Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Hands-on experience with solar installations interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Hands-on experience with solar installations Interview

Q 1. Describe your experience with different types of solar panels (monocrystalline, polycrystalline, thin-film).

My experience encompasses all three major types of solar panels: monocrystalline, polycrystalline, and thin-film. Each has its strengths and weaknesses. Monocrystalline panels, known for their black color and high efficiency (typically 18-22%), are made from a single silicon crystal. This results in higher power output per unit area, making them ideal for space-constrained installations. However, they are generally more expensive. Polycrystalline panels, identifiable by their blueish appearance and slightly lower efficiency (around 15-17%), are made from multiple silicon crystals, leading to a more cost-effective option. Thin-film panels, using materials like amorphous silicon, cadmium telluride, or copper indium gallium selenide (CIGS), are known for their flexibility and lighter weight, often suitable for integrating into building materials. Their efficiency is generally lower (around 7-13%), but they can be more cost-effective for large-scale projects and benefit from less material usage. In practice, I’ve found monocrystalline panels to be increasingly popular for residential installations due to their superior energy output and aesthetic appeal, while polycrystalline panels still hold their place in larger commercial installations where cost is a significant factor. Thin-film panels are often considered for unique applications or when flexibility is crucial.

Q 2. Explain the process of installing solar panels on a residential roof.

Residential roof solar panel installation is a multi-step process that begins with a thorough site assessment, including roof inspection for structural integrity, shading analysis, and optimal panel orientation. Next, we design the system based on the homeowner’s energy needs and available roof space. Then comes the installation itself, which involves mounting the racking system (typically using either rails or individual mounts) securely to the roof. This requires careful consideration of the roof type – asphalt shingles, tile, metal, etc. – and proper penetration sealing to prevent leaks. Once the racking is in place, the panels are carefully attached, ensuring proper spacing for ventilation and optimal performance. Wiring is meticulously done, connecting each panel to the string inverters, which convert DC power from the panels into AC power for home use. The system is then grounded for safety, and finally, we conduct a thorough inspection and testing before connecting to the electrical grid.

For example, on a sloped asphalt shingle roof, we would use specialized flashing to ensure a waterproof seal around each penetration point of the mounting system. On a flat roof, we might use ballasted racking systems to avoid penetrations altogether. Each step is crucial for the long-term reliability and safety of the system.

Q 3. How do you ensure the safety of yourself and others during a solar installation?

Safety is paramount. We adhere strictly to OSHA regulations and best practices. This starts with proper personal protective equipment (PPE): hard hats, safety glasses, fall protection harnesses, and insulated gloves are always worn. We use insulated tools to prevent electrical shocks and work with caution around high-voltage wiring. Before starting any work, we ensure the main electrical breaker is switched off and locked out/tagged out. Detailed safety briefings are given to the team before each job. We continuously assess the work site for potential hazards and take necessary precautions, such as using scaffolding or fall protection systems when working at heights. Regular safety checks and toolbox talks are part of our routine to maintain a safe work environment for both ourselves and the homeowner.

Q 4. What are the common challenges you face during solar panel installations?

Challenges vary, but common issues include unexpected roof conditions (e.g., rot, poor structural integrity), shading from trees or buildings that reduces energy production, difficult access to the roof, and permit acquisition delays. Unforeseen issues like the presence of asbestos or lead paint can also significantly impact the installation timeline and budget. Weather can also be a significant challenge; extreme heat, rain, or wind can cause delays or require adjustments to the installation plan. Another common challenge is managing client expectations regarding energy production estimates, which can be affected by factors outside of our control like weather patterns and equipment limitations. Finally, navigating complex building codes and interconnection requirements adds another layer of complexity to every project.

Q 5. How do you troubleshoot a solar system that is not producing expected power output?

Troubleshooting a low-performing solar system involves a systematic approach. First, we verify that the panels are producing the expected voltage and current using a multimeter at the panel’s junction box. Then, we check for shading, loose connections, and damaged wiring. We examine the inverters for error codes, checking their functionality and monitoring power output. We inspect the circuit breakers and other electrical components. A detailed visual inspection of the entire system is essential. Advanced diagnostic tools might be employed, such as infrared cameras to detect hot spots indicating potential issues. If the problem persists, we might need to analyze the data logged by the system’s monitoring software to pinpoint any anomalies. In some cases, a thorough cleaning of the panels can resolve the issue.

For example, if one inverter is malfunctioning, it can affect the entire string of panels connected to it, leading to reduced output. Identifying and replacing the faulty inverter often solves the problem.

Q 6. What are your experiences with different mounting systems for solar panels?

My experience includes working with various mounting systems, including ground mounts, roof mounts (tilt and fixed), and integrated mounts. Ground mounts are typically used for large-scale projects or when roof space is limited. They can range from simple post mounts to more complex systems suitable for uneven terrain. Roof mounts offer flexibility in terms of tilt angle to maximize energy production, especially important in varying climates. Fixed-tilt mounts are simpler and less expensive, whereas adjustable tilt mounts allow for seasonal optimization. Integrated mounts are designed to seamlessly integrate panels into the building’s design. The choice of mounting system depends on many factors, including roof type, building structure, aesthetic preferences, and land availability. In practice, we carefully consider all these factors to select the most suitable and structurally sound mounting system for each project. Ensuring proper grounding and structural integrity is always the highest priority.

Q 7. Describe your knowledge of electrical wiring and grounding procedures for solar systems.

I have extensive knowledge of electrical wiring and grounding procedures for solar systems, adhering strictly to the National Electrical Code (NEC) and all applicable local regulations. This includes understanding the differences between DC wiring from the panels to the inverters and AC wiring from the inverters to the main panel. Proper wire sizing is critical to avoid voltage drop and ensure optimal system performance. Grounding is essential for safety and protection against electrical surges and lightning strikes. We use grounding rods and conductors to provide a safe path to the earth for fault currents. All connections are made with properly rated connectors and wire nuts, and all wiring is carefully organized and labeled for easy troubleshooting. Before connecting to the grid, a thorough inspection and testing are conducted to ensure the system meets all safety standards and regulations. Proper grounding practices prevent electrical shocks and damage to equipment.

Q 8. How do you test the functionality of a completed solar installation?

Testing a completed solar installation is crucial to ensure safety and optimal performance. It’s a multi-step process involving several checks. First, we visually inspect all connections, ensuring there are no loose wires or damaged components. Then, we use a multimeter to verify voltage and current readings at various points in the system – from the panels to the inverter and the main panel. This confirms the panels are producing the expected power and the inverter is functioning correctly. We also check the ground fault circuit interrupters (GFCIs) to ensure they’re properly functioning, a critical safety measure. Finally, we utilize data loggers or monitoring software to track system performance over several days, checking for inconsistencies or anomalies that might indicate a problem. For instance, a sudden drop in power output might signal shading issues or a faulty panel. This comprehensive testing guarantees a safe and efficient solar system.

Q 9. What are your experiences with inverters and their role in a solar system?

Inverters are the heart of any solar power system. They convert the direct current (DC) electricity generated by solar panels into alternating current (AC) electricity, which is what our homes and businesses use. I’ve worked extensively with both string inverters and microinverters (I’ll detail microinverters in a later answer). String inverters handle the power output of multiple solar panels, making them cost-effective for larger installations. However, if one panel is shaded or malfunctions, it can affect the entire string’s output. I’ve encountered situations where a shaded panel significantly reduced the entire string’s efficiency, highlighting the importance of proper panel placement and regular maintenance. We also carefully choose inverters based on their efficiency rating (measured by MPPT – Maximum Power Point Tracking), which impacts the overall energy yield of the system. A higher-efficiency inverter means more energy harvested from the panels, leading to a better return on investment for the client.

Q 10. Explain the process of connecting solar panels to an inverter.

Connecting solar panels to an inverter is a precise and safety-critical process. First, we always disconnect the power to both the inverter and the solar array before starting any work – safety is paramount! Next, we carefully connect the DC positive (+) and negative (-) wires from the solar panels to the corresponding terminals on the inverter’s input side. This is often done using MC4 connectors, which are designed for outdoor use and quick disconnects. It’s essential to ensure that the wiring is correctly matched to the inverter’s specifications, especially concerning voltage and amperage. We use appropriate wire sizes and protective conduit to protect the wires from the elements and prevent damage. Incorrect wiring can lead to system malfunctions, fires, or even electrical shocks. After connecting, we meticulously check all connections for tightness and proper polarity. Only after this rigorous verification do we reconnect the power and test the system’s functionality. I always follow the manufacturer’s instructions very carefully as each inverter model has specific requirements.

Q 11. What is your experience with different types of batteries for solar energy storage?

My experience includes working with several battery technologies for solar energy storage, each with its own set of advantages and drawbacks. Lead-acid batteries are the most traditional and cost-effective option, but they have a shorter lifespan and require more maintenance. Lithium-ion batteries are becoming increasingly popular due to their longer lifespan, higher energy density, and lower maintenance requirements. However, they come at a higher initial cost. I’ve also worked with some newer technologies like flow batteries, which are ideal for large-scale applications, but they are currently more expensive. The choice of battery technology depends heavily on the client’s budget, energy needs, and the specific application. For example, a homeowner with a limited budget might opt for lead-acid, while a business aiming for long-term energy independence might choose lithium-ion. Careful consideration of factors like cycle life, depth of discharge, and environmental impact is crucial for selecting the best option for each project.

Q 12. Describe your experience working with microinverters and their advantages and disadvantages.

Microinverters are a popular choice in many residential and commercial projects. Unlike string inverters, each microinverter optimizes the power output of a single solar panel. This offers several advantages. First, if one panel is shaded or malfunctions, it doesn’t affect the others. This is a significant improvement over string inverters, maximizing energy harvest even with partial shading. Second, microinverters generally have higher efficiency rates and often a longer warranty period. However, they are generally more expensive than string inverters per kilowatt installed, and the added complexity can increase installation time and potentially the total installation cost. I’ve personally found that the advantages of maximized energy yield and increased system reliability often outweigh the higher initial cost, particularly in areas with significant shading or complex roof layouts. This decision is always made in consultation with the client, weighing their budget against the long-term benefits.

Q 13. How do you ensure the proper orientation and tilt angle of solar panels?

Proper orientation and tilt angle are crucial for maximizing solar energy production. The ideal orientation is typically due south in the Northern Hemisphere and due north in the Southern Hemisphere to receive maximum sunlight throughout the day. The optimal tilt angle depends on the latitude and the time of year. We use solar design software to determine the ideal tilt angle for each specific location, aiming to optimize energy production year-round. For example, a steeper tilt angle is generally better in locations with high winter sun angles, and a flatter angle is preferred in areas with high summer sun angles. To ensure the correct positioning, we use precise measuring tools and levelers during installation. Slight deviations from the optimal angle can reduce energy output considerably, emphasizing the importance of careful planning and accurate installation. We also consider factors like potential shading from trees or buildings when determining the final positioning of the panels.

Q 14. What safety equipment do you use regularly during solar installations?

Safety is my top priority. During solar installations, I regularly use several pieces of safety equipment. This includes insulated gloves and tools to prevent electrical shocks, safety glasses to protect my eyes from debris, and hard hats to protect my head from falling objects. We also use fall protection equipment, like harnesses and safety lines, when working at heights. Furthermore, we employ lockout/tagout procedures to de-energize equipment before working on it, preventing accidental energization. Fire extinguishers are always readily available on site. And finally, we adhere strictly to all relevant safety regulations and best practices provided by OSHA (Occupational Safety and Health Administration) and the relevant local electrical codes. Regular safety training is essential to ensure we’re always working safely and efficiently.

Q 15. Describe your experience with different types of racking systems.

My experience encompasses a wide range of racking systems, crucial for securely mounting solar panels on various roof types and ground mounts. I’ve worked extensively with:

- Fixed-tilt racking: This is the most common type, simple and cost-effective for optimally angled roofs. I’ve installed numerous systems using adjustable rails to fine-tune the panel angle for maximum sunlight capture throughout the year. For example, I recently completed a project on a sloped asphalt shingle roof where we used fixed-tilt racking to achieve an optimal 25-degree tilt.

- Adjustable racking: Provides flexibility to adjust panel tilt for seasonal optimization, particularly beneficial in areas with significant variations in sun angle. We used this on a project with a flat roof, optimizing tilt throughout the year based on seasonal changes in solar path.

- Ballasted racking: Ideal for flat roofs where penetration is undesirable, using weight to secure the system. I’ve successfully installed this type on several commercial flat roofs, ensuring the ballast weight is evenly distributed and meets local building codes.

- Ground-mount racking: Designed for ground-mounted solar arrays, often requiring more robust structures to withstand wind and snow loads. I’ve worked on large-scale ground mount projects, utilizing different foundation types depending on the soil conditions, always emphasizing safety and structural integrity.

Choosing the right racking system depends on factors like roof type, panel orientation, local building codes, and client budget. My expertise allows me to assess these factors and select the most suitable and efficient solution.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle difficult roof conditions during solar panel installations?

Difficult roof conditions present unique challenges in solar installations, demanding careful planning and execution. My approach involves a multi-step process:

- Thorough Roof Assessment: This includes a detailed inspection of the roof’s structure, material, condition, and any potential hazards like weak points, leaks, or damaged areas. We use drone technology to get an aerial perspective when necessary.

- Structural Engineering Consultation (When Necessary): For complex or questionable roof conditions, we consult with structural engineers to ensure the roof can safely support the weight of the solar array. This is particularly important for older roofs or roofs with unusual designs.

- Appropriate Racking System Selection: Choosing the right racking system is critical for difficult roofs. Ballasted racking might be ideal for fragile roofs, while specialized mounts can be used for uneven surfaces. I’ve had to work with specialized flashing and sealant to ensure a completely waterproof installation on a complex roof with many valleys.

- Specialized Installation Techniques: Experienced installers are crucial. We employ techniques to minimize roof penetration and damage, using specialized tools and safety equipment to maintain structural integrity. Our team has undergone extensive training in safe roof access and working at heights.

- Safety Precautions: Safety is paramount. We always adhere to strict safety protocols, using harnesses, fall protection systems, and implementing controlled access procedures to prevent accidents.

For example, on a project with a slate roof, we used a ballasted system to avoid damaging the fragile tiles and ensure a watertight installation. We meticulously planned the system placement to minimize stress points on the roof.

Q 17. Explain the process of obtaining necessary permits and inspections for solar installations.

Navigating the permitting and inspection process is a crucial aspect of solar installations. It varies by location, but the general steps are:

- Preliminary Site Assessment: We start by verifying local building codes and zoning regulations. This often involves checking with the local permitting authority to understand their requirements.

- Permit Application: We prepare and submit a complete application including site plans, system specifications, and electrical designs. This often involves detailed calculations, energy modeling, and compliance documentation.

- Permit Review and Approval: The permitting authority reviews the application and may request clarifications or modifications. This can be a time-consuming step, so we strive to get it right the first time.

- Installation: Once the permits are approved, we proceed with the installation, strictly adhering to all specified requirements and safety regulations.

- Inspections: Throughout the installation, we schedule inspections as required by the local authority. This usually includes electrical inspections, structural inspections, and a final inspection to ensure compliance with the permit conditions.

- Final Approval and Commissioning: After the final inspection is passed, we receive the final permit approval and can then commission the system, which involves connecting the system to the grid, final safety checks, and system testing.

I have extensive experience in handling all aspects of the permitting process, ensuring timely approvals and compliance with all local codes. I understand how navigating these bureaucratic processes can affect project timelines and costs.

Q 18. What is your experience with solar system design and calculations?

Solar system design and calculations are fundamental to my work. I utilize specialized software (e.g., PVsyst, Helioscope) to model and optimize system performance. This involves:

- Site Assessment: Analyzing site-specific factors such as roof orientation, shading, solar irradiance, and energy consumption patterns. I use tools like Google Earth and shading analysis software to accurately assess available sunlight.

- System Sizing: Calculating the optimal size of the solar array to meet the client’s energy needs, considering factors like energy consumption, battery storage (if applicable), and available roof space. I ensure the system’s rated capacity properly offsets the customer’s electricity usage.

- Component Selection: Choosing appropriate solar panels, inverters, racking systems, and other components based on system requirements, budget, and performance expectations. I balance efficiency, cost, and durability in component selection.

- Energy Production Estimation: Predicting the annual energy production of the solar system using sophisticated simulation software. This allows clients to make informed decisions based on realistic energy yield expectations.

- Electrical Design: Designing the electrical system, including wiring, grounding, and protection devices, ensuring safety and code compliance. I carefully work out the circuit layouts to ensure proper safety protocols are followed.

My experience enables me to design efficient and reliable solar systems that meet or exceed client expectations. I’ve consistently delivered designs that optimize energy production and minimize costs.

Q 19. How do you manage your time and prioritize tasks during a solar installation project?

Effective time management is critical in solar installations. I employ several strategies:

- Detailed Project Planning: I create comprehensive project schedules, breaking down tasks into smaller, manageable units. This includes allocating specific timelines for each stage of the project, from site assessment to final commissioning.

- Prioritization: I prioritize tasks based on their importance and urgency, focusing on critical path activities to maintain the project’s timeline. This involves using project management software to track progress and identify potential delays.

- Team Coordination: Effective communication and collaboration with the team are crucial for maintaining project momentum. Daily team huddles are standard procedure to communicate task completion and roadblocks.

- Resource Allocation: Efficiently allocating resources, including personnel, equipment, and materials, prevents delays and bottlenecks. I schedule materials deliveries meticulously to avoid potential project slowdowns.

- Contingency Planning: Addressing potential risks and delays by developing contingency plans. This involves anticipating possible issues and having backup solutions in place to minimize their impact on the project schedule.

By systematically managing time and resources, I consistently deliver projects on schedule and within budget. My ability to anticipate and mitigate potential challenges is a key aspect of my success.

Q 20. Describe your experience working as part of a team on a large-scale solar installation.

I thrive in team environments, particularly on large-scale solar installations. My experience includes:

- Collaboration: Working effectively with electricians, roofers, engineers, and other specialists to ensure seamless project execution. Open communication and mutual respect are essential.

- Coordination: Coordinating tasks and responsibilities within the team to maintain project efficiency and avoid conflicts. I’ve worked within formalized project management approaches including Agile and Waterfall.

- Problem-Solving: Collaboratively addressing and solving unexpected problems and challenges that arise during large-scale projects. My experience has trained me to quickly identify potential solutions and allocate resources to swiftly resolve issues.

- Mentorship: Sharing my knowledge and experience with less experienced team members, promoting skill development and team growth. I regularly conduct onboarding and training for new team members.

- Safety: Promoting a culture of safety within the team, ensuring that all team members adhere to safety regulations and procedures. Safety is always our top priority and is addressed in daily briefings.

On a recent 1MW ground-mount project, I was the lead installer overseeing a team of 15. Effective communication and coordination were essential in ensuring the timely and safe completion of the project, on-budget and ahead of schedule.

Q 21. How do you handle unexpected problems or delays during a solar installation?

Unexpected problems and delays are inherent in solar installations. My approach emphasizes proactive problem-solving:

- Assessment: Quickly and accurately assess the nature and extent of the problem. I carefully consider the impact on the project timeline and budget.

- Communication: Immediately communicate the problem to relevant stakeholders, including the client, project manager, and team members. Transparency is critical.

- Problem-Solving: Develop and implement a solution, leveraging my experience and expertise to find the most effective and efficient approach. I always consider both short-term and long-term solutions.

- Risk Mitigation: Implement measures to prevent similar problems from occurring in the future. This may involve refining processes, updating procedures, or improving communication.

- Documentation: Thoroughly document the problem, the solution, and any resulting changes to the project schedule or budget. This ensures efficient record-keeping.

For example, we once encountered unexpected soil conditions during a ground mount installation. We quickly assessed the situation, consulted with a geotechnical engineer, revised the foundation design, and implemented the changes while minimizing project delays.

Q 22. Explain your understanding of NEC codes related to solar installations.

The National Electrical Code (NEC) is a crucial document for safe and compliant solar installations. My understanding encompasses articles specifically relevant to solar photovoltaic (PV) systems, including Article 690. This article details requirements for sizing conductors, grounding, overcurrent protection, and system grounding. For example, NEC 690.8 dictates the requirements for disconnecting means, specifying that the disconnect must be readily accessible and clearly labeled. I’m also familiar with the requirements for rapid shutdown systems (NEC 690.12), which are designed to improve the safety of firefighters responding to emergencies at solar installations. In my experience, understanding these codes isn’t just about passing inspection; it’s about ensuring the longevity and safety of the system. One project involved a situation where a previous installer hadn’t adhered to NEC 690.11 concerning grounding electrode conductors; correcting this prevented a potential fire hazard. I am meticulous about applying the correct NEC articles to each project, ensuring that the system operates efficiently and safely.

- NEC Article 690: Covers all aspects of solar PV system installations.

- NEC 690.8: Addresses disconnecting means requirements.

- NEC 690.12: Details requirements for rapid shutdown systems.

- NEC 690.11: Outlines requirements for grounding electrode conductors.

Q 23. What is your experience with solar panel cleaning and maintenance procedures?

Solar panel cleaning and maintenance are critical for optimal performance. I’ve developed a robust cleaning procedure that prioritizes safety and efficiency. This typically involves using deionized water and soft-bristled brushes to avoid scratching the panels. I also ensure all cleaning equipment is properly grounded to prevent electrical shock. The frequency of cleaning depends on environmental factors; in dusty areas, more frequent cleaning (e.g., monthly) might be necessary, whereas less dusty locations might only need quarterly cleaning. Beyond cleaning, regular inspections are key. I check for signs of damage, such as cracks, hot spots, or loose connections. Monitoring the system’s performance through its monitoring system also helps identify potential issues. For example, a noticeable drop in power output might indicate soiling or damage, prompting a more thorough inspection. In one instance, regular maintenance revealed a small crack on a panel that, if left unnoticed, could have led to larger issues. Early detection saved the need for a costly replacement.

Q 24. How do you ensure the proper sealing and waterproofing of solar panel installations?

Proper sealing and waterproofing are paramount to prevent water ingress, which can severely damage the system and create safety hazards. My approach involves using high-quality sealant specifically designed for outdoor applications and UV resistance. I meticulously seal all penetrations through the roof, such as conduit entries, and ensure a proper flashing system is in place around the array’s mounting structure. The type of sealant will vary depending on the roofing material, and I always check the manufacturer’s instructions to ensure compatibility. I also utilize weatherproof junction boxes and use proper techniques to ensure cable glands are correctly installed. I meticulously inspect all seals after installation. I recently worked on a project where the previous installer had used substandard sealant. The result was water damage to the mounting structure, requiring extensive repairs. This experience reinforced the importance of selecting and applying high-quality sealants and using correct techniques.

Q 25. Describe your experience with troubleshooting issues related to solar panel wiring.

Troubleshooting solar panel wiring requires a systematic approach. I begin with a visual inspection, checking for any obvious signs of damage, loose connections, or corrosion. I use a multimeter to test voltage and current at various points in the system to pinpoint the location of the fault. I also utilize infrared cameras to detect hotspots, which can indicate wiring issues. The use of a clamp meter is critical for measuring currents precisely. One common issue is loose connections at the combiner box, which can result in voltage drops. Another example involves understanding the wiring diagrams provided by the manufacturer. For instance, a recent project involved a faulty connection at the inverter. Using a multimeter, I quickly identified the loose connection, corrected it, and restored the system to full functionality.

Q 26. What is your familiarity with different types of solar trackers?

My familiarity with solar trackers includes single-axis and dual-axis trackers. Single-axis trackers rotate along one axis (typically east-west), maximizing sun exposure throughout the day. Dual-axis trackers rotate along two axes, optimizing energy production by constantly following the sun’s path. The choice between them depends on factors like site conditions, budget, and desired energy output. Single-axis trackers are generally less expensive but provide slightly lower energy generation compared to dual-axis trackers. I have experience installing both types, understanding their mechanics, control systems, and associated wiring. For example, I worked on a project using dual-axis trackers, where precise alignment and proper programming were crucial for optimal performance. Understanding the programming software is as critical as the physical installation for maximizing efficiency.

Q 27. How do you manage and dispose of solar panel waste responsibly?

Responsible management and disposal of solar panel waste are crucial for environmental protection. I always adhere to local and national regulations when dealing with discarded panels. This includes proper handling to avoid damage and ensuring panels are transported to certified recycling facilities. Many components can be recycled or reused, including silicon, aluminum, and copper. Improper disposal can lead to environmental contamination due to the presence of hazardous materials. We document all disposal procedures meticulously and maintain records of where the panels are sent to guarantee proper recycling or disposal. Education of the client on the importance of responsible solar panel disposal is also an integral part of the service we provide.

Q 28. What are your experiences with different types of interconnection equipment?

My experience encompasses various interconnection equipment, including combiner boxes, inverters (both string and microinverters), and rapid shutdown devices. Combiner boxes consolidate the output from multiple strings of panels. Inverters convert the DC electricity generated by panels into AC electricity usable in homes and businesses. String inverters handle the output of multiple strings, whereas microinverters process the energy from individual panels. Rapid shutdown devices are crucial for safety during emergency situations. I am familiar with the various types of inverters, their specifications, and the process of selecting the appropriate equipment for a particular system. For example, a recent project required microinverters due to the complex shading conditions on the roof. The selection of the appropriate interconnection equipment is crucial, not only for optimal performance but also to ensure compliance with safety standards.

Key Topics to Learn for Hands-on Experience with Solar Installations Interviews

- Solar Panel Installation Techniques: Understanding various mounting systems (roof-mount, ground-mount, etc.), safe handling procedures, and proper wiring techniques. Be prepared to discuss your experience with different panel types and their installation specifics.

- Electrical System Design and Integration: Discuss your knowledge of designing and installing DC and AC wiring, understanding combiner boxes, inverters, and their role in the system. Highlight experience with troubleshooting electrical issues within solar arrays.

- Safety Procedures and Regulations: Detail your understanding and application of relevant safety standards (e.g., OSHA, NEC), including fall protection, electrical safety, and lockout/tagout procedures. Be ready to discuss your experience working with permits and inspections.

- Troubleshooting and Diagnostics: Explain your approach to identifying and resolving common problems in solar installations, such as faulty panels, wiring issues, inverter malfunctions, or system performance discrepancies. Describe specific examples where you used your troubleshooting skills.

- Grounding and Bonding: Discuss the importance of proper grounding and bonding techniques to ensure system safety and performance. Explain your experience implementing these techniques and understanding the related codes.

- System Monitoring and Maintenance: Describe your experience with monitoring solar system performance using data loggers or monitoring software. Detail your knowledge of preventative maintenance procedures and system optimization.

- Understanding Different Solar Technologies: Be prepared to discuss your experience with various solar technologies like monocrystalline, polycrystalline, thin-film solar panels, and their respective advantages and disadvantages.

Next Steps

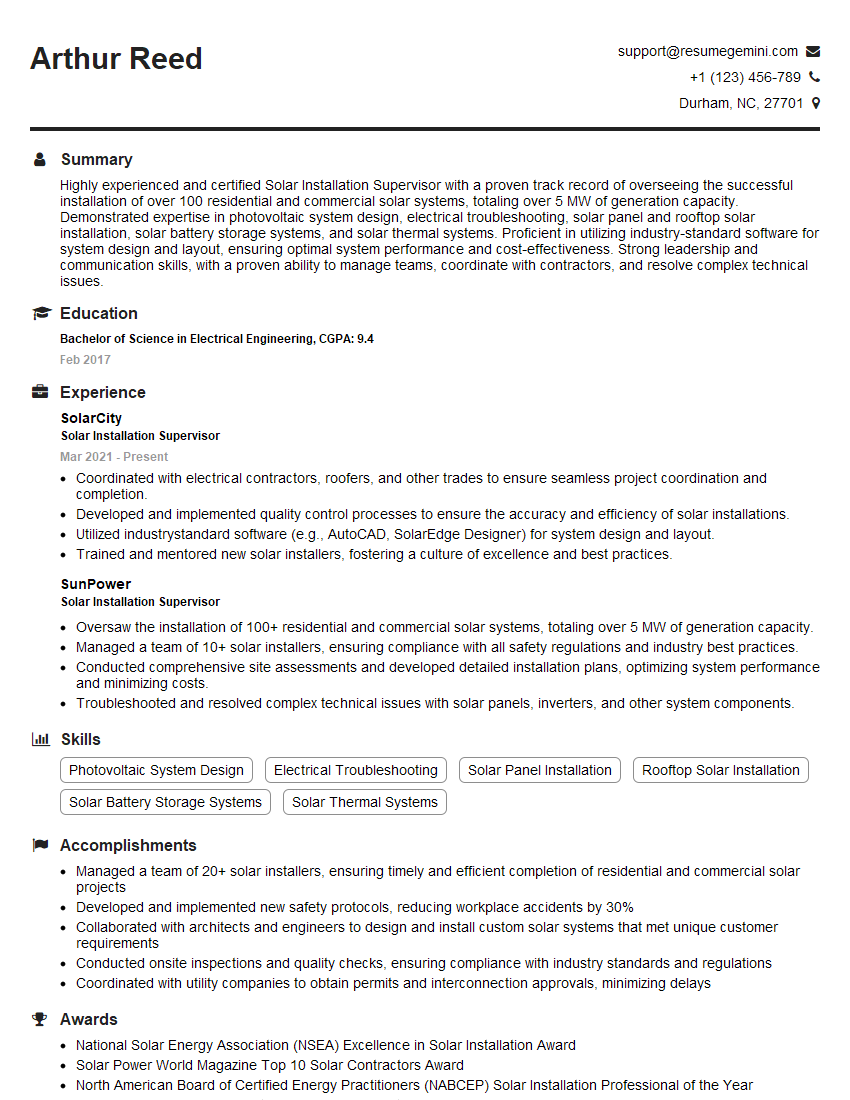

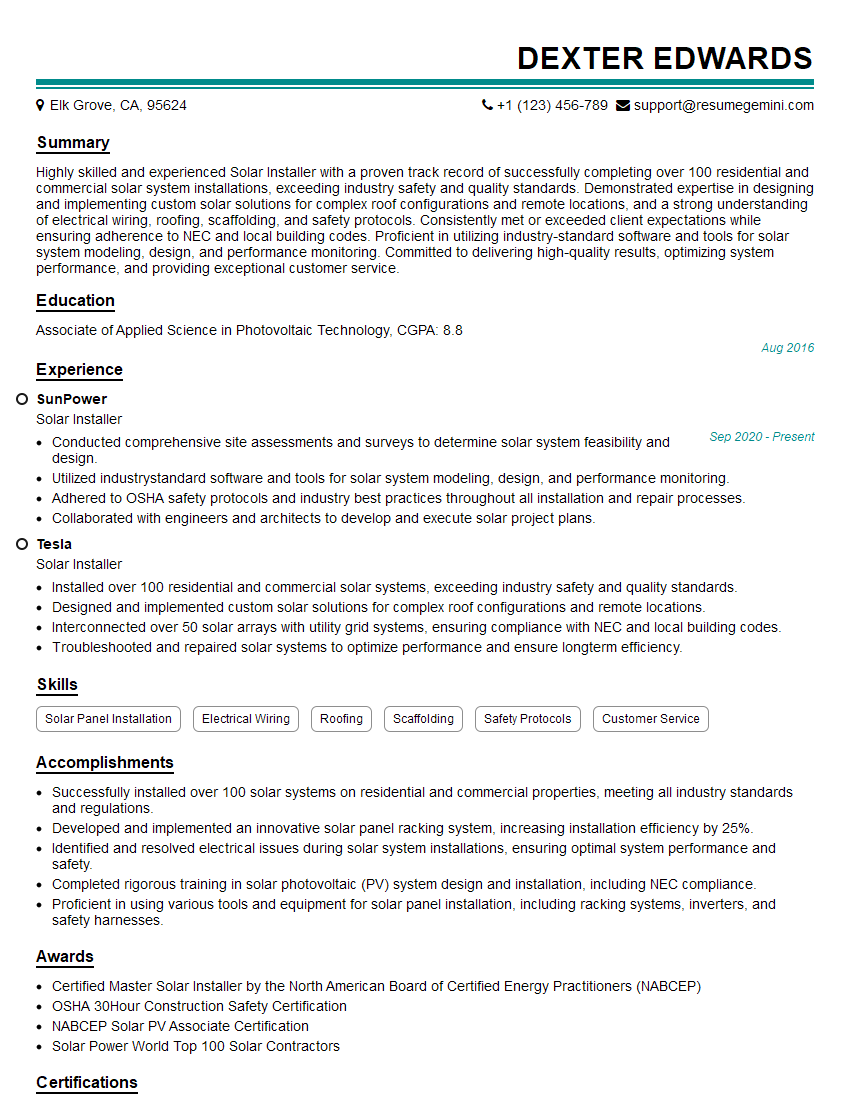

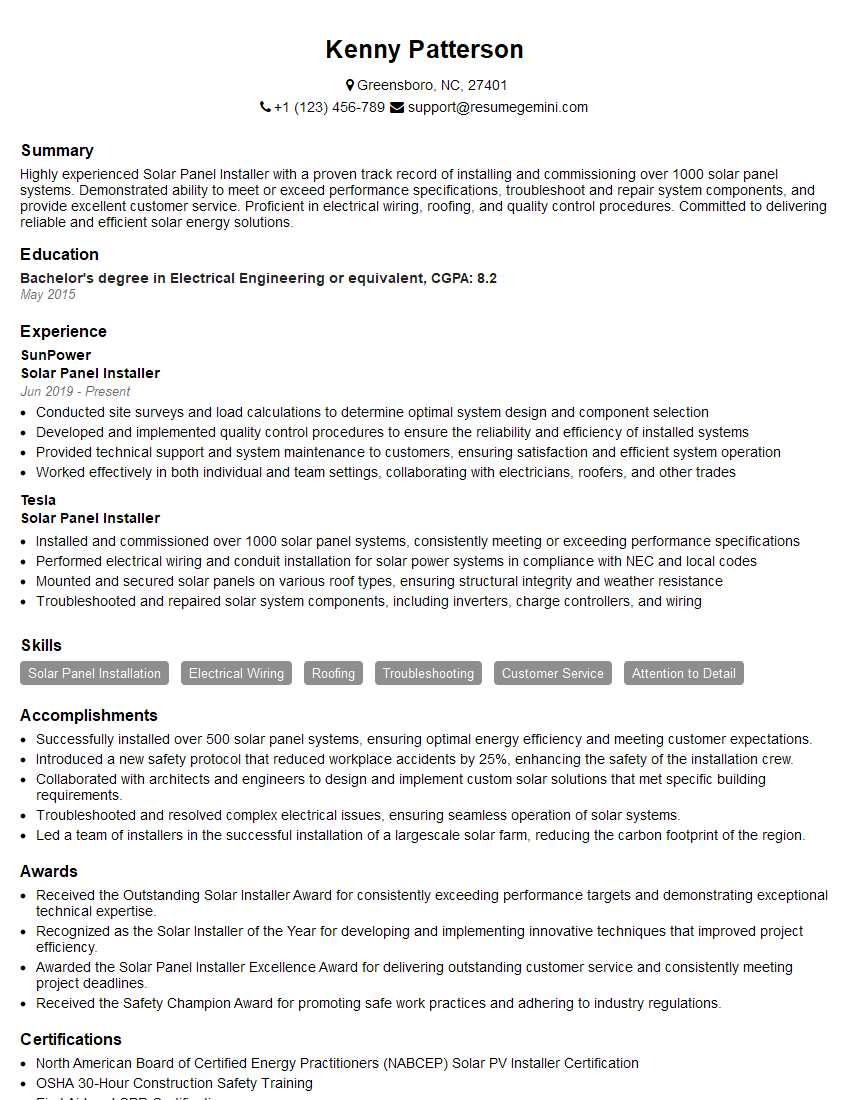

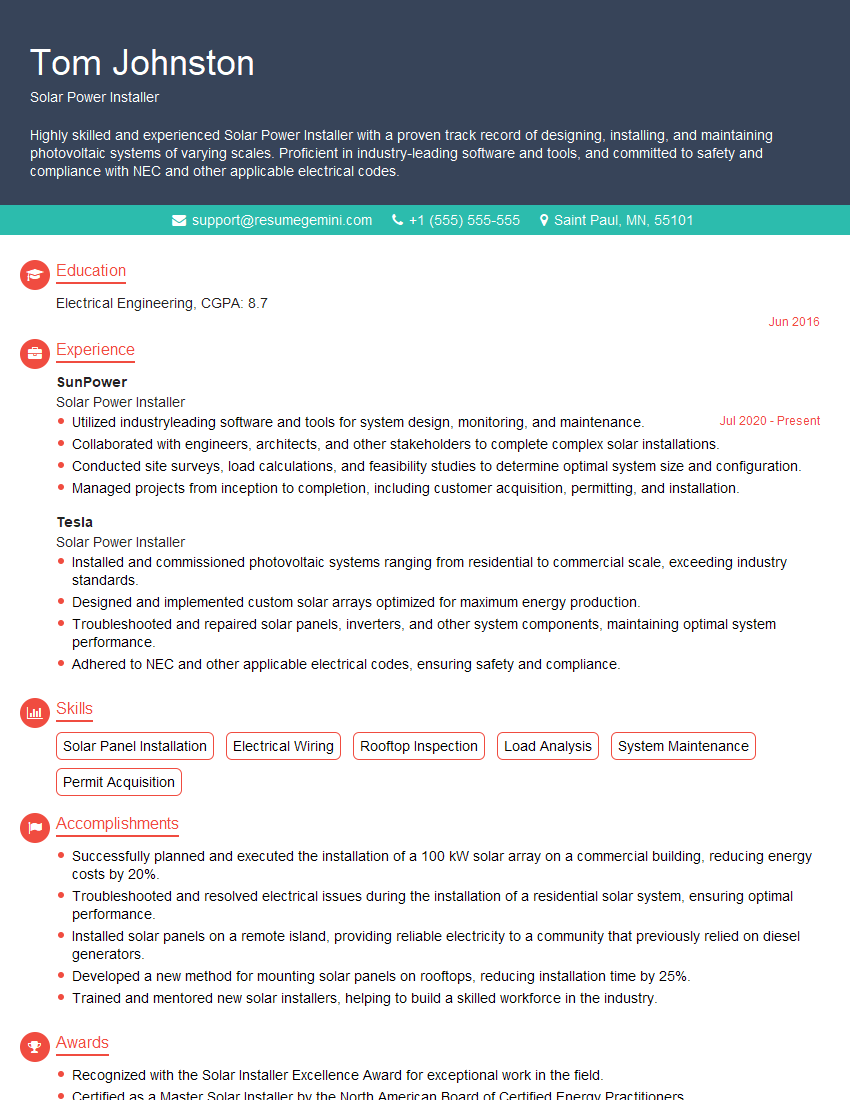

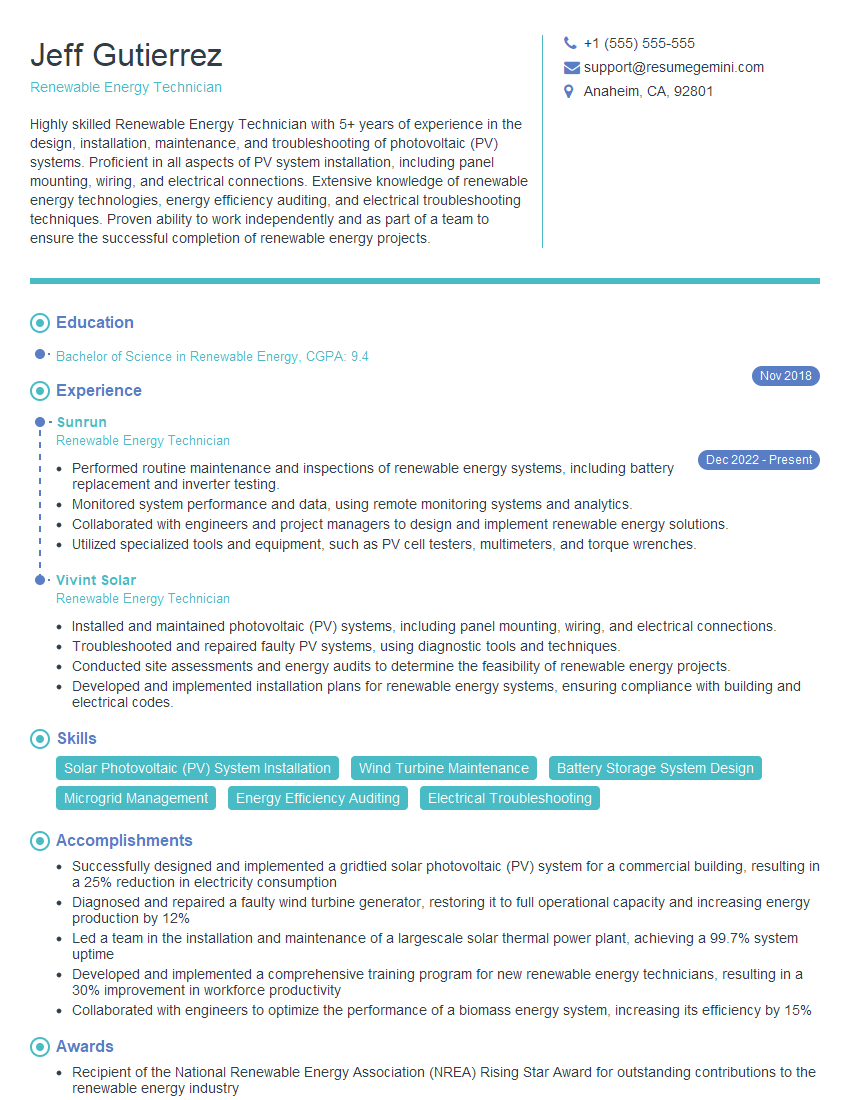

Mastering hands-on experience with solar installations is crucial for a successful and rewarding career in the renewable energy sector. This specialized knowledge opens doors to diverse roles and advancement opportunities. To maximize your job prospects, create a strong, ATS-friendly resume that effectively showcases your skills and experience. ResumeGemini is a trusted resource that can help you build a professional and impactful resume, tailored to highlight your expertise in solar installations. Examples of resumes specifically designed for candidates with hands-on experience in solar installations are available to help guide you. Invest time in creating a compelling resume – it’s your first impression to potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good