Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Foundry Process Optimization interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Foundry Process Optimization Interview

Q 1. Describe your experience with different casting processes (sand casting, die casting, investment casting, etc.).

My experience encompasses a wide range of casting processes, each with its own strengths and weaknesses. Let’s start with sand casting, a highly versatile and cost-effective method ideal for producing large, complex parts. I’ve worked extensively with both green sand and resin-bonded sand, optimizing mold-making techniques to minimize defects and improve dimensional accuracy. Then there’s die casting, a high-speed process perfect for mass production of intricate components. My experience here includes both high-pressure and low-pressure die casting, focusing on optimizing die life and controlling metal fluidity. I’ve also worked extensively with investment casting (lost-wax casting), which allows for exceptionally detailed and complex geometries. Here, my expertise lies in optimizing ceramic shell preparation and controlling the pouring parameters to ensure consistent part quality. Finally, I have some experience with permanent mold casting, offering a good balance between production rate and part complexity. Throughout my career, I’ve focused on optimizing each process to achieve the best possible surface finish, dimensional tolerances, and mechanical properties.

For example, in one project involving die casting, we implemented a new mold cooling system that reduced cycle time by 15%, significantly boosting productivity. In another project involving investment casting, we fine-tuned the ceramic shell composition resulting in a 20% reduction in scrap rate.

Q 2. Explain your understanding of gating and risering design.

Gating and risering design are crucial for successful casting. The gating system directs molten metal into the mold cavity, while the risering system provides a reservoir of molten metal to compensate for shrinkage during solidification. Poor design can lead to various defects, including cold shuts, misruns, and porosity. My approach involves using specialized software for simulation and analysis, considering factors such as metal flow dynamics, heat transfer, and solidification behavior. I typically start with a thorough understanding of the part geometry and material properties. I then design the gating system to ensure smooth and consistent metal flow, minimizing turbulence and air entrapment. The riser design is equally critical; it should be sized to provide sufficient molten metal to feed the casting, preventing shrinkage cavities. The placement is also carefully considered to ensure efficient heat transfer and minimal chilling effects.

For instance, in a recent project, we redesigned the gating system for a complex automotive component. The simulation showed that the original design caused turbulence and air entrapment, leading to porosity. The redesigned system, incorporating strategically placed sprues and runners, resulted in a significant reduction in defects and improved surface finish.

Q 3. How do you identify and troubleshoot common casting defects?

Identifying and troubleshooting casting defects requires a systematic approach. I typically begin by visually inspecting the castings, noting the location, size, and type of defect. Common defects include shrinkage porosity (caused by insufficient molten metal), gas porosity (caused by trapped air or gases), cold shuts (incomplete fusion of molten metal), misruns (incomplete filling of the mold cavity), and inclusions (foreign material embedded in the casting). After visual inspection, I often use metallurgical techniques such as microscopy and chemical analysis to determine the root cause. This might involve examining the microstructure of the casting or analyzing the chemical composition of the metal. Once the root cause is identified, appropriate corrective actions can be implemented, which could involve adjusting pouring parameters, modifying the mold design, or changing the casting process itself.

Example: If gas porosity is prevalent, I might investigate the mold venting or the melting practices to reduce gas content in the molten metal. If shrinkage cavities are an issue, I’d likely adjust the risering design or the pouring temperature.

Q 4. What are the key performance indicators (KPIs) you monitor in foundry operations?

Key performance indicators (KPIs) in foundry operations are crucial for evaluating efficiency and quality. Some of the most important KPIs I monitor include:

- Yield: The percentage of good castings produced relative to the total number of castings poured. A high yield indicates efficient operation and minimal defects.

- Cycle time: The time it takes to produce one casting. Reducing cycle time increases productivity.

- Defect rate: The number of defective castings produced per unit of time. A low defect rate signifies high-quality production.

- Scrap rate: The percentage of castings that must be scrapped due to defects. A low scrap rate reduces material waste and costs.

- Cost per casting: The total cost of producing one casting, including material, labor, and overhead. Minimizing this cost is vital for profitability.

- Energy consumption: Monitoring energy use helps identify opportunities for efficiency improvements and cost savings.

Regular monitoring and analysis of these KPIs provide insights for continuous improvement.

Q 5. Describe your experience with implementing lean manufacturing principles in a foundry.

Implementing lean manufacturing principles in a foundry involves eliminating waste and maximizing efficiency. My experience includes successfully implementing several lean initiatives, such as 5S (Sort, Set in Order, Shine, Standardize, Sustain) to improve workplace organization and Value Stream Mapping to identify and eliminate non-value-added steps in the casting process. I’ve also implemented Kaizen (continuous improvement) events, focusing on small, incremental improvements to optimize processes. In addition, Kanban systems were implemented to manage material flow and reduce inventory. These strategies helped improve productivity, reduce lead times, and minimize waste. We also adopted Poka-Yoke (error-proofing) techniques to prevent defects and ensure consistent quality.

For example, in one foundry, implementing 5S reduced material handling time by 20%, while value stream mapping identified a bottleneck in the pouring process which was subsequently eliminated leading to a 15% reduction in cycle time.

Q 6. How do you optimize metal flow in a casting process?

Optimizing metal flow is essential for producing high-quality castings. This involves careful design of the gating system, as discussed earlier, but also includes considerations such as metal temperature, pouring rate, and mold design. The metal temperature should be high enough to ensure fluidity but not so high as to cause excessive erosion or burning. The pouring rate should be controlled to avoid turbulence and air entrapment. The mold design should be optimized to promote smooth metal flow and prevent premature solidification. Utilizing simulation software helps predict and optimize metal flow and solidification behavior. This allows for adjustments to the gating system or mold design before actual production begins, minimizing risks and costs associated with defects. In addition, proper mold preparation, including appropriate venting and surface coatings, helps prevent defects related to gas porosity or metal adhesion.

For example, the use of CFD (Computational Fluid Dynamics) simulations enabled us to optimize runner and sprue dimensions to minimize turbulence and ensure uniform filling of the mold cavity in a complex pump housing casting.

Q 7. Explain your experience with statistical process control (SPC) in a foundry setting.

Statistical Process Control (SPC) is vital for ensuring consistent casting quality. My experience involves implementing and utilizing various SPC tools, including control charts (e.g., X-bar and R charts) to monitor key process parameters like metal temperature, pouring time, and casting dimensions. Data from these charts helps identify trends, variations and potential issues early on, enabling timely corrective actions. I also utilize process capability analysis to evaluate the ability of a process to meet specified tolerances. This helps to assess the effectiveness of process improvements and identify areas needing further optimization. SPC techniques are also integral for analyzing the effectiveness of implemented process changes and for confirming that these changes continue to have the desired effect.

For example, by monitoring the metal temperature with control charts, we were able to identify a pattern of increasing temperature variation that was subsequently traced to a malfunctioning heating element. This early detection prevented the production of defective castings and saved considerable material and time.

Q 8. How do you manage and reduce scrap and rework in a foundry?

Reducing scrap and rework in a foundry is crucial for profitability and efficiency. It’s a multifaceted problem requiring a systematic approach focusing on process control, worker training, and proactive quality management.

My strategy begins with meticulously analyzing the root causes of defects. This involves using statistical process control (SPC) charts to identify trends and patterns in scrap generation. For example, if we consistently see a high rate of misruns in a specific mold type, we investigate factors like sand moisture content, molding machine settings, and the pouring technique.

- Improved Molding Techniques: We implement standardized procedures for mold making, including precise measurements and consistent compaction, minimizing the chance of misruns or cold shuts. We also utilize techniques like pre-coated sand to improve mold surface quality.

- Preventive Maintenance: A robust preventative maintenance program for molding equipment is essential. Regularly scheduled maintenance prevents unexpected breakdowns that cause delays and defects. Think of it like regular car servicing – preventing small issues from becoming major problems.

- Raw Material Control: Strict quality control checks on incoming raw materials, like sand and metal alloys, are vital. Inconsistencies in these materials directly affect the final product’s quality.

- Operator Training: Comprehensive training for foundry workers is key. We use hands-on training, visual aids, and regular refresher courses to ensure everyone understands best practices and safety procedures. Skilled operators are less likely to produce defective castings.

- Continuous Improvement: We actively encourage a culture of continuous improvement through regular process reviews, employee feedback sessions, and the adoption of lean manufacturing principles. Kaizen events, for instance, can be particularly effective in identifying and eliminating waste in the foundry process.

By addressing these areas, we can significantly reduce scrap and rework, leading to cost savings and improved efficiency. In one project, implementing these strategies resulted in a 15% reduction in scrap within six months.

Q 9. Describe your experience with different types of foundry molding sand.

My experience encompasses a wide range of foundry molding sands, each with its own properties and applications. The choice of sand significantly impacts casting quality, productivity, and overall costs.

- Green Sand: This is the most common type, a mixture of silica sand, clay, and water. Its properties are easily controlled and it’s relatively inexpensive, but it has limitations in terms of dimensional accuracy and surface finish. My experience includes optimizing the clay content and moisture level to achieve consistent mold strength and permeability.

- Synthetic Sands: These sands, often made from olivine or zircon, offer improved thermal stability, dimensional accuracy, and surface finish compared to green sand. I’ve worked with projects incorporating these sands to improve complex casting quality, particularly for intricate parts requiring high precision.

- No-Bake Sands: These chemically bonded sands require no baking or drying, resulting in quicker turnaround times and energy savings. I have experience implementing no-bake systems, including the selection of appropriate binders and careful control of mixing and curing processes to optimize strength and collapsibility.

- Shell Molding Sands: This process uses a thin shell mold coated with a thermosetting resin. My experience includes optimizing the resin system, shell thickness, and curing process to achieve the desired casting properties. This process is particularly useful for high-volume production of smaller castings with excellent surface finish.

Selecting the appropriate sand type and optimizing its properties is crucial. For example, using a synthetic sand for a complex aerospace casting allows for higher dimensional accuracy and improved surface finish, which is essential for the application.

Q 10. What are your strategies for improving energy efficiency in a foundry?

Improving energy efficiency in a foundry is crucial for both economic and environmental reasons. My approach is multifaceted, focusing on both process improvements and equipment upgrades.

- Furnace Optimization: This is a major area of focus. We use advanced control systems to monitor and optimize furnace temperature profiles, reducing energy consumption without sacrificing casting quality. Implementing strategies like preheating the metal reduces the overall energy required for melting.

- Heat Recovery: Capturing and reusing waste heat is crucial. Installing heat recovery systems on furnaces and melting equipment can significantly reduce energy consumption. This can involve using the waste heat to preheat incoming materials or to generate hot water for other foundry operations.

- Improved Insulation: Upgrading insulation in furnaces and other equipment minimizes heat loss, resulting in greater efficiency. Regular inspections and maintenance of insulation are also vital to prevent degradation and energy losses.

- Energy-Efficient Equipment: Investing in energy-efficient melting and casting equipment, like induction furnaces or low-pressure molding machines, significantly reduces energy consumption over time.

- Process Optimization: Analyzing the entire casting process to identify areas of energy waste. This could involve optimizing pour rates, mold design, or using automated systems to minimize energy-intensive manual processes.

For example, in one project, we implemented a heat recovery system and optimized furnace operation, resulting in a 10% reduction in energy consumption within a year. This translated into significant cost savings and a reduced environmental footprint.

Q 11. How do you ensure the quality of raw materials in a foundry?

Ensuring the quality of raw materials is paramount in a foundry. A robust quality control system is essential for preventing defects and maintaining consistent casting quality.

- Supplier Selection: Choosing reliable suppliers with a proven track record of providing high-quality materials is the first step. This often involves auditing potential suppliers and verifying their quality management systems.

- Incoming Inspection: Every batch of raw materials undergoes rigorous inspection upon arrival. This involves checking chemical composition, grain size, and other relevant properties to ensure they meet specifications. We often use spectrometry and other analytical techniques for precise measurements.

- Material Traceability: A robust tracking system is essential to identify the source of any problems. Each batch of material is meticulously documented, allowing us to trace its path through the foundry process.

- Storage and Handling: Proper storage and handling of materials prevent contamination and degradation. This includes appropriate storage facilities and techniques to prevent moisture absorption or other forms of deterioration.

- Regular Audits: Periodic audits of the entire supply chain ensure ongoing compliance with quality standards and identify areas for improvement.

Implementing this system allows us to identify and address potential problems early, avoiding costly rework and production delays. For example, early detection of impurities in a metal alloy batch prevented a significant production disruption and potential for defective castings.

Q 12. Explain your experience with implementing and managing preventative maintenance programs.

Implementing and managing preventative maintenance programs is crucial for maximizing equipment uptime and minimizing unexpected breakdowns. My approach is based on a combination of planning, execution, and continuous improvement.

- Equipment Assessment: A comprehensive assessment of all foundry equipment is conducted to identify critical components and potential failure points. This often involves analyzing historical maintenance data to identify recurring issues.

- Maintenance Schedule: A detailed preventative maintenance schedule is developed based on equipment specifications and historical data. This schedule includes regular inspections, lubrication, cleaning, and replacement of worn parts.

- Work Order System: A well-organized work order system ensures that all maintenance tasks are completed on time and efficiently. This system often includes software for scheduling, tracking progress, and managing spare parts inventory.

- Training and Documentation: Proper training of maintenance personnel is essential. This includes technical training on specific equipment as well as training on safety procedures. Detailed maintenance procedures and documentation are critical for consistency and knowledge sharing.

- Performance Monitoring: Regularly monitoring equipment performance and maintenance costs allows for continuous improvement of the program. This may involve analyzing data to identify areas where maintenance tasks can be optimized or where additional preventative measures are needed.

In one case, the implementation of a comprehensive preventative maintenance program reduced equipment downtime by 20% and decreased overall maintenance costs by 15% within a year. This translated to improved production efficiency and significant cost savings.

Q 13. How do you ensure worker safety in a foundry environment?

Ensuring worker safety in a foundry environment is paramount. It’s not just a legal requirement, but a moral obligation. My approach is based on a multi-layered safety program integrating engineering controls, administrative controls, and personal protective equipment (PPE).

- Engineering Controls: This involves designing the foundry layout and equipment to minimize hazards. This can include installing safety guards on machinery, improving ventilation to reduce dust and fumes, and providing adequate lighting.

- Administrative Controls: These are procedural controls, such as implementing lockout/tagout procedures for equipment maintenance, establishing safe work practices, and providing regular safety training. This also includes implementing robust reporting systems for near misses and incidents.

- Personal Protective Equipment (PPE): Providing and ensuring the correct use of PPE, such as safety glasses, hearing protection, respirators, and heat-resistant clothing, is crucial. Regular inspections and replacement of worn PPE are essential.

- Emergency Response Plan: A comprehensive emergency response plan must be in place, including procedures for handling fires, spills, and medical emergencies. Regular emergency drills are essential to ensure preparedness.

- Safety Culture: Creating a strong safety culture where all employees are actively involved in identifying and reporting hazards is crucial. This includes open communication, regular safety meetings, and proactive engagement from management.

A proactive and comprehensive safety program is not just about compliance, but about creating a safe and productive work environment, minimizing accidents, and fostering a sense of shared responsibility among employees.

Q 14. Describe your experience with the use of simulation software in foundry process optimization.

Simulation software plays a vital role in optimizing foundry processes. It allows us to model different scenarios, test various parameters, and identify potential problems before they occur in the real world. My experience includes using various simulation tools for different applications.

- Casting Simulation: Software like MAGMASoft allows us to simulate the filling of molds, solidification of castings, and the development of residual stresses. This helps us optimize gating systems, riser designs, and pouring parameters to minimize defects like porosity, shrinkage, and hot tears. For instance, we can simulate different mold materials and cooling rates to find optimal parameters.

- Mold Filling Simulation: Simulations can predict the flow of molten metal in the mold, allowing us to identify potential problems like air entrapment or incomplete filling. This allows for design adjustments before actual casting, saving time and resources.

- Heat Transfer Simulation: Software can model heat transfer within the mold and casting, predicting temperature gradients and solidification rates. This helps optimize cooling strategies and prevent defects related to rapid cooling or slow cooling.

- Process Optimization: Simulation is used to analyze and optimize various foundry processes, such as sand mixing, mold making, and heat treatment. For example, we can simulate different sand compositions and compaction pressures to achieve the optimal mold properties.

The use of simulation software allows us to conduct ‘what-if’ analyses, significantly reducing the time and cost associated with trial-and-error experimentation. It’s like having a virtual foundry where we can test and refine processes without impacting production. This resulted in a 10% reduction in casting defects in a recent project, significantly improving product quality.

Q 15. How do you utilize data analytics to improve foundry processes?

Data analytics is crucial for optimizing foundry processes. We use it to identify bottlenecks, predict failures, and improve overall efficiency. Think of it like a detective using clues to solve a mystery – the data provides the clues to improve our processes.

For example, we might analyze sensor data from furnaces to predict when maintenance is needed, preventing costly downtime. We can also analyze casting defect rates to pinpoint the root cause and implement corrective actions. Statistical process control (SPC) charts are instrumental in tracking key parameters like temperature, pouring time, and alloy composition, flagging anomalies early for swift intervention. Machine learning algorithms can further process this data to identify complex correlations and predict future outcomes, leading to proactive adjustments in the production process. In one project, we used regression analysis on historical data to predict optimal pouring temperature, resulting in a 15% reduction in defect rates.

- Predictive Maintenance: Analyzing sensor data to predict equipment failures.

- Defect Analysis: Identifying root causes of casting defects through statistical analysis.

- Process Optimization: Using machine learning to optimize process parameters.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are your strategies for reducing cycle times in a foundry?

Reducing cycle times in a foundry requires a multifaceted approach focusing on streamlining every stage of production. It’s like optimizing a relay race – each runner (process step) needs to be efficient for the team to win (produce castings faster).

Strategies include lean manufacturing principles, such as eliminating waste (muda) through value stream mapping. This helps identify non-value-added activities that can be removed or improved. We often use techniques like 5S (Sort, Set in Order, Shine, Standardize, Sustain) to improve workplace organization, reducing searching time and improving worker efficiency. Automating processes where possible is another key strategy – for example, automating pouring or using robotic arms for handling castings. Finally, investing in advanced equipment, such as high-speed melting furnaces, can drastically reduce cycle times.

In a recent project, implementing a new automated pouring system reduced the cycle time for a specific casting by 20%, translating directly to increased production output.

Q 17. Describe your experience with implementing automation in a foundry.

I have extensive experience implementing automation in foundries, focusing on robotic automation and programmable logic controllers (PLCs). We’ve seen significant improvements in safety, consistency, and efficiency by using automation.

For example, we implemented robotic arms for handling molds and pouring molten metal, significantly reducing the risk of burns and other workplace injuries. We also automated the core-making process using robotic systems, improving precision and reducing defects. PLCs control many aspects of the process, such as furnace temperature and mold clamping, ensuring consistent conditions and improving quality control. Each automation implementation requires careful planning and integration with existing systems, considering factors like safety protocols and compatibility with existing equipment. Post-implementation monitoring is also crucial to identify potential issues and fine-tune the automated system.

The transition to automation often requires employee retraining, ensuring the workforce is equipped to maintain and operate the new systems. This can involve a phased approach, gradually introducing automation and providing thorough training programs.

Q 18. Explain your knowledge of different types of furnaces used in foundries.

Foundries use various furnaces depending on the casting material, production volume, and desired metal quality. Each furnace type has its own strengths and weaknesses.

- Cupola Furnaces: These are older but still used for melting ferrous metals. They are relatively inexpensive but less precise in temperature control and produce more emissions compared to modern options.

- Induction Furnaces: These utilize electromagnetic induction to melt metal. They offer excellent temperature control and are efficient but can be more expensive than cupolas.

- Electric Arc Furnaces: These use an electric arc to melt metal, often used for large-scale operations. They are capable of handling a wide variety of metals but may consume more energy.

- Coreless Induction Furnaces: These provide precise temperature control and are ideal for high-quality castings.

Choosing the right furnace is critical and depends on the specific needs of the foundry. Factors like metal type, required production rate, budget constraints, and environmental regulations all contribute to the selection process.

Q 19. How do you manage and control the chemical composition of molten metal?

Managing and controlling the chemical composition of molten metal is paramount to produce castings with the desired properties. Impurities can significantly affect the strength, hardness, and other critical characteristics.

We achieve this using a combination of techniques. Before melting, the raw materials are carefully analyzed for composition to ensure they meet the required specifications. During melting, we use spectroscopy to monitor the composition of the molten metal in real-time. Spectrometers provide instantaneous analysis, enabling immediate adjustments if necessary. Alloying additions are precisely controlled, using pre-weighed quantities to achieve the target composition. Sampling and analysis of the molten metal before pouring is a critical final step to ensure the desired composition is achieved before casting.

We also employ computer models to simulate the melting process, predicting the final composition given the initial raw materials and alloying additions. This helps optimize the process and minimize waste.

Q 20. Describe your experience with different heat treatment processes for castings.

Heat treatment is crucial for enhancing the mechanical properties of castings, tailoring them to specific applications. The choice of heat treatment depends heavily on the casting material and its intended use.

- Annealing: This process reduces internal stresses and improves machinability.

- Normalizing: Improves homogeneity and mechanical properties.

- Hardening: Increases hardness and strength through rapid cooling.

- Tempering: Reduces brittleness in hardened steel.

- Stress Relieving: Reduces residual stresses from welding or casting processes.

My experience includes working with various heat treatment furnaces, ensuring proper temperature control and cycle times for achieving the desired properties. We meticulously document and track the heat treatment parameters for each batch of castings to ensure consistency and traceability. Understanding the metallurgical changes that occur during each heat treatment process is vital for success.

Q 21. How do you ensure compliance with environmental regulations in a foundry?

Environmental compliance is a top priority in any foundry operation. We adhere strictly to local, national, and international regulations to minimize our environmental impact.

This involves several key strategies: We employ efficient dust collection systems to capture particulate matter released during the melting and pouring processes. We monitor and control emissions of greenhouse gases and other pollutants, adhering to strict limits. Proper waste management is crucial – we recycle scrap metal and implement environmentally sound disposal methods for other wastes. Regular environmental audits are carried out to ensure continuous compliance and identify areas for improvement. We also invest in technologies that reduce energy consumption and emissions, such as energy-efficient furnaces and improved insulation. Finally, we engage in environmental awareness programs for our employees, promoting best practices and responsibility.

Working with regulatory agencies is critical for staying informed on updated regulations and ensuring we meet all compliance requirements. This includes maintaining thorough records and documentation to demonstrate our adherence to regulations.

Q 22. What is your experience with designing and implementing process control systems?

Designing and implementing process control systems in foundry operations involves a multi-faceted approach, integrating hardware and software to precisely monitor and manage critical parameters. My experience encompasses the entire lifecycle, from initial design and selection of sensors and actuators (like temperature probes, flow meters, and robotic arms) to programming Programmable Logic Controllers (PLCs) and Supervisory Control and Data Acquisition (SCADA) systems. I’ve worked with various systems, including Allen-Bradley PLC’s and Wonderware SCADA, to create real-time monitoring dashboards and automated control loops for critical processes such as pouring temperature, mold filling speed, and cooling rates. This allows for optimized production, minimized defects, and improved overall efficiency. For instance, in a previous role, I designed a system that automatically adjusted the pouring temperature based on real-time metal analysis, resulting in a 15% reduction in porosity defects.

- Sensor Selection and Placement: Careful consideration of sensor accuracy, reliability, and placement is crucial for accurate data acquisition.

- PLC Programming: Developing robust and efficient PLC programs that manage the automated control sequences is a core skill.

- SCADA System Integration: Connecting the PLCs to a SCADA system enables visualization, historical data analysis, and remote monitoring of the process.

- Data Analysis and Reporting: Generating meaningful reports that track key process parameters and identify areas for improvement.

Q 23. How do you handle unexpected process disruptions or equipment failures?

Unexpected disruptions, like equipment failures or material inconsistencies, are inevitable in foundry operations. My approach focuses on rapid response, effective troubleshooting, and preventative measures. First, I prioritize safety and contain the immediate problem. This might involve shutting down affected equipment, isolating the faulty area, or implementing emergency procedures. Next, I initiate a structured investigation using a root cause analysis methodology (like the 5 Whys or Fishbone diagrams). This helps to pinpoint the underlying cause rather than just treating symptoms. For example, if a furnace malfunction occurs, the analysis might reveal problems with aging components, improper maintenance, or operator error. Once the root cause is identified, corrective actions are implemented to prevent recurrence. This could include equipment repairs, operator retraining, or process adjustments. Finally, preventative maintenance schedules are reviewed and updated to minimize the likelihood of future incidents. I also advocate for incorporating redundancy into the system wherever feasible; having backup equipment or alternative processes can minimize downtime.

Q 24. Describe your experience with root cause analysis and problem-solving techniques.

Root cause analysis is fundamental to process optimization. I’m proficient in several techniques, including the 5 Whys, Fishbone diagrams (Ishikawa diagrams), and Fault Tree Analysis (FTA). The 5 Whys method involves repeatedly asking ‘why’ to drill down to the root cause of a problem. For instance, if castings are exhibiting excessive porosity, we might ask: Why is there porosity? (Incorrect pouring temperature). Why was the temperature incorrect? (Faulty thermocouple). Why did the thermocouple fail? (Lack of regular calibration). Fishbone diagrams provide a visual representation of potential causes categorized into different areas (e.g., materials, methods, manpower, machinery). FTA, on the other hand, focuses on identifying the possible events that could lead to a specific failure, which helps in creating a preventative plan. Combining these methods helps develop a holistic understanding and implement effective, targeted solutions. In my experience, this rigorous approach reduces repetitive problems and leads to lasting improvements.

Q 25. How familiar are you with different types of casting alloys and their properties?

My familiarity with casting alloys extends to a wide range, including aluminum, ferrous (cast iron, steel), magnesium, zinc, and copper alloys. I understand the impact of alloy composition on mechanical properties like strength, ductility, and machinability, as well as the influence on casting characteristics like fluidity, shrinkage, and susceptibility to defects. For example, I know that the addition of silicon to aluminum alloys enhances fluidity, enabling the casting of complex shapes. Conversely, higher carbon content in cast iron increases its hardness but reduces its ductility. I’m also well-versed in the specification standards (like ASTM) used to define the chemical composition and mechanical properties of these alloys. Understanding these material properties is crucial in selecting the appropriate alloy for a given application and optimizing the casting process to minimize defects.

Q 26. Explain your understanding of the solidification process in casting.

The solidification process in casting is a complex interplay of heat transfer, nucleation, and crystal growth. It begins with the molten metal entering the mold cavity. Heat is transferred from the metal to the mold, causing the metal to cool and solidify. Nucleation, the formation of the first solid crystals, is crucial; it dictates the grain structure of the final casting. The subsequent crystal growth continues until the entire casting solidifies. The cooling rate significantly impacts the microstructure and, subsequently, the mechanical properties and defect formation. Faster cooling rates result in finer grain structures, which tend to be stronger but potentially more brittle. Slower cooling rates lead to coarser grain structures, which are often tougher but may have reduced strength. Understanding the different stages – nucleation, growth, and grain refinement – is critical for controlling the microstructure and quality of the casting.

Q 27. How do you optimize the cooling rate during the casting process?

Optimizing cooling rate is essential for achieving the desired microstructure and minimizing casting defects. Several methods are employed: Mold design: Thicker mold sections provide slower cooling rates, while thinner sections promote faster cooling. Mold materials: Different materials have varying thermal conductivities; metals cool faster than sand molds. Chill design: Strategic placement of chills (metal inserts) in the mold accelerates cooling in specific regions. Cooling systems: Utilizing fans or water cooling systems can precisely control the cooling rate. Insulation: Adding insulation to the mold slows down cooling. In practice, I use thermal simulation software to predict the temperature profile during solidification, allowing me to optimize mold design and cooling parameters before actual casting. This predictive approach minimizes experimentation and saves time and resources. For example, by carefully designing a chill system for a complex aluminum casting, we improved the mechanical properties while reducing internal stress and cracking.

Q 28. Describe your experience with improving the surface finish of castings.

Improving surface finish involves addressing several factors throughout the casting process. Mold preparation: A smooth, clean mold surface is paramount. This may involve using mold coatings, improving mold-making techniques, or employing specialized mold materials. Pouring techniques: Controlled pouring reduces turbulence and minimizes surface defects. Gating and risering design: Proper design minimizes turbulence and air entrapment. Post-processing: Techniques like shot blasting, tumbling, or vibratory finishing can significantly improve surface roughness. In addition to these methods, chemical treatments such as etching or anodizing can be applied for specialized finishes or increased corrosion resistance. In my experience, a systematic approach, combining improvements to mold preparation, controlled pouring, and strategic post-processing techniques, delivers the best results. For example, implementing a new mold coating in a zinc die casting process resulted in a significant reduction in surface porosity and a smoother surface finish, leading to increased customer satisfaction and reduced rework.

Key Topics to Learn for Foundry Process Optimization Interview

- Process Mapping and Value Stream Mapping: Understanding and analyzing current foundry processes to identify bottlenecks and areas for improvement. Practical application includes using Lean methodologies to optimize material flow and reduce waste.

- Statistical Process Control (SPC): Implementing and interpreting control charts to monitor process stability and identify potential sources of variation. This includes understanding capability analysis and process improvement techniques like Six Sigma.

- Melting and Pouring Optimization: Analyzing factors influencing metal quality, yield, and energy efficiency during the melting and pouring stages. Practical application includes optimizing furnace parameters and pouring techniques to minimize defects.

- Casting Defects and Root Cause Analysis: Identifying common casting defects (porosity, inclusions, etc.) and employing root cause analysis techniques (e.g., 5 Whys, Fishbone diagrams) to address their underlying causes.

- Automation and Robotics in Foundry Processes: Understanding the application of automation technologies to improve efficiency, safety, and consistency in various foundry operations. This includes familiarity with robotic casting systems and automated inspection methods.

- Data Analytics and Predictive Modeling: Utilizing data analytics to identify trends, predict potential issues, and optimize process parameters. This includes experience with relevant software and data interpretation skills.

- Sustainability and Environmental Considerations: Understanding environmental regulations and implementing sustainable practices within foundry operations to minimize waste and emissions.

- Safety and Risk Management: Implementing safety protocols and risk assessments to ensure a safe working environment and minimize workplace accidents within foundry settings.

Next Steps

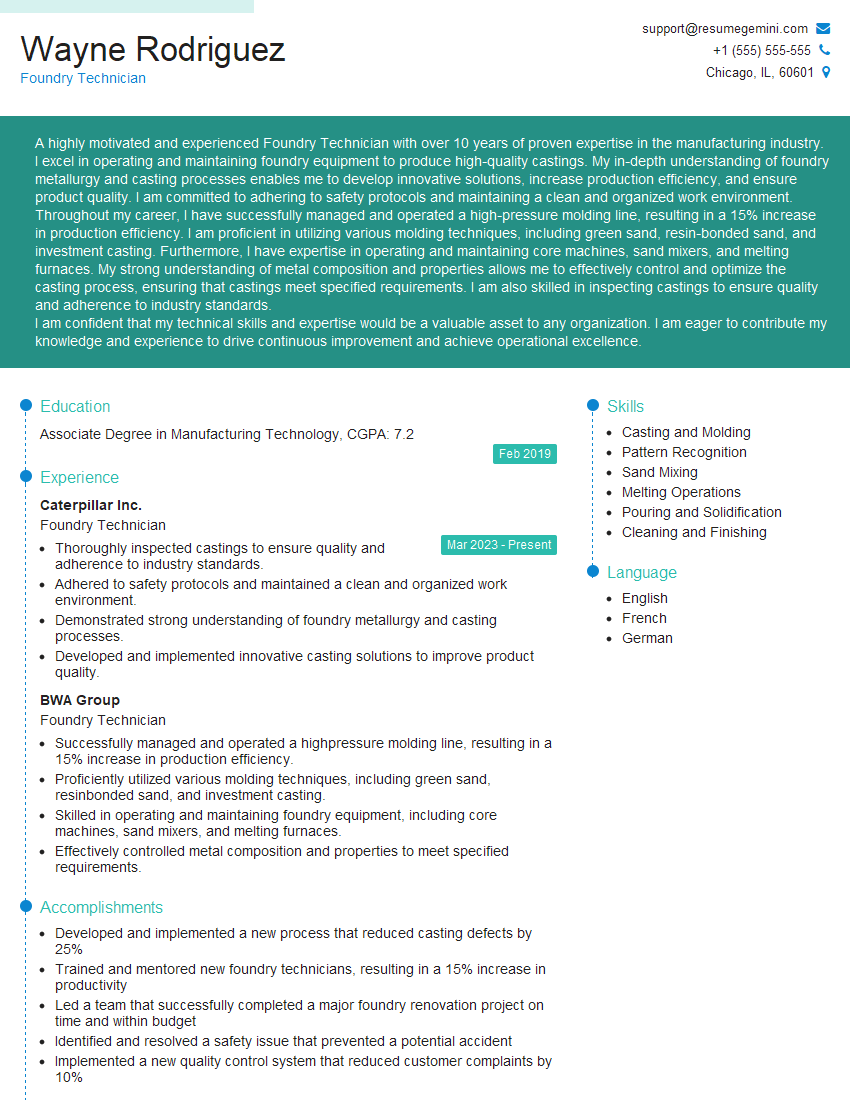

Mastering Foundry Process Optimization is crucial for career advancement in the manufacturing sector, opening doors to leadership roles and higher earning potential. A well-crafted resume is your key to unlocking these opportunities. An ATS-friendly resume, optimized for applicant tracking systems, significantly increases your chances of getting your application noticed. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to the specific requirements of Foundry Process Optimization roles. Examples of resumes optimized for this field are available to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good