Preparation is the key to success in any interview. In this post, we’ll explore crucial Experience with sheet materials interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Experience with sheet materials Interview

Q 1. Describe your experience with different sheet metal materials (e.g., aluminum, steel, stainless steel).

My experience with sheet metal materials spans a wide range, encompassing aluminum, steel, and stainless steel, each with distinct properties influencing their application. Aluminum, known for its lightweight yet strong nature, is ideal for applications requiring corrosion resistance and ease of fabrication, such as aerospace components or automotive parts. I’ve worked extensively with various aluminum alloys, understanding their differing strengths, machinability, and weldability. Steel, offering high strength and rigidity, is frequently used in construction and manufacturing where durability is paramount. I’ve encountered various grades, from mild steel to high-strength low-alloy (HSLA) steels, each tailored to specific load-bearing requirements. Finally, stainless steel, prized for its exceptional corrosion resistance, finds applications in food processing, chemical handling, and medical equipment. My experience includes working with different grades of stainless steel, understanding their varying compositions and suitability for different environments.

For example, in one project, we needed a lightweight yet strong enclosure for sensitive electronics. Aluminum 6061-T6 was the ideal choice due to its excellent strength-to-weight ratio and corrosion resistance. In another project involving industrial equipment exposed to harsh chemicals, 316L stainless steel was essential for its superior corrosion resistance.

Q 2. What are the common processes used in sheet metal fabrication?

Sheet metal fabrication employs a variety of processes, each contributing to the final product’s form and function. Common processes include:

- Shearing: Cutting sheet metal to precise dimensions using a shear press. This is a fundamental starting point for many projects.

- Punching: Creating holes or other shapes using a punch press. This is efficient for high-volume production of parts with repetitive features.

- Bending: Forming the sheet metal into desired shapes using press brakes. This process allows for the creation of complex 3D forms.

- Drawing: Deep drawing involves pulling sheet metal into a cavity to form cups or other complex shapes. This requires careful consideration of material properties and tooling design.

- Welding: Joining pieces of sheet metal together using various welding techniques like MIG, TIG, or spot welding. The choice of welding method depends heavily on the material and desired joint strength.

- Roll forming: Continuously forming sheet metal into long, repetitive shapes using rollers. This is highly efficient for producing large quantities of identical parts, such as roofing panels or gutters.

Selecting the appropriate process often involves considering factors like part complexity, production volume, material properties, and cost-effectiveness. For instance, simple shapes might be efficiently produced by shearing and bending, while more complex parts may require drawing or forming with multiple processes combined.

Q 3. Explain the importance of material selection in sheet metal design.

Material selection is critical in sheet metal design as it directly impacts the product’s performance, durability, cost, and manufacturability. The choice of material must consider the application’s requirements. For instance, strength, corrosion resistance, weight, and cost are all key factors.

Consider a design requiring high strength and rigidity. Steel might be chosen over aluminum due to its superior strength-to-weight ratio for structural components. In contrast, if weight reduction is paramount (like in aerospace), aluminum alloys would be preferred despite potentially higher costs. If the application involves exposure to corrosive environments, stainless steel’s resistance to corrosion is essential. Careful consideration of material properties is therefore crucial for a successful design.

Q 4. How do you determine the appropriate sheet metal gauge for a specific application?

Determining the appropriate sheet metal gauge is a crucial step in design, balancing strength and weight. The gauge refers to the thickness of the sheet metal, with lower gauges indicating thicker material. The selection process considers several factors:

- Application requirements: What load will the part bear? High loads necessitate thicker gauges.

- Part geometry: Complex shapes often require thicker gauges to prevent deformation during bending or forming.

- Manufacturing process: Some processes, such as deep drawing, have limitations on the minimum gauge that can be used effectively.

- Cost: Thicker gauges generally cost more.

Often, a balance needs to be struck. Using Finite Element Analysis (FEA) software can simulate stresses and strains under various loading conditions to determine the optimal gauge while maintaining cost-effectiveness.

For example, a simple bracket might only need a 20-gauge sheet, while a load-bearing component may require a much thicker gauge like 12 or even 10.

Q 5. What are the different types of sheet metal joints and their applications?

Sheet metal joints are crucial for assembling components. Several types exist, each suitable for specific applications:

- Lap Joints: Simple, overlapping sheets fastened with rivets, welds, or screws. Easy to manufacture but less strong than other methods. Used where strength requirements are not stringent.

- Seam Welds: Continuous welds joining edges. Strong and leak-proof, ideal for enclosures or containers. Requires specialized welding equipment.

- Edge Welds: Welds joining the edges of two sheets. Offer strong, relatively simple joints.

- Flanged Joints: One sheet’s edge is bent to overlap another. Simple, can be fastened with screws or rivets. Suitable for simple assemblies.

- Crimped Joints: Edges mechanically interlocked. Fast and often used in automotive and appliance manufacturing. Requires specialized crimping tools.

Choosing the correct joint type depends heavily on the application’s required strength, aesthetics, and manufacturing feasibility. A pressure vessel, for instance, would necessitate a strong seam weld, whereas a simple enclosure might use lap joints with screws.

Q 6. Describe your experience with CAD software for sheet metal design.

My experience with CAD software for sheet metal design is extensive. I’m proficient in SolidWorks, AutoCAD, and Inventor, leveraging their capabilities for creating detailed 3D models, generating flat patterns, and simulating assembly processes. I routinely utilize these tools to design complex sheet metal parts, considering factors such as bend radii, material thickness, and tolerances. The software allows me to create precise models and ensure manufacturability before actual production commences, saving time and reducing errors.

For example, when designing a complex enclosure, SolidWorks’ sheet metal tools allowed me to automatically generate the flat pattern, factoring in bend allowances and ensuring proper clearances for tooling. The simulation features also enabled me to test the design for strength and potential deformations before manufacturing, leading to a more optimized and robust design.

Q 7. How do you interpret engineering drawings for sheet metal fabrication?

Interpreting engineering drawings for sheet metal fabrication requires a keen eye for detail and a thorough understanding of drafting conventions. I begin by reviewing the title block for material specifications, tolerances, and other critical information. I then carefully examine the views, dimensions, and annotations to understand the part’s geometry and assembly requirements. Symbols representing bends, holes, and other features are key elements that dictate the fabrication process.

Understanding the material specifications, such as thickness and material type, is crucial. Dimensions are essential for cutting and bending the metal to the correct shape and size, and tolerances define the acceptable range of variation in the final product. I’ve learned to spot potential issues like inconsistent dimensions or unrealistic bend radii early in the process. This allows for clarification with the design engineers to prevent errors during manufacturing.

Q 8. What are the safety precautions you take when working with sheet metal machinery?

Safety is paramount when working with sheet metal machinery. My approach is based on a layered safety system, starting with thorough machine familiarization and adhering to all manufacturer’s safety guidelines. This includes understanding the specific safety features of each machine, such as emergency stops, guards, and light curtains.

- Personal Protective Equipment (PPE): I always wear appropriate PPE, including safety glasses, hearing protection, and cut-resistant gloves. The type of PPE varies depending on the specific task – for example, a face shield might be necessary when grinding or using a cutting torch.

- Machine Maintenance and Inspection: Before operating any machine, I carefully inspect it for any damage or malfunction. I’m trained to identify potential hazards and report them immediately. Regular maintenance is crucial to prevent accidents.

- Lockout/Tagout Procedures: When performing maintenance or repairs, I strictly follow lockout/tagout procedures to ensure the machine is completely de-energized and prevented from accidental start-up. This is non-negotiable.

- Safe Work Practices: Beyond the machinery itself, I maintain a clean and organized workspace. Clutter and poor housekeeping contribute significantly to accidents. I also avoid distractions and focus entirely on the task at hand.

- Training and Awareness: Continuous training is essential. I regularly update my knowledge of safety regulations and best practices to stay ahead of potential risks. I also actively participate in safety meetings and training sessions.

For instance, when operating a press brake, I ensure the die is properly aligned and the material is securely clamped before activating the machine. Neglecting any of these steps could result in serious injury.

Q 9. Describe your experience with different sheet metal forming processes (e.g., bending, punching, stamping).

My experience encompasses a wide range of sheet metal forming processes. I’ve worked extensively with:

- Bending: I’m proficient in using press brakes, both manually and with CNC controls, to bend sheet metal to precise angles. I understand the importance of factors such as bend radius, material thickness, and die selection in achieving accurate and consistent bends. I’ve worked with various materials, including mild steel, stainless steel, and aluminum.

- Punching: I have experience operating turret punches and other punching machines to create holes, notches, and other features in sheet metal. Understanding the tooling is crucial here – selecting the right punch and die to avoid damaging the material or the tooling itself is key. I’ve worked with dies of varying complexities, from simple holes to more intricate shapes.

- Stamping: I have experience with progressive stamping dies, particularly in high-volume production. This requires a deep understanding of die design and setup to achieve the desired part geometry and quality. The process involves understanding material flow and optimizing the die to minimize springback.

For example, in one project, I used a CNC press brake to create complex bends in stainless steel for a medical device. Precise control over bend angle and radius was crucial to ensure the device met its functionality requirements.

Q 10. How do you ensure dimensional accuracy in sheet metal fabrication?

Dimensional accuracy is critical in sheet metal fabrication. Achieving it involves a multi-faceted approach starting with the design phase.

- Precise Drawings and Models: I start by carefully reviewing the design drawings and 3D models, ensuring they are complete, accurate, and feasible to manufacture. I often work with CAD software to verify dimensions and tolerances.

- Proper Tooling and Calibration: Using well-maintained and correctly calibrated tools and machinery is essential. Regular calibration checks, including measuring tools and press brake back gauges, are crucial to maintain accuracy.

- Material Selection and Control: The properties of the sheet metal itself affect its final dimensions. Material selection and proper handling are important to minimize distortion.

- Process Control: Monitoring each step of the fabrication process is crucial. For example, during bending, I carefully control factors like bend angle, springback (the tendency of the material to return to its original shape after bending), and material thickness to achieve the desired dimensions. The press brake’s backgauge is vital for repeatability.

- Quality Control Checks: Throughout the process, I use precision measuring instruments, such as calipers and height gauges, to verify dimensions against the specifications. I document all measurements to maintain traceability.

For instance, when fabricating enclosures, even a small deviation from the specified dimensions can lead to assembly problems. By meticulously controlling each step of the process, I ensure the final product meets the required tolerances.

Q 11. Explain your experience with quality control procedures in sheet metal manufacturing.

Quality control is an integral part of my workflow. My experience involves a combination of in-process inspections and final product checks.

- Visual Inspection: I perform visual inspections at each stage of production to detect any defects, such as scratches, dents, or misalignments.

- Dimensional Measurement: I use precision measuring instruments to verify that all dimensions meet the specified tolerances. This is typically done at several points in the process, including after cutting, bending, and any other major operations.

- Material Testing: Where necessary, I utilize material testing techniques to verify the properties of the sheet metal, such as tensile strength and hardness, to ensure they comply with specifications.

- Documentation: I meticulously document all inspection findings, including any defects or deviations from the specifications. This detailed documentation provides a complete history of the product’s quality throughout the manufacturing process.

- Statistical Process Control (SPC): In high-volume production environments, I apply SPC techniques to monitor process variability and identify potential issues before they become major problems. Control charts are a key component of this approach.

For example, in one project involving the fabrication of a large number of identical parts, I implemented a sampling plan for dimensional checks to detect and address any systematic issues early, avoiding a large batch of defective products.

Q 12. How do you troubleshoot common problems encountered during sheet metal fabrication?

Troubleshooting in sheet metal fabrication often involves identifying the root cause of the problem and implementing corrective actions. My approach is systematic:

- Identify the Problem: Clearly define the problem. Is it a dimensional inaccuracy, a surface defect, a tooling issue, or something else?

- Analyze the Process: Examine each step of the fabrication process to identify potential sources of the problem. Review the tooling, the machine settings, the material properties, and the operator’s technique.

- Gather Data: Collect data related to the problem. This might include measurements, visual observations, or machine logs.

- Implement Corrective Actions: Based on the analysis, implement corrective actions. This might involve adjusting machine settings, replacing tooling, modifying the process, or retraining the operator.

- Verify the Solution: After implementing corrective actions, verify that the problem has been solved. This may involve repeating the process and performing quality checks.

For example, if a series of parts shows consistent dimensional inaccuracies in a bend, I’d check the press brake’s backgauge accuracy, the die condition, and the material’s consistency to determine the cause and rectify it. It could be as simple as a miscalibration or as complex as a faulty die needing replacement.

Q 13. Describe your experience with CNC machining of sheet metal.

I have extensive experience with CNC machining of sheet metal, primarily using CNC routers, lasers, and punches. This involves programming and operating CNC machines to cut, form, and punch sheet metal parts with high precision and repeatability.

- Programming: I’m proficient in using CAM software to create CNC programs from CAD models. This involves translating the design into machine-readable instructions, considering factors such as tool selection, cutting speeds, and feed rates to optimize the machining process and prevent tool breakage or material damage.

- Machine Operation: I’m skilled in operating and maintaining various types of CNC machines, including laser cutters, waterjet cutters, and punch presses. This requires understanding machine controls, setting up tooling, and monitoring the machine’s performance during operation.

- Tooling and Setup: I’m experienced in selecting the appropriate tooling for different materials and operations, considering factors such as tool life, cutting efficiency, and surface finish. Proper tool setup and maintenance are critical to prevent errors and ensure accurate part production.

- Quality Control: I incorporate quality control checks at every stage of the CNC machining process to ensure that the parts meet the required tolerances and quality standards.

For instance, I recently used a CNC laser cutter to create intricate designs in thin stainless steel for a decorative panel. The accuracy and speed of the laser were crucial to achieve the desired level of detail.

Q 14. What are the advantages and disadvantages of using different sheet metal joining techniques (e.g., welding, riveting, adhesives)?

Different sheet metal joining techniques offer unique advantages and disadvantages:

- Welding:

- Advantages: Strong, permanent joint; suitable for various materials; automation possible.

- Disadvantages: Can distort the metal; requires specialized skills and equipment; potential for weld defects; heat-affected zone can alter material properties.

- Riveting:

- Advantages: Relatively simple and inexpensive; creates a strong mechanical joint; suitable for various materials; no heat affected zone.

- Disadvantages: Not as strong as welding for many applications; visible fasteners; requires precise hole placement.

- Adhesives:

- Advantages: Clean and aesthetically pleasing; no heat or mechanical stress; can join dissimilar materials.

- Disadvantages: Limited strength compared to welding or riveting; susceptible to environmental factors (temperature, humidity); curing time needed; surface preparation crucial.

The choice of joining technique depends on various factors such as the application requirements (strength, aesthetics, cost), the materials being joined, and the production volume. For example, welding would be preferred for a structural component requiring high strength, while adhesives might be better for a cosmetic application requiring a clean finish.

Q 15. How do you calculate material costs for sheet metal projects?

Calculating material costs for sheet metal projects involves several key steps. First, you need precise dimensions of all the parts. Next, you must account for material waste during cutting and fabrication. This waste factor varies depending on the cutting method (laser, waterjet, shearing) and part complexity. Finally, you factor in the material cost per unit area (e.g., $/sq ft or $/sq m).

Example: Let’s say we need 100 identical parts, each requiring 0.5 sq ft of 1/8” aluminum sheet. The aluminum costs $5/sq ft. If our cutting process generates 20% waste, we’ll need 100 parts * 0.5 sq ft/part * 1.2 (waste factor) = 60 sq ft of aluminum. The total material cost would then be 60 sq ft * $5/sq ft = $300.

Other factors to consider include material type (different grades have different costs), order quantities (bulk orders often get discounts), and any necessary coatings or finishes, which add to the overall cost.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your experience with laser cutting or waterjet cutting of sheet metal.

I have extensive experience with both laser cutting and waterjet cutting of sheet metals. Laser cutting offers high precision and speed for thinner materials, particularly when intricate designs are needed. It’s ideal for creating clean, burr-free cuts. However, thicker materials can require longer processing times and may lead to heat-affected zones.

Waterjet cutting, on the other hand, excels with thicker materials and a wider variety of materials, including those less suited for laser cutting, like stainless steel or titanium. It produces minimal heat-affected zones. The trade-off is that the process is slower than laser cutting and the cut edges might require additional finishing.

In practice, I select the method based on material thickness, design complexity, required edge quality, and cost considerations. For instance, I’d use laser cutting for rapid prototyping of thin aluminum parts with intricate features, while waterjet would be preferred for cutting thick steel plates for a structural component.

Q 17. What is your experience with press brake bending, including die selection and setup?

My experience with press brake bending is comprehensive, covering all aspects from die selection to setup and operation. Die selection is crucial. The correct die must be chosen based on material thickness, bend radius, and the desired bend angle. Improper die selection can result in poor quality bends, damage to the dies, or even damage to the press brake.

The setup process involves accurately positioning the workpiece, selecting the appropriate bending tonnage, and programming the machine. I’m proficient in using various bending methods, such as air bending, bottom bending, and coining, selecting the most appropriate method based on material properties and desired result.

Example: Bending a 1/4” thick aluminum sheet to a 90-degree angle requires a specific die set capable of handling this material thickness and generating the correct bend radius. I would carefully align the workpiece, set the tonnage according to manufacturer specifications, and monitor the bending process to ensure the angle is accurate and consistent across multiple bends. Regular maintenance and calibration of the press brake are also vital aspects of my workflow.

Q 18. Describe your experience with automated sheet metal production lines.

I’ve worked extensively with automated sheet metal production lines, integrating various machines such as laser cutters, press brakes, punch presses, and robotic welding systems. My expertise lies in understanding the programming and control systems of these lines and optimizing their efficiency. This includes designing appropriate tooling, setting up and monitoring the production process, and troubleshooting malfunctions.

Effective management of automated lines requires a solid understanding of production scheduling, quality control procedures, and maintenance strategies. I’ve been involved in improving overall equipment effectiveness (OEE) by identifying and eliminating bottlenecks, reducing downtime, and improving the quality of the output. A practical example involves programming a robotic system to automatically feed, bend, and weld components for a large-scale assembly project. This minimizes human intervention, ensuring consistent output and cost savings.

Q 19. How do you manage inventory and material handling in a sheet metal shop?

Managing inventory and material handling in a sheet metal shop involves a strategic approach combining efficient storage, inventory tracking, and optimized material flow. We employ a combination of first-in, first-out (FIFO) and just-in-time (JIT) inventory management strategies depending on the material and project requirements. FIFO prevents material from expiring or degrading, while JIT minimizes storage costs and reduces waste by ensuring materials arrive only when needed.

We use a computerized inventory management system to track material quantities, locations, and usage, providing real-time visibility into our inventory levels. This helps us predict future demand, plan purchases, and prevent stockouts. Proper material handling includes using appropriate racking systems, forklifts, and cranes to ensure materials are stored safely and accessed easily, minimizing damage and improving efficiency.

Q 20. What is your experience with sheet metal finishing processes (e.g., polishing, painting, powder coating)?

My experience with sheet metal finishing encompasses a range of processes, including polishing, painting, and powder coating. Polishing enhances the surface finish, improving aesthetics and sometimes corrosion resistance. Different polishing techniques exist, from simple hand-polishing to more advanced electropolishing, chosen based on the material and the desired level of finish.

Painting provides protection against corrosion and allows for customization. Powder coating offers superior durability and a wider range of colors and textures compared to liquid paint. Each process requires specific preparation steps, such as cleaning and surface treatment, to ensure proper adhesion and longevity. Quality control throughout the finishing process is crucial to ensure consistent results and meet customer specifications.

Example: For a project requiring a high-gloss finish on stainless steel components, electropolishing is selected followed by a clear coat to enhance the corrosion resistance. For a project requiring high durability and a specific color, powder coating is chosen for its superior protection and diverse color options.

Q 21. Explain your experience with designing for manufacturability in sheet metal.

Designing for manufacturability (DFM) in sheet metal is critical for cost-effectiveness and efficient production. This involves understanding the limitations and capabilities of sheet metal fabrication processes. For example, sharp corners can be challenging to create precisely and might require additional finishing, while radii should be designed to accommodate bending processes without cracking.

Standardization of parts, where feasible, simplifies production and reduces costs. This includes using standard sizes of sheets and minimizing the number of unique parts. Features should be designed to minimize the use of secondary operations, such as welding or manual finishing, wherever possible.

Example: During design, I would avoid overly complex geometries that require intricate tooling or multiple bending operations. Instead, I would explore ways to simplify the design, potentially by using standard bends or utilizing features that can be created efficiently using the available equipment. This approach results in a design that is both aesthetically pleasing and economically viable to manufacture.

Q 22. Describe a challenging sheet metal project you worked on and how you overcame the challenges.

One particularly challenging project involved fabricating a complex chassis for a high-performance racing car. The design incorporated numerous intricate bends, deep draws, and tight tolerances, demanding precision and a deep understanding of sheet metal forming principles. The primary challenge was minimizing distortion during the deep drawing process, as the thin-gauge aluminum alloy was prone to wrinkling and tearing.

To overcome this, we implemented a multi-pronged approach. First, we optimized the design using Finite Element Analysis (FEA) software to predict stress concentrations and potential failure points. This allowed us to make informed design modifications, such as incorporating radii and adding reinforcing features to minimize stress. Second, we carefully selected the appropriate die materials and lubricants for the deep drawing operation, ensuring a smooth and controlled process. Finally, we employed incremental drawing techniques, performing the deep drawing operation in multiple stages with intermediate annealing steps to relieve stresses and prevent cracking. Through this meticulous planning and execution, we successfully produced the chassis components to the required tolerances, demonstrating both resilience and meticulous attention to detail.

Q 23. What software are you proficient in for sheet metal design and manufacturing?

I’m proficient in several software packages crucial for sheet metal design and manufacturing. My expertise includes Autodesk Inventor, SolidWorks, and AutoCAD. I’m also familiar with CAM software such as Mastercam and FeatureCAM, which are vital for generating CNC programs for cutting, bending, and punching sheet metal parts. These programs enable the creation of detailed 3D models, flattened patterns, and precise CNC toolpaths ensuring efficient and accurate production.

Example: In Inventor, I can create a 3D model of a part and automatically unfold it into a 2D flat pattern, accounting for bend allowances and kerf.Q 24. How do you ensure the structural integrity of a sheet metal component?

Ensuring structural integrity in sheet metal components requires a holistic approach encompassing design, material selection, and manufacturing processes. This begins with a thorough understanding of the intended loads and stresses the component will experience.

- Design for Strength: Features like stiffening ribs, gussets, and strategically placed beads can significantly enhance rigidity and prevent buckling. Think of how a corrugated cardboard box is stronger than a flat sheet of the same material.

- Material Selection: The choice of material is paramount. Higher-strength steels, aluminum alloys, or even exotic materials like titanium might be necessary depending on the application and the required strength-to-weight ratio.

- Manufacturing Processes: The forming processes (bending, punching, stamping) themselves can introduce stresses. Carefully controlling these processes and potentially using techniques like stress relieving annealing can mitigate these issues.

- Finite Element Analysis (FEA): FEA is an invaluable tool for simulating the structural behavior of the component under various load conditions, allowing for iterative design improvements and early detection of potential weaknesses.

By combining these elements, I can optimize the design for strength and durability, resulting in a robust and reliable component.

Q 25. What are your preferred methods for creating detailed sheet metal fabrication drawings?

My preferred method for creating detailed sheet metal fabrication drawings relies heavily on CAD software, specifically Autodesk Inventor and SolidWorks. These allow me to generate accurate and comprehensive drawings that include:

- 3D Model: A complete 3D representation of the component is the foundation. This allows for better visualization and error detection during the design phase.

- Flat Pattern: The software automatically generates the unfolded 2D pattern, including bend allowances and other essential information for the fabrication process. This eliminates manual calculations, reducing errors and saving time.

- Detailed Views: Multiple views (top, side, isometric) are included to provide a comprehensive understanding of the part’s geometry.

- Bill of Materials (BOM): The BOM lists all the materials needed, streamlining procurement.

- Dimensions and Tolerances: Critical dimensions and tolerances are clearly specified, ensuring consistent and accurate production.

- Annotations: Clear and concise annotations specify material type, surface finish, and any special instructions for fabrication.

These drawings are then converted into suitable formats (PDF, DWG) for sharing with manufacturers.

Q 26. How do you handle tolerances and specifications in sheet metal work?

Handling tolerances and specifications in sheet metal work is critical for successful manufacturing. I diligently incorporate industry-standard tolerance specifications, usually based on ASME Y14.5 or ISO standards, depending on the project’s requirements. Understanding the implications of different tolerance grades is essential.

Practical Application: For example, a tighter tolerance on a bend radius might necessitate a more precise bending process (e.g., CNC press brake) and possibly a more expensive material. A loose tolerance allows for more flexibility in the manufacturing process but may result in a less precise final product. I carefully balance these factors during the design phase to optimize cost and quality. This involves working closely with manufacturers to ensure their capabilities align with the specified tolerances.

Any deviation from these specifications is documented and reviewed, ensuring quality control throughout the manufacturing process.

Q 27. Describe your understanding of different sheet metal surface finishes and their applications.

My understanding of sheet metal surface finishes encompasses a wide range of options, each tailored to specific applications and aesthetic requirements. The choice of finish impacts not only the appearance but also the durability, corrosion resistance, and functionality of the component.

- Mill Finish: A basic, untreated surface left after the sheet metal forming process. Economical but offers limited corrosion resistance.

- Powder Coating: A durable, attractive, and versatile finish offering good corrosion protection and a wide range of colors and textures.

- Painting: A widely used finish offering good aesthetics and corrosion protection, available in various colors and finishes (gloss, matte).

- Anodizing (for aluminum): An electrochemical process enhancing the aluminum’s corrosion resistance and creating a hard, wear-resistant surface.

- Electroplating: Applying a thin layer of another metal (e.g., chrome, nickel, zinc) to enhance corrosion resistance, appearance, or other properties.

The selection of the appropriate surface finish is often dictated by the application’s demands. For instance, a component exposed to harsh weather conditions would require a finish with excellent corrosion resistance, like powder coating or anodizing, while a component in an interior application may only need a simple paint finish.

Q 28. Explain your experience with managing and interpreting sheet metal production schedules.

My experience with managing and interpreting sheet metal production schedules involves a combination of planning, communication, and problem-solving skills. I start by carefully reviewing the project specifications, material availability, and the manufacturing capabilities.

I then create a detailed production schedule, often using project management software, outlining key milestones, resource allocation, and potential bottlenecks. Regular monitoring of progress is crucial, and I leverage tools such as Gantt charts to visually track progress against the schedule. When issues arise (e.g., material delays, equipment malfunctions), I work collaboratively with the manufacturing team to find solutions, often involving prioritization and rescheduling activities to minimize delays. Clear communication with all stakeholders is essential to ensure everyone is aware of the project’s status and any necessary adjustments to the schedule.

Ultimately, successfully managing a sheet metal production schedule requires proactive planning, efficient communication, and a willingness to adapt to unforeseen circumstances.

Key Topics to Learn for Experience with Sheet Materials Interview

- Material Properties: Understanding the characteristics of various sheet materials (e.g., metals, plastics, composites) including strength, flexibility, density, and thermal properties. This includes knowing how these properties affect material selection for specific applications.

- Manufacturing Processes: Familiarity with common sheet material processing techniques such as cutting, bending, forming, welding, and joining. Be prepared to discuss the advantages and disadvantages of each method and their suitability for different materials.

- Design Considerations: Knowledge of how sheet material thickness, geometry, and support structures impact overall product performance and durability. This includes understanding stress analysis and potential failure points.

- Quality Control & Testing: Experience with inspection methods to ensure quality and adherence to specifications. This could involve dimensional checks, surface finish evaluations, and material testing procedures.

- Safety Procedures: Demonstrating awareness of safety protocols and best practices related to handling and processing sheet materials, including proper use of equipment and personal protective equipment (PPE).

- Problem-Solving & Troubleshooting: Be ready to discuss instances where you’ve identified and resolved issues related to sheet material processing, quality, or design. Highlight your analytical and problem-solving skills.

- Software Proficiency: Depending on the role, you may need to showcase your expertise in CAD software (e.g., AutoCAD, SolidWorks) or other relevant design and simulation tools used in sheet metal work.

Next Steps

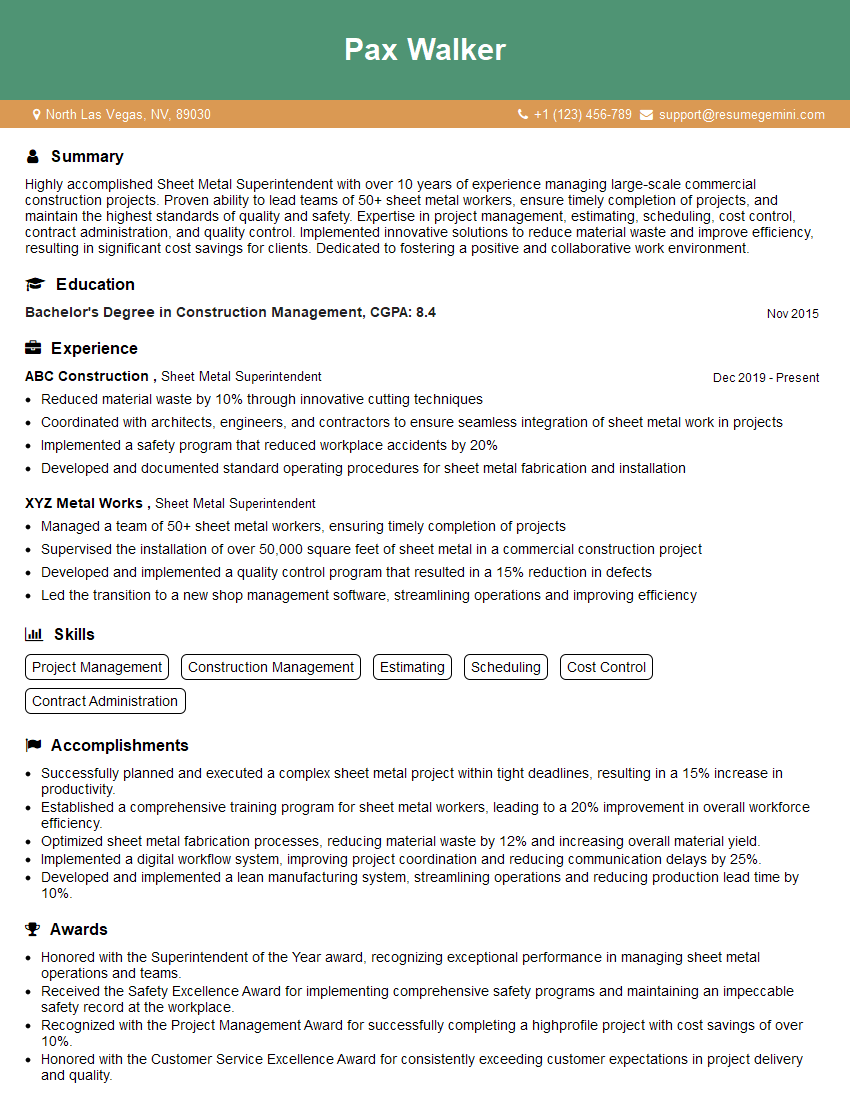

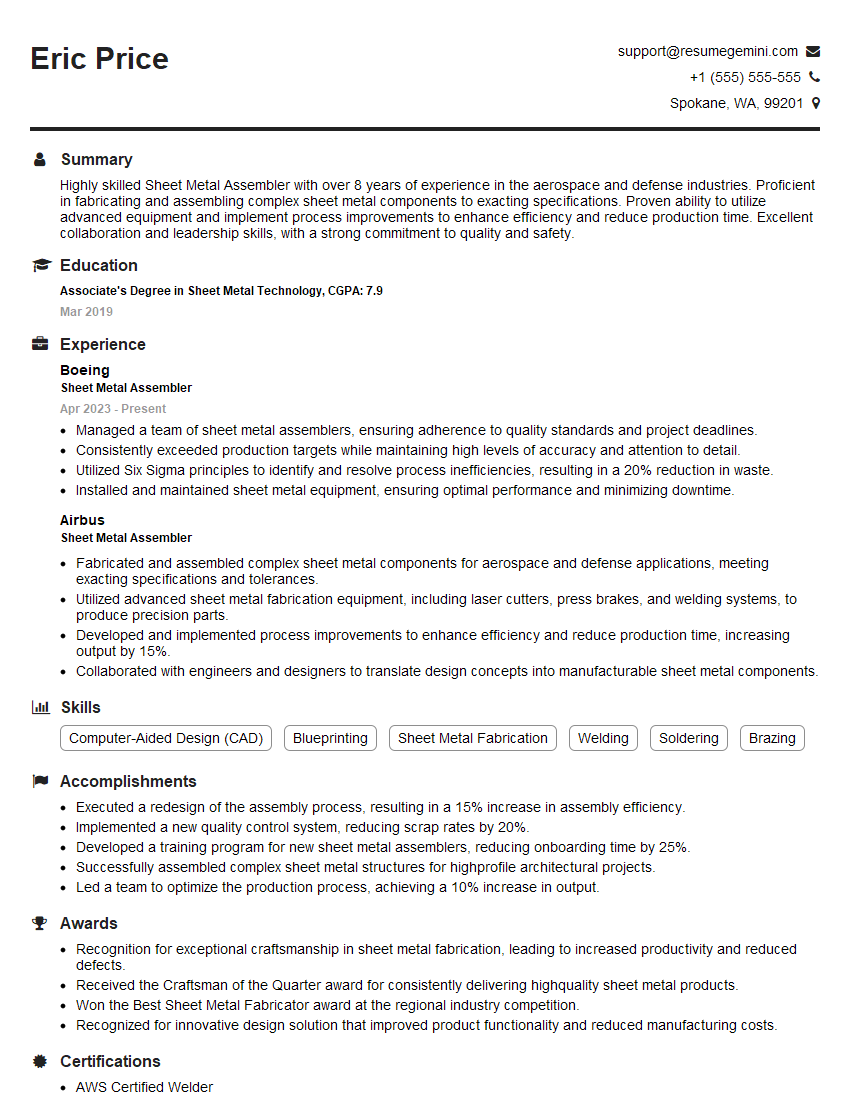

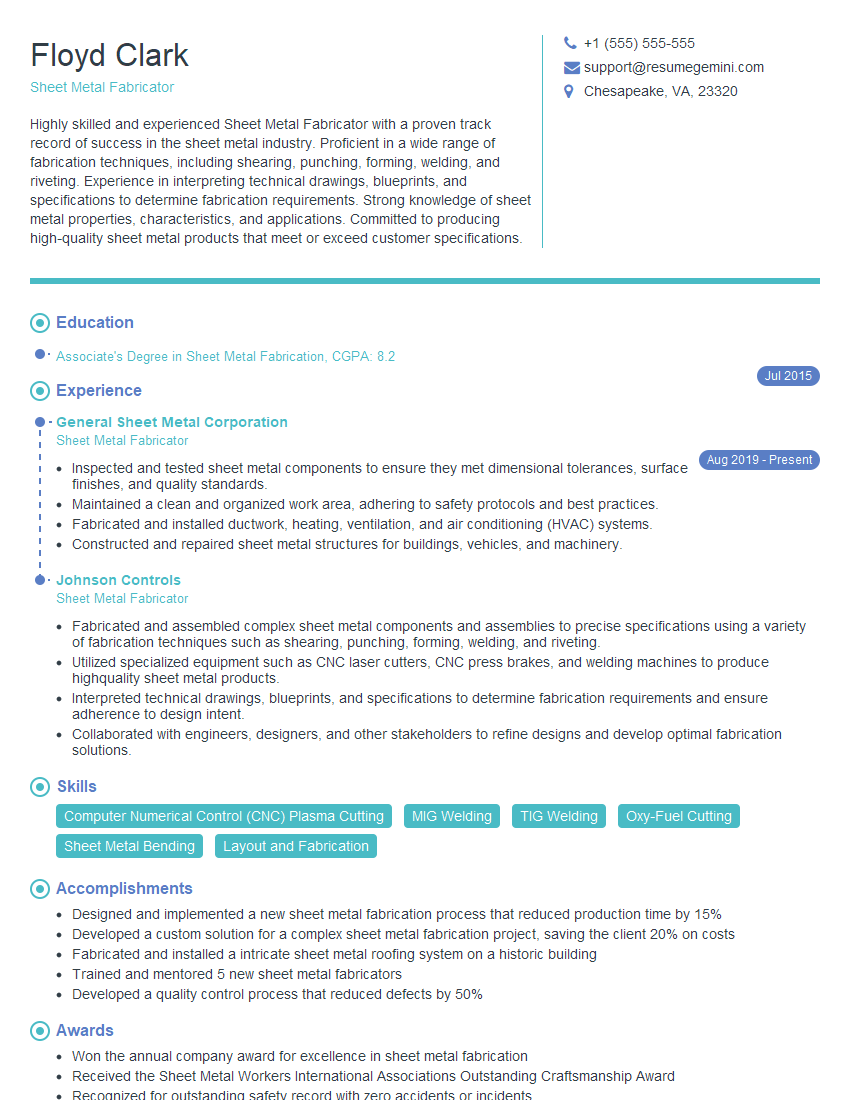

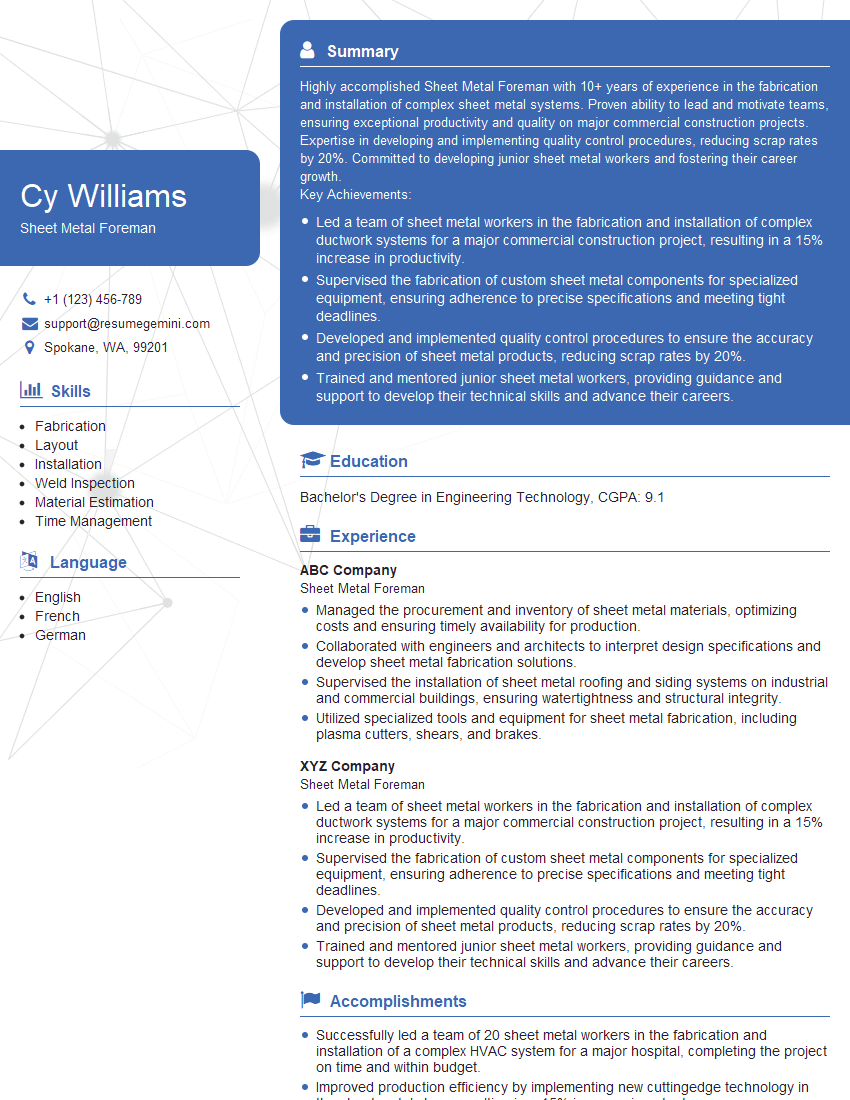

Mastering sheet material expertise opens doors to exciting career opportunities in manufacturing, engineering, and design. A strong understanding of these concepts significantly improves your job prospects. To maximize your chances, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional resume tailored to your specific experience. Examples of resumes tailored to sheet material experience are available to guide you. Invest time in crafting a compelling resume – it’s your first impression and a critical step towards landing your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

support@inboxshield-mini.com

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good