Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top FEA Post-Processing interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in FEA Post-Processing Interview

Q 1. Explain the difference between linear and nonlinear FEA post-processing.

The core difference between linear and nonlinear FEA post-processing lies in the nature of the problem being solved and, consequently, the type of data being analyzed. Linear analysis assumes a proportional relationship between load and response; deformations are small, and material properties remain constant. Nonlinear analysis, however, accounts for large deformations, material nonlinearities (plasticity, hyperelasticity), and contact interactions, leading to a more complex response.

In linear post-processing, we typically examine static results like displacement, stress, and strain using simple visualizations. Interpreting the results is straightforward because the response is directly proportional to the applied load. For instance, doubling the load would double the displacement.

Nonlinear post-processing, on the other hand, involves analyzing results that change with time or load increments. We might look at load-displacement curves to understand the material’s behavior under increasing load, or we could examine the evolution of plastic zones over time. Interpreting these results requires a deeper understanding of material behavior and the nonlinear solver’s convergence history because the response isn’t linear.

Think of it like this: linear analysis is like using a spring scale – the more you pull, the more it stretches, linearly. Nonlinear analysis is more like stretching a rubber band – the more you pull, the less it stretches per unit of force, and it might even break at some point.

Q 2. Describe your experience with various visualization techniques in FEA post-processing (e.g., contour plots, deformed shapes, animations).

My experience encompasses a wide range of visualization techniques crucial for effective FEA post-processing. I’m proficient in using contour plots to represent the spatial distribution of various quantities like stress, strain, and temperature. For instance, a contour plot of von Mises stress helps identify regions prone to yielding. I routinely utilize deformed shape plots to visually assess the overall deformation pattern of the structure, especially valuable for understanding large displacements.

Beyond static visualizations, I extensively use animations to illustrate the dynamic behavior of structures under transient loads or dynamic events. This can be immensely insightful, showing how stress waves propagate through a component or how a structure responds to impact. I frequently combine these visualization techniques – for example, overlaying contour plots of stress onto a deformed shape animation, to gain a comprehensive understanding of the structural behavior.

I also leverage vector plots to visualize quantities like flow fields or displacement vectors, particularly useful for fluid-structure interaction problems. Furthermore, I’m skilled in creating XY plots to track critical parameters like load versus displacement or stress versus strain, providing quantitative data for deeper analysis.

In my previous role, I used these techniques to analyze the stress distribution in a turbine blade under cyclic loading. The animation clearly showcased the fatigue hotspots and the propagation of cracks, information essential for designing a more robust component.

Q 3. How do you identify and interpret critical areas in FEA results?

Identifying critical areas in FEA results is a crucial step in design optimization and validation. My approach involves a combination of visual inspection and quantitative analysis. I start by visually examining contour plots of key parameters like stress (von Mises, principal stresses), strain, and displacement, focusing on areas with high values or unusual gradients.

Following visual inspection, I perform quantitative analysis by sorting the results to pinpoint elements or nodes with the maximum values. This process identifies potential failure points, areas with high stress concentrations, or regions exceeding design limits. I then use element-wise stress values to find areas experiencing high stress concentrations; these zones often necessitate more attention to mesh refinement or design adjustments. Additionally, I examine the deformed shape to find any excessive deflections that may indicate areas of weakness.

For example, in analyzing a pressure vessel, I would look for high hoop stress near welds or at locations with abrupt changes in geometry. Any areas exceeding the material’s yield strength are immediately flagged as critical.

I always cross-reference these findings with engineering judgment. For example, a high stress concentration at a sharp corner may be expected and not necessarily indicate failure, whereas high stress in a supposedly low-stress region warrants further investigation.

Q 4. What are common errors encountered during FEA post-processing, and how do you address them?

Common errors in FEA post-processing can lead to misleading or inaccurate conclusions. One frequent error is misinterpreting the results without understanding the underlying assumptions and limitations of the FEA model. For instance, overlooking boundary conditions, material properties, or mesh quality can lead to erroneous interpretations.

Another common mistake is neglecting to check the convergence of the solution. A poorly converged solution can yield inaccurate results and lead to incorrect conclusions. I rigorously check convergence plots and assess the solver’s performance to ensure reliable results.

Incorrect scaling or units are also frequently encountered. It is essential to validate the units used in both the pre-processing and post-processing stages to prevent discrepancies and misinterpretations of stress, strain, or displacement values. I always verify units carefully throughout the analysis.

Mesh dependency is a critical concern. If the mesh is too coarse, the results may not accurately capture the details of the stress distribution. I address this by performing mesh refinement studies and comparing the results to check for convergence and independence of the solution from the mesh density. Improper selection of output requests can result in missing critical data. To prevent this, I carefully plan the output quantities required beforehand.

To avoid these issues, I follow a systematic approach that includes thorough validation of input data, convergence checks, unit verification, mesh refinement studies, and careful review of results in the context of the engineering problem.

Q 5. Explain your experience with different FEA software packages (e.g., ANSYS, ABAQUS, Nastran).

My experience spans several leading FEA software packages, including ANSYS, ABAQUS, and Nastran. I’m proficient in utilizing the post-processing capabilities of each, leveraging their specific strengths to suit the needs of the project. For example, ANSYS excels in its user-friendly interface and comprehensive visualization tools, making it ideal for complex simulations requiring detailed analysis.

ABAQUS offers powerful capabilities for nonlinear analysis, including advanced material models and contact algorithms. I’ve utilized ABAQUS extensively for solving challenging problems involving plasticity, large deformations, and contact interactions. Its robust scripting capabilities facilitate automation and customization of post-processing workflows.

Nastran, known for its strength in linear analysis, particularly in aerospace applications, provides powerful tools for modal analysis and frequency response analysis. I’ve utilized its capabilities for detailed stress and vibration analysis of structural components.

Regardless of the software, I consistently follow best practices for model creation, solver settings, and result interpretation. My approach is tailored to the specific software but guided by the fundamental principles of FEA.

Q 6. How do you validate FEA results?

Validating FEA results is crucial for ensuring their accuracy and reliability. My validation strategy involves a multi-pronged approach. Firstly, I compare the FEA results with experimental data, if available. This might involve comparing FEA-predicted displacements to measured displacements from a physical test. Discrepancies need careful examination and may necessitate model refinements.

Secondly, I perform sensitivity studies to assess the influence of input parameters on the results. This helps understand the uncertainties associated with the model and assesses how robust the results are to changes in material properties, geometry, or boundary conditions. For example, I may vary the material’s Young’s modulus by a small amount and examine the impact on stress.

Thirdly, I utilize independent verification methods. This could involve comparing results obtained using different FEA solvers or different mesh densities. Consistency between these independent approaches boosts confidence in the accuracy of the results.

Lastly, I employ engineering judgment and physical intuition to assess the reasonableness of the results. Unrealistic or unexpected results warrant a thorough review of the entire FEA process, starting from model creation to post-processing. In one project, comparing FEA predictions to physical strain gauge measurements helped identify a minor error in the material model that was significantly impacting the results.

Q 7. Describe your experience with mesh refinement techniques and their impact on post-processing.

Mesh refinement techniques significantly impact post-processing by improving the accuracy and resolution of the results. A coarse mesh may smooth out stress concentrations or other localized effects, leading to inaccurate predictions of peak stresses or displacements. Refining the mesh, particularly in regions with high stress gradients or geometric complexities, provides a more detailed representation of the actual stress field.

I employ several refinement strategies, including h-refinement (reducing element size), p-refinement (increasing polynomial order of elements), and r-refinement (relocating nodes). The choice of technique depends on the specific needs of the analysis and the software’s capabilities. I often use adaptive mesh refinement, where the software automatically refines the mesh in areas of high stress to optimally improve accuracy.

The impact on post-processing is substantial. A refined mesh enables a more precise identification of critical areas, allowing for a more accurate assessment of stress concentrations and other localized effects. It also allows for more detailed visualization of the results. Comparing results from different mesh densities helps assess mesh independence and ensure convergence, a cornerstone of reliable FEA. In a prior project involving a complex casting, adaptive mesh refinement significantly improved the prediction of stress concentrations near the casting’s gate, leading to a more robust design.

Q 8. How do you handle large datasets in FEA post-processing?

Handling large datasets in FEA post-processing requires a multi-pronged approach focusing on efficient data management, visualization techniques, and computational optimization. Imagine trying to analyze a skyscraper’s structural integrity – the sheer amount of data generated is enormous.

- Data Reduction Techniques: Instead of processing every single element’s data, we employ techniques like averaging, smoothing, and sub-sampling. For example, instead of visualizing stress on every single node, we might average stress over a region or along a specific path. This significantly reduces processing time without sacrificing crucial information.

- High-Performance Computing (HPC): For exceptionally large datasets, distributing the workload across multiple processors using HPC clusters is vital. This parallel processing greatly accelerates post-processing, handling complex analyses in a reasonable timeframe.

- Appropriate Software Selection: Choosing post-processing software optimized for handling large datasets is paramount. Some FEA packages incorporate advanced data management tools and parallel processing capabilities that streamline the process. It is similar to selecting a high-capacity storage drive for a large video collection.

- Database Management Systems (DBMS): Integrating a DBMS allows for effective organization and querying of the vast amount of data. We can then extract specific data subsets for analysis, drastically reducing the data load for each visualization or calculation. This approach allows for much more flexible data access than searching through files.

The selection of technique is often project-specific, depending on dataset size, available resources, and the desired level of detail in the analysis. A combination of these methods is frequently the optimal solution.

Q 9. Explain your understanding of convergence in FEA and its relation to post-processing.

Convergence in FEA refers to the process where the solution stabilizes as the mesh is refined or the number of iterations increases. Think of it as zooming in on a map – initially, the view is coarse; as you zoom in, the details become clearer. Similarly, in FEA, the solution gets closer to the true value as the mesh is refined or more iterations are performed.

Convergence is crucial because it indicates the accuracy and reliability of the FEA results. A non-converged solution is unreliable and should not be used for post-processing. In post-processing, the convergence behavior itself needs to be considered, examining the plots of convergence to ensure a solution of sufficient accuracy was reached before proceeding.

The connection between convergence and post-processing is direct: We only proceed with post-processing once we are confident that the FEA solver has reached a converged solution. If convergence isn’t achieved, the post-processed results, regardless of how sophisticated the analysis techniques are, will be invalid and potentially misleading.

Q 10. Describe your experience with different types of boundary conditions and their influence on post-processing results.

Boundary conditions significantly influence FEA results and consequently, the post-processing interpretations. Think about analyzing a bridge; the supports at either end strongly affect how the bridge deforms under load.

- Fixed Support: This condition restricts all degrees of freedom at a specific point or surface, preventing any movement. In post-processing, we see zero displacement at these points, and stress concentrations may develop nearby.

- Pinned Support: This allows rotation but restricts displacement in certain directions. Post-processing will show zero displacement in the restricted directions, but rotations are possible and could lead to specific stress distribution.

- Roller Support: This allows displacement in one direction but restricts movement in others. This type of support often leads to bending moments in the structure, which should be carefully examined in post-processing.

- Pressure Loads: Applied pressure on surfaces introduces forces, affecting stresses and displacements. Post-processing needs to visualize pressure distribution along with other results to understand its effects.

- Temperature Loads: Thermal gradients induce stresses and deformations that must be considered in post-processing. Thermal stress analysis is particularly important for components exposed to temperature changes.

Proper identification and application of boundary conditions during the pre-processing phase are vital for obtaining accurate and meaningful results. Misapplication or incorrect definition of boundary conditions can lead to completely inaccurate and misleading post-processed data.

Q 11. How do you present FEA results to non-technical stakeholders?

Presenting FEA results to non-technical stakeholders necessitates translating complex numerical data into easily understandable visuals and concise narratives. Instead of showing stress tensors, we use clear, informative illustrations.

- Visualizations: Use contour plots, deformed shapes, and animations to showcase key results. For example, a color-coded stress contour plot clearly shows stress distribution, even without detailed numerical data. Animations are also very helpful to visualize movement, like a bridge flexing under a load.

- Simplified Reports: Focus on key findings and avoid technical jargon. Use clear and concise language. Instead of “principal stress,” explain that this corresponds to the highest tension experienced by the material.

- Analogies and Comparisons: Use relatable analogies to explain complex concepts. For instance, comparing stress to pressure in a water pipe helps visualize the concept.

- Summary Tables: Summarize key results in tables, emphasizing the most important values – the maximum stress, displacement, or safety factor. This provides at-a-glance information about structural integrity.

- Interactive Dashboards: Leverage interactive dashboards to allow stakeholders to explore the data at their own pace, choosing relevant results based on their interests.

The key is to effectively communicate the findings’ implications without overwhelming the audience with technical detail. The focus should be on the conclusions that are relevant to the decision-making process.

Q 12. How do you determine the appropriate level of detail for your FEA post-processing reports?

Determining the appropriate level of detail for FEA post-processing reports hinges on the project’s objectives, intended audience, and available resources. It’s about finding the right balance between comprehensiveness and conciseness. Imagine writing a report on a car crash analysis – are you presenting it to a court or to a design engineer?

For internal design reviews, detailed reports including stress tensors, strain distributions, and nodal displacements are appropriate. However, for presentations to management, a summary highlighting critical areas of concern might suffice. The level of detail is inversely proportional to the audience’s technical expertise. Non-technical stakeholders need a summary report highlighting overall integrity; engineers need in-depth data. We create different reports for different targets.

We also must consider the time and resources. In-depth analyses are time-consuming. A balance is required, selecting results that are relevant and impactful within given constraints.

Q 13. Explain your experience with automated post-processing techniques.

Automated post-processing techniques significantly improve efficiency and consistency in analyzing FEA results. They streamline repetitive tasks, freeing engineers to focus on interpretation and design improvements. These are particularly useful when performing parametric studies. Instead of reviewing each data set individually, we automate the process.

- Scripting Languages: Python and MATLAB are frequently used to automate tasks such as data extraction, report generation, and visualization. A script can automatically read results files, calculate key metrics (e.g., maximum stress, safety factor), and generate reports.

- Custom Macros and Add-ins: Many FEA packages allow creating custom macros or add-ins to automate specific post-processing workflows. This is efficient for repetitive tasks within a particular software.

- Data Processing Pipelines: Utilizing data processing frameworks like Pandas (Python) allows for efficient data manipulation and analysis. This is extremely useful when working with larger data sets and multiple simulations.

- Automated Report Generation: Templates and automation features can produce reports that include summary tables, key results, and pre-set visualizations. This maintains consistency in reporting across multiple projects and analyses.

Automation streamlines analysis and reduces the chance of human error, leading to more efficient and reliable results. Using automation for routine tasks frees time for higher-level engineering tasks.

Q 14. How do you handle discrepancies between FEA results and experimental data?

Discrepancies between FEA results and experimental data require careful investigation. Several factors can cause these differences, and identifying the root cause is key to improving the accuracy of future simulations. It’s like comparing a weather forecast to reality; there will be minor differences, but significant discrepancies require attention.

- Model Idealization: Simplifications made in the FEA model (e.g., material properties, boundary conditions, geometry) can lead to discrepancies. Re-evaluating these assumptions is crucial. Perhaps simplifying a complex geometry led to an inaccurate representation.

- Mesh Refinement: An insufficiently refined mesh can affect accuracy. Refining the mesh, particularly in regions of high stress concentration, often improves the correlation. This is like zooming in on a map to get more accurate details.

- Material Properties: Inaccuracies in material properties used in the FEA model can significantly impact results. Experimental characterization of material properties is crucial to refine the model. Using accurate material data is very important.

- Experimental Error: Experimental data itself can contain errors due to measurement limitations or variations in the testing environment. We need to evaluate the quality and accuracy of the experimental data itself.

- Boundary Condition Differences: Discrepancies between the actual boundary conditions in the experiment and the model can lead to differences. Carefully reviewing and refining the boundary conditions is essential.

A systematic investigation is needed, carefully evaluating each potential source of error, and iteratively improving the FEA model to achieve better agreement with experimental data. Addressing these issues leads to improved FEA models and predictions.

Q 15. Describe your experience with different types of FEA elements and their suitability for specific applications.

Finite Element Analysis (FEA) uses various element types, each suited to specific applications. Choosing the right element is crucial for accuracy and efficiency. For instance, simple elements like linear 2D triangles (CST) or 3D tetrahedra are computationally inexpensive but can be less accurate for complex geometries or stress gradients. Higher-order elements, such as quadratic elements (e.g., quadratic triangles or tetrahedra), offer better accuracy but require more computational resources. Shell elements are ideal for thin structures like plates and shells, capturing bending behavior efficiently. Beam elements are best for slender structural components like beams and columns, simplifying the analysis. Solid elements are versatile and can model complex geometries, often used for 3D stress analysis. The choice depends on the geometry, material properties, and desired accuracy.

- Linear elements (CST, Tetrahedra): Suitable for preliminary analyses or large models where computational cost is a priority. Think of a basic stress analysis of a large, simple part.

- Quadratic elements: Ideal for capturing stress concentrations accurately, especially around holes or sharp corners. Imagine a detailed analysis of a component with a complex geometry.

- Shell elements: Used extensively in automotive and aerospace applications for analyzing thin-walled parts like car bodies or aircraft fuselages. Analyzing the stress and deformation of a car door would be a good example.

- Beam elements: Efficient for analyzing structures such as bridges or building frames, where bending and shear effects dominate. Analyzing the deflection of a simply supported beam is a classic example.

- Solid elements: Used for modeling complex 3D structures, offering great versatility. Think of stress analysis of a turbine blade or a complex engine component.

Career Expert Tips:

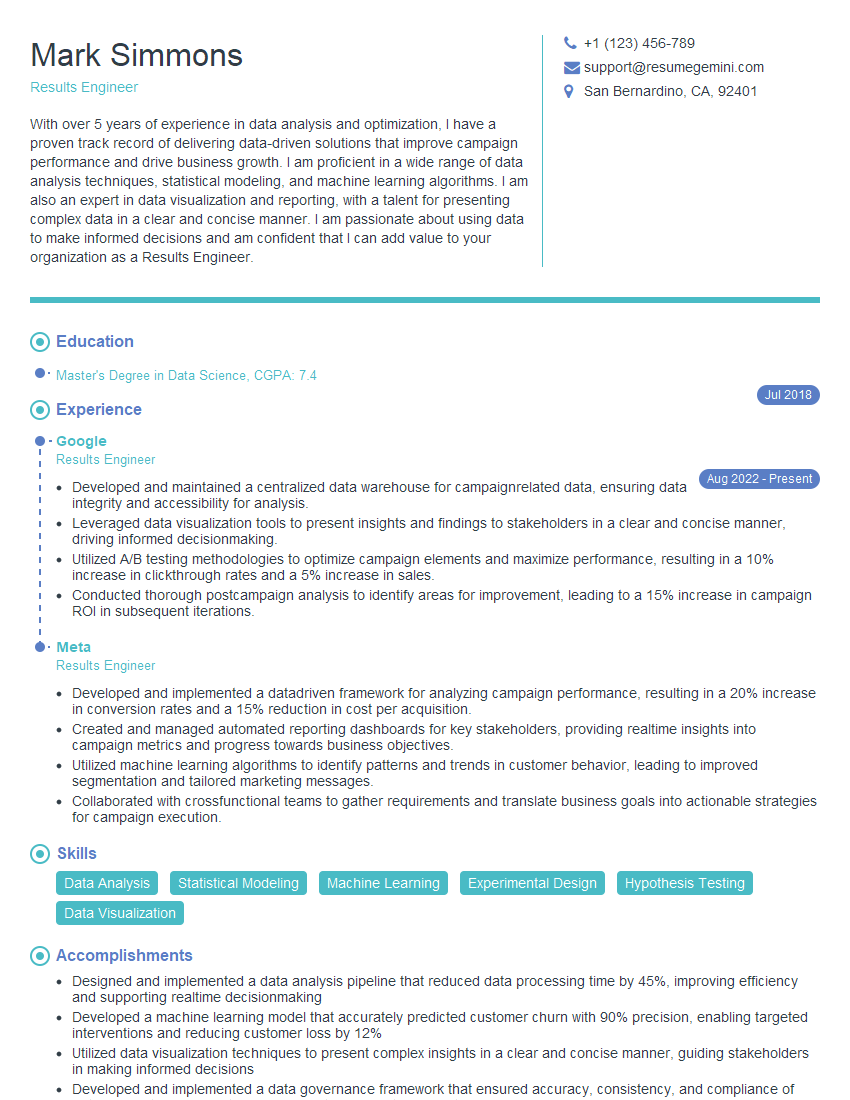

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your understanding of stress concentration and how it is shown in FEA post-processing.

Stress concentration occurs when stress levels significantly increase locally, often due to geometric discontinuities like holes, notches, or sharp corners. In FEA post-processing, these high-stress regions are identified through visualization tools. We typically look at the von Mises stress, a scalar measure combining all stress components. High stress concentrations are shown as regions of intense color on contour plots or as peaks on deformed shape plots. The location and magnitude of these peaks indicate potential failure points. For example, a small hole in a plate under tension will create a significant stress concentration around the hole, which is visually apparent in the post-processing results.

Identifying stress concentrations is crucial to prevent failures. Post-processing lets you zoom into these areas for a deeper look, offering quantitative data (stress values) at specific points. Then we compare them to the material’s yield strength or fatigue limits to assess the safety factor.

Q 17. How do you use FEA post-processing to identify design flaws?

FEA post-processing is invaluable for identifying design flaws. By carefully examining stress, displacement, and strain results, potential weaknesses are highlighted. For instance, excessive deformation in a specific area suggests a part might be too flexible. High stress concentrations, as mentioned before, indicate points prone to failure. Areas with unexpected high strain might signal material yield or plastic deformation. Another common flaw is improper load transfer between components, often visible as stress concentrations at interfaces.

I’ve personally used FEA to identify flaws in a pressure vessel design, where stress concentration at weld points were significantly higher than anticipated, necessitating design modifications for improved safety and robustness. A step-by-step approach involves visualizing results, quantifying stress, strain, and displacement, and finally comparing these quantities to allowable limits.

Q 18. Explain the process of creating effective visualizations of FEA results.

Creating effective visualizations is key to interpreting FEA results. I typically start with contour plots to show the distribution of stress, strain, or displacement across the model. Deformed shape plots visually demonstrate how the structure deforms under load. These are often overlaid on the undeformed shape for easy comparison. For detailed analysis, I use animation capabilities to see how the stress changes over time during a dynamic simulation. Moreover, I often create vector plots of forces or displacements to understand flow or movement patterns.

Choosing appropriate color scales is critical; a poor color scale can obscure important details. Clear annotations and legends are essential to improve clarity. Finally, generating multiple visualizations focusing on different aspects of the model adds to the comprehensiveness of the analysis. For example, a side-by-side comparison of stress contours and deformed shape, or animations showing dynamic stress distribution under changing loads.

Q 19. How do you ensure the accuracy of FEA post-processing results?

Ensuring accuracy is paramount. This begins with the FEA model itself – proper mesh generation, appropriate element type selection, and accurate material properties are crucial. Mesh refinement in critical areas, such as stress concentrations, improves accuracy. After the simulation, I verify results by comparing them to analytical solutions (if available) or experimental data. Checking for convergence is important; the solution should stabilize as the mesh refines. Additionally, I always review the solution for any unusual or unexpected patterns that might point to modeling errors. Understanding potential sources of error, such as boundary condition inaccuracies or limitations in the element formulations, is essential for a robust assessment of accuracy.

Q 20. Describe your experience with fatigue analysis and its post-processing.

Fatigue analysis predicts a component’s lifespan under cyclic loading. Post-processing focuses on identifying locations susceptible to fatigue failure. Software packages typically calculate parameters like stress range, mean stress, and fatigue life based on stress history data from the FEA simulation. Visualization techniques include contour plots of fatigue life, allowing for quick identification of critical areas. These plots often use a color scale to show the predicted lifespan at each point on the component.

In my experience, a detailed fatigue analysis requires defining the loading spectrum and selecting an appropriate fatigue life prediction method (e.g., S-N curves, Miner’s rule). Post-processing involves extracting stress cycles from the simulation results and applying the chosen method to estimate the fatigue life at various locations. Visualization of the fatigue life distribution allows for informed design decisions and identification of potential weak points.

Q 21. Explain your experience with modal analysis and its post-processing.

Modal analysis determines the natural frequencies and mode shapes of a structure. Post-processing focuses on interpreting the resulting mode shapes, which represent the structure’s deformation at each natural frequency. Visualization typically involves animated mode shapes, showing the structure’s vibrational patterns at each frequency. These animations allow us to identify areas of high displacement or stress associated with each mode.

In practical applications, this helps avoid resonance issues. For instance, in the design of a bridge, post-processing helps determine if any natural frequencies coincide with expected environmental excitation (wind, traffic) – a vital step to ensure structural integrity. The output will clearly identify the natural frequencies, mode shapes, and the corresponding participation factors, which helps us understand which modes are most likely to be excited under operational conditions.

Q 22. How do you interpret the results of a buckling analysis?

Interpreting buckling analysis results involves understanding the critical load, buckling mode shapes, and factors of safety. The critical load represents the lowest load at which the structure will buckle, transitioning from stable to unstable equilibrium. Buckling mode shapes visualize the deformation pattern at this critical load, indicating the areas of highest stress concentration and potential failure. The factor of safety compares the critical load to the expected applied load, showing how much margin exists before buckling occurs. A factor of safety less than one indicates a potential buckling failure.

For example, imagine analyzing a slender column. The buckling analysis might reveal a critical load of 10 kN and a mode shape showing a sideways bending. If the expected load is only 5 kN, the factor of safety is 2, indicating a safe design. However, if the expected load is 15 kN, the factor of safety is less than 1, highlighting a high risk of buckling and needing design modification, such as increasing the column’s cross-sectional area or shortening its length. Post-processing tools visualize both the critical load and the mode shapes, which are essential in understanding the failure mechanism and improving the design.

Q 23. Describe your experience with thermal analysis and its post-processing.

My experience with thermal analysis and its post-processing is extensive. I’ve worked on various projects, from analyzing the temperature distribution in electronic components to simulating the heat transfer in building structures. In thermal analysis, post-processing focuses on visualizing temperature fields, heat fluxes, and thermal stresses. I regularly utilize contour plots to display temperature gradients, helping pinpoint hotspots and potential thermal failure points. I also use vector plots to visualize heat fluxes, showing the direction and magnitude of heat flow. Furthermore, I extract data on maximum temperatures, temperature gradients, and thermal stresses to assess the integrity of the design.

For instance, in analyzing a microchip, I would utilize post-processing to identify areas of excessive temperature rise. By examining temperature contours, I could identify potential hot spots leading to device failure. The analysis might reveal a peak temperature exceeding the chip’s operating limit. Based on this, I could recommend design changes such as adding heat sinks or optimizing the thermal path.

Q 24. How do you identify and address issues related to mesh dependency in FEA results?

Mesh dependency in FEA refers to the situation where the results change significantly depending on the mesh density. This is an indicator of potential inaccuracies in the solution. To address this, I use a mesh refinement strategy. I start with a relatively coarse mesh, and then progressively refine the mesh in areas of interest, such as high stress gradients or areas of geometric complexity. By comparing results from different mesh densities, I can assess the convergence of the solution. If the results don’t change significantly with further refinement, it suggests that the mesh is sufficiently fine and the solution is mesh-independent.

Think of it like drawing a circle: a coarse mesh might give you a rough polygon, while a finer mesh gets closer to a true circle. If the area calculated doesn’t change much after several refinement steps, you’ve likely achieved a mesh-independent solution. If the differences are significant, further mesh refinement is necessary. Tools such as mesh convergence studies allow for a systematic approach to this process.

Q 25. Explain your experience with using scripting languages (e.g., Python, APDL) for FEA post-processing automation.

I’m proficient in using both Python and APDL for automating FEA post-processing. Python offers flexibility and vast libraries for data manipulation and visualization. I’ve used it to create scripts that automatically extract data from FEA results files, generate custom plots and reports, and compare results from multiple simulations. APDL, the ANSYS Parametric Design Language, allows for direct interaction with the ANSYS environment, enabling automation of complex post-processing tasks within the software itself.

For example, a Python script can extract nodal displacements and stresses from an output file, calculate principal stresses, and generate a 3D plot of the von Mises stress distribution. Similarly, an APDL macro can automate the process of generating contour plots, creating animations of deformation, and performing data analysis directly within the ANSYS interface, streamlining the analysis workflow.

#Example Python snippet (Illustrative):

import matplotlib.pyplot as plt

# ... load data from FEA result file ...

plt.contourf(x, y, stress)

plt.colorbar()

plt.show()Q 26. How do you perform data extraction from FEA results for further analysis?

Data extraction from FEA results is crucial for further analysis and reporting. The methods depend on the FEA software and the desired data. Most FEA software provides tools for exporting results to various formats such as text files (.txt, .csv), spreadsheet formats (.xlsx), or even directly into scripting languages. I commonly use these built-in tools to export nodal data (displacements, stresses, temperatures), element data (stress tensors, strain tensors), and reaction forces.

For instance, to extract the maximum stress in a specific region of a component, I would first define that region in the FEA software and then export the stress data only for the elements within that region. This exported data can then be easily imported into spreadsheet software or scripting languages for further analysis or charting. Proper data filtering and selection is essential to avoid working with unnecessary data.

Q 27. Describe your experience with using custom post-processing scripts or macros.

I have significant experience developing custom post-processing scripts and macros to streamline workflows and extend the capabilities of commercial FEA software. This is particularly useful when dealing with repetitive tasks or when standard post-processing tools are insufficient. For example, I’ve written macros to automatically generate customized reports including images, tables, and calculations based on FEA results. I’ve also developed scripts to process large datasets, automating tasks like filtering data, identifying critical regions, and performing statistical analysis.

One example involves creating a macro that automates the generation of fatigue life predictions based on stress results from a FEA simulation. This macro would take the stress data as input, apply a suitable fatigue model, and output a fatigue life contour plot, significantly reducing the manual effort and time needed for such analysis.

Q 28. How do you ensure the quality of your FEA post-processing work?

Ensuring the quality of my FEA post-processing involves a multi-step approach. Firstly, I always verify the accuracy of the data by comparing it to known values or theoretical predictions whenever possible. Secondly, I perform thorough checks for inconsistencies or anomalies in the results, which might point to errors in the model or the analysis. Thirdly, I use multiple visualization techniques to examine the results from different perspectives. For instance, I might use contour plots, vector plots, and deformed shape plots to gain a complete understanding of the results.

Furthermore, I document my entire post-processing workflow, including the steps taken, the tools used, and any assumptions made. This detailed documentation facilitates future review, comparison, and troubleshooting. Finally, I always seek peer review or independent verification of my results, especially for critical applications. This rigorous approach ensures the reliability and accuracy of my work, contributing to informed decision-making in engineering design and analysis.

Key Topics to Learn for FEA Post-Processing Interview

- Understanding Results: Interpreting stress, strain, displacement, and other relevant results from FEA software. This includes understanding the limitations and potential inaccuracies of the simulation.

- Data Visualization: Mastering techniques for effectively visualizing FEA results, including contour plots, vector plots, and animations. Knowing when to use each visualization method to best communicate findings.

- Result Validation: Critically evaluating FEA results by comparing them to theoretical predictions, experimental data, or engineering standards. Understanding sources of error and how to mitigate them.

- Meshing Considerations: Understanding how mesh quality impacts the accuracy of post-processing results. Knowing how to identify and troubleshoot mesh-related issues.

- Advanced Post-Processing Techniques: Familiarity with advanced techniques such as fatigue analysis, fracture mechanics, and optimization studies, depending on the specific role.

- Practical Application: Being able to explain how you’ve applied FEA post-processing to solve real-world engineering problems. Focus on the process, your approach, and the outcomes.

- Software Proficiency: Demonstrating a strong understanding of at least one FEA post-processing software package (e.g., Abaqus, ANSYS, Nastran). Highlight your expertise in specific features and functionalities.

Next Steps

Mastering FEA post-processing significantly enhances your value to any engineering team, opening doors to more challenging and rewarding roles. To maximize your job prospects, crafting a compelling and ATS-friendly resume is crucial. ResumeGemini can help you build a professional resume that highlights your FEA expertise and catches the eye of recruiters. We offer examples of resumes tailored to FEA Post-Processing roles to help you get started. Invest the time to create a strong resume – it’s your first impression!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good