Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Furnace Loading and Unloading interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Furnace Loading and Unloading Interview

Q 1. Describe the safety procedures you follow when loading a furnace.

Safety is paramount when loading a furnace. My procedure always begins with a thorough risk assessment specific to the materials being loaded and the furnace type. This involves checking the Material Safety Data Sheets (MSDS) for any hazards like flammability, toxicity, or reactivity. I always wear appropriate Personal Protective Equipment (PPE), including heat-resistant gloves, safety glasses, and a full-face respirator if necessary. The furnace area needs to be clear of obstructions to prevent accidents. Before loading, I visually inspect the furnace and the loading mechanism for any damage or defects. I follow a step-by-step loading sequence, ensuring that materials are loaded carefully and evenly to prevent overloading or instability, thereby avoiding collapses or spills. For instance, when loading heavy pieces, I use appropriate lifting equipment and follow safe lifting techniques to prevent back injuries. Regular communication with the furnace operator is crucial throughout the loading process to coordinate and ensure a safe operation.

Q 2. Explain the different types of furnace loading methods you are familiar with.

Several methods exist for loading furnaces, each with its advantages and disadvantages depending on the furnace type, material properties, and production requirements. I’m familiar with:

- Manual Loading: This involves manually placing materials into the furnace, typically using tongs, shovels, or other hand tools. This is suitable for smaller furnaces and lower throughput operations but is labor-intensive and prone to human error.

- Automated Loading: This utilizes robotic arms or conveyor systems to load materials efficiently and consistently. It’s ideal for high-volume production, enhancing speed, accuracy, and safety by minimizing human interaction with hot surfaces.

- Batch Loading: The entire charge is loaded at once. This is commonly used for heat treatments where uniform heating is crucial.

- Continuous Loading: Materials are fed continuously into the furnace. This is typical in processes like sintering or annealing where a constant flow of material is required.

- Layer Loading: Materials are loaded in layers to ensure even heating and prevent voids. For example, in a sintering furnace, the careful arrangement of powder ensures a consistent density throughout the finished product.

The choice of method is critically determined by factors like the material’s size, shape, fragility, and temperature sensitivity.

Q 3. How do you ensure the correct placement of materials within the furnace?

Accurate placement is vital for consistent heating and optimal process results. My approach uses a combination of visual inspection, pre-planned loading sequences based on material properties and furnace geometry, and sometimes specialized loading fixtures. For instance, if loading delicate components, I may use custom trays or supports to ensure proper positioning and prevent damage during heating. Using jigs or templates provides a consistent pattern, particularly when handling repetitive loading. In batch furnaces, visual confirmation is essential to ensure the charge is evenly distributed to minimize temperature gradients. In continuous furnaces, the feeding mechanism itself dictates the placement, requiring regular checks to ensure smooth and uninterrupted material flow. This meticulous approach prevents uneven heating, which can lead to product defects.

Q 4. What are the potential hazards associated with furnace loading and unloading?

Furnace loading and unloading present several hazards:

- Burns: Contact with hot surfaces, materials, or gases is a major risk.

- Inhalation Hazards: Exposure to toxic fumes or dust generated from the heating process.

- Material Handling Injuries: Lifting heavy materials incorrectly can cause back injuries or strains.

- Mechanical Hazards: Moving parts of the furnace or loading equipment can cause crushing or cutting injuries.

- Thermal Shock: Rapid temperature changes can cause material breakage or cracking.

- Fire Hazards: Flammable materials can ignite if not handled properly.

These hazards are mitigated through rigorous adherence to safety protocols, including using proper PPE, following established procedures, regular equipment inspections and maintenance, and thorough worker training.

Q 5. How do you identify and handle damaged or defective materials?

Identifying and handling damaged or defective materials is a critical step to prevent process failures and ensure product quality. My process involves a visual inspection of each material before loading. Damaged or defective items are clearly marked, segregated, and removed from the loading area. Detailed documentation is kept to trace the source of the defects and prevent recurrence. For instance, cracked components might be rejected and sent for scrap. If there’s a possibility of repair, they are processed separately according to established procedures. In some cases, specific testing might be required to determine the extent of damage. This careful scrutiny safeguards against introducing defects that could ruin an entire batch or cause furnace damage.

Q 6. Explain the process of unloading a furnace after a heating cycle.

Unloading a furnace after the heating cycle requires careful consideration of safety and efficiency. First, I verify that the furnace has cooled down to a safe temperature. The specific cooling time varies significantly based on the furnace type and the materials processed. I then use appropriate unloading methods, which may include manual removal using suitable tools (like tongs or specialized gripping mechanisms), automated unloading systems (robots or conveyors), or a combination of both. I always wear appropriate PPE during unloading. The unloaded materials are inspected to assess the success of the heating cycle. Any issues like discoloration, cracking, or distortion are noted and investigated. The careful handling and inspection of unloaded materials prevents damage and ensures that the process was successful.

Q 7. What are the key indicators that a furnace requires maintenance or repair?

Several key indicators signal the need for furnace maintenance or repair:

- Inconsistent Temperatures: Variations in temperature readings throughout the furnace indicate potential issues with heating elements, insulation, or control systems.

- Increased Energy Consumption: Higher-than-usual energy consumption could mean compromised insulation or inefficiencies in the heating system.

- Unusual Noises: Rattling, grinding, or other unusual sounds might suggest mechanical problems requiring attention.

- Leaks: Gas leaks or other leaks can indicate serious safety hazards.

- Reduced Productivity: Longer cycle times or lower throughput are often signs of deteriorating furnace components.

- Safety Interlock Failures: If any safety mechanisms fail, immediate attention is necessary.

Regular preventative maintenance schedules help detect potential issues before they escalate into major problems. A proactive approach to maintenance significantly reduces downtime and ensures optimal furnace performance and safety.

Q 8. How do you maintain a clean and organized work area around the furnace?

Maintaining a clean and organized work area around a furnace is paramount for safety, efficiency, and preventing equipment damage. Think of it like a surgeon’s operating room – meticulous cleanliness is essential.

- Regular sweeping and cleaning: This removes debris that could cause slips, trips, or falls, and prevents contamination of materials. I always make sure to sweep around the furnace base and remove any spilled materials immediately.

- Proper storage of materials: Raw materials and finished products should be stored in designated areas, away from the furnace, to avoid accidental contamination or damage. We use clearly labeled bins and racks to maintain order.

- Designated waste disposal: Each furnace type has specific waste disposal needs. For example, some require specialized containers for hazardous materials. Following safety protocols meticulously is my priority.

- Preventative maintenance: A regularly scheduled cleaning of the furnace itself (following manufacturer guidelines) is crucial to optimize performance and prevent buildup that could create safety hazards. This might include cleaning exhaust vents and inspecting for leaks.

In one instance, maintaining a clean workspace prevented a serious accident. A coworker almost tripped on some spilled refractory material, highlighting the crucial role of cleanliness in safety.

Q 9. What are your experience with different types of furnaces (e.g., batch, continuous)?

My experience encompasses both batch and continuous furnaces, each with unique loading and unloading procedures. Batch furnaces are like ovens – you load them, process the materials, and then unload the finished product. Continuous furnaces, on the other hand, are more like assembly lines, with a constant flow of materials in and out.

- Batch Furnaces: I’ve worked extensively with various sizes of batch furnaces, including those used in heat treating and ceramic firing. The loading process involves carefully arranging materials to ensure even heating and efficient space utilization. Unloading requires using appropriate tools to avoid damage to the finished goods, considering the high temperatures involved.

- Continuous Furnaces: My experience includes working with conveyor belt systems and automated loading mechanisms for continuous furnaces. These require a different skill set, focused on monitoring the consistent flow of materials and addressing any jams or blockages. Maintaining the correct feed rate is crucial for product quality.

The key difference lies in the rhythm of the work. Batch furnaces require concentrated bursts of activity during loading and unloading, whereas continuous furnaces demand consistent attention to ensure a smooth, uninterrupted process.

Q 10. Describe your experience with specific materials and their handling requirements.

I’ve handled a wide range of materials with varying handling requirements, emphasizing safety and preventing contamination.

- Metals: Working with metals like steel and aluminum requires careful handling to prevent scratching or deformation. Specific tools and techniques are used based on the metal’s properties and the desired outcome.

- Ceramics: Ceramics are fragile and require gentle handling to avoid breakage. Specialized loading techniques are employed to ensure even heating and prevent cracking during the process.

- Powdered Materials: Handling powdered materials such as metal powders demands extra caution. Special precautions are taken to prevent inhalation of dust and ensure proper ventilation during loading and unloading. This involves using appropriate personal protective equipment (PPE).

For example, when handling titanium, which is highly reactive at elevated temperatures, I employ specialized techniques to minimize the risk of oxidation and maintain material integrity. Each material presents its unique challenges, requiring adaptable and safety-conscious practices.

Q 11. How do you handle emergency situations during furnace operation?

Emergency situations require quick thinking and decisive action. My training emphasizes safety protocols and immediate responses to potential hazards.

- Fire: In case of fire, I’m trained to immediately shut down the furnace, activate the fire alarm, and evacuate the area, following the established emergency procedures. Knowing the location of fire extinguishers and how to use them is also critical.

- Equipment Malfunction: If equipment malfunctions, I follow the safety protocols specific to that furnace and immediately report the issue to my supervisor. This might involve turning off the power supply, isolating the malfunctioning component, or securing the area until the problem is resolved.

- Material Spill: If a material spills, I carefully assess the situation, put on appropriate safety gear (if needed), contain the spill, and clean it up accordingly. Hazardous spills require extra precautions and reporting to relevant authorities.

For example, during one incident involving a malfunctioning thermocouple, my immediate response to isolate the affected section of the furnace and report it prevented a larger breakdown and potential damage.

Q 12. What are the temperature ranges you have worked with in furnaces?

My experience spans a wide range of furnace temperatures, from relatively low temperatures used in annealing processes (e.g., 300-500°C) to extremely high temperatures in sintering processes (e.g., 1200-1600°C). The specific temperature range is determined by the material being processed and the desired outcome.

Working with these extreme temperatures requires specialized equipment and safety procedures. Personal protective equipment (PPE), like heat-resistant gloves and clothing, is essential at high temperatures. Precise temperature control is crucial to achieve the desired results and prevent damage to the materials.

Q 13. What is your understanding of different furnace atmospheres (e.g., oxidizing, reducing)?

Understanding furnace atmospheres is crucial because the atmosphere directly impacts the material’s properties during the process. Think of it as the environment in which the materials are ‘cooked’.

- Oxidizing Atmosphere: An oxidizing atmosphere, typically rich in oxygen, promotes oxidation of the material. This can be beneficial in some cases, such as creating protective oxide layers on metals, but detrimental in others, causing undesirable changes in material properties.

- Reducing Atmosphere: A reducing atmosphere, low in oxygen and often containing reducing gases like hydrogen or carbon monoxide, prevents oxidation and may even reduce existing oxides. This is frequently used in heat treating to prevent scaling and improve material properties.

- Inert Atmosphere: An inert atmosphere, such as argon or nitrogen, prevents any reaction with the material, useful when protecting materials susceptible to oxidation or other reactions.

For example, in the heat treatment of steel, a controlled atmosphere furnace might be used to achieve specific properties. Using a reducing atmosphere prevents the formation of scale and allows for precise control of carbon content.

Q 14. How do you monitor the temperature and pressure within the furnace?

Monitoring temperature and pressure within the furnace is essential to maintain consistent quality and prevent accidents. This is done using a variety of sensors and monitoring systems, both manual and automated.

- Temperature Monitoring: Thermocouples and pyrometers are commonly used to measure the temperature within the furnace. These sensors are strategically placed to provide accurate readings throughout the heating chamber. Automated systems continuously record and display the temperature, providing real-time data.

- Pressure Monitoring: Pressure sensors measure the pressure inside the furnace, particularly important when using controlled atmospheres. This ensures the correct gas flow and prevents leaks or pressure build-up that could damage the equipment or pose safety risks.

- Data Logging: Modern furnaces often have sophisticated data logging systems, recording temperature and pressure changes over time. This data is crucial for process optimization, troubleshooting, and quality control.

Any deviation from the set parameters triggers alarms, allowing for timely intervention and prevention of material damage or other issues. Continuous monitoring is key to smooth and safe operations.

Q 15. Explain the importance of maintaining consistent loading and unloading procedures.

Consistent loading and unloading procedures are paramount for safety, efficiency, and product quality in furnace operations. Inconsistent practices lead to increased risk of accidents, damage to materials, and variations in the final product. Think of it like baking a cake – if you don’t follow the recipe consistently, the result will vary.

- Safety: Standardized procedures minimize the chance of human error, reducing the risk of burns, injuries from dropped materials, or equipment malfunctions.

- Efficiency: A well-defined process streamlines workflows, reducing downtime and maximizing throughput. Everyone knows their role and how to perform it safely and quickly.

- Product Quality: Consistent loading ensures uniform heating and cooling, resulting in a more predictable and higher-quality end product. Variations in loading can cause inconsistencies in the final product’s properties.

For example, a consistent procedure might dictate the specific placement of materials within the furnace to ensure even heat distribution, avoiding hotspots or cold spots that can degrade product quality. This also includes specific steps for securing loads to prevent shifting during operation.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure the proper documentation of furnace operations?

Proper documentation is crucial for traceability, compliance, and continuous improvement in furnace operations. We use a combination of digital and paper-based systems to ensure complete and accurate records.

- Logbooks: Detailed logbooks record each furnace cycle, including date, time, materials loaded, temperature profiles, cycle duration, and any observed anomalies. These provide a chronological record of furnace operations.

- Computerized Systems: Modern furnaces are often integrated with computerized control systems that automatically log key operational parameters. This data is then stored digitally, allowing for easy retrieval and analysis.

- Maintenance Records: We meticulously document all maintenance activities, including inspections, repairs, and calibrations. This ensures that equipment remains in optimal working condition and enhances safety.

- Material Tracking: We track the origin, quantity, and quality of all materials entering and leaving the furnace. This ensures accountability and helps identify potential sources of problems if defects occur.

These records are essential for audits, troubleshooting, and demonstrating compliance with safety and quality standards. In the event of a quality issue, we can trace the process back to pinpoint exactly what went wrong.

Q 17. What are your skills in using forklift and other material handling equipment?

I am highly proficient in operating various material handling equipment, including forklifts, overhead cranes, and pallet jacks. I possess all the necessary certifications and have extensive hands-on experience in safe and efficient material handling within a furnace environment.

- Forklift Operation: I am certified to operate forklifts in various capacities and am experienced in safely navigating confined spaces, loading and unloading furnaces, and stacking materials.

- Overhead Crane Operation: I am skilled in operating overhead cranes for lifting and positioning heavy loads into the furnace, ensuring precision and safety.

- Pallet Jack Operation: I am proficient in using pallet jacks for moving smaller loads efficiently and safely within the furnace area.

- Safety Procedures: I am intimately familiar with and strictly adhere to all safety regulations regarding the operation of these machines, including pre-operational checks and load securing techniques.

My experience ensures that materials are handled with precision and care, minimizing the risk of damage to both the materials and the equipment.

Q 18. Describe your experience with computerized furnace control systems.

I have extensive experience with computerized furnace control systems, including programming, monitoring, and troubleshooting. My expertise spans various systems, from simple programmable logic controllers (PLCs) to sophisticated supervisory control and data acquisition (SCADA) systems.

- Programming: I can program PLCs to control furnace parameters such as temperature, atmosphere, and cycle timing. I’m familiar with ladder logic and other programming languages used in industrial automation.

- Monitoring: I am adept at monitoring real-time data from the control system, identifying potential issues before they escalate into major problems. This often involves interpreting graphical displays and sensor data.

- Troubleshooting: I am skilled in diagnosing and resolving issues related to the control system, ranging from minor software glitches to hardware malfunctions. I approach troubleshooting systematically, employing a logical process of elimination.

- Data Analysis: I can analyze data from the control system to identify trends, optimize furnace performance, and improve overall efficiency.

For example, I once used historical data from a SCADA system to identify a pattern of temperature fluctuations that was leading to inconsistent product quality. By analyzing the data and making adjustments to the control program, I was able to significantly improve consistency and reduce waste.

Q 19. How do you troubleshoot common problems encountered during furnace loading and unloading?

Troubleshooting is a key aspect of furnace loading and unloading. I employ a systematic approach to identify and resolve common problems.

- Identify the Problem: Begin by clearly defining the issue. Is it a loading problem, an unloading problem, or a problem with the furnace itself?

- Gather Information: Collect relevant data, such as error messages, operational logs, temperature readings, and visual observations.

- Check Safety: Prioritize safety. If the problem involves a potential hazard, shut down the furnace and address the safety issue before proceeding.

- Systematic Troubleshooting: Proceed through a systematic process, checking the most likely causes first. For example, if materials are not heating evenly, check for blockages in the air flow or inconsistencies in loading.

- Document Actions: Meticulously document all troubleshooting steps, including the problem, the actions taken, and the results. This helps prevent the same issue from recurring.

For example, if a material is sticking to the furnace lining, I might investigate the cause by checking the material properties, furnace temperature profile, or the presence of any contaminants.

Q 20. What is your understanding of OSHA regulations related to furnace operation?

I possess a thorough understanding of OSHA (Occupational Safety and Health Administration) regulations concerning furnace operation. My knowledge encompasses all relevant standards, including those pertaining to lockout/tagout procedures, personal protective equipment (PPE), confined space entry, and hazard communication.

- Lockout/Tagout: I am proficient in implementing and following lockout/tagout procedures to ensure that equipment is safely shut down before maintenance or repairs.

- PPE: I always wear appropriate PPE, including heat-resistant gloves, safety glasses, and protective clothing, to minimize the risk of burns, eye injuries, or other hazards.

- Confined Space Entry: I understand the procedures for safely entering and working in confined spaces associated with furnace maintenance or repairs. This includes proper ventilation, atmospheric monitoring, and the use of safety harnesses and other equipment.

- Hazard Communication: I am familiar with hazard communication standards and can identify, assess, and communicate the risks associated with furnace operation.

Safety is my utmost priority. I adhere strictly to all OSHA regulations and ensure that all team members are aware of and comply with these standards.

Q 21. How do you prioritize tasks during periods of high workload in the furnace area?

During periods of high workload, I prioritize tasks using a combination of urgency and importance. I use a system based on urgency and impact.

- Urgent and Important: Tasks that are both urgent and have a significant impact on production or safety are prioritized first. These might include addressing a malfunctioning furnace or fulfilling a critical order.

- Important but Not Urgent: Tasks that are important but not immediately time-sensitive are scheduled for later. These could include preventative maintenance or planning for future operations.

- Urgent but Not Important: Tasks that are urgent but have a low impact are delegated or handled efficiently. This might involve responding to a minor equipment issue.

- Neither Urgent Nor Important: Tasks that fall into this category are postponed until there is more capacity.

I communicate clearly with my team about priorities and ensure that everyone understands their roles. This prevents bottlenecks and ensures efficient workflow even under pressure. Effective communication and teamwork are crucial for handling high-volume periods.

Q 22. Describe your experience with quality control measures in furnace operations.

Quality control in furnace operations is paramount to ensuring consistent product quality and minimizing defects. It’s a multi-faceted process that starts before the material even enters the furnace and continues until it’s safely stored after processing. My experience involves meticulous attention to detail at every stage.

- Pre-loading Inspection: Before loading, we rigorously inspect materials for size, uniformity, and any signs of damage. This prevents introducing defects that could propagate during heating. For instance, if we’re working with metal sheets, we carefully check for scratches, dents, or inconsistencies in thickness that might lead to uneven heating and warping.

- Loading Optimization: Proper loading maximizes furnace utilization and minimizes temperature variations across the batch. We use specific loading patterns—sometimes employing specialized software for complex shapes—to ensure even heat distribution, leading to consistent processing. For example, in a batch furnace, we carefully arrange parts to avoid hot spots or cold spots, ensuring all materials receive the required heat treatment.

- In-process Monitoring: During the heating cycle, we continuously monitor temperature, pressure, and other parameters to ensure they remain within the specified range. Deviations are immediately addressed to prevent defects. Real-time data logging and alarms help in swift identification and correction of issues.

- Post-processing Inspection: After unloading, we conduct another inspection to verify that the materials meet the required specifications, such as dimensions, hardness, or microstructure. This often involves non-destructive testing (NDT) methods like ultrasonic testing or X-ray inspection.

- Data Analysis and Improvement: We maintain detailed records of all operations, including loading configurations, process parameters, and quality control results. We use this data to identify areas for improvement, optimize processes, and reduce defects.

Through this comprehensive approach, we ensure high-quality products and minimal waste, leading to greater efficiency and customer satisfaction.

Q 23. How do you prevent damage to materials during loading and unloading?

Preventing damage during loading and unloading requires a combination of careful planning, appropriate equipment, and skilled operators. The goal is to minimize stress on the materials throughout the entire process.

- Protective Packaging: Fragile materials are carefully packaged using appropriate materials like cushioning, pallets, and containers to absorb shocks and vibrations during transport and handling.

- Proper Lifting Techniques: We utilize appropriate lifting equipment, such as cranes, forklifts, or robotic arms, ensuring proper load distribution and careful handling. Operators are trained on safe lifting procedures to avoid dropping or damaging materials.

- Specialized Handling Tools: For delicate parts, specialized handling tools, such as vacuum lifters or magnetic grippers, are used to prevent scratches or deformation.

- Slow and Controlled Movements: Rapid movements can damage materials. We use slow and controlled movements during loading and unloading, especially when dealing with fragile or delicate items. This is crucial for minimizing impact forces.

- Surface Protection: When necessary, we apply protective coatings or films to the materials to protect them from scratches or abrasion during handling. This is particularly important for materials with sensitive surface finishes.

By employing these techniques, we ensure the materials reach the furnace and storage areas in optimal condition, minimizing damage and reducing waste.

Q 24. Explain your experience with different types of furnace loading equipment.

My experience encompasses a wide range of furnace loading equipment, each suited for specific applications and material types.

- Manual Loading: This involves manual placement of materials into the furnace, typically suitable for small-scale operations or unique piece parts. While less efficient, it allows for precise placement when automated systems aren’t feasible.

- Automated Guided Vehicles (AGVs): AGVs are used for transporting materials from storage to the furnace. These systems enhance efficiency and reduce the risk of human error, especially when dealing with large and heavy loads.

- Robotic Loaders: Robotic systems offer precise and repeatable loading patterns, maximizing furnace utilization and ensuring consistent product quality. These are often programmed for specific parts and orientations, optimizing space and heat distribution.

- Conveyor Systems: Conveyor systems are commonly used for continuous processing furnaces, transferring materials smoothly and efficiently from loading to unloading points. These systems can handle high volumes and are ideal for mass production.

- Charging Machines: For larger furnaces, charging machines are used to load and unload bulk materials, such as metal scrap or powders. These machines are designed for high throughput and can manage large quantities efficiently.

My expertise lies in selecting and operating the most suitable equipment based on the specific requirements of each project, balancing factors like material properties, production volume, and budgetary constraints.

Q 25. How do you ensure the safe and efficient transfer of materials from furnace to storage?

Safe and efficient transfer from furnace to storage is crucial for maintaining product integrity and worker safety. This involves a coordinated approach incorporating several elements.

- Cooling Procedures: Materials often require controlled cooling after processing to avoid thermal shock and warping. We follow specific cooling protocols, sometimes using controlled cooling chambers or specialized equipment to manage this crucial step. Rushing the cooling process can lead to material failure.

- Unloading Techniques: Appropriate unloading techniques, similar to the loading process, ensure the materials are handled carefully to prevent damage. This might involve using specialized tools or equipment to gently extract materials from the furnace.

- Material Handling Equipment: We use appropriate material handling equipment like conveyors, robotic arms, or forklifts to move materials from the furnace to the storage area, minimizing manual handling and reducing the risk of injury or damage.

- Storage Organization: The storage area must be organized efficiently to ensure easy retrieval and prevent damage to stored materials. Proper stacking methods and use of racking systems are essential to prevent collapsing or damaging materials. This also facilitates inventory management.

- Safety Protocols: Stringent safety protocols are followed during transfer, including wearing appropriate personal protective equipment (PPE) such as heat-resistant gloves and safety glasses. Strict adherence to safety rules minimizes the risks to workers.

By integrating these considerations, we ensure that the materials reach storage in pristine condition while maintaining a safe working environment.

Q 26. What measures do you take to minimize material waste and energy consumption?

Minimizing material waste and energy consumption is a continuous focus in furnace operations. We achieve this through various strategies.

- Precise Loading and Unloading: Efficient loading techniques maximize furnace space utilization, minimizing the need for multiple batches and reducing energy consumption. Precise unloading prevents unnecessary damage and waste.

- Optimized Heating Cycles: Sophisticated temperature control systems allow us to tailor heating cycles to the specific requirements of the materials, minimizing energy waste. This involves detailed process simulations to find the optimal heating profiles.

- Regular Maintenance: Regular maintenance of the furnace and its equipment ensures optimal performance and minimizes energy losses due to inefficiencies or breakdowns. This includes regular inspection and prompt repairs.

- Material Selection: Careful material selection plays a vital role in reducing waste. Choosing materials with appropriate properties minimizes the risk of defects and rejects. This also minimizes the need for rework.

- Recycling and Waste Management: We implement robust waste management programs to recycle scrap materials or byproducts whenever possible. This reduces landfill waste and contributes to environmental sustainability. This includes separation and sorting of different waste streams.

By implementing these measures, we create a leaner, more efficient operation, reducing both operational costs and environmental impact.

Q 27. Describe your experience working in a team environment within a furnace operation setting.

Working in a team environment within a furnace operation is critical for efficient and safe operations. Teamwork involves clear communication, mutual respect, and shared responsibility.

- Clear Roles and Responsibilities: We have clearly defined roles for each team member. This ensures everyone understands their responsibilities, minimizing confusion and maximizing efficiency. For example, one team member might focus on loading while another monitors temperature and pressure.

- Effective Communication: Open and transparent communication is crucial. We use regular briefings, shift handovers, and real-time communication systems to keep everyone informed about the process and any potential issues. This prevents delays and reduces risks.

- Collaborative Problem-Solving: When challenges arise, we work collaboratively to find solutions. Sharing experience and expertise is encouraged, and every team member contributes to finding the best approach. This fosters a culture of continuous improvement.

- Safety as a Shared Responsibility: Safety is a shared responsibility. Everyone is responsible for ensuring a safe working environment for themselves and their colleagues. Regular safety training and discussions are crucial in reinforcing this shared responsibility.

- Mutual Respect and Support: We foster a respectful and supportive environment where team members are encouraged to help each other and share their knowledge. This leads to a more positive and productive work environment, boosting team morale.

Through these strategies, we’ve built a high-performing team capable of handling the complex and demanding tasks associated with furnace operations, resulting in superior productivity and safety.

Key Topics to Learn for Furnace Loading and Unloading Interview

- Safety Procedures and Regulations: Understanding and adhering to all safety protocols, including PPE requirements, lockout/tagout procedures, and emergency response plans. Practical application: Describe your experience implementing and maintaining a safe work environment during furnace operations.

- Furnace Operation and Maintenance: Knowledge of furnace types, temperature control mechanisms, and basic maintenance tasks. Practical application: Explain how you’ve monitored furnace performance and addressed minor issues to maintain optimal operation.

- Material Handling Techniques: Safe and efficient methods for loading and unloading materials, including understanding material properties and potential hazards. Practical application: Describe your experience with different loading and unloading equipment and techniques, emphasizing efficiency and safety.

- Quality Control and Inspection: Methods for inspecting materials before and after processing to ensure quality and identify potential defects. Practical application: Explain your process for ensuring the quality of loaded materials and identifying any issues that might impact the furnace operation.

- Troubleshooting and Problem-Solving: Identifying and resolving common issues related to furnace loading, unloading, and operation. Practical application: Describe a situation where you successfully identified and resolved a problem related to furnace operations.

- Record Keeping and Documentation: Maintaining accurate records of furnace operations, materials handled, and any maintenance performed. Practical application: Explain your experience with documenting furnace operations and maintaining detailed records.

- Teamwork and Communication: Effective collaboration with colleagues to ensure smooth and efficient furnace operations. Practical application: Describe your experience working as part of a team in a fast-paced industrial environment.

Next Steps

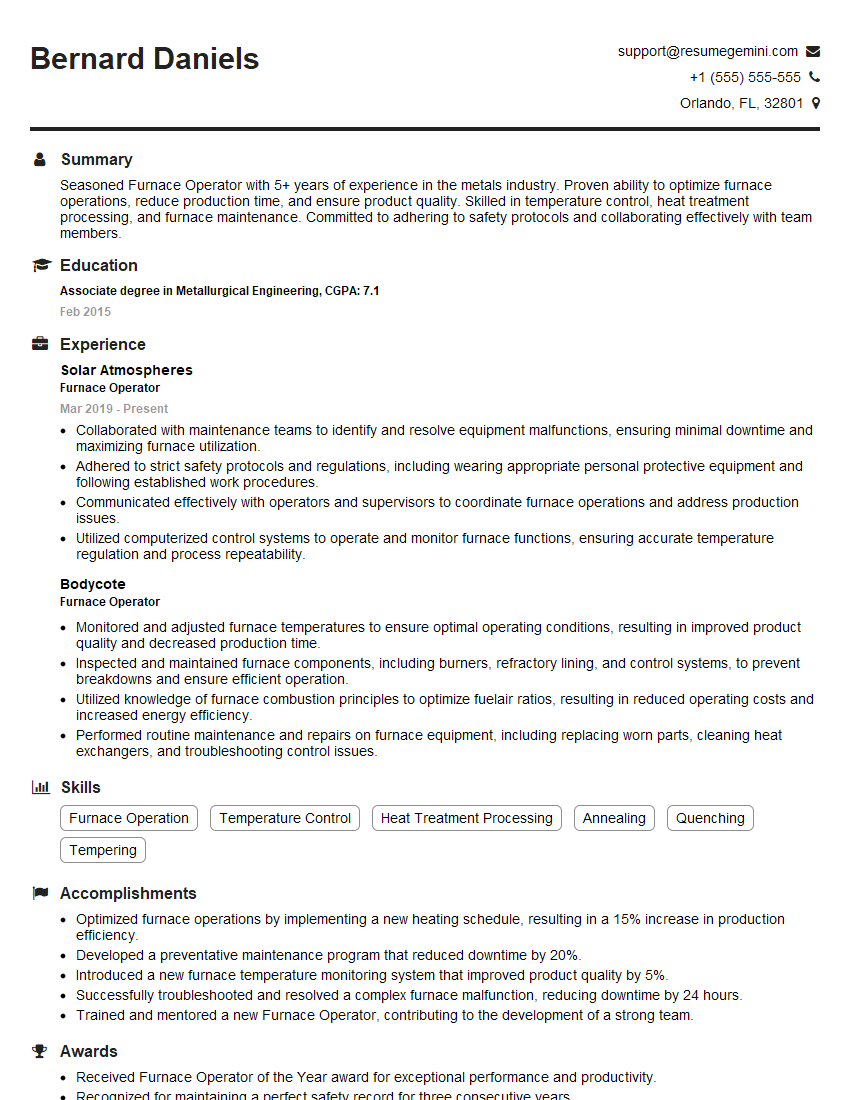

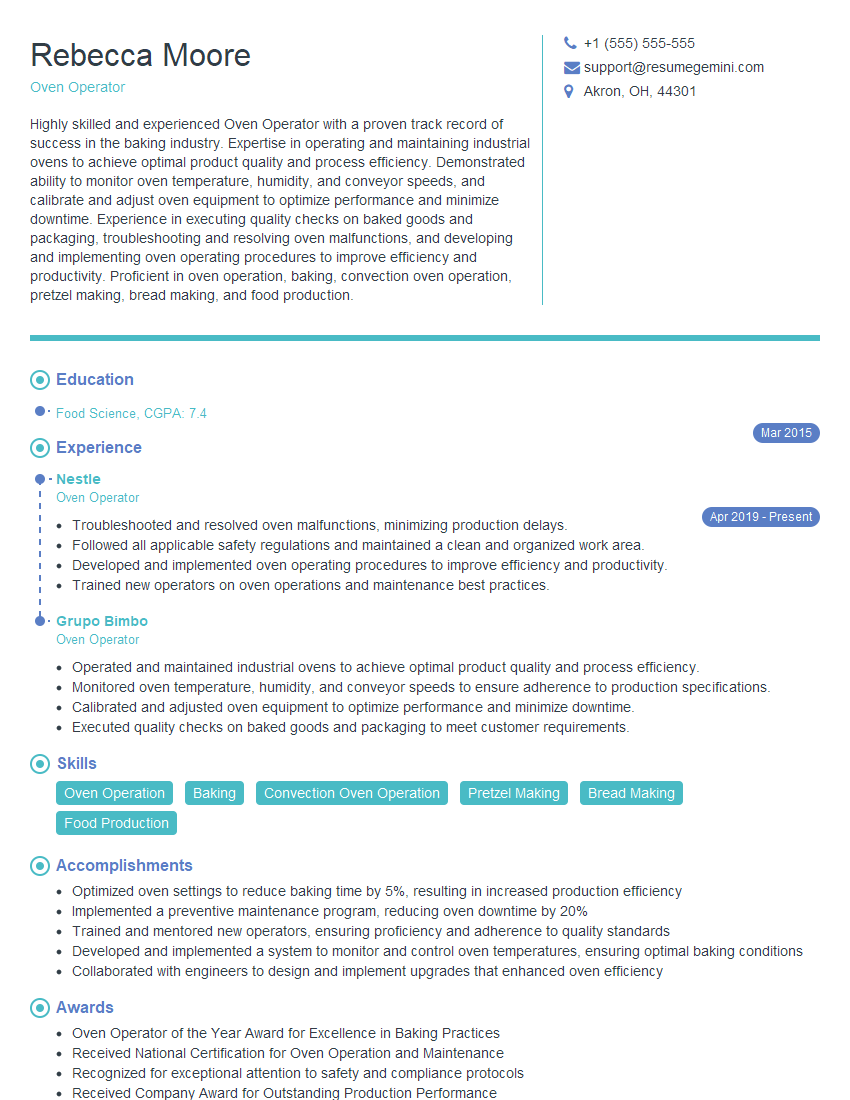

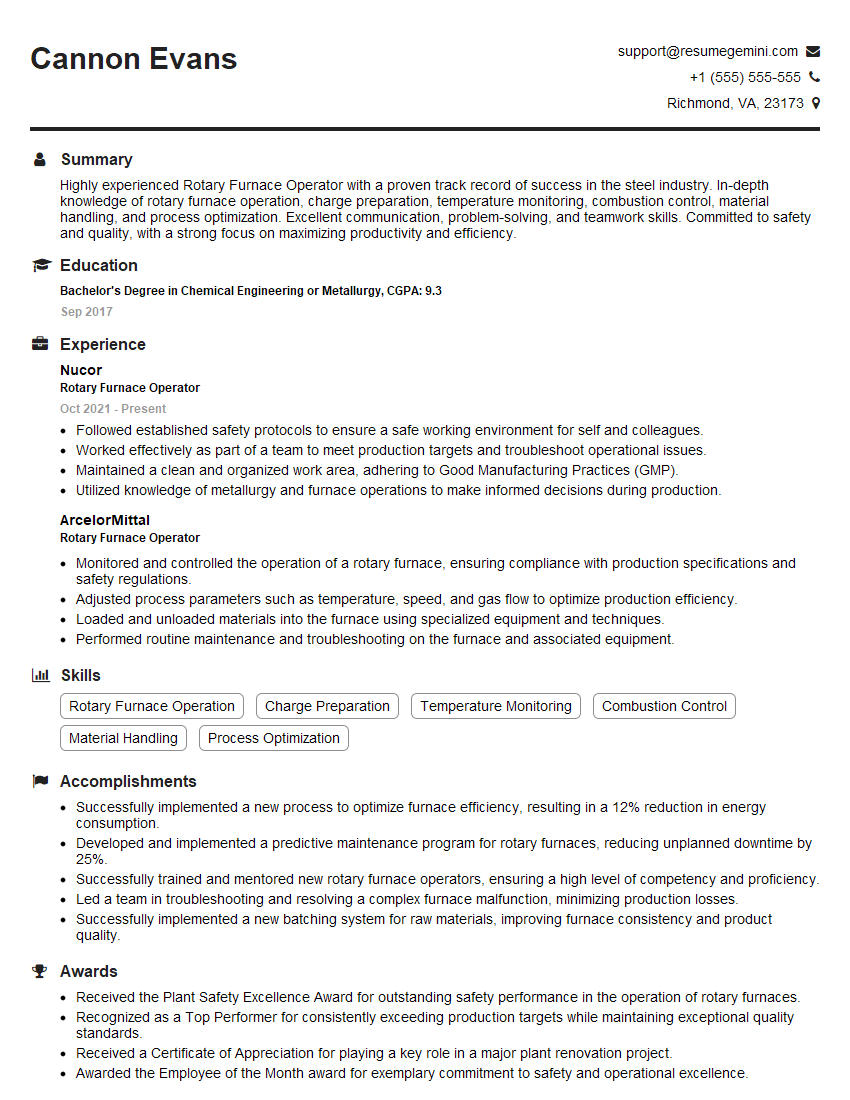

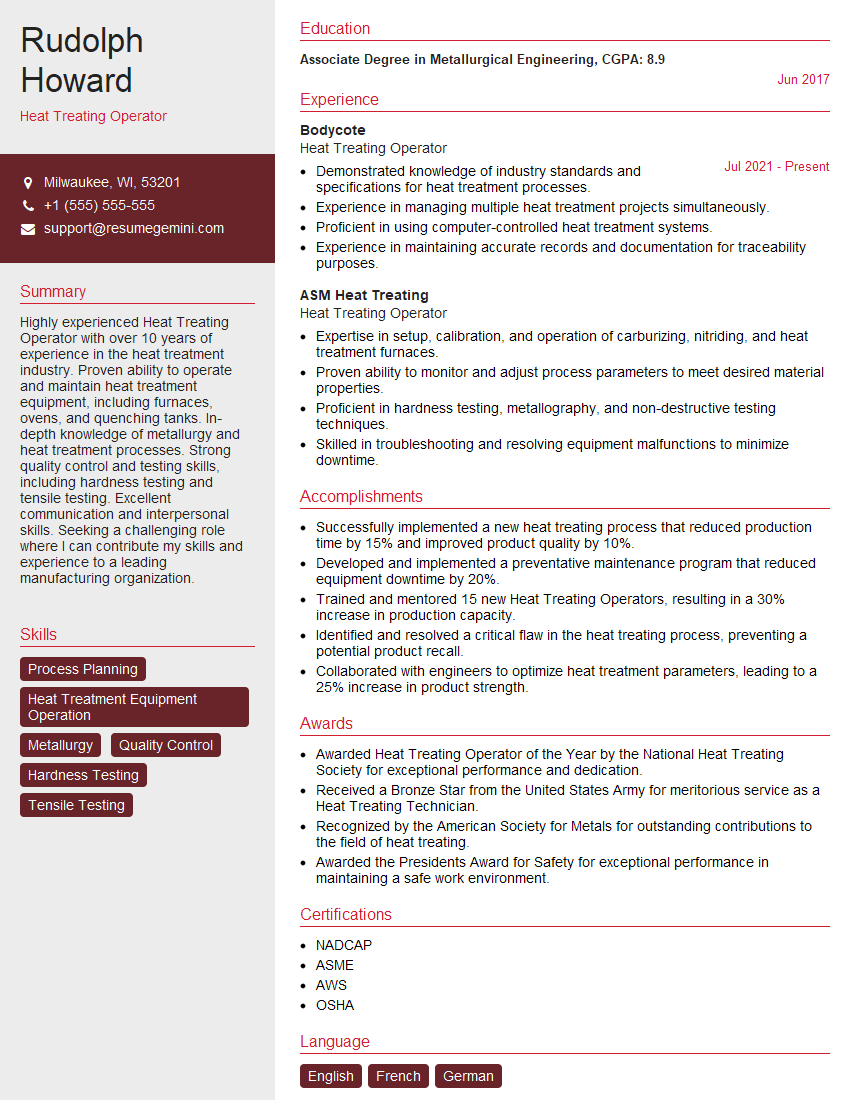

Mastering Furnace Loading and Unloading opens doors to a rewarding career with excellent growth potential in various industries. A strong understanding of these processes is highly valued by employers. To maximize your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. We offer examples of resumes tailored to Furnace Loading and Unloading positions to guide you in crafting your own compelling application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good