Cracking a skill-specific interview, like one for ForkliftOperation, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in ForkliftOperation Interview

Q 1. What types of forklifts have you operated?

Throughout my career, I’ve operated a variety of forklift types, each suited to different tasks and environments. This includes:

- Counterbalance forklifts: These are the most common type, ideal for general warehouse work and outdoor applications. I’m proficient in both gas-powered and electric models, understanding the nuances of each – from fuel efficiency to battery charging cycles.

- Reach trucks: I have extensive experience operating reach trucks, crucial for accessing high-level racking in narrow aisles. The precision required for this type of forklift demands careful maneuvering and a keen awareness of surroundings.

- Sit-down rider forklifts: These offer greater stability and control for heavier loads. My experience encompasses handling a wide range of weights with these machines, prioritizing safety through appropriate speed and load distribution.

- Order picker forklifts: Efficient for picking orders from high shelves, I’m adept at using order pickers to maximize throughput without compromising safety. This often involves operating within complex shelving systems.

My experience spans various load capacities and operating conditions, giving me a comprehensive understanding of different forklift functionalities.

Q 2. Describe your experience with pre-operational inspections.

Pre-operational inspections are paramount for safe forklift operation. I meticulously follow a checklist, ensuring every component is functioning correctly. This includes:

- Visual Inspection: Checking for any visible damage to the forks, tires, mast, and body. I look for cracks, leaks, or any signs of wear and tear.

- Fluid Levels: Verifying the levels of hydraulic fluid, engine oil (if applicable), and coolant, ensuring they are within the acceptable ranges. Low fluid levels can lead to malfunctions.

- Tire Condition: Examining the tires for proper inflation and wear. Under-inflated or worn tires compromise stability and maneuverability.

- Lights and Horn: Testing the functionality of all lights, horns, and safety features to guarantee clear communication and visibility.

- Brakes and Steering: Testing the responsiveness of brakes and steering mechanisms to ensure they are effective and safe. A malfunctioning brake system is a serious safety hazard.

- Operational Test: A brief operational test to check the functionality of the lift mechanism, hydraulics, and overall performance, ensuring there are no unusual sounds or vibrations.

Documenting the inspection is crucial. I consistently record findings, reporting any issues immediately to the supervisor to prevent potential accidents. Think of it like a pre-flight check for an airplane – essential for a safe operation.

Q 3. Explain the proper procedures for loading and unloading cargo.

Safe loading and unloading involves a methodical approach emphasizing safety and efficiency. Here’s my procedure:

- Assessment: Carefully assess the weight, dimensions, and stability of the load. Understanding the center of gravity is key to preventing tipping.

- Positioning: Position the forklift as close as possible to the loading point and ensure level ground for stability. Avoid uneven surfaces that could cause imbalance.

- Fork Placement: Insert forks fully under the load, ensuring proper and even distribution of weight. Incorrect fork placement can lead to damage or spills.

- Lifting: Lift the load slowly and smoothly, checking for any shifting or instability. If there is any movement during lifting, lower the load and reposition it for safer lifting.

- Transportation: Transport the load at a safe speed and avoid sharp turns or sudden braking, being mindful of surroundings.

- Unloading: Carefully lower the load to the designated unloading area. Ensure the area is clear of obstructions before unloading.

I always prioritize the safety of myself, coworkers, and the load. Each step is executed methodically, avoiding rush that can lead to error.

Q 4. How do you ensure the safety of pedestrians in a warehouse environment?

Pedestrian safety is my top priority. I employ several strategies to mitigate risks:

- Awareness: Maintaining constant awareness of pedestrian traffic using mirrors and observation. I never assume pedestrians can see me.

- Horn Usage: Utilizing the horn appropriately to alert pedestrians of my approach, especially in blind corners or congested areas.

- Slow Speed: Driving at a safe and slow speed, especially when in areas with heavy pedestrian traffic. Speed is a major contributor to accidents.

- Designated Pathways: Adhering to designated pedestrian pathways and avoiding areas where pedestrians might unexpectedly cross.

- Communication: Communicating clearly and effectively with pedestrians and colleagues to avoid confusion. A simple hand signal can prevent a potential accident.

- Warning Signals: Using warning lights and other safety devices to enhance visibility and alert pedestrians.

Proactive pedestrian safety measures are crucial. It’s not just about reacting to situations but preventing them altogether.

Q 5. What are the different types of forklift attachments and their uses?

Forklift attachments significantly broaden the capabilities of the machine. Some common attachments include:

- Side Shifters: Allow for lateral movement of the forks, improving placement accuracy and efficiency, especially when working with pallets in tight spaces.

- Rotators: Rotate the forks to facilitate the handling of loads that require specific orientations. This is common in manufacturing and construction.

- Clamps: Used for handling various materials such as paper rolls, lumber, or other items not suitable for standard forks.

- Carriage Extensions: Extend the reach of the forks, useful when handling longer or wider items that wouldn’t fit otherwise.

- Push-Pull Attachments: Enable the forklift to push and pull heavier loads that require more power than typical forklifts can provide.

The choice of attachment depends entirely on the type of load being handled. Understanding the capabilities and limitations of each attachment is vital for safe and efficient operation.

Q 6. How do you handle different types of loads (e.g., fragile, oversized)?

Handling different load types requires adapting techniques for safety and damage prevention:

- Fragile Loads: Requires careful handling, slower speeds, and potentially specialized attachments like cushioned forks to protect the goods from damage.

- Oversized Loads: Requires additional caution, thorough assessment of the center of gravity, and potentially the use of additional support or personnel to prevent accidents.

- Unstable Loads: Requires securing the load with straps or other securing devices to prevent shifting during transportation. The forklift’s stability must be prioritized.

- Hazardous Materials: Requires specialized training, equipment, and adherence to strict safety protocols, including proper signage and personal protective equipment.

Understanding load characteristics and adapting techniques is critical. I never compromise on safety when dealing with unusual or challenging loads.

Q 7. What is your experience with load capacity and weight limits?

Load capacity and weight limits are non-negotiable. I always adhere strictly to the manufacturer’s specified limits for the forklift I am operating. Exceeding these limits significantly increases the risk of tipping, equipment damage, and injury. I understand that each forklift model has a unique load capacity, which is often displayed on a data plate on the forklift itself. This is checked before commencing any operation and is fundamental to safe operation. Furthermore, I consider the load’s center of gravity and ensure it’s within the safe operating parameters.

In my experience, neglecting load limits can have devastating consequences. I prioritize safe operation by understanding and respecting the limits and using appropriate equipment for the given load.

Q 8. Describe your experience with maintaining forklift operation logs.

Maintaining accurate forklift operation logs is crucial for safety, regulatory compliance, and efficient fleet management. My experience involves meticulously recording each forklift’s daily operation, including operator’s name, date, time, hours of operation, type of work performed, any maintenance conducted, and importantly, any incidents or near misses. I utilize both digital and paper-based logging systems, ensuring data integrity and easy accessibility for audits or analysis. For example, in my previous role, we used a digital system that automatically tracked operational hours and location via GPS, significantly improving accuracy and reducing manual data entry errors. This data was then used to schedule preventative maintenance, identify potential safety hazards based on operational patterns, and optimize forklift utilization within the warehouse.

In situations where digital logging isn’t possible, I ensure the paper logs are kept clean, organized, and stored in a secure, dry location. This is essential for compliance with workplace safety regulations and for tracking operational history effectively.

Q 9. What are the common causes of forklift accidents and how can they be prevented?

Forklift accidents are often caused by a combination of human error and environmental factors. Common causes include: Improper training and certification – Operators unfamiliar with safe operating procedures are a significant risk. Unsafe operating practices – speeding, overloading, operating in unsafe conditions (poor visibility, uneven surfaces), and failing to follow safety protocols. Mechanical failure – faulty brakes, steering issues, or other malfunctions necessitate regular maintenance and inspections. Poor visibility – blind spots, obstructed views, or insufficient lighting can lead to collisions. Environmental hazards – wet floors, cluttered aisles, and inadequate signage contribute to accidents.

Preventing these accidents requires a multi-faceted approach: Comprehensive training programs for all operators, including practical hands-on training and regular refresher courses. Strict adherence to safety protocols, including speed limits, load capacity regulations, and pre-operational checks. Regular forklift maintenance and inspections to ensure mechanical integrity. Improved warehouse layout and organization to enhance visibility and minimize congestion in walkways and aisles. Clear signage and warning systems, as well as effective communication between forklift operators and pedestrians.

For instance, in one warehouse, we implemented a system of colored floor markings to delineate walkways and forklift traffic lanes, significantly reducing near misses.

Q 10. What are your experience with different types of warehouse layouts?

My experience encompasses various warehouse layouts, including traditional narrow-aisle layouts, wide-aisle configurations, and high-bay warehouses utilizing very narrow aisle (VNA) racking systems. Each layout presents unique challenges and demands specific operating strategies. Narrow-aisle layouts, for example, demand precision and careful maneuvering, necessitating skilled operators proficient in operating equipment suited for such environments (like reach trucks). Wide-aisle setups generally allow for greater maneuverability, but efficient space utilization remains critical. High-bay warehouses, often involving the use of high-lift forklifts and order pickers, require additional training and expertise in managing height restrictions and load stability at elevated levels.

I’m adept at adapting my operating techniques to suit the specific characteristics of each layout, prioritizing safety and efficiency in all situations. Understanding the layout is critical; I always take time before commencing work to familiarize myself with the layout, locations of obstacles, and designated traffic flow routes. This ensures smooth operation and prevents potential accidents.

Q 11. How do you manage tight spaces and difficult maneuvers with a forklift?

Navigating tight spaces and complex maneuvers requires a combination of skill, experience, and careful planning. Before attempting any maneuver, I assess the space, noting any obstacles, potential blind spots, and the proximity of other equipment or personnel. I use mirrors and spotters when necessary to improve visibility. Slow and controlled movements are paramount; sudden jerky actions can easily lead to accidents. I adjust my speed and approach angle to maximize space utilization and minimize risk.

For instance, when maneuvering around corners in a narrow aisle, I utilize a technique where I turn the forklift slowly and gradually, ensuring all wheels stay in contact with the floor to prevent instability and minimize potential damage to racking or other items. I also take advantage of the forklift’s features, such as the ability to adjust the forks and tilt them to better manage the load height and optimize its footprint within a confined area. Prioritizing safety always over speed is critical in such situations.

Q 12. How do you handle emergency situations involving a forklift?

Emergency situations involving forklifts demand immediate and decisive action. My approach involves: Immediate assessment of the situation – determining the nature of the emergency and the potential risks. Securing the immediate area – preventing further accidents by clearing the path and alerting others to the danger. Shutting down the forklift – turning off the ignition and engaging the parking brake to prevent further movement. Calling for emergency assistance – contacting relevant personnel (e.g., emergency services, supervisors, maintenance) as needed. Providing first aid – administering basic first aid, if properly trained and the situation allows. Cooperating with emergency responders – assisting them in accessing the situation and providing information about the incident.

For example, if a forklift malfunctions and begins to roll uncontrollably, I would immediately attempt to safely bring it to a halt (if possible without endangering myself), then activate the emergency stop, and alert others to vacate the area. Post-incident, I would complete a thorough incident report documenting all events to prevent recurrence.

Q 13. What is your experience with using different types of forklift controls?

I am proficient in operating forklifts with various control systems, including both lever and steering wheel controls. Lever controls are common in older models and require a different operating technique compared to steering wheel controls, which are more intuitive and commonly found in newer models. I adapt easily between the two, understanding the nuances of each system and prioritizing safety in both scenarios. The transition between different control systems primarily involves adjusting my hand and foot movements to optimize control and precision. Regardless of the control system, I always prioritize a smooth and deliberate approach to maximize safety and minimize the risk of accidents. Proper training and practice are crucial for safe operation, regardless of the control type.

Q 14. Describe your experience with refueling or battery changing procedures.

Refueling and battery-changing procedures must adhere strictly to safety protocols to prevent fires, explosions, or other hazards. My experience encompasses both propane/LPG refueling and battery changing procedures for electric forklifts. When refueling LPG forklifts, I ensure the area is well-ventilated, the forklift is turned off, and I use an approved refueling nozzle and follow all manufacturer guidelines. For electric forklifts, I utilize proper lifting equipment (e.g., battery handling carts) and follow safety precautions to avoid back injuries and short circuits. The battery compartment is thoroughly cleaned, and the new battery is properly secured and connected. Always I will refer to the relevant manufacturer’s guidelines and the company’s safety procedures before starting any procedure.

In both cases, I meticulously follow all safety protocols, including wearing appropriate safety gear (gloves, eye protection), ensuring proper ventilation, and grounding the equipment where necessary.

Q 15. How do you handle situations with malfunctioning equipment?

My first priority when encountering malfunctioning equipment is safety. I immediately cease operation and report the issue to my supervisor. Before doing anything, I ensure the forklift is in a safe and stable position, away from traffic and potential hazards. Then, depending on the nature of the malfunction, I may take some preliminary steps. For instance, if it’s a minor issue like a low battery indicator, I might check the charging procedures. However, for anything beyond basic troubleshooting, such as hydraulic leaks or engine problems, I will not attempt repairs myself. My training emphasizes that only qualified mechanics should address such problems to prevent further damage or injury. I’ll thoroughly document the malfunction, noting the time, location, and specific issue observed, including any unusual sounds or behaviors the forklift exhibited. This detailed reporting is crucial for efficient repairs and safety analysis.

For example, once I noticed a strange clicking sound from the forklift’s hydraulic system while lifting a heavy pallet. Instead of continuing operation, I immediately stopped and reported it to the maintenance team. Their inspection revealed a damaged hydraulic hose that could have caused a catastrophic failure if ignored. This highlights the importance of proactively addressing even seemingly minor malfunctions.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are your experience with working at heights using a forklift?

Working at heights with a forklift requires meticulous attention to safety. I have experience using forklifts to place pallets on high racking systems, but this is always approached cautiously and in full compliance with company safety protocols. Before undertaking any lift at height, I carefully assess the stability of the racking, the condition of the floor, and the weight of the load to ensure everything is within the forklift’s and my own capabilities. I never exceed the rated capacity of the forklift, nor do I exceed the height limits of the mast, and regularly check the load stability during lifting.

Moreover, I am always mindful of the surrounding environment. I ensure that no obstructions or personnel are near the lift path, particularly underneath the load. And of course, I always wear my safety harness and use appropriate safety equipment as mandated by the company and OSHA guidelines. Clear communication with colleagues working in the area is crucial. Before lifting, I would announce my intended movement to warn those nearby, especially if they are working below.

Q 17. What is your understanding of OSHA regulations concerning forklift operation?

My understanding of OSHA regulations concerning forklift operation is comprehensive. I’m well-versed in the requirements for operator training, certification, and ongoing safety procedures. This includes knowing the pre-operation inspection checklist, understanding load capacity limitations, practicing safe operating procedures in various conditions (e.g., wet floors, limited visibility), and maintaining awareness of pedestrian and other equipment traffic. I am also familiar with the regulations concerning the maintenance and regular inspection of forklifts themselves, ensuring they are in safe and operable condition. Additionally, I know the requirements for reporting accidents and near-miss incidents promptly and accurately. Finally, I understand the importance of wearing personal protective equipment (PPE) at all times.

One critical OSHA regulation that I always adhere to is the requirement for regular operator training and certification. This ensures that I am up-to-date on the latest safety standards and techniques. Neglecting this aspect could lead to accidents and compromise workplace safety.

Q 18. How do you maintain a clean and organized work area?

Maintaining a clean and organized work area is not just about tidiness; it’s a vital safety precaution. A cluttered environment increases the risk of accidents. My approach is proactive. After completing each task, I immediately put away tools, materials, and empty pallets. I make sure that aisles are kept clear and free from obstructions. This ensures smooth and efficient operation for myself and my colleagues. I also regularly sweep and clean the floor to eliminate debris that could create tripping hazards. Furthermore, I report any damage to racking systems or the floor immediately. Having a designated area for storage and waste disposal helps in maintaining the cleanliness and orderliness of the warehouse.

For example, I developed the habit of putting away empty pallets after every order, preventing blockages in the aisle and improving workflow efficiency. This small act prevents a potential major safety hazard.

Q 19. Describe your experience with inventory management using a forklift.

My experience with inventory management using a forklift involves accurate and efficient stock movement. I am proficient in using a forklift for loading and unloading goods, staging inventory in designated areas, and transporting materials within the warehouse. My tasks involve verifying inventory against pick lists, ensuring correct stock rotation (FIFO – First-In, First-Out), and accurately placing items in storage locations to streamline picking. I always ensure that the load is properly secured and balanced to prevent spills or damage.

In a previous role, I implemented a system for organizing pallets based on urgency of need and expiry dates, improving inventory turnover and minimizing waste. This system involved using specific racking sections and color-coding labels to clearly indicate priority and expiry dates. This simple organizational strategy improved efficiency and reduced order fulfillment time.

Q 20. How do you communicate effectively with other warehouse personnel?

Effective communication is crucial in a warehouse environment. I always prioritize clear and concise communication with my colleagues. Before starting any task that may affect others, I’ll make sure to communicate my intentions – for instance, announcing my movements, especially when operating in confined spaces or near other workers. I also make sure to actively listen to instructions and respond promptly and accurately. If I notice any potential problems or safety hazards, I always communicate these concerns immediately to the supervisor. I use hand signals and verbal communication where appropriate, ensuring that everyone understands the planned actions.

For example, during a busy period, I noticed that another forklift driver was about to enter an area where I was maneuvering a heavy load. I quickly signaled to him, preventing a potential collision. Proactive and clear communication prevented an accident.

Q 21. Describe your problem-solving skills in the context of forklift operation.

My problem-solving skills in forklift operation are rooted in a methodical approach. When confronted with a challenge, my first step is to assess the situation safely and carefully. I identify the problem, considering all possible causes. Next, I evaluate potential solutions, considering safety implications and efficiency. I prioritize safe solutions over speed. If unsure, I consult with a supervisor or more experienced colleague. I then implement the chosen solution, carefully monitoring its effectiveness and making adjustments as needed. Finally, I document the issue, the solution, and the outcome, helping in future problem-solving and preventative measures.

For example, I once encountered a situation where a pallet was jammed in a narrow aisle. Instead of forcing it, I assessed the situation and decided to use a smaller forklift to maneuver the pallet more efficiently. By using a different approach, I resolved the problem safely and without causing damage.

Q 22. What is your experience with different warehouse management systems (WMS)?

My experience with Warehouse Management Systems (WMS) spans several leading platforms, including Oracle WMS, SAP EWM, and Blue Yonder. I’m proficient in using these systems to manage inventory, track orders, optimize picking routes, and generate reports. I understand the crucial role a WMS plays in efficient forklift operation, as it dictates tasks, directs movement, and provides real-time information about inventory locations and order priorities. For example, in a previous role using Oracle WMS, I relied on the system’s directed putaway and picking functionalities to improve accuracy and efficiency by up to 15%, minimizing travel time and reducing errors. I’m adept at integrating forklift data into WMS reporting to track performance metrics such as cycle times and throughput.

Furthermore, I’m comfortable working with different WMS interfaces, including handheld scanners and voice-directed systems. My understanding extends beyond just using the software; I can troubleshoot minor system issues and collaborate with IT to resolve more complex problems. I’m also familiar with the importance of data integrity within the WMS and how it affects the accuracy of forklift operations.

Q 23. How do you prioritize tasks in a busy warehouse environment?

Prioritizing tasks in a busy warehouse is critical for maintaining efficiency and meeting deadlines. My approach involves a combination of factors. First, I always check the WMS for the most urgent orders, typically those with imminent shipping deadlines or high priority customer requests. This is usually based on order due dates, product criticality, or client importance. Second, I assess the location of items and optimize my route to minimize travel time. This often means using a ‘cluster picking’ approach where I gather multiple items for different orders that are located in the same area, reducing unnecessary movement.

Safety is paramount. If an area needs immediate attention for safety reasons (e.g., a spill or obstructed aisle), I will prioritize addressing that before resuming other tasks. I also factor in my own energy levels and the condition of my equipment. I’ll avoid taking on tasks requiring intense concentration if I’m fatigued. Communication is key; I regularly update my supervisor about any delays or challenges to allow for proactive adjustments to the schedule.

Q 24. How do you stay up-to-date on forklift safety regulations?

Staying current on forklift safety regulations is a continuous process. I regularly review the OSHA guidelines and any relevant state or local regulations. I actively participate in company safety training and refresher courses, ensuring I’m aware of any updates or changes in best practices. I also stay informed through industry publications, online resources, and professional organizations like the Industrial Truck Association (ITA). I consider safety a personal responsibility; I regularly conduct pre-operational checks on forklifts, ensuring they are in optimal working condition and adhering to all safety protocols. This includes checking brakes, lights, horns, and load capacity, and reporting any issues immediately to maintenance personnel.

Q 25. What is your approach to continuous improvement in forklift operation?

My approach to continuous improvement in forklift operation revolves around data analysis and proactive problem-solving. I regularly track key performance indicators (KPIs) such as cycle times, order accuracy, and near-miss incidents. By analyzing this data, I can identify areas where improvement is needed. For instance, if cycle times are consistently high, I might investigate potential bottlenecks in the workflow, such as inefficient racking systems or inadequate aisle space. I then work collaboratively with supervisors and other team members to suggest and implement solutions. This might involve reorganizing the warehouse layout, optimizing picking routes, or suggesting new equipment or training programs. I always document my observations and improvements to track progress and prevent recurrence of issues.

Q 26. Describe a time you had to troubleshoot a forklift malfunction.

During a busy shift, the forklift I was operating suddenly lost power. My first reaction was to safely bring the forklift to a complete stop, ensuring no collisions or injuries. Following safety protocols, I activated the hazard lights and informed my supervisor immediately. I then conducted a preliminary inspection, checking the battery connections and power switch. After confirming the problem wasn’t a simple fix, I contacted the maintenance team who arrived within 15 minutes. The issue turned out to be a faulty battery connection. The maintenance team resolved the problem quickly, and after a thorough check of the forklift, I was able to resume my work. This experience highlighted the importance of following safety procedures, clear communication, and the value of a well-equipped maintenance team.

Q 27. How do you adapt to changes in warehouse operations or procedures?

Adapting to changes is a fundamental aspect of warehouse work. I’m comfortable with implementing new technologies, operational procedures, or even warehouse layouts. My approach involves active listening during any change announcement, asking clarifying questions to fully understand the modifications, and actively participating in any training sessions provided. I take a proactive approach by identifying potential challenges early and seeking solutions. For example, if a new WMS is implemented, I would familiarize myself with the system well in advance of its launch to minimize disruption to my workflow. I also understand that change may require adjustments to my work habits, and I’m willing to embrace the learning curve to maximize the benefits of those changes. Open communication with my team and supervisors is crucial throughout the adaptation process.

Q 28. What are your salary expectations?

My salary expectations are commensurate with my experience and skills in forklift operation, as well as the responsibilities and demands of this role. Based on my research of similar positions and my performance record, I’m targeting a salary range between [Insert Salary Range] annually. I’m open to discussing this further, and I’m confident that my contributions to your team will quickly justify this investment.

Key Topics to Learn for Forklift Operation Interview

- Forklift Types and Classifications: Understanding the different types of forklifts (e.g., counterbalance, reach truck, order picker) and their applications in various warehouse settings.

- Safe Operation Procedures: Mastering pre-operational checks, load handling techniques, maneuvering in confined spaces, and adherence to safety regulations (OSHA guidelines).

- Load Stability and Weight Distribution: Understanding center of gravity, load capacity limits, and the proper techniques for securing and transporting loads to prevent accidents.

- Maintenance and Inspection: Knowledge of routine maintenance checks, identifying potential mechanical issues, and reporting necessary repairs to prevent equipment malfunctions.

- Warehouse Layout and Logistics: Familiarity with warehouse organization, efficient routing, and understanding the flow of goods within the facility.

- Inventory Management and Order Fulfillment: Understanding the role of forklifts in efficient inventory management and the processes involved in order picking and delivery.

- Troubleshooting and Problem-Solving: Developing the ability to identify and address common forklift operational issues, such as mechanical problems or logistical challenges.

- Communication and Teamwork: Highlighting the importance of effective communication with colleagues and supervisors, and working collaboratively within a team environment.

Next Steps

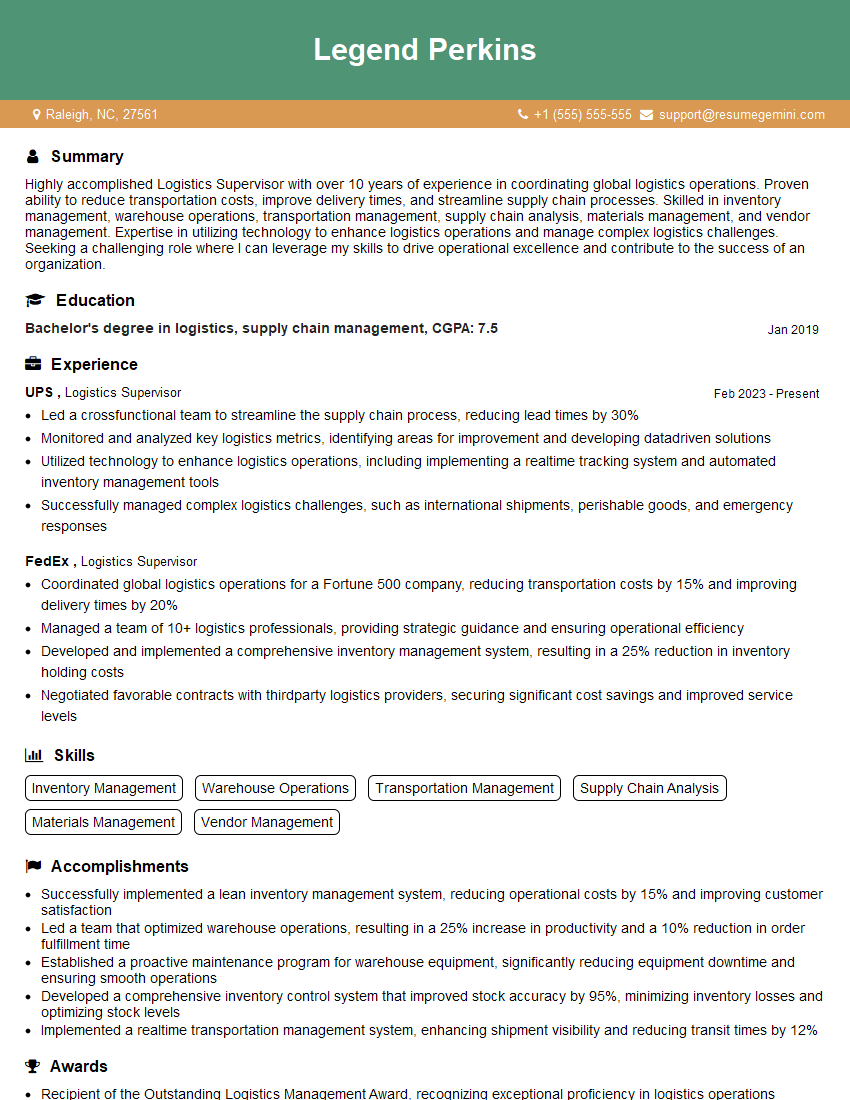

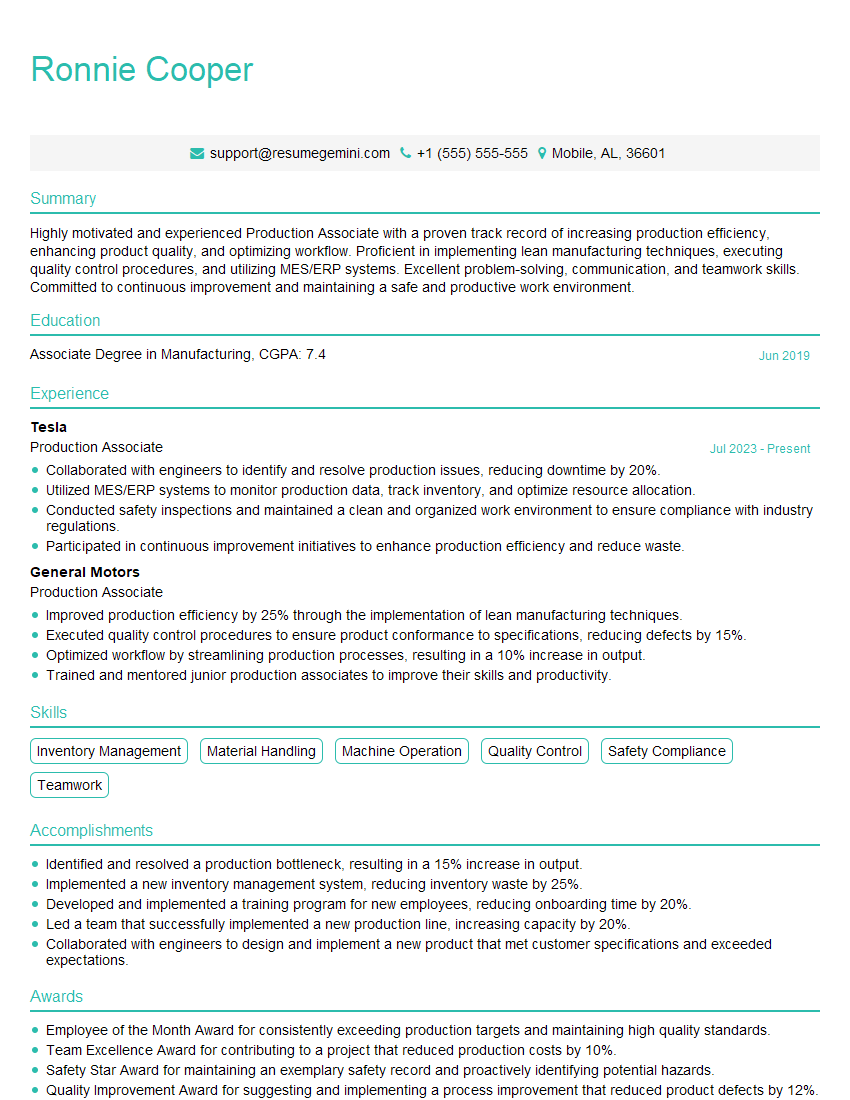

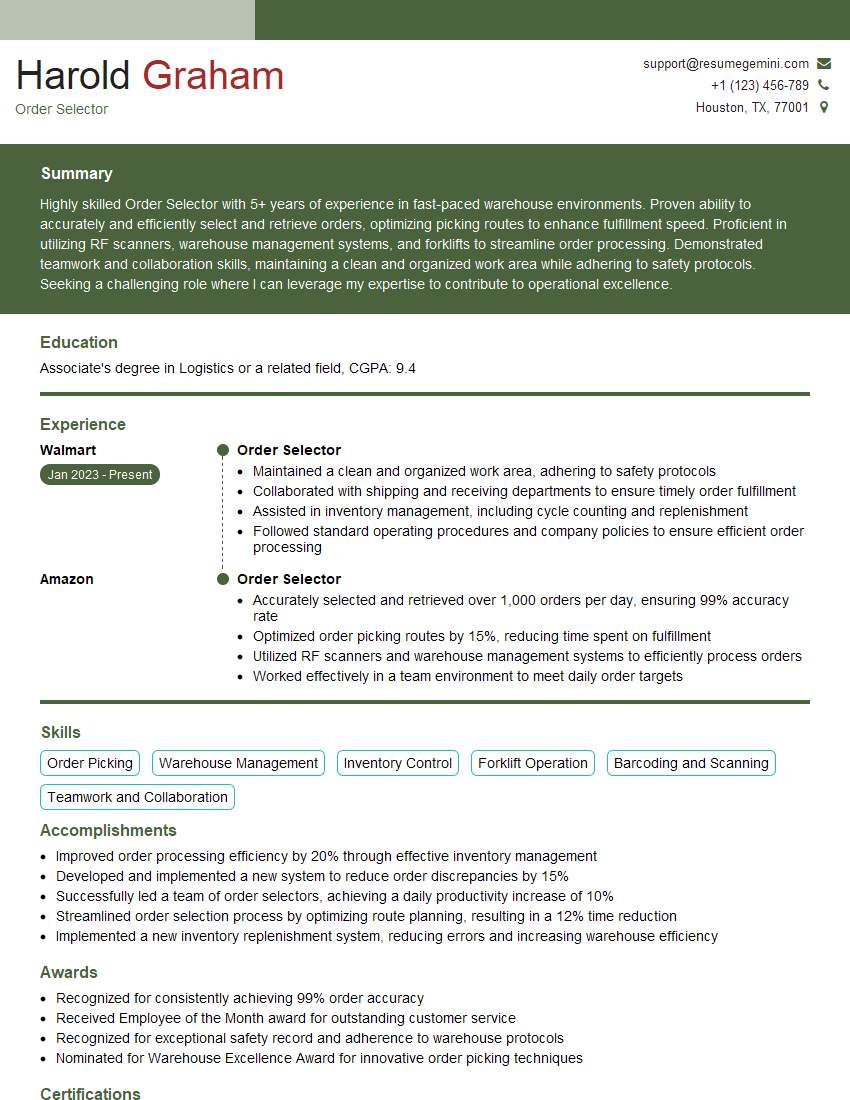

Mastering forklift operation opens doors to a wide range of rewarding careers in logistics, warehousing, and manufacturing, offering opportunities for growth and advancement. To increase your chances of landing your dream job, focus on crafting an ATS-friendly resume that showcases your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. We provide examples of resumes tailored specifically to forklift operation roles to guide you through the process. Take the next step towards your successful career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good