Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Drilling Program Optimization interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Drilling Program Optimization Interview

Q 1. Explain the importance of real-time data analysis in drilling program optimization.

Real-time data analysis is crucial for drilling program optimization because it allows for immediate adjustments based on the current conditions, maximizing efficiency and minimizing costly delays. Imagine driving without a speedometer – you wouldn’t know if you’re going too fast or too slow. Similarly, without real-time data, you’re essentially driving blind in a drilling operation.

Real-time data, such as rate of penetration (ROP), weight on bit (WOB), rotational speed (RPM), mud pressure, and torque, provides insights into the drilling process. Analyzing this data as it’s collected allows for immediate detection of anomalies. For instance, a sudden drop in ROP might indicate a change in formation or a problem with the bit. Immediate intervention, based on real-time analysis, can prevent further complications and significantly reduce non-productive time (NPT).

Sophisticated software platforms can process this data, generating alerts and recommendations for parameter adjustments. This proactive approach is significantly more efficient than relying solely on periodic reports that might only highlight issues after considerable time and resources have been wasted.

Q 2. Describe different methods for optimizing drilling parameters (ROP, WOB, RPM).

Optimizing drilling parameters—ROP, WOB, and RPM—involves finding the balance between maximizing penetration rate and minimizing equipment wear and potential problems. It’s a delicate balancing act, like finding the ‘sweet spot’ on a golf swing.

Automated Drilling Systems (ADS): These advanced systems use real-time data and algorithms to automatically adjust parameters. They constantly monitor the drilling process and make minor adjustments, often more effectively than human operators, especially during complex scenarios. The algorithms are typically trained on historical data to improve decision making.

Statistical Methods: Techniques like regression analysis can help determine the optimal relationships between parameters. For example, we can use data from previous wells to model the relationship between WOB, RPM, and ROP for a particular formation, and then use this model to predict optimal parameters for a new well.

Expert Systems: These rule-based systems leverage the experience of expert drillers to codify best practices and decision-making processes. This can be particularly helpful in scenarios where the data is limited or complex and expert knowledge can fill in data gaps.

Machine Learning (ML): ML models can learn complex relationships between drilling parameters and geological formations from large datasets, allowing for more accurate predictions of optimal settings. Reinforcement learning techniques can also be applied to train agents that learn to optimize drilling parameters over time.

The selection of the best method depends on various factors including the availability of data, the complexity of the geological formation, and the budget constraints.

Q 3. How do you identify and mitigate risks in a drilling program?

Risk identification and mitigation are paramount. It’s akin to carefully planning a mountaineering expedition; overlooking a potential risk can have devastating consequences. A thorough risk assessment is conducted at every stage of a drilling program.

Methods for identifying risks include:

Hazard Identification: We utilize tools like HAZOP (Hazard and Operability) studies, checklists, and previous project experience to identify potential hazards related to geological formations, wellbore stability, equipment failure, and environmental considerations.

Risk Assessment: We assess the likelihood and severity of each identified hazard. This involves estimating the probability of occurrence and the potential impact of an event.

Quantitative Risk Assessment: We utilize probabilistic models and historical data to numerically determine the risk associated with different drilling scenarios.

Mitigation strategies include:

Engineering Controls: This involves implementing measures such as using stronger drilling equipment, advanced well control systems, and improved mud programs to reduce the likelihood of failures.

Administrative Controls: Implementing comprehensive safety protocols, well-planned operations, and stringent quality checks for equipment and personnel.

Emergency Response Planning: Developing detailed plans for handling various emergencies, including well control scenarios, equipment failures, and environmental incidents. This includes having pre-positioned emergency resources and trained personnel.

Q 4. What are the key performance indicators (KPIs) you would use to measure drilling efficiency?

Key Performance Indicators (KPIs) are crucial for tracking drilling efficiency. They’re the vital signs of our operation, providing a clear picture of performance.

Rate of Penetration (ROP): The speed at which the drill bit penetrates the formation. Higher ROP translates to faster drilling and cost savings.

Non-Productive Time (NPT): Time spent on tasks not directly related to drilling, such as equipment maintenance, rig moves, and unexpected issues. Minimizing NPT is essential for efficiency.

Trip Time: The time spent running casing or drilling tools in and out of the hole. Efficient trip operations are critical for improving overall efficiency.

Cost per Meter (or foot): The total cost of the drilling operation divided by the drilled depth. This provides a comprehensive measure of economic efficiency.

Days to TD (Total Depth): The total number of days it takes to reach the target depth of the well. Faster completion translates to reduced operational costs and quicker return on investment.

Drilling Safety Metrics: Metrics like Total Recordable Injury Frequency (TRIF), Lost Time Injury Frequency (LTIF), and environmental incident rates are critical and should be carefully monitored.

Q 5. Explain your experience with different drilling optimization software.

I have extensive experience with various drilling optimization software packages, including:

Drilling Simulator Software: I’ve utilized simulators to model various drilling scenarios, including different bit types, mud properties, and geological formations, allowing for the optimization of parameters and cost-effective decisions before actual drilling. This reduces risks and potential errors in the field.

Real-time Data Acquisition and Analysis Systems: I have practical expertise in using systems that collect data from various sensors on the drilling rig and analyze it in real time, to provide actionable insights leading to immediate corrections. This helps reduce NPT and improves drilling efficiency significantly.

Advanced Analytics and Machine Learning Platforms: These platforms allow me to analyze large datasets from past projects, build predictive models, and identify trends, greatly helping to enhance decision-making and optimization across multiple wells and projects.

My experience encompasses both the implementation and practical application of these software tools. I’m proficient in data interpretation, model building, and utilizing the insights generated to improve drilling operations.

Q 6. How do you manage unexpected events or issues during drilling operations?

Unexpected events, such as equipment failures or geological surprises, are inevitable. My approach to handling these situations is based on a systematic and proactive strategy:

Rapid Assessment: Immediate assessment of the situation to understand the nature of the problem and its potential impact on the drilling program.

Communication: Clear and efficient communication with the entire team, including rig crew, engineers, and management, to ensure everyone is informed and working towards a common goal.

Problem Solving: Utilizing my experience and knowledge to formulate a solution, often involving consultation with specialists if necessary. The solution must consider safety, efficiency, and cost effectiveness.

Implementation: Efficiently implementing the chosen solution, monitoring its effectiveness, and making necessary adjustments as needed.

Post-Incident Analysis: Conducting a thorough post-incident analysis to identify root causes, prevent similar incidents in the future, and update risk assessments.

This structured approach ensures efficient response and minimizes the disruption caused by unexpected events.

Q 7. Describe your approach to optimizing drilling fluids for specific geological formations.

Optimizing drilling fluids is essential for efficient and safe drilling, particularly when encountering diverse geological formations. It’s like choosing the right lubricant for different mechanical parts; the wrong fluid can lead to serious damage.

My approach involves a thorough understanding of the geological formations to be drilled, and includes:

Formation Evaluation: A detailed study of the geological formation’s properties, including porosity, permeability, and potential challenges (e.g., shale instability, high pressure zones).

Fluid Design: Selecting or designing drilling fluids with properties optimized for the specific challenges posed by the formation. This might involve adjusting parameters like density, viscosity, and chemical additives.

Real-time Monitoring: Constant monitoring of the drilling fluid properties, including mud weight, pH, and rheology, throughout the drilling process, making adjustments as needed.

Fluid Testing: Regular testing of the drilling fluid in a laboratory to ensure it maintains its desired properties and to help inform the design of the next stage of the mud program.

Waste Management: Developing a plan for managing drilling waste in an environmentally responsible manner, adhering to all relevant regulations.

This holistic approach minimizes issues such as wellbore instability, stuck pipe, and formation damage, thus leading to better drilling efficiency and wellbore integrity.

Q 8. How do you balance cost optimization with safety and environmental regulations during drilling?

Balancing cost optimization with safety and environmental regulations in drilling is a delicate act of prioritization. It’s not about choosing one over the other, but rather finding the optimal intersection. We achieve this through a multi-pronged approach.

- Proactive Risk Assessment: Before any drilling operation begins, we conduct thorough hazard identification and risk assessments, identifying potential environmental impacts and safety hazards. This involves considering factors like proximity to sensitive ecosystems, potential for wellbore instability, and the risks associated with specific drilling fluids.

- Technology and Innovation: Investing in advanced drilling technologies, such as automated drilling systems and real-time monitoring, can significantly improve safety and reduce environmental impact. For instance, using managed pressure drilling (MPD) minimizes the risk of well control incidents and reduces the release of harmful drilling fluids.

- Optimized Drilling Parameters: Through advanced modeling and simulation, we can optimize drilling parameters (e.g., weight on bit, rotational speed) to minimize drilling time and reduce the consumption of resources, thereby decreasing both costs and environmental footprint. This might involve fine-tuning the mud weight to prevent wellbore instability while minimizing the environmental burden of disposing of large quantities of drilling mud.

- Strict Adherence to Regulations: Complying with all relevant safety and environmental regulations is paramount. This includes obtaining necessary permits, conducting regular environmental monitoring, and employing appropriate waste management strategies. We document every step of the process to ensure transparency and accountability.

- Continuous Improvement: Regular safety audits and environmental reviews are crucial for identifying areas for improvement and preventing future incidents. This iterative process helps us refine our approach and continuously improve our performance.

For example, in one project, we used a novel drilling fluid formulation that reduced the environmental impact by 30% while also increasing Rate of Penetration (ROP) by 15%, resulting in significant cost savings.

Q 9. Explain your understanding of directional drilling optimization techniques.

Directional drilling optimization focuses on achieving the desired well trajectory in the most efficient and cost-effective manner. This involves precise control over the wellbore path, often deviating significantly from a vertical line, to reach target formations deep underground.

- Advanced Navigation Systems: We utilize advanced measurement-while-drilling (MWD) and logging-while-drilling (LWD) tools that provide real-time data on the wellbore position, inclination, and azimuth. This data is crucial for making course corrections and maintaining the desired trajectory.

- Trajectory Planning Software: Sophisticated software packages allow us to plan optimal well paths based on geological data, reservoir characteristics, and operational constraints. These programs simulate the drilling process and help optimize parameters like drilling speed and directional drilling parameters to minimize time and cost.

- Real-Time Adjustments: The ability to make real-time adjustments to the drilling plan based on the incoming MWD/LWD data is essential. This dynamic approach allows us to mitigate unexpected challenges (e.g., encountering unexpected geological formations) and optimize the well path during the operation itself.

- Bit Selection and Optimization: The choice of drill bit significantly impacts the efficiency of directional drilling. Selecting the right bit for the specific geological formation and drilling parameters is crucial for maximizing ROP and minimizing wear.

- Mud Motor Selection and Control: The mud motor is the heart of directional drilling, providing the torque and rotary motion for controlling the wellbore trajectory. Optimizing the mud motor parameters is essential for accurate steering.

Imagine trying to navigate a maze with a very long, flexible tube; directional drilling is akin to that, only many times more complex, and with immense pressure and temperature.

Q 10. How do you incorporate geological data into the optimization of a drilling program?

Geological data is the cornerstone of drilling program optimization. It provides the fundamental understanding of subsurface formations, enabling us to make informed decisions about well placement, trajectory design, and drilling parameters.

- Formation Evaluation: Seismic data, well logs, core samples, and other geological data provide crucial information about the rock properties, including strength, porosity, permeability, and fluid content. This information directly influences wellbore stability analysis and the choice of drilling fluids.

- Reservoir Characterization: Understanding reservoir properties helps us optimize well placement to maximize hydrocarbon production. For example, identifying high-permeability zones helps us design well trajectories to intersect those zones more effectively.

- Prediction of Drilling Challenges: Geological data helps predict potential drilling challenges, such as encountering unstable formations or high-pressure zones. This enables proactive planning and mitigation strategies, minimizing downtime and cost overruns.

- Integration into Drilling Simulation: Geological data is integrated into drilling simulation software to predict drilling performance and optimize drilling parameters. This enables us to anticipate potential issues and develop contingency plans.

- Real-time Data Integration: Integrating real-time data from MWD/LWD tools with geological models allows for dynamic adjustment of the drilling plan, improving the efficiency and safety of the operation.

For example, identifying a fault zone in the geological model before drilling allows for changes in the well trajectory to avoid the zone, potentially preventing a stuck pipe situation.

Q 11. Describe your experience with wellbore stability analysis and its impact on drilling optimization.

Wellbore stability analysis is critical to drilling optimization. It involves predicting the likelihood of wellbore instability issues, such as formation fracturing, shale swelling, or borehole collapse. These issues can lead to significant non-productive time (NPT), increased costs, and even safety hazards.

- Geomechanical Modeling: We utilize geomechanical models to simulate the stress state within the wellbore and predict the behavior of the formation under different drilling conditions. This involves incorporating geological data, such as pore pressure, stress tensors, and rock strength properties.

- Mud Weight Optimization: Wellbore stability analysis is crucial for optimizing mud weight. Using mud that is too light can lead to formation fracturing, while mud that is too heavy can cause formation collapse. The analysis helps us determine the optimal mud weight range to maintain wellbore stability while minimizing environmental impact.

- Drilling Fluid Selection: The selection of appropriate drilling fluids is critical for maintaining wellbore stability. Different formations require different fluid properties, such as viscosity, density, and chemical composition. The analysis guides us in selecting fluids that minimize wellbore instability.

- Drilling Parameter Optimization: Wellbore stability analysis influences the optimization of drilling parameters, such as rate of penetration (ROP) and weight on bit (WOB). By understanding the stress state of the formation, we can optimize parameters to minimize the risk of inducing instability.

- Real-time Monitoring and Adjustment: Continuous monitoring of wellbore conditions during drilling allows for real-time adjustments to drilling parameters and mud properties, helping to mitigate emerging instability issues.

In one project, detailed geomechanical modeling prevented a costly wellbore collapse by allowing us to adjust the mud weight proactively, avoiding significant downtime and cost overruns.

Q 12. How do you use predictive modeling to improve drilling program performance?

Predictive modeling plays a significant role in improving drilling program performance. By analyzing historical data and incorporating geological and engineering information, we can predict various aspects of the drilling process, leading to proactive decision-making.

- Predicting Rate of Penetration (ROP): Using machine learning algorithms, we can predict ROP based on factors such as formation properties, bit type, and drilling parameters. This allows us to optimize drilling parameters in real-time to maximize efficiency.

- Predicting Non-Productive Time (NPT): By identifying factors that contribute to NPT, such as equipment failures or unexpected geological conditions, predictive models help us anticipate and mitigate potential delays, minimizing downtime and cost overruns.

- Predicting Wellbore Stability Issues: As discussed earlier, predictive models can forecast the likelihood of wellbore instability, allowing for proactive adjustments to drilling parameters and mud properties.

- Predicting Cost and Schedule: By integrating various factors, including geological conditions, drilling parameters, and equipment performance, we can develop accurate cost and schedule predictions, allowing for better budget allocation and project planning.

- Optimizing Drilling Fluids: Predictive models help optimize the selection and usage of drilling fluids, minimizing environmental impact and optimizing cost.

Example: A simple predictive model for ROP could be ROP = a*WOB + b*RPM + c*Formation Hardness, where a, b, and c are coefficients determined through regression analysis.

This allows for data-driven decisions, improving efficiency and reducing the reliance on guesswork.

Q 13. How would you optimize a drilling program for a specific well type (e.g., horizontal, deviated)?

Optimizing a drilling program for a specific well type, such as a horizontal or deviated well, requires a tailored approach that considers the unique challenges of each well type.

- Horizontal Wells: Optimizing a horizontal well program focuses on maximizing the contact with the reservoir while minimizing drilling time and cost. This involves:

- Extended Reach Drilling Techniques: These techniques are crucial for reaching target formations at long distances from the surface location.

- Advanced Trajectory Planning: Precise trajectory planning is essential to ensure the wellbore stays within the reservoir zone.

- Optimized Mud Motor Selection and Control: Proper mud motor selection and control are essential for accurate steering in horizontal sections.

- Wellbore Stability Management: Managing wellbore stability is crucial in long horizontal sections, often involving specialized drilling fluids and advanced monitoring techniques.

- Deviated Wells: Optimizing a deviated well program involves a similar approach, but the degree of deviation is typically less extreme than horizontal wells. Key considerations include:

- Precise Trajectory Planning: Ensuring the wellbore follows the planned trajectory while minimizing dog legs (sharp changes in direction).

- Proper Bit Selection: Selecting bits suitable for both vertical and deviated sections.

- Careful Monitoring of Wellbore Parameters: Close monitoring of wellbore pressure, temperature, and inclination to ensure stability.

For instance, in optimizing a long-reach horizontal well, we might employ advanced drilling technologies such as rotary steerable systems (RSS) and managed pressure drilling (MPD) to navigate complex geological formations and maintain wellbore stability.

Q 14. Describe your experience with managing drilling contractors and subcontractors.

Managing drilling contractors and subcontractors requires strong communication, coordination, and oversight to ensure safety, efficiency, and adherence to the drilling program. It’s about building a collaborative environment where everyone works towards a shared goal.

- Clear Communication: Establishing clear communication channels and regular meetings with contractors is essential to ensure everyone is on the same page. This includes detailed specifications, well plans, and safety protocols.

- Performance Monitoring: Regular monitoring of contractor performance against key performance indicators (KPIs) like ROP, NPT, and safety incidents helps to identify areas for improvement and address potential issues proactively. We use progress reports, data dashboards, and field visits to monitor performance.

- Risk Management: Working closely with contractors to identify and mitigate potential risks, both safety and operational, is critical. This includes regular safety meetings, safety audits, and development of contingency plans.

- Contract Management: Effective contract management ensures compliance with contractual obligations, including payment terms, performance standards, and safety regulations. We have standardized contracts with key performance indicators (KPIs) and penalties for non-compliance.

- Building Relationships: Cultivating strong working relationships with contractors fosters trust and mutual respect. It encourages open communication and collaboration in addressing challenges.

In one instance, I had to negotiate a change order with a contractor due to unforeseen geological conditions. Effective communication and a collaborative approach allowed us to agree on a mutually beneficial solution, completing the well safely and on a revised schedule.

Q 15. How do you ensure data integrity and accuracy in drilling optimization processes?

Data integrity is paramount in drilling optimization. We achieve this through a multi-layered approach focusing on data acquisition, validation, and management. At the acquisition stage, we utilize calibrated and regularly maintained sensors and instruments, implementing rigorous quality control checks at every stage. This includes verifying sensor readings against known parameters and flagging any outliers for investigation. Validation involves cross-referencing data from multiple sources (e.g., comparing mud logging data with drilling parameters). Finally, data is stored in a secure, version-controlled database, using established protocols to track changes and ensure traceability. Imagine building a house: using faulty materials (bad data) will lead to a flawed structure. Similarly, faulty drilling data leads to poor optimization strategies and potentially costly mistakes.

For instance, in a recent project, we identified a systematic bias in the weight-on-bit (WOB) readings due to a faulty sensor. By rigorously analyzing the data and comparing it against other drilling parameters, we were able to correct the bias, leading to a significant improvement in the accuracy of our drilling models and optimization strategies.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your approach to communicating technical information to non-technical stakeholders?

Communicating technical information to non-technical stakeholders requires a shift in perspective. Instead of focusing on technical jargon, I employ visual aids like charts, graphs, and even simple analogies. For example, explaining drilling rate of penetration (ROP) as ‘how fast we’re digging’ is more relatable than referencing complex mathematical models. I also prioritize concise language, avoiding unnecessary technical details. Focus is on the ‘what’ and ‘why’ – the impact of the optimization on overall project goals (cost, time, safety) – rather than the ‘how’.

In one instance, I presented a complex optimization model’s results to the project’s executive team using a simple dashboard showing key performance indicators (KPIs) like cost savings and time reduction. This clear visualization allowed them to quickly grasp the value proposition without needing to understand the underlying technical complexities. Storytelling is also key; highlighting successes and challenges with relatable narratives can significantly improve understanding and engagement.

Q 17. Explain your experience with the application of automation and robotics in drilling.

Automation and robotics are transforming drilling operations, significantly improving efficiency and safety. My experience encompasses the application of automated drilling systems (ADS) which optimize drilling parameters in real-time based on pre-programmed algorithms and real-time sensor data. This reduces human error and allows for more precise control. Robotics are playing an increasingly important role in challenging environments, such as remotely operated vehicles (ROVs) for subsea inspections and maintenance. I’ve worked on projects utilizing data-driven decision support systems that leverage machine learning to predict potential problems and optimize the drilling plan proactively.

For example, I was part of a team that implemented an ADS in a deepwater project. This system optimized the mud weight and rotary speed, resulting in a 15% reduction in non-productive time and a significant improvement in the drilling rate. The automation also improved safety by reducing the number of manual interventions in hazardous environments.

Q 18. How do you handle conflicting priorities (e.g., speed vs. cost) in a drilling program?

Balancing conflicting priorities, such as speed and cost, requires a structured approach. We typically employ a multi-criteria decision-making (MCDM) framework, weighing the importance of each objective according to the project’s overall goals. This involves assigning weights to different criteria (e.g., cost reduction, time savings, safety) and then evaluating various drilling scenarios based on these weighted criteria. The result is an optimized drilling plan that achieves the best balance between competing objectives.

For instance, in a recent project, we had to balance the need for faster drilling with cost constraints. Using an MCDM framework, we found that optimizing the drilling parameters and implementing a proactive risk management strategy provided the optimal solution. This approach resulted in a 10% reduction in drilling costs without significantly compromising the overall project timeline.

Q 19. Describe your experience with drilling optimization in challenging environments (e.g., deepwater, arctic).

Drilling optimization in challenging environments like deepwater and arctic requires specialized expertise and advanced technologies. In deepwater, I’ve worked on projects involving the use of advanced drilling fluids, real-time monitoring systems, and sophisticated well control procedures to mitigate the risks associated with high pressure and high temperature (HPHT) wells. In arctic conditions, careful planning and execution are essential to account for factors such as ice conditions, cold temperatures, and remote locations. This often involves using specialized drilling rigs and equipment designed to withstand extreme conditions. Safety protocols and contingency planning are significantly intensified in these challenging settings.

A specific example from a deepwater project involved optimizing the mud weight to prevent wellbore instability and reduce the risk of kicks. This careful balancing act minimized the risk of blowouts while maintaining an efficient drilling rate. The sophisticated monitoring systems and real-time analysis allowed us to adjust the drilling parameters as needed, ensuring the safety and efficiency of the operation.

Q 20. How do you measure the success of a drilling optimization strategy?

Measuring the success of a drilling optimization strategy involves a combination of quantitative and qualitative metrics. Quantitative metrics include reductions in drilling costs, time, non-productive time (NPT), and improvement in drilling rate of penetration (ROP). We also track key performance indicators (KPIs) such as reduced incidents, increased safety, and improved wellbore stability. Qualitative metrics might include improvements in team collaboration, better communication, and increased efficiency of the decision-making process. Benchmarking against similar projects provides valuable context for assessing the effectiveness of the optimization strategies.

For example, in one project, we tracked a 12% reduction in total drilling costs, a 15% increase in ROP, and a 20% decrease in NPT following the implementation of our optimization strategy. This data, coupled with positive qualitative feedback from the project team, clearly demonstrated the success of our efforts.

Q 21. Explain your understanding of different drilling bit types and their selection criteria.

Drilling bit selection is crucial for optimizing drilling performance. Different bit types are designed for specific rock formations and drilling conditions. Common types include roller cone bits (tricone bits), polycrystalline diamond compact (PDC) bits, and diamond bits. Roller cone bits are effective in softer formations, while PDC bits excel in harder, abrasive formations. Diamond bits are ideal for extremely hard formations or when precise hole diameter is crucial. The selection process involves considering various factors such as rock hardness, abrasiveness, formation type, drilling depth, and drilling fluid properties.

We use geological data, well logs, and previous drilling experience to predict the formation properties at various depths. Based on this information, we select the optimal bit type for each section of the wellbore. For instance, we might use a tricone bit for the initial section of a well that passes through softer shale formations, and then switch to a PDC bit for harder sandstone formations at greater depth. This strategy maximizes drilling efficiency and minimizes the risk of bit failure. Bit selection is a crucial component of overall optimization, affecting drilling speed, cost, and ultimately, the success of the drilling operation.

Q 22. Describe your experience with drilling hazard identification and risk assessment.

Drilling hazard identification and risk assessment is a crucial aspect of safe and efficient drilling operations. It involves systematically identifying potential hazards, analyzing their likelihood and severity, and implementing mitigation strategies to minimize risks. This process is iterative, adapting as new information becomes available during the drilling process.

My experience includes using a combination of qualitative and quantitative methods. Qualitative methods involve leveraging experience, best practices, and historical data to identify potential issues like wellbore instability, equipment failures, and environmental hazards. For example, drilling in a known fault zone requires more rigorous risk assessment and potentially more expensive measures like real-time formation evaluation to minimize the risk of a kick.

Quantitative methods involve using software and data analysis to assess probabilities and consequences. This often includes Fault Tree Analysis (FTA) and Bow-Tie analysis to visualize potential failure pathways and implement preventative and mitigating controls. A Bow-Tie analysis, for example, helps us identify precursors to a major event (e.g., loss of well control) and implement early warning systems and mitigation procedures.

I’ve also implemented a robust risk register which is dynamically updated throughout the drilling project. This ensures transparent communication and continuous monitoring of risks.

Q 23. How do you optimize drilling operations for different well architectures?

Optimizing drilling operations for different well architectures requires a tailored approach, considering factors like well type (vertical, horizontal, deviated), formation characteristics, and target depth. The strategy is not a one-size-fits-all solution.

For vertical wells, optimization focuses on maximizing drilling rate while ensuring wellbore stability. We might prioritize selecting optimal drill bit types and weight-on-bit to match the formation properties and maximize penetration rate. Real-time monitoring of drilling parameters (ROP, torque, weight on bit) helps us adjust drilling parameters and prevent issues like bit balling.

Horizontal wells present unique challenges due to longer reach, increased wellbore friction, and potential for wellbore instability. Here, optimization strategies focus on minimizing friction, maintaining wellbore stability, and efficient placement of the wellbore in the target reservoir zone. Advanced drilling techniques like managed pressure drilling (MPD) and underbalanced drilling might be used to reduce the risk of formation damage or wellbore instability. Detailed wellbore trajectory planning using specialized software is crucial to maximize reservoir contact and minimize drilling time.

Deviated wells require careful planning to manage wellbore trajectory and avoid potential hazards. Advanced surveying techniques are used for accurate placement and real-time adjustments. Optimization might involve selecting directional drilling tools and adjusting drilling parameters to maintain the desired wellbore path while maximizing ROP and minimizing costs.

In all cases, the optimization process involves a data-driven approach, using real-time data from the rig to monitor performance and adapt the drilling plan accordingly. Sophisticated modeling tools and simulation software help in pre-planning and predicting potential challenges.

Q 24. Explain your experience with data visualization techniques used in drilling optimization.

Data visualization is critical for drilling optimization, enabling quick identification of trends, anomalies, and potential problems. I’ve extensively used various techniques, from simple line graphs and histograms to more sophisticated interactive dashboards.

For instance, real-time monitoring of drilling parameters like Rate of Penetration (ROP), torque, and weight on bit is often displayed on interactive dashboards. These dashboards allow the drilling team to quickly see the impact of changes in drilling parameters and make necessary adjustments to optimize performance. Anomalies such as a sudden drop in ROP might indicate a problem with the drill bit or a change in formation properties, triggering proactive intervention.

I’ve also used more advanced visualization techniques like 3D models of the wellbore trajectory, coupled with formation properties, to identify potential challenges such as high-pressure zones or fault intersections. These visualizations allow for better understanding of the subsurface and improve the decision-making process.

Furthermore, I have implemented statistical process control charts to monitor key performance indicators (KPIs), enabling early detection of deviations from the plan and prompt corrective actions. This empowers preventative maintenance and ensures that drilling stays within acceptable operational limits.

Q 25. How do you ensure compliance with relevant industry standards and regulations?

Compliance with industry standards and regulations is paramount in drilling operations. My approach involves a multi-faceted strategy incorporating proactive measures and regular audits.

Firstly, I ensure that all drilling activities adhere to the relevant regulations set by organizations like the API (American Petroleum Institute), IADC (International Association of Drilling Contractors), and local governmental agencies. This includes implementing and maintaining a robust safety management system (SMS) and adhering to strict environmental regulations for waste disposal and emissions control.

Secondly, I conduct regular audits to verify compliance and identify any gaps in procedures or training. These audits cover various aspects of the operation, including well control procedures, safety protocols, and environmental impact assessments. Any non-compliance issues are immediately addressed with corrective and preventative actions.

Thirdly, I ensure the drilling team undergoes regular training on safety procedures, environmental protection, and relevant regulations. This includes competency assessments to confirm that the team understands and can apply these regulations in their daily work. Documentation is rigorously maintained to demonstrate continuous compliance.

Q 26. Describe your experience with integrating drilling data from different sources.

Integrating drilling data from disparate sources is critical for effective drilling optimization. This usually involves data from various sources including the drilling rig’s mud logging system, downhole sensors, seismic surveys, and geological models. I’ve successfully used various methods to achieve seamless integration.

A key element is the utilization of a centralized data management system that combines data from different sources into a single, accessible repository. This might involve using a specialized drilling data management software or a cloud-based platform. This facilitates data analysis and visualization. Data cleaning and standardization are crucial to ensure data quality and consistency.

I’ve also implemented ETL (Extract, Transform, Load) processes to automate the data integration process. This ensures that data is consistently updated and readily available for analysis. Data transformation might involve converting data from different formats into a standard format suitable for analysis.

Moreover, I use APIs (Application Programming Interfaces) to connect different software applications and automate data exchange. This helps in streamlining data flows and reducing manual effort. The selection of the proper data integration method depends on the specific requirements and the scale of the drilling operation.

Q 27. How would you address a significant deviation from the planned drilling program?

Significant deviations from the planned drilling program necessitate a structured and decisive response to ensure safety and minimize operational disruptions. My approach involves a systematic investigation and a collaborative decision-making process.

Step 1: Immediate Action: The first step is to immediately stop drilling and assess the situation. Ensure the well is secured, and personnel safety is prioritized. This might involve implementing well control procedures if necessary.

Step 2: Investigation and Root Cause Analysis: A thorough investigation is then undertaken to determine the root cause of the deviation. This involves reviewing all available data, including drilling parameters, geological data, and equipment performance records. Root cause analysis tools such as the 5 Whys or Fishbone diagrams are useful here.

Step 3: Develop Corrective Actions: Based on the root cause analysis, corrective actions are developed and implemented to address the underlying issues. This might involve changing drilling parameters, using different drilling tools, or making adjustments to the well plan. This stage also includes implementing preventive measures to prevent similar deviations in the future.

Step 4: Replanning and Execution: A revised drilling plan is developed, taking into account the learnings from the deviation. This revised plan might involve adjustments to the drilling trajectory, wellbore design, or drilling parameters. The updated plan is then carefully reviewed and approved before resuming drilling operations.

Step 5: Lessons Learned and Documentation: Finally, a comprehensive review is conducted to document the events, identify lessons learned, and share this knowledge across the organization to prevent similar incidents in future projects. This includes a detailed report to the relevant stakeholders.

Q 28. Explain your understanding of the role of well planning in overall drilling optimization.

Well planning forms the bedrock of successful drilling optimization. It’s a crucial upstream activity that significantly impacts the efficiency, safety, and cost-effectiveness of the entire drilling process. Think of it as creating a detailed roadmap before embarking on a journey—without a well-defined plan, you risk wasting resources and time.

Well planning involves a multi-disciplinary approach, integrating geological, geophysical, and engineering data to design the optimal well trajectory, select appropriate drilling equipment and parameters, and anticipate potential challenges. This includes geological modeling to accurately represent subsurface formations, reservoir simulations to predict well performance, and detailed engineering designs for well construction.

The output of well planning directly influences many aspects of drilling optimization. For instance, accurate geological models help in selecting optimal drilling parameters like weight-on-bit and rotary speed, minimizing drilling time and maximizing rate of penetration. Wellbore trajectory planning helps to avoid geological hazards and optimize reservoir contact. Proper selection of drilling equipment and fluids reduces the risk of wellbore instability and formation damage.

Effective well planning also includes risk assessment and mitigation strategies. By identifying and assessing potential hazards beforehand, we can implement appropriate preventative and mitigation measures during the drilling process, minimizing the likelihood of delays and cost overruns. A well-planned project allows for more effective resource allocation, reducing non-productive time and optimizing overall project cost.

Key Topics to Learn for Drilling Program Optimization Interview

- Well Planning & Design: Understanding the interplay between drilling parameters, geological models, and well trajectory optimization to minimize costs and maximize efficiency.

- Drilling Fluids Engineering: Analyzing the impact of mud properties on drilling performance, including rate of penetration (ROP), wellbore stability, and environmental considerations. Practical application includes optimizing mud weight and rheology for specific formations.

- Drilling Mechanics & BHA Optimization: Applying principles of mechanics to analyze bit selection, bottom hole assembly (BHA) design, and weight-on-bit optimization to improve ROP and reduce drilling time.

- Data Analysis & Interpretation: Utilizing drilling data (ROP, torque, drag, etc.) to identify trends, diagnose problems, and make data-driven decisions for optimizing drilling operations. This includes proficiency with relevant software and analytical techniques.

- Cost Optimization Strategies: Developing and implementing cost-reduction strategies throughout the drilling process, considering factors such as time, materials, and personnel. This encompasses budgeting, forecasting, and variance analysis.

- Directional Drilling & Well Control: Understanding the principles of directional drilling and the procedures for managing well control issues to ensure safe and efficient operations. This includes knowledge of relevant safety regulations and best practices.

- Risk Management & Mitigation: Identifying and mitigating potential risks associated with drilling operations, including geological hazards, equipment failures, and environmental concerns.

- Performance Monitoring & Reporting: Tracking key performance indicators (KPIs), generating reports to highlight areas for improvement, and communicating findings effectively to stakeholders.

Next Steps

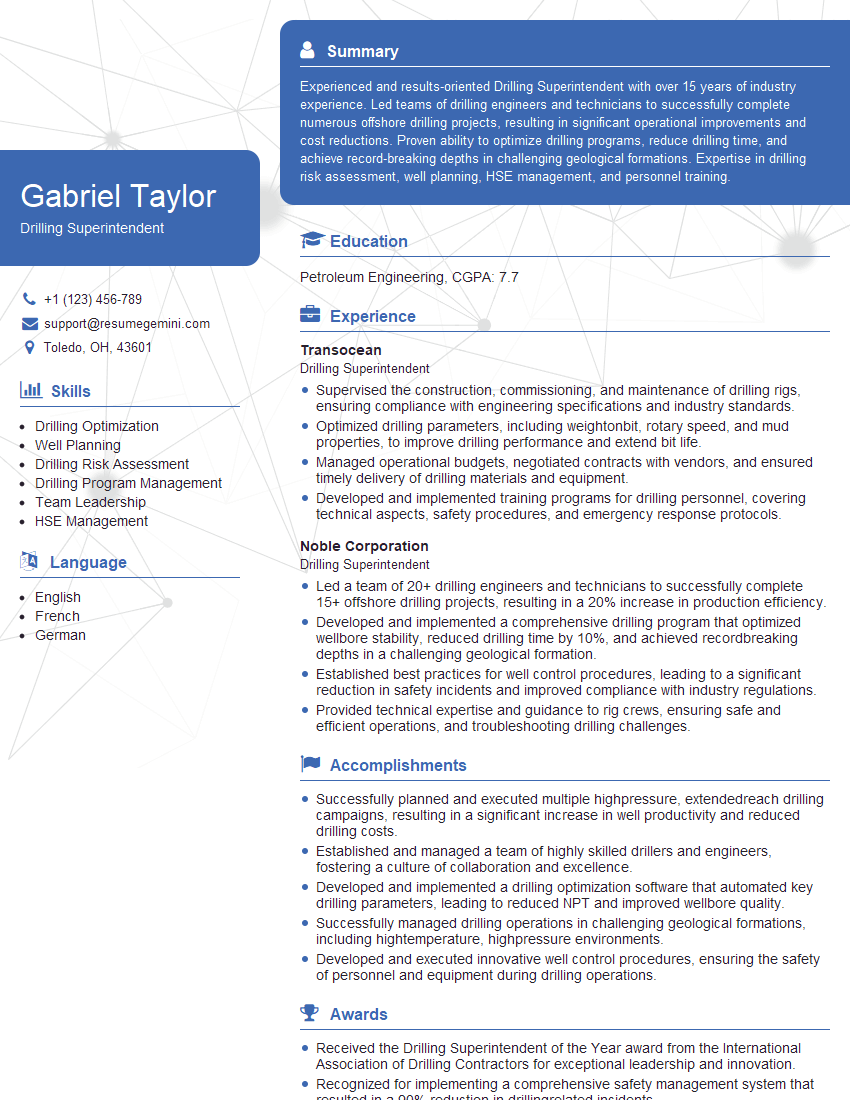

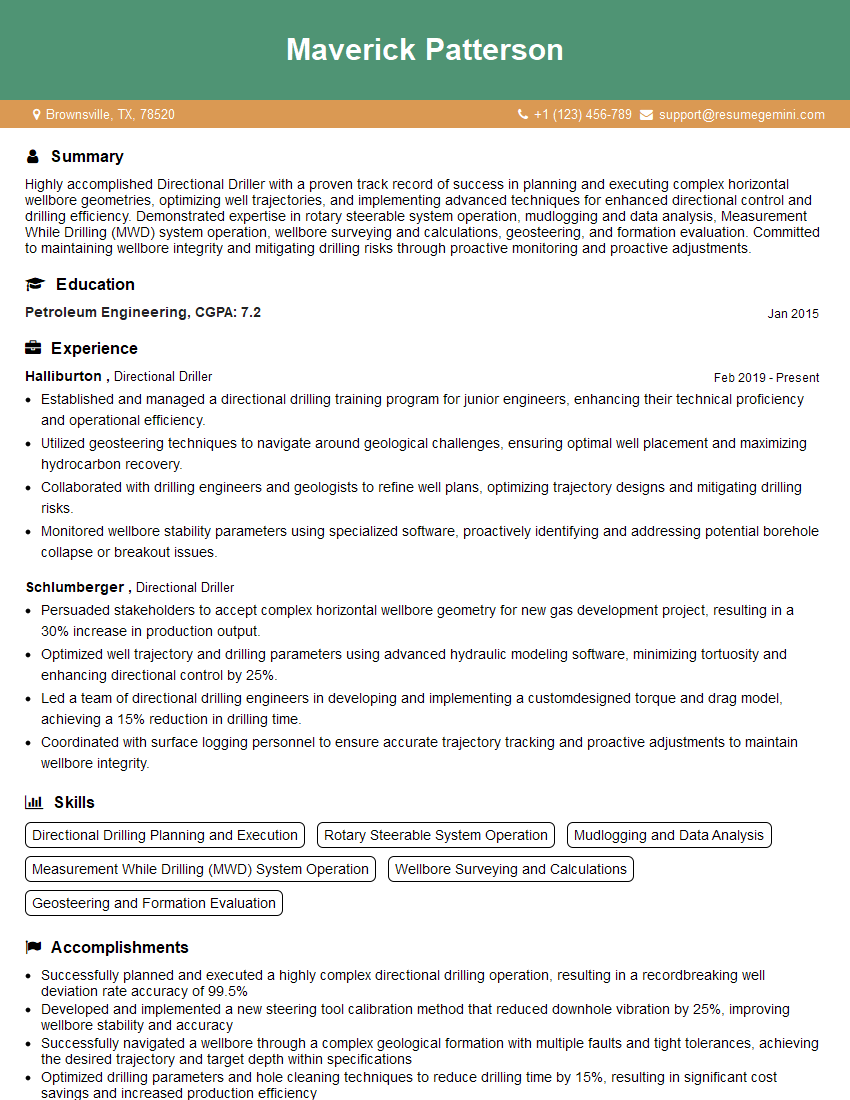

Mastering Drilling Program Optimization is crucial for accelerating your career in the energy sector. It demonstrates a deep understanding of drilling operations and positions you as a valuable asset to any team. To significantly improve your job prospects, crafting an ATS-friendly resume is paramount. ResumeGemini is a trusted resource that can help you build a compelling resume showcasing your skills and experience effectively. Examples of resumes tailored to Drilling Program Optimization are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good