The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Drilling rig operation interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Drilling rig operation Interview

Q 1. Explain the different types of drilling rigs and their applications.

Drilling rigs are categorized based on their mobility, size, and the type of drilling operation they perform. We have land rigs and offshore rigs, each further subdivided.

- Land Rigs: These are used for onshore drilling. Subtypes include:

- Jackknife Rigs: Smaller, simpler rigs, often used for shallow wells or exploratory drilling. Think of them as the pickup trucks of the drilling world.

- Truck-mounted Rigs: Highly mobile, ideal for quick setup and relocation, perfect for smaller projects or those in difficult-to-access locations.

- Mast Rigs: Larger and more powerful than jackknife and truck-mounted rigs, capable of drilling deeper and more challenging wells. These are the workhorses of onshore operations.

- Offshore Rigs: Used for drilling in marine environments, they are significantly more complex and expensive. Some examples are:

- Jack-up Rigs: These rigs raise their legs to elevate the drilling platform above the water’s surface. Think of them as giant stilts. They’re suitable for relatively shallow water depths.

- Semi-submersible Rigs: These rigs float on pontoons, offering greater stability in deeper waters than jack-up rigs. They’re adaptable and can handle challenging conditions.

- Drill Ships: These are self-propelled vessels equipped with drilling equipment, offering the highest mobility and allowing drilling operations in even deeper waters. These are the titans of offshore drilling.

The choice of rig depends on factors like water depth, well depth, terrain, and the overall project budget.

Q 2. Describe the process of drilling a well from spudding to completion.

Drilling a well is a multi-stage process. Let’s trace it from start to finish:

- Spudding: This is the initial act of beginning the drilling process. The bit starts cutting into the earth.

- Drilling: The drill string (composed of drill pipes, drill collars, and the drill bit) rotates, breaking up the rock and creating a wellbore. This involves regular monitoring and adjustments of parameters like weight on bit (WOB) and rotary speed.

- Casing and Cementing: As the wellbore deepens, steel pipes (casing) are inserted to protect the wellbore from collapse and prevent contamination. Cement is pumped into the annulus (space between the casing and the wellbore) to further provide stability and prevent fluid leakage.

- Directional Drilling (If Applicable): For some wells, a directional drilling system is used to deviate from a vertical path, allowing access to reservoirs not directly below the surface location. This often involves specialized equipment like mud motors and steerable drilling systems.

- Completion: Once the target depth is reached, completion operations begin to prepare the well for production. This involves setting production tubing, installing downhole equipment, and conducting well testing to determine productivity.

Each stage has its own complexities and challenges, demanding precision and meticulous monitoring. For example, losing circulation (the drilling mud not returning to the surface) during drilling can be a major setback.

Q 3. What are the key components of a drilling rig and their functions?

A drilling rig is a complex machine with many vital components. Here are some key ones:

- Derrick/Mast: A tall tower that supports the drilling equipment and hoisting system.

- Crown Block and Traveling Block: A system of sheaves (pulleys) and cables used to lift and lower the drilling string.

- Drawworks: A powerful winch that controls the hoisting of the drill string.

- Rotary Table/Top Drive: The device that rotates the drill string.

- Mud Pumps: These pumps circulate drilling mud through the drill string to cool the bit, lubricate the drill string, remove cuttings, and maintain wellbore stability. Think of them as the rig’s circulatory system.

- Drill String: The assembly of drill pipes, drill collars, and the drill bit that penetrates the earth.

- Drill Bit: The cutting element at the bottom of the drill string.

- Mud System: This encompasses everything related to the drilling mud, including the mud tanks, shakers, desanders, and desilters.

Each component is crucial for the smooth and safe operation of the drilling rig. A failure in any part can have significant consequences, leading to delays, cost overruns, or even accidents.

Q 4. How do you maintain well control during drilling operations?

Maintaining well control is paramount in drilling operations. It involves preventing unwanted flow of fluids (formation fluids or drilling mud) into or out of the wellbore. Key strategies include:

- Proper Mud Weight: Maintaining the appropriate mud weight (density) is critical to prevent formation fluids from flowing into the well (kicks) or the wellbore from collapsing.

- Use of Blowout Preventers (BOPs): These are critical safety devices located at the wellhead that can prevent the uncontrolled flow of formation fluids to the surface. They’re often compared to a giant valve system to seal the well in case of emergencies.

- Careful Monitoring: Continuous monitoring of parameters like mud weight, pressure, flow rates, and gas indicators is vital to detecting potential problems early.

- Well Control Procedures: Rigorous adherence to well control procedures, including emergency shutdown protocols, is crucial for preventing accidents.

- Regular Training: Rig crews need extensive training in well control techniques and emergency response procedures. Regular drills and simulations keep this expertise sharp.

Loss of well control can lead to significant environmental damage, financial losses, and, most critically, serious injury or death. It’s a constant priority in drilling.

Q 5. What are the safety procedures for operating a drilling rig?

Safety on a drilling rig is paramount. Procedures encompass every aspect of the operation:

- Pre-job Safety Meetings: These are mandatory before any operation begins, reviewing potential hazards and safety protocols.

- Personal Protective Equipment (PPE): Mandatory use of helmets, safety glasses, high-visibility clothing, and appropriate footwear is strictly enforced.

- Emergency Shutdown Procedures: All personnel must be thoroughly trained on emergency shutdown procedures, ensuring quick and effective response in case of accidents.

- Permit-to-Work System: A formal system for authorizing high-risk tasks, ensuring necessary safety measures are in place before the work commences.

- Regular Safety Audits and Inspections: Regular inspections of the equipment and work areas are crucial to identify and address potential hazards.

- Emergency Response Plan: A comprehensive plan detailing procedures for handling various emergencies, including well control incidents, fires, and medical emergencies. This includes designated assembly points and evacuation routes.

Safety is not just a set of rules; it’s a mindset that must be ingrained in every member of the drilling crew.

Q 6. Explain the concept of mud weight and its importance in drilling.

Mud weight, or mud density, refers to the weight of a given volume of drilling mud. It’s usually expressed in pounds per gallon (ppg) or kilograms per cubic meter (kg/m³). It’s a crucial parameter in drilling because it directly impacts wellbore stability and prevents unwanted fluid flow.

Importance:

- Formation Pressure Control: The hydrostatic pressure exerted by the mud column must be greater than the formation pressure to prevent formation fluids from entering the wellbore. If the mud weight is too low, a kick (influx of formation fluids) can occur.

- Wellbore Stability: Proper mud weight helps maintain the wellbore stability by preventing wellbore collapse or shale swelling. It acts as a counter force to the earth’s pressure.

- Cuttings Removal: The density of the mud influences its ability to carry cuttings (rock fragments) to the surface.

Determining the optimal mud weight involves careful analysis of formation pressure data, lithology (rock type), and other relevant factors. This is a crucial decision during drilling planning.

Q 7. How do you identify and troubleshoot common drilling problems?

Troubleshooting in drilling involves a systematic approach:

- Identify the problem: Clearly define the issue; this might involve reviewing the drilling parameters, checking mud properties, and assessing wellbore conditions.

- Gather data: Collect relevant data, such as drilling parameters (weight on bit, rotary speed, torque), mud properties (weight, viscosity, pH), and any observed anomalies.

- Analyze the data: Use your knowledge and experience to analyze the collected data and identify the possible causes.

- Develop a solution: Based on the analysis, develop a plan to address the issue. This might involve adjusting drilling parameters, changing mud properties, running specialized tools, or implementing well control procedures.

- Implement the solution: Carefully implement the chosen solution, closely monitoring its effectiveness.

- Evaluate the results: After the solution is implemented, evaluate its impact on the drilling process. Make necessary adjustments if required.

Examples of common problems and their possible causes include: stuck pipe (due to differential sticking or key seating), lost circulation (due to fractures or permeable formations), and kicks (due to insufficient mud weight). Each of these demands different, immediate responses.

Q 8. What are the different types of drilling fluids and their properties?

Drilling fluids, also known as mud, are crucial in drilling operations. They serve multiple functions, from cleaning the wellbore to stabilizing the formations. Different types cater to specific well conditions and challenges.

- Water-based muds (WBM): The most common type, cost-effective and environmentally friendly. They are easily prepared and can be tailored with various additives to control properties like viscosity and density. However, they can be less effective in highly reactive formations.

- Oil-based muds (OBM): Offer excellent lubricity and shale inhibition, making them suitable for challenging formations prone to swelling or instability. They are more expensive and pose greater environmental concerns, requiring careful management and disposal.

- Synthetic-based muds (SBM): Combine the benefits of oil-based muds with reduced environmental impact. They are less toxic than OBM and perform similarly in terms of lubricity and shale inhibition. However, they remain more expensive than WBMs.

- Polymer muds: These are water-based muds enhanced with polymers to improve their rheological properties, offering better hole cleaning and carrying capacity. They are often preferred for environmentally sensitive areas.

The properties of drilling fluids are meticulously controlled to achieve optimal wellbore stability and efficient drilling. Key properties include density (to control formation pressure), viscosity (for carrying cuttings), and filtration control (to minimize fluid loss into the formation).

Q 9. Describe the process of running casing and cementing a well.

Running casing and cementing is a critical step in well construction, ensuring wellbore stability and preventing unwanted fluid flow. It involves lowering steel pipes (casing) into the borehole and filling the annulus (space between the casing and the borehole wall) with cement.

- Running the Casing: The casing string, made up of individual joints connected by threads, is carefully lowered into the hole using a top drive system. This process requires precise control to prevent damage to the casing or borehole.

- Cementing: Once the casing is at the desired depth, cement slurry is pumped down the annulus, displacing the drilling fluid and filling the gap between the casing and the formation. This process creates a strong, impermeable barrier, preventing fluid flow and providing support for the wellbore.

- Cement Evaluation: After cementing, various techniques such as cement bond logs are used to verify the quality and integrity of the cement job, ensuring a complete seal.

Think of it like building a house – the casing is the skeleton and the cement is the concrete foundation, providing strength and stability.

Different types of cement are selected based on the formation properties, temperature, and pressure. Properly cemented casing is vital for preventing blowouts, maintaining pressure control, and ensuring the long-term integrity of the well.

Q 10. How do you manage the drilling crew and ensure effective teamwork?

Managing a drilling crew effectively requires strong leadership, clear communication, and a focus on safety. It’s about building a team, not just managing individuals.

- Clear Roles and Responsibilities: Establishing clear roles and responsibilities from the outset is vital. Each crew member must understand their tasks and how they contribute to the overall objective.

- Open Communication: Regular meetings, shift handovers, and open communication channels are essential for ensuring everyone is informed and any issues are addressed promptly. A safe environment encourages open dialogue.

- Safety First: Safety is paramount in drilling operations. Regular safety training, risk assessments, and strict adherence to safety protocols are non-negotiable. Leading by example is key.

- Motivation and Teamwork: Recognizing and rewarding good work fosters a positive and productive environment. Promoting teamwork and collaboration improves efficiency and morale.

- Conflict Resolution: Addressing conflicts fairly and promptly is crucial to maintaining a harmonious work environment. This requires listening, understanding perspectives, and finding mutually agreeable solutions.

In my experience, a well-managed drilling crew is a highly efficient and productive team. This translates to faster drilling times, reduced costs, and most importantly, a safe working environment.

Q 11. Explain the importance of daily drilling reports and their contents.

Daily drilling reports (DDRs) are crucial for tracking progress, managing costs, and making informed decisions throughout the drilling process. They provide a concise summary of the day’s activities and key performance indicators.

A typical DDR includes information such as:

- Well data: Depth drilled, rate of penetration (ROP), wellbore diameter, casing information.

- Mud data: Mud weight, viscosity, filtration properties.

- Mechanical data: Torque, hook load, pump pressures.

- Personnel data: Crew hours worked, safety incidents.

- Geological data: Formation descriptions, encountered challenges.

- Cost information: Expenditures, planned vs. actual costs.

DDRs are vital for: monitoring drilling progress, identifying potential problems early, optimizing drilling parameters, managing costs, and providing historical data for future well planning. Inaccurate or incomplete DDRs can lead to poor decision-making and potentially costly setbacks.

Q 12. What are the environmental considerations in drilling operations?

Environmental considerations are increasingly important in drilling operations. Minimizing the environmental impact requires careful planning and implementation of best practices.

- Wastewater Management: Proper treatment and disposal of drilling fluids and cuttings are essential to prevent contamination of soil and water resources. This often involves using specialized treatment facilities and adhering to strict regulatory guidelines.

- Air Emissions: Reducing emissions of harmful gases (e.g., methane) requires the use of efficient equipment and emission control technologies.

- Noise Pollution: Minimizing noise pollution through the use of noise reduction equipment and careful planning of drilling operations is crucial to protect wildlife and nearby communities.

- Spill Prevention and Response: Having robust spill prevention and response plans in place is essential to minimize the impact of any accidental spills of drilling fluids or other hazardous materials.

- Habitat Protection: Protecting sensitive habitats through careful site selection and operational practices is vital for preserving biodiversity.

Environmental regulations vary by location, and compliance is mandatory. Companies often employ environmental specialists to ensure adherence to all relevant regulations and best practices.

Q 13. Describe your experience with directional drilling techniques.

Directional drilling techniques allow for the precise control of wellbore trajectory, enabling access to reservoirs that cannot be reached with vertical drilling. I have extensive experience with various directional drilling methods, including:

- Rotary Steerable Systems (RSS): These systems use downhole motors to control wellbore direction and inclination without the need for wireline tools, resulting in increased efficiency and speed. I’ve successfully used RSS in multiple wells, navigating complex geological formations to reach target zones.

- Measurement While Drilling (MWD): MWD tools provide real-time information on wellbore trajectory, inclination, and azimuth, allowing for precise adjustments during the drilling process. This significantly enhances the accuracy and efficiency of directional drilling.

- Geosteering: This technique combines real-time data from MWD and formation evaluation tools to guide the wellbore through specific geological formations, maximizing reservoir contact and hydrocarbon recovery. I’ve successfully used geosteering to optimize well placement in challenging geological settings.

My experience encompasses various applications, from horizontal drilling for shale gas production to deviated wells targeting specific reservoir sections. The choice of techniques depends on several factors, including geological conditions, target reservoir location, and operational requirements.

Q 14. How do you manage and interpret drilling data (ROP, torque, etc.)?

Drilling data such as rate of penetration (ROP), torque, and weight on bit (WOB) are crucial for monitoring drilling performance and identifying potential problems. Effective data management and interpretation are essential for optimizing drilling efficiency and preventing complications.

Data Management: Modern drilling operations use sophisticated drilling automation systems that automatically collect and record drilling data in real-time. This data is then stored and analyzed using specialized software. I have experience using various drilling data management software and platforms.

Data Interpretation: Analyzing drilling parameters helps in determining optimal drilling parameters, such as WOB, RPM, and mud properties. For example:

- ROP: A sudden decrease in ROP could indicate a change in formation properties, a stuck drill bit, or other issues that need immediate attention.

- Torque: High torque could indicate a problem with the drillstring or downhole tools, possibly requiring remedial actions such as pulling the string or changing the bit.

- WOB: Excessive WOB can damage the drill bit and increase wear, whereas insufficient WOB might lead to slow drilling rates.

By monitoring these parameters and comparing them against historical data and geological models, we can identify potential problems and make informed decisions to optimize drilling efficiency and minimize downtime. This requires a strong understanding of both drilling mechanics and the geological formations being drilled.

Q 15. What are the different types of bits and their applications?

Drilling bits are the cutting tools at the bottom of the drill string, responsible for breaking up rock formations and creating the wellbore. Different formations require different bits, each designed for optimal performance in specific conditions.

- Roller Cone Bits: These bits use rotating cones with teeth or inserts to crush and grind the rock. They’re excellent for hard, abrasive formations and are relatively inexpensive. Think of them as a giant, rotating rock crusher. I’ve used them extensively in shale formations where their aggressive cutting action is crucial.

- Polycrystalline Diamond Compact (PDC) Bits: These bits have synthetic diamonds embedded in a matrix. They cut through rock using a shearing action, making them ideal for softer formations and providing a smoother, straighter wellbore. They are more expensive than roller cone bits but offer superior performance and longer life in appropriate formations. I’ve found them particularly effective in softer sandstone and limestone formations.

- Insert Bits: These bits use replaceable inserts of carbide or other hard materials. They combine aspects of both roller cone and PDC bits, offering a balance of cost-effectiveness and performance across a range of formations. They’re a good middle ground, often used when dealing with formations exhibiting variable hardness.

The choice of bit depends on several factors, including the formation’s hardness, abrasiveness, and the desired rate of penetration (ROP). Experienced drillers like myself carefully consider these parameters before selecting the right bit for a specific well.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the process of tripping in and out of the hole.

Tripping is the process of raising (tripping out) or lowering (tripping in) the drill string—the long column of pipes connecting the surface equipment to the bit at the bottom of the well. It’s a critical operation, requiring careful coordination and precise execution to prevent accidents.

Tripping Out: This involves disconnecting the drill string from the bottom-hole assembly (BHA), gradually unscrewing each joint of pipe, and raising it to the surface. It’s essential to maintain proper weight and tension on the string to avoid damaging the pipes or equipment. We use top drives or travelling blocks to manage the weight and speed of the operation.

Tripping In: This is the reverse process, carefully lowering the drill string back into the well, joint by joint, until the bit reaches the bottom. Careful monitoring of weight, torque, and rate of penetration are crucial. Precise alignment is paramount to prevent damaging the wellbore or causing other issues.

Both processes involve meticulous attention to detail, including proper communication between the driller, the roughneck crew, and the toolpusher. Safety procedures are rigorously followed, including using proper lifting equipment and employing a comprehensive safety plan.

Q 17. How do you handle emergency situations on a drilling rig?

Emergency situations on a drilling rig can range from minor equipment malfunctions to major well control events. Our response is dictated by established protocols and requires swift, decisive action.

- Equipment Malfunctions: For minor issues, we follow established troubleshooting procedures, often involving replacement of parts or adjustments. A detailed maintenance log helps us identify common problems and implement preventive measures.

- Well Control Events: These are critical situations such as a kick (influx of formation fluids into the wellbore), blowout, or other uncontrolled pressure events. We immediately shut down the rig, activate the well control equipment, and follow established kill procedures, which involves circulating the well and/or using specialized equipment to regain control. The exact procedure depends on the severity and nature of the emergency. Our response is always dictated by the well control manual, and every crew member is thoroughly trained in these procedures.

- Personal Injuries: Immediate medical assistance is provided, with procedures varying depending on the severity of the injury. Accident investigation will follow, to pinpoint the cause and prevent future occurrences.

Rigorous training, regular drills, and adherence to strict safety protocols are paramount to handling emergencies effectively. Communication is key, ensuring everyone understands their role in the emergency response.

Q 18. Describe your experience with well control equipment.

My experience with well control equipment is extensive. I’m proficient in operating and maintaining various types of equipment, including:

- Blowout Preventers (BOPs): I’m experienced with both annular and ram-type BOPs, understanding their functions, testing procedures, and limitations. I’ve participated in numerous BOP testing procedures, ensuring their readiness in case of well control emergencies.

- Choke Manifolds and Valves: I can effectively control well pressure using choke manifolds and various valves, critical during well control operations. Understanding the pressure limitations of each valve is crucial.

- Mud Pumps and Mud Systems: I understand the role of the mud system in well control, including managing mud weight and rheology to prevent kicks. Correct mud properties are often the first line of defense.

- Emergency Shutdown Systems: I know how to activate and utilize emergency shutdown systems, enabling a rapid and safe response to critical situations.

Safety is paramount. I always ensure that the well control equipment is regularly inspected, tested, and maintained to the highest standards to minimize risks. A well-maintained BOP stack is crucial for drilling safety.

Q 19. What is your experience with different types of logging tools?

My experience with logging tools encompasses various types used to gather information about the subsurface formations. This data helps us understand the geology, reservoir properties, and wellbore conditions.

- Wireline Logging: I’ve worked with various wireline tools, including gamma ray, resistivity, porosity, and density logs. These tools are lowered into the borehole on a wireline cable and provide continuous readings of formation properties. I’ve often been involved in interpreting the data obtained, correlating it with other geological information, and subsequently assisting with decisions on the next steps of the drilling operation.

- LWD (Logging While Drilling): I’ve also used LWD tools, which are incorporated into the drill string and provide real-time data during the drilling process. This technology saves time and allows for faster decision-making. I’ve used this technology particularly effectively in directional drilling, allowing real-time adjustments to the well path.

- MWD (Measurement While Drilling): This involves the use of tools for directional drilling, enabling real-time tracking and steering of the wellbore.

Understanding the limitations and capabilities of different logging tools is crucial for accurate interpretation of data and informed decision-making during the drilling operation.

Q 20. How do you ensure the safety of the drilling crew and the environment?

Ensuring the safety of the drilling crew and the environment is a top priority. We employ a multi-layered approach.

- Safety Training and Procedures: All crew members receive comprehensive training in safety protocols, emergency response, and the use of personal protective equipment (PPE). Regular safety meetings and drills ensure that everyone is prepared to handle various scenarios. We adhere strictly to the company’s safety guidelines and industry best practices.

- Risk Assessment and Mitigation: We conduct regular risk assessments to identify potential hazards and implement appropriate mitigation strategies. This involves regular inspections of equipment, adherence to weight and pressure limits, and implementation of preventative measures.

- Environmental Protection: We follow strict environmental regulations, including proper waste disposal, containment of drilling fluids, and minimizing the environmental impact of our operations. This includes regular monitoring of discharge, adhering to environmental permits, and minimizing emissions.

- Emergency Response Plan: A comprehensive emergency response plan is in place, covering various scenarios, including well control events, personal injuries, and environmental incidents. Regular drills and training prepare the crew for effective responses.

A strong safety culture, fostered through communication, accountability, and proactive measures, is paramount in maintaining a safe and environmentally responsible drilling operation.

Q 21. Describe your experience with preventive maintenance of drilling equipment.

Preventive maintenance is essential for maximizing uptime, preventing costly breakdowns, and ensuring the safety of the drilling operation. My approach involves a combination of scheduled maintenance and condition-based monitoring.

- Scheduled Maintenance: We follow manufacturer’s recommendations and industry best practices for scheduled maintenance of all drilling equipment. This includes regular inspections, lubrication, and replacement of worn-out parts. Detailed maintenance logs are kept and tracked for every piece of equipment.

- Condition-Based Monitoring: We use various methods to monitor the condition of equipment, including vibration analysis, oil analysis, and thermal imaging. This allows us to identify potential problems before they escalate into major failures, significantly reducing downtime and improving the efficiency of the entire operation.

- Data-Driven Maintenance: We utilize data collected from sensors and monitoring systems to identify trends, predict potential failures, and optimize maintenance schedules. This helps in prioritizing maintenance tasks and proactively addressing potential problems.

A well-planned and executed preventive maintenance program is crucial for efficient and safe drilling operations. It’s an investment in preventing costly downtime and ensuring the smooth functioning of the entire rig.

Q 22. Explain the process of managing drilling waste and disposal.

Managing drilling waste is crucial for environmental protection and regulatory compliance. It’s a multi-step process starting with segregation at the source. We categorize waste into different streams: drilling muds, cuttings, produced water, and other debris. Each stream requires a specific handling method.

Treatment is the next critical step. Drilling muds, for example, might undergo processes like solids control (using shale shakers, desanders, and desilters) to remove larger particles. Produced water often requires treatment to remove oil and other contaminants before disposal. Cuttings are typically processed to remove hazardous materials, and sometimes, they are used in land reclamation projects.

Disposal methods vary based on waste type and local regulations. Some materials can be recycled, some are sent to designated landfills, and others might require specialized disposal facilities. We maintain detailed records of all waste generated, treated, and disposed of, ensuring complete traceability and compliance with environmental regulations.

For instance, on a recent project in the North Sea, we implemented a closed-loop mud system, significantly reducing the volume of waste requiring disposal. This not only saved costs but also minimized our environmental impact.

Q 23. How do you calculate the cost-effectiveness of different drilling techniques?

Comparing the cost-effectiveness of drilling techniques involves a detailed cost-benefit analysis. We consider several factors:

- Initial investment costs: This includes the cost of equipment, specialized tools, and labor required for each technique.

- Operational costs: These encompass daily operating expenses like fuel, chemicals, and crew wages.

- Drilling rate and efficiency: Faster drilling rates translate to lower overall costs and shorter project durations.

- Wellbore stability and quality: Techniques that enhance wellbore stability reduce the risk of complications and costly remedial work.

- Environmental impact: This includes the cost of waste management, potential fines for non-compliance, and environmental remediation.

We often use spreadsheet models or specialized software to input these parameters and generate a comparative analysis. For example, comparing rotary drilling with directional drilling, we might find that although directional drilling has higher initial equipment costs, its ability to access multiple targets from a single location can lead to significant cost savings over multiple wells.

Q 24. What software and technology are you familiar with related to drilling operations?

My experience encompasses a range of software and technologies. I’m proficient in well planning software like Petrel and Landmark, which aid in designing well trajectories, optimizing drilling parameters, and predicting formation properties. I also utilize drilling optimization software like Drilling Simulator for real-time monitoring and data analysis, allowing for proactive adjustments to drilling parameters.

In terms of technology, I’m familiar with various downhole tools such as measurement-while-drilling (MWD) and logging-while-drilling (LWD) systems that provide real-time data on formation properties, wellbore conditions, and drilling progress. Experience with automated drilling systems and remote operation technologies further enhances efficiency and safety.

Q 25. Describe your experience with different types of drilling formations.

I’ve worked with a variety of drilling formations, each presenting unique challenges.

- Shale formations: These are notoriously unstable and require specialized drilling fluids and techniques to prevent wellbore collapse and maintain stability.

- Sandstone formations: These can be prone to sand production, requiring careful well completion design and potentially the use of sand control measures.

- Carbonate formations: These can be hard and abrasive, requiring specialized drill bits and drilling parameters to optimize drilling rates and prevent bit wear.

- Fractured formations: These require careful well design and completion strategies to manage fluid flow and optimize production.

For instance, on a project in the Bakken shale, we utilized a highly engineered drilling fluid system, incorporating polymer additives to minimize shale swelling and improve wellbore stability. This resulted in significant improvements in drilling efficiency and reduced non-productive time.

Q 26. How do you handle conflicts and disagreements within the drilling crew?

Conflict resolution within the drilling crew is paramount for safety and efficiency. My approach involves open communication and a collaborative problem-solving approach. I encourage team members to openly express concerns and differing perspectives in a respectful manner.

I focus on understanding the root cause of disagreements and finding mutually acceptable solutions. This often involves mediating between conflicting parties, ensuring fair consideration of all viewpoints. Sometimes, this requires clarifying roles and responsibilities, addressing any performance issues, or escalating issues to higher management if necessary.

Building a strong team culture of trust and respect is key to preventing conflicts. This involves clear communication channels, regular team meetings, and fostering a positive work environment where everyone feels valued and heard.

Q 27. Explain your understanding of regulatory compliance in drilling operations.

Regulatory compliance is non-negotiable in drilling operations. It’s crucial to understand and adhere to all applicable regulations at the local, national, and international levels. This includes environmental regulations (e.g., discharge permits, waste management regulations), safety regulations (e.g., OSHA, HSE), and well control regulations (e.g., API standards).

We maintain meticulous records of all drilling activities, regularly conduct safety audits and inspections, and ensure that all personnel receive appropriate safety training. We also proactively engage with regulatory bodies to ensure compliance and address any potential issues promptly. Non-compliance can lead to significant financial penalties, operational disruptions, and reputational damage.

For example, ensuring that all drilling muds meet the required environmental standards before discharge, obtaining necessary permits for waste disposal, and implementing stringent well control procedures are all critical aspects of our compliance efforts.

Q 28. Describe your experience with project planning and execution in drilling projects.

Project planning and execution are fundamental to successful drilling projects. It begins with a comprehensive risk assessment, followed by a detailed well plan outlining the drilling strategy, operational parameters, and cost estimates.

This plan is then broken down into manageable work packages with assigned responsibilities and timelines. Regular progress meetings and performance monitoring are essential to ensure adherence to the plan and to proactively address any deviations. Effective communication and collaboration among all stakeholders (operators, contractors, and regulatory bodies) are crucial for successful project execution.

On a recent deepwater drilling project, meticulous planning, combined with proactive risk management, enabled us to complete the well ahead of schedule and under budget. This was achieved by using advanced drilling technologies, optimizing wellbore trajectory, and effective coordination between different teams.

Key Topics to Learn for Drilling Rig Operation Interview

- Rig Mechanics and Systems: Understanding the intricate workings of a drilling rig, including the derrick, drawworks, mud pumps, and top drive system. Practical application: Troubleshooting common mechanical issues and preventative maintenance procedures.

- Drilling Fluids (Mud) Management: Knowledge of mud properties, functions, and the importance of maintaining optimal mud weight and rheology. Practical application: Interpreting mud logs and adjusting mud parameters to optimize drilling performance and wellbore stability.

- Well Control Procedures: Mastering well control techniques, including recognizing and responding to kicks, applying various well control equipment, and understanding the importance of safety protocols. Practical application: Scenario-based problem-solving related to well control emergencies.

- Directional Drilling and MWD/LWD: Familiarity with directional drilling techniques, including the use of measurement-while-drilling (MWD) and logging-while-drilling (LWD) tools. Practical application: Interpreting directional drilling data and adjusting drilling parameters to achieve desired well trajectories.

- Safety Procedures and Regulations: Deep understanding of OSHA regulations and industry best practices for safety on a drilling rig. Practical application: Demonstrating knowledge of emergency response plans and personal protective equipment (PPE) usage.

- Basic Geology and Formation Evaluation: Understanding fundamental geological principles relevant to drilling operations, including formation types and properties. Practical application: Interpreting geological data to predict potential drilling challenges and optimize drilling strategies.

- Production and Completion: Understanding the basic principles of well completion and production, including casing design and cementing operations. Practical application: Explaining the connection between drilling operations and subsequent production activities.

Next Steps

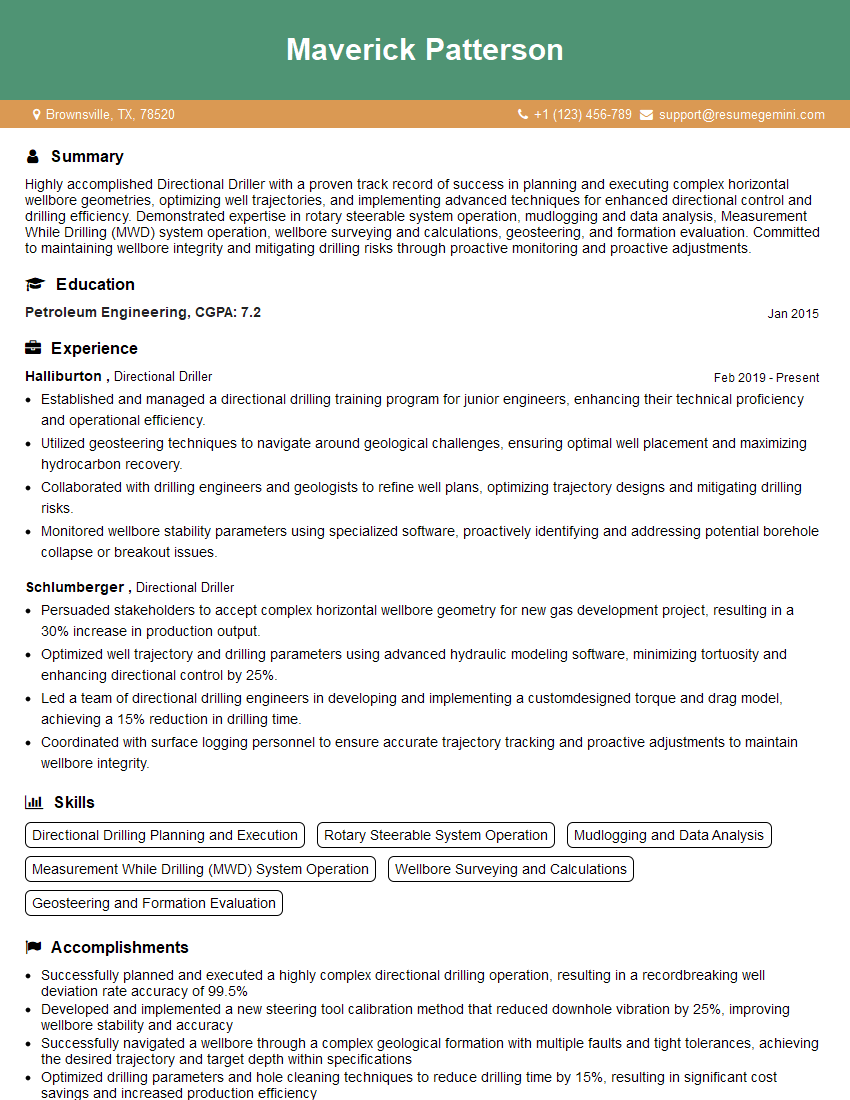

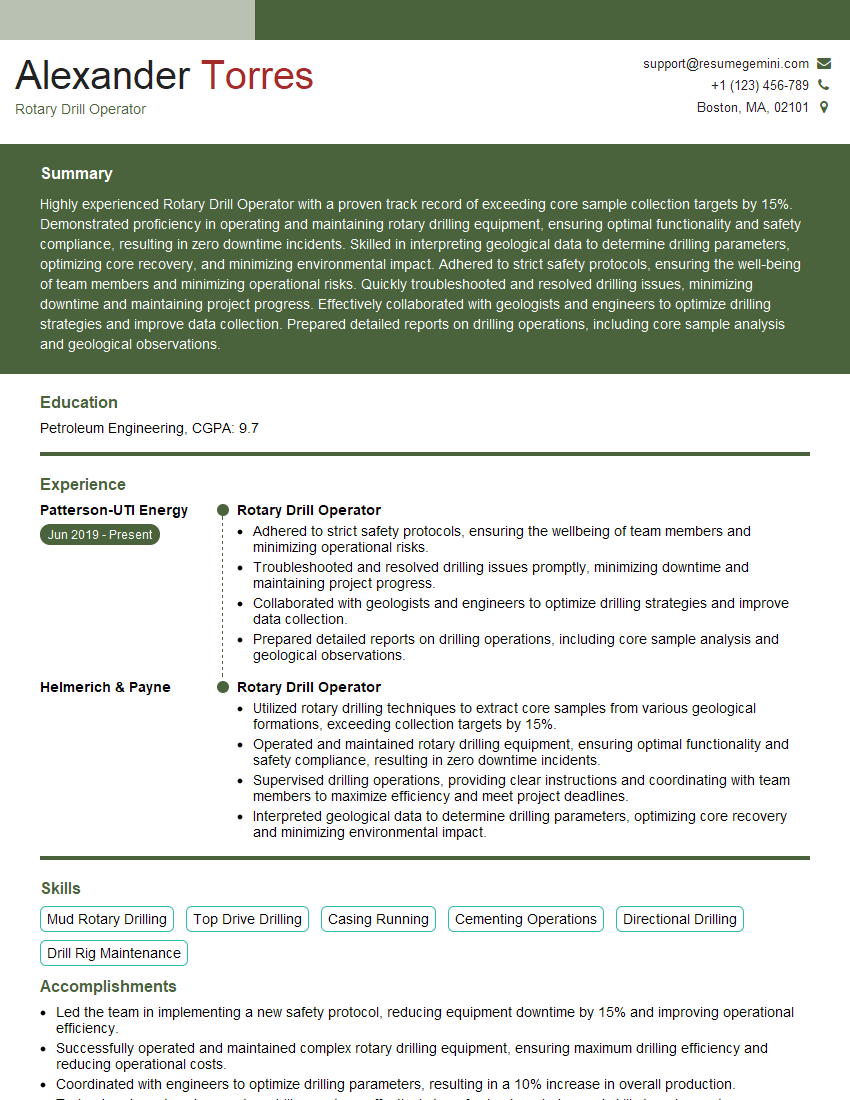

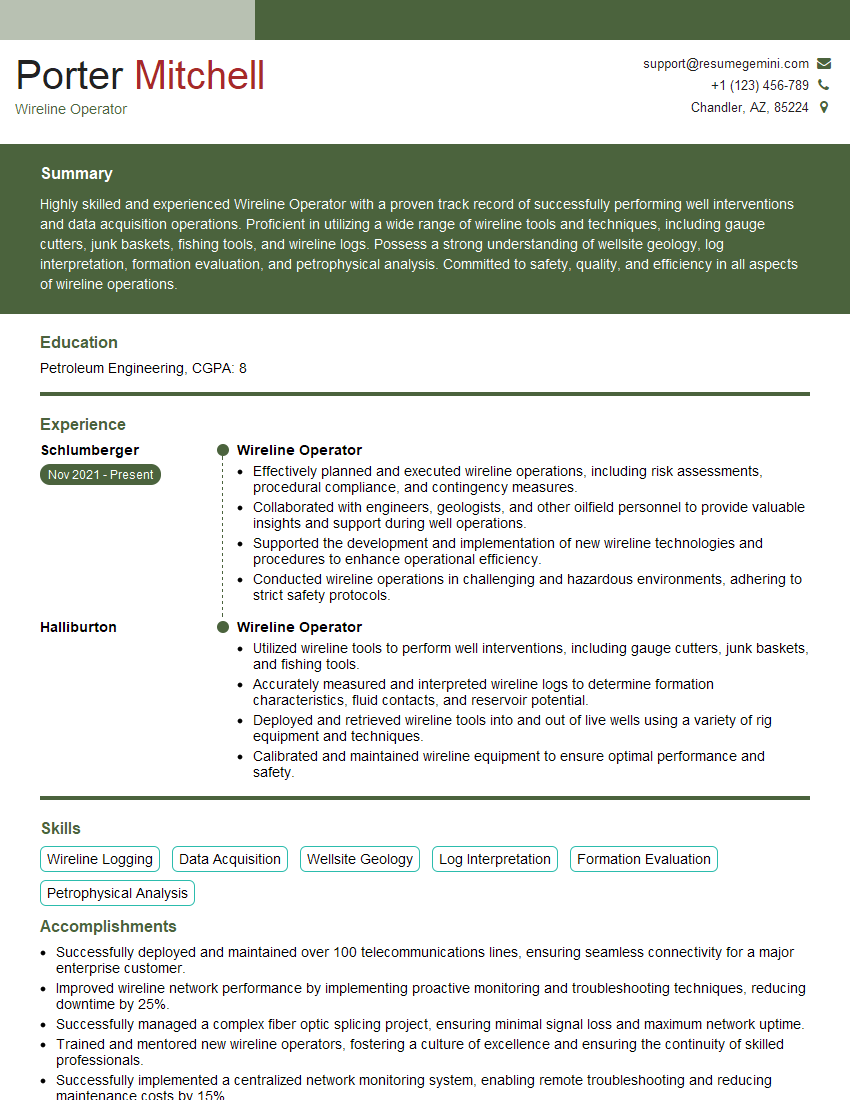

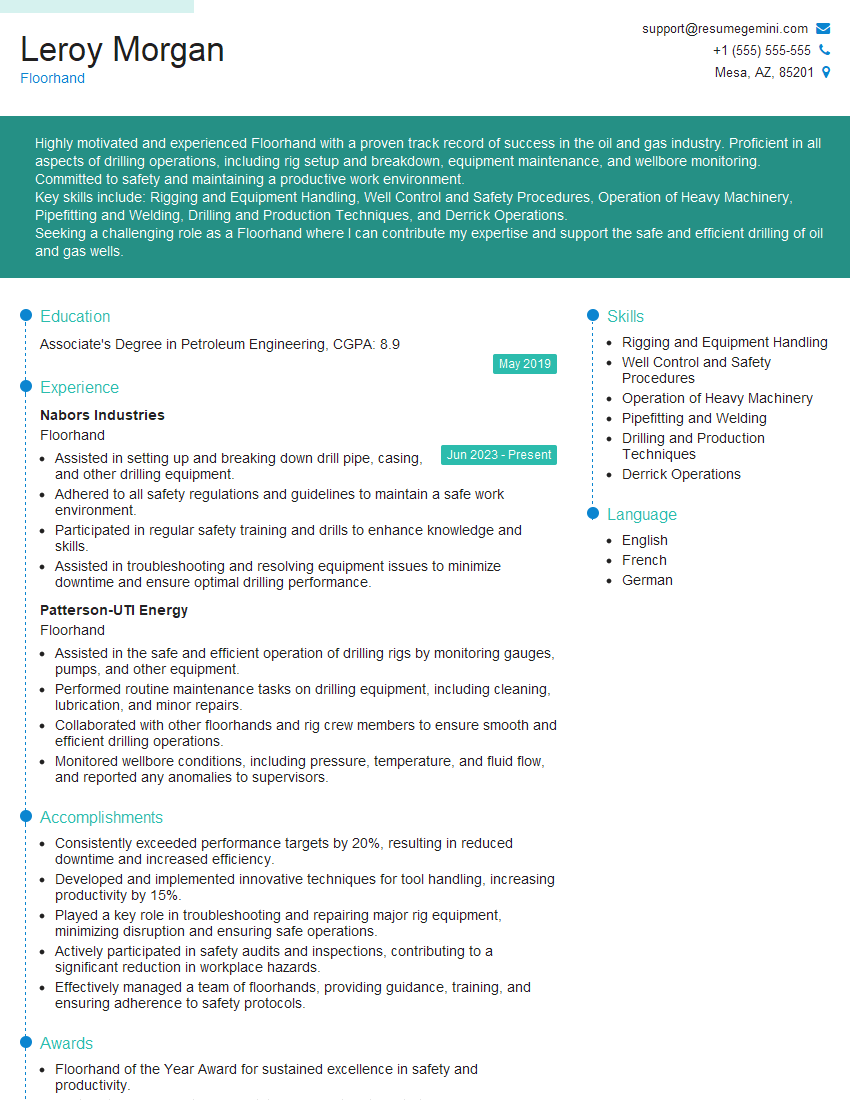

Mastering drilling rig operation opens doors to a rewarding and high-demand career with excellent growth potential. To maximize your job prospects, it’s crucial to present your skills and experience effectively. Creating an ATS-friendly resume is paramount in today’s competitive job market. We highly recommend using ResumeGemini to craft a professional and impactful resume that highlights your unique qualifications. ResumeGemini provides examples of resumes tailored specifically to drilling rig operation roles, giving you a head start in showcasing your capabilities to potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).