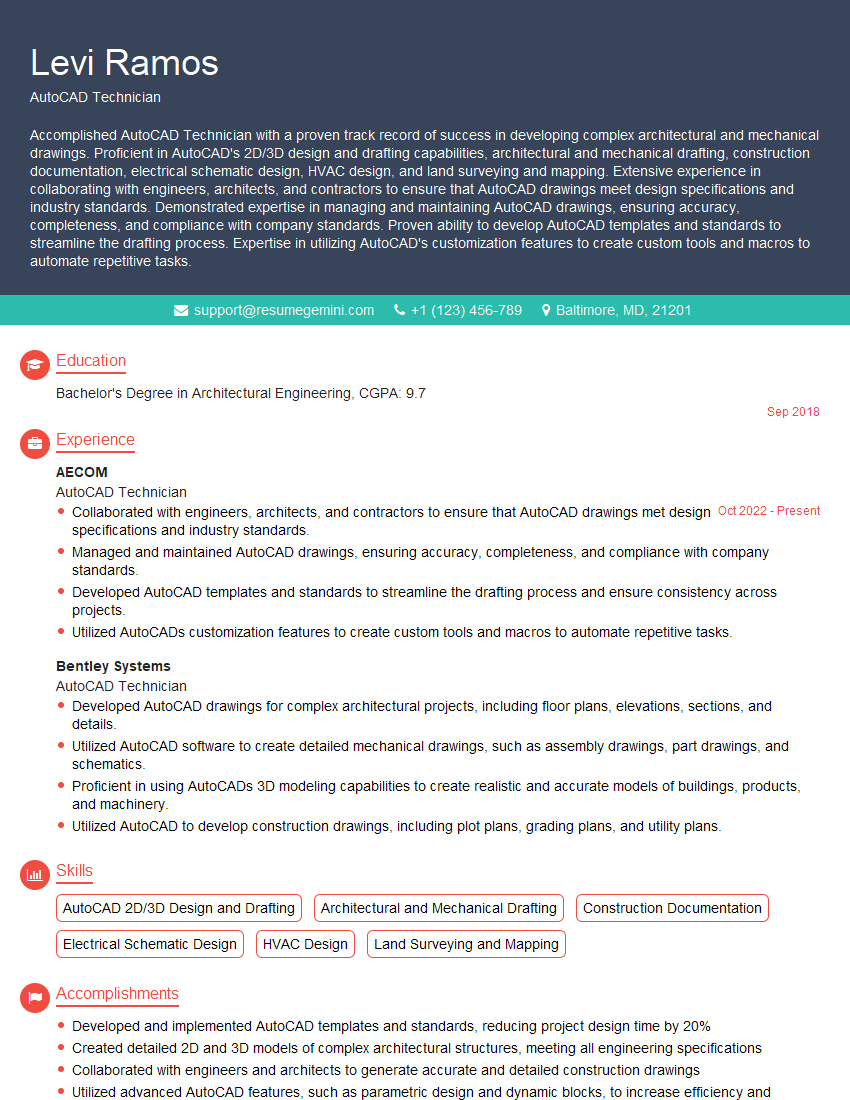

Mastering Computer-Aided Design and Modeling opens doors to exciting and rewarding careers in engineering, architecture, manufacturing, and more. To maximize your job prospects, it’s crucial to present your skills effectively. Creating an ATS-friendly resume is key to getting noticed by recruiters and hiring managers. ResumeGemini is a trusted resource that can help you build a professional and impactful resume, tailored to highlight your CAD and modeling expertise. Examples of resumes tailored to Computer-Aided Design (CAD) and Modeling are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

good