The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Irrigation system automation interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Irrigation system automation Interview

Q 1. Explain the different types of irrigation controllers you’ve worked with.

I’ve worked extensively with a variety of irrigation controllers, ranging from basic, time-clock based systems to sophisticated, weather-responsive controllers with advanced features. Let’s break down some examples:

- Time-Clock Controllers: These are the simplest type, using a pre-programmed schedule to activate valves at set times and durations. Think of them as a basic timer for your sprinklers. They’re cost-effective but lack the flexibility to adapt to changing weather conditions. I’ve used these in smaller residential settings or for very simple, low-maintenance applications.

- Weather-Based Controllers: These controllers incorporate weather data (often from a local weather station or an online service) to adjust watering schedules based on rainfall, temperature, and evapotranspiration. They are significantly more efficient than time-clock controllers as they prevent overwatering. I’ve extensively used these in commercial agricultural settings and larger landscaping projects.

- Smart Controllers with Soil Moisture Sensors: This is a more advanced version of weather-based controllers. They add real-time soil moisture data into the equation. This allows for precise water application only when needed, resulting in maximal water conservation and plant health. This is the type of controller I prefer for optimal efficiency.

- Centralized Control Systems: For large-scale irrigation projects, I frequently work with centralized control systems. These systems manage multiple controllers and zones from a single interface, often utilizing SCADA (Supervisory Control and Data Acquisition) software for monitoring and control.

Q 2. Describe your experience with various irrigation scheduling methods (e.g., evapotranspiration, weather-based).

Irrigation scheduling is crucial for efficient water use. I’ve used various methods, each with its own advantages and disadvantages:

- Fixed Scheduling: This is the simplest method, where irrigation runs for a set time interval. It’s the least efficient but easiest to implement. I only utilize this approach in very simple applications where precision isn’t critical.

- Evapotranspiration (ET)-based Scheduling: ET represents the water lost to the atmosphere from plants and soil. I use ET calculations, often incorporating local weather data and plant-specific factors (crop coefficient), to determine the appropriate irrigation amount. This method offers good efficiency but requires more upfront data collection and calculation.

- Weather-based Scheduling: This is perhaps the most common approach. I integrate weather data (rain, temperature, humidity, wind) into the scheduling algorithm to adjust watering duration and frequency. I find that this method is generally more efficient than fixed scheduling, but can still lead to overwatering if soil moisture isn’t considered.

- Soil Moisture-based Scheduling: This is the most efficient method. Soil moisture sensors provide real-time data on water availability in the root zone. The irrigation system then activates only when the soil moisture falls below a predetermined threshold. This requires sensors and a more advanced controller but optimizes water use dramatically.

- Combination Methods: In many cases, I combine these methods. For instance, an ET-based schedule can be modified based on real-time weather data or soil moisture readings to optimize water usage and account for unexpected weather events.

Q 3. How do you troubleshoot common issues in an automated irrigation system?

Troubleshooting automated irrigation systems involves a systematic approach. Here’s a common strategy:

- Identify the problem: What exactly is malfunctioning? Is a zone not activating? Is the system running continuously? Are there low water pressures?

- Check the obvious: Start with the simple things – is the power on? Are there any visible leaks or damaged lines? Are the valves functioning correctly? Is the water source providing enough pressure?

- Check the controller: Is the programming correct? Are there any error messages displayed on the controller’s screen? Are the run times appropriately set?

- Inspect wiring and valves: Check all wiring connections for corrosion or damage. Manually operate each valve to ensure they are opening and closing correctly. Low pressure often implies a blocked line, a valve issue, or a problem with the water source.

- Use diagnostic tools: Some controllers offer built-in diagnostics that can help pinpoint the problem. Flow meters can be used to measure water flow rates in individual zones to identify blockages or leaks.

- Sensor issues: If the system relies on sensors (soil moisture, rain), inspect them for damage or malfunction. Ensure they’re properly calibrated and positioned. A faulty sensor can lead to inaccurate irrigation decisions.

- Seek professional assistance: If you can’t find the problem, it’s always best to call in a professional irrigation technician.

Q 4. What software or programming languages are you proficient in for irrigation automation?

My proficiency in software and programming languages relevant to irrigation automation includes:

- Python: I use Python extensively for data analysis, creating custom scripts to process sensor data, generate reports, and integrate with third-party APIs for weather data.

# Example Python code snippet for processing sensor data: data = process_sensor_data('soil_moisture.csv') - C# and .NET: I’ve worked with these for developing custom interfaces for centralized control systems and integrating with SCADA systems.

- SQL: I frequently use SQL to manage and query large datasets of irrigation data stored in databases.

- JavaScript: I use JavaScript for front-end development, creating user-friendly dashboards and interfaces for system monitoring and control.

- Various SCADA software packages: I’m proficient in using several industry-standard SCADA packages like those offered by Schneider Electric, Siemens, and others. These packages usually have their own scripting languages or integration capabilities.

Q 5. Explain your experience with SCADA systems in irrigation management.

SCADA (Supervisory Control and Data Acquisition) systems are essential for managing large-scale irrigation projects. My experience includes designing, implementing, and maintaining SCADA systems for agricultural and landscaping projects. Here’s a breakdown:

- Data Acquisition: I use SCADA systems to collect data from various sensors (soil moisture, weather, flow meters) located across multiple irrigation zones.

- Centralized Monitoring: SCADA systems provide a centralized dashboard to monitor the entire irrigation network in real-time, allowing for quick identification of problems.

- Remote Control: SCADA allows remote operation and control of irrigation systems, crucial for large areas or areas difficult to access regularly.

- Data Analysis and Reporting: I use SCADA systems to generate reports on water usage, energy consumption, and system performance, assisting in optimization strategies.

- Alarm and Alerting: SCADA systems can automatically trigger alarms if sensors detect abnormalities (e.g., low water pressure, excessive run times), allowing for prompt intervention and preventing system failures.

For example, I worked on a project where we used a SCADA system to manage an irrigation network across 1000 acres of farmland. The system significantly improved water efficiency and reduced labor costs by automating many irrigation tasks.

Q 6. Describe your experience with sensor integration in irrigation systems (e.g., soil moisture, weather sensors).

Sensor integration is crucial for creating intelligent irrigation systems. I’ve worked with many types of sensors, each providing valuable data for optimizing water use:

- Soil Moisture Sensors: These sensors measure the volumetric water content in the soil. I commonly use tensiometers, capacitance probes, and time-domain reflectometry (TDR) sensors. The data helps determine when irrigation is actually needed, preventing overwatering.

- Weather Sensors: These provide data on rainfall, temperature, humidity, solar radiation, and wind speed. I use this data to fine-tune irrigation schedules and predict ET rates. Integrating weather forecasts allows for proactive adjustments to irrigation schedules before a rainfall event.

- Flow Meters: These sensors measure the volume of water flowing through the irrigation system. This helps detect leaks or blockages, ensuring the system is operating efficiently. Unexpected flow rate drops can signal a leak, allowing for quick repair before significant water loss.

- Water Level Sensors: Used in reservoirs and ponds to monitor water levels, allowing for automated refill when the level drops below a certain threshold.

I find that combining soil moisture and weather data is extremely effective, leading to substantial water savings. For example, one project showed a 30% reduction in water usage by combining these data streams.

Q 7. How do you ensure efficient water usage in automated irrigation systems?

Efficient water usage is paramount in automated irrigation systems. Here’s how I ensure it:

- Appropriate Scheduling: Using weather-based, ET-based, or preferably soil moisture-based scheduling ensures water is applied only when and where it’s needed. This avoids overwatering, which wastes water and can harm plant health.

- Sensor Integration: Integrating soil moisture and weather sensors provides real-time feedback for adaptive irrigation control, optimizing water usage based on actual conditions.

- Regular System Maintenance: Regular checks for leaks, blockages, and damaged components are crucial to minimize water loss. Addressing these issues promptly prevents water waste and system malfunctions.

- Proper System Design: The efficient irrigation system design considers factors such as terrain, soil type, and plant water requirements. Uniform water distribution through well-designed layouts minimizes water waste.

- Water-efficient Irrigation Methods: Utilizing efficient irrigation methods such as drip irrigation or micro-sprinklers significantly reduces water waste compared to traditional sprinkler systems.

- Data Analysis and Optimization: Regularly analyzing data from the irrigation system (water usage, sensor data) allows for identifying areas for improvement and optimizing irrigation strategies over time.

In practice, I often develop custom algorithms that analyze historical data to create even more efficient irrigation schedules. This iterative approach continually refines water usage and increases overall efficiency.

Q 8. What are your experiences with different irrigation technologies (e.g., drip, sprinkler, micro-spray)?

My experience spans various irrigation technologies, each suited for different applications. Drip irrigation, for example, is ideal for high-value crops or landscapes where water conservation is paramount. It delivers water directly to the plant roots, minimizing evaporation and runoff. I’ve worked extensively on drip system designs, including the selection of emitters, tubing, and filtration systems. Sprinkler irrigation, on the other hand, is more suitable for larger areas and turfgrass, providing a broader coverage. I’ve designed numerous sprinkler systems, optimizing nozzle selection, spacing, and pressure for even water distribution. Finally, micro-spray systems offer a balance between the precision of drip and the coverage of sprinklers. They are often used in landscape settings and are particularly effective in areas with varying terrain or plant density. I’ve incorporated micro-spray systems in projects requiring efficient irrigation of smaller shrubs and flowers.

For instance, in a recent vineyard project, we opted for drip irrigation to maximize water efficiency and prevent fungal diseases. In a large park project, we used a combination of sprinkler and micro-spray systems to meet the diverse needs of different plant types and areas.

Q 9. Describe your process for designing an automated irrigation system for a specific landscape.

Designing an automated irrigation system involves a systematic process. It starts with a thorough site analysis, encompassing soil type, slope, sun exposure, and plant requirements. Next, I create a detailed landscape plan, identifying different irrigation zones based on plant needs and water requirements. I determine the appropriate irrigation technology (drip, sprinkler, micro-spray) for each zone, ensuring optimal water distribution and minimizing waste. The design also includes the selection of controllers, valves, pumps, and other components, considering factors like water pressure, flow rate, and power availability. Finally, I create detailed schematics, including piping layouts, valve locations, and sensor placements. Throughout the design process, I use specialized irrigation design software to simulate system performance, ensuring efficiency and accuracy. The software allows me to model water distribution, calculate pressure drops, and adjust the system to meet specific demands. The entire design process is documented and reviewed to ensure quality and efficiency.

Q 10. How do you handle unexpected events or system failures in an automated irrigation system?

Handling unexpected events and system failures is crucial in automated irrigation. We incorporate several layers of redundancy and monitoring. This includes the use of sensors to detect leaks, low water pressure, and other anomalies. The system is programmed to alert me via email or text message when such events occur, allowing for timely intervention. In addition, the system includes backup power sources (like batteries) to ensure operation during power outages. For more extensive failures, the system is designed to isolate affected zones to minimize damage and disruptions to other areas. Regular system maintenance and inspections also play a crucial role in preventing failures. This includes checking for leaks, cleaning filters, and verifying the proper function of all components. We also maintain detailed logs of system performance, aiding in the identification of potential issues before they escalate. For example, a sudden increase in water usage might signal a leak, while a drop in pressure could indicate a clogged filter.

Q 11. Explain your understanding of hydraulic design principles in irrigation.

Hydraulic design principles are fundamental to efficient irrigation. They involve understanding how water flows through pipes and emitters under varying pressures. Key concepts include calculating pressure drops along pipelines using the Hazen-Williams equation or similar methods, determining the flow rates required to meet plant water needs, selecting appropriate pipe sizes to minimize friction losses, and designing pressure-regulating devices to ensure even distribution. Proper hydraulic design is critical to avoid over-watering in some areas and under-watering in others. For example, neglecting pressure drop calculations can lead to insufficient water delivery in distant parts of the system. I leverage specialized irrigation design software to model and optimize the hydraulic performance of systems, ensuring that the design accounts for all relevant factors and meets the specific needs of the site.

Q 12. How do you ensure the security of an automated irrigation system against unauthorized access?

Security is a growing concern in automated irrigation systems. We implement several measures to prevent unauthorized access and control. This includes using strong passwords and regularly updating firmware to patch security vulnerabilities. Network security protocols, such as firewalls and intrusion detection systems, are employed to protect the system from external threats. Access control mechanisms, such as user roles and permissions, limit access to sensitive system functions to authorized personnel. Data encryption ensures that sensitive information is protected during transmission and storage. In some high-security applications, we might use multi-factor authentication to add an extra layer of protection. Regular security audits are conducted to assess the system’s vulnerabilities and implement necessary improvements.

Q 13. Describe your experience with data logging and analysis in automated irrigation systems.

Data logging and analysis are crucial for optimizing irrigation system performance and water management. Our systems are equipped with sensors that collect data on various parameters, including soil moisture, water pressure, and flow rates. This data is logged and stored for later analysis, providing valuable insights into system efficiency and plant water needs. We use specialized software to analyze the data, identifying trends, anomalies, and areas for improvement. For example, analyzing soil moisture data can help us refine irrigation schedules, ensuring that plants receive the right amount of water at the right time. Analyzing flow rate data can help us identify leaks or malfunctions within the system. The data analysis also supports the development of predictive models that anticipate future water requirements, enabling proactive adjustments to the irrigation schedule.

Q 14. What are the key considerations for selecting appropriate irrigation equipment for a particular site?

Selecting appropriate irrigation equipment involves careful consideration of several factors. These include the type of landscape (turf, trees, shrubs, etc.), soil conditions, water availability, budget constraints, and climate. The water source needs to be assessed, determining the pressure and volume available. For example, a high-pressure municipal water supply will dictate different equipment choices compared to a low-pressure well. Energy efficiency should be considered, choosing energy-saving pumps and controllers. We also consider the durability and longevity of equipment, selecting components that can withstand environmental conditions and minimize maintenance requirements. For example, in arid climates, corrosion-resistant materials might be necessary. Finally, the automation level needed is also a factor, determining the selection of controllers and sensors. The entire selection process involves evaluating various options and ensuring compatibility between different components to create a cohesive and efficient irrigation system.

Q 15. Explain your experience with preventative maintenance of automated irrigation systems.

Preventative maintenance is crucial for ensuring the longevity and efficiency of automated irrigation systems. My approach involves a multi-faceted strategy encompassing regular inspections, cleaning, and component testing. Think of it like a car – regular oil changes and tune-ups prevent major breakdowns.

- Regular Inspections: I visually inspect all components, including valves, pipes, sensors, and controllers, checking for leaks, cracks, corrosion, or any signs of damage. This includes checking for proper alignment and ensuring all connections are secure.

- Cleaning: Regular cleaning of filters, nozzles, and emitters is vital to prevent clogging and ensure optimal water distribution. Clogged emitters are like blocked arteries – they reduce efficiency and can cause damage.

- Component Testing: This involves testing the functionality of each component individually, ensuring valves open and close correctly, sensors provide accurate readings, and controllers respond appropriately. I use specialized tools to test the electrical circuits and ensure proper communication between components.

- Scheduled Maintenance: I create a preventative maintenance schedule tailored to the specific system and environmental conditions. This schedule includes specific tasks, their frequency, and responsible personnel. For example, a system in an arid climate might require more frequent filter cleaning than one in a humid environment.

Following this rigorous preventative maintenance strategy has significantly reduced downtime and repair costs in past projects, ensuring optimal system performance and extending its lifespan.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you manage and interpret data from irrigation sensors and controllers?

Managing and interpreting data from irrigation sensors and controllers involves understanding the data being collected, recognizing patterns, and using that information to optimize the irrigation schedule. It’s like reading a patient’s vital signs – the data tells a story about the system’s health and performance.

- Data Acquisition: I utilize various methods to collect data, including direct readings from controllers, using dedicated software applications, and remotely accessing data through cloud-based platforms. This involves understanding the different communication protocols (e.g., BACnet, Modbus).

- Data Analysis: I analyze soil moisture data, weather data (temperature, rainfall, evapotranspiration), and flow rate data to assess the effectiveness of the irrigation system. Software analysis often helps to visualize trends and patterns more easily.

- Interpreting Data: High soil moisture readings might indicate overwatering, low readings might suggest insufficient irrigation, and inconsistencies in flow rate may point towards a leak or a malfunctioning valve. I use this information to adjust the irrigation schedule and resolve any issues.

- Reporting: I generate reports that summarize the data and highlight any areas of concern. These reports are crucial for stakeholders to understand the system’s performance and identify areas for improvement. They also provide historical data for trend analysis.

By effectively managing and interpreting this data, I can optimize water usage, minimize operational costs, and maintain the health of the landscape being irrigated. For example, I successfully reduced water consumption by 15% in a recent project by adjusting the irrigation schedule based on real-time soil moisture data.

Q 17. Describe your experience with integrating automated irrigation systems with other building management systems.

Integrating automated irrigation systems with Building Management Systems (BMS) enhances efficiency and centralized control. Imagine a building’s central nervous system – the BMS – coordinating all its functions, including irrigation.

My experience includes integrating irrigation systems using various protocols, such as BACnet and Modbus. This integration allows for monitoring and control of the irrigation system from the central BMS interface. It also allows for the incorporation of other building parameters into irrigation scheduling. For example, real-time occupancy data can help prioritize irrigation based on specific building zone use.

- Protocol Selection: Choosing the right communication protocol is crucial for seamless integration. The selection depends on the BMS and irrigation controller capabilities and is a critical early-stage decision.

- Data Mapping: This involves mapping data points between the BMS and the irrigation system. For example, this might include mapping soil moisture sensors from the irrigation system to the relevant area in the BMS.

- Testing & Commissioning: Once integrated, rigorous testing ensures that data is transmitted correctly and that the irrigation system responds appropriately to commands from the BMS.

- Security Considerations: Access control and data security must be addressed during integration. A well-planned approach to security and encryption is key for a robust solution.

In a recent project, I successfully integrated an automated irrigation system with a BMS, enabling remote monitoring and control, and allowing for real-time adjustments based on occupancy and weather conditions, resulting in significant water savings and improved system efficiency.

Q 18. How do you calculate the water requirements for a specific irrigation system?

Calculating water requirements for an irrigation system involves considering various factors. It’s not simply filling a bucket; it’s about understanding the plant’s needs, the environment, and the irrigation system’s efficiency.

The process usually involves these steps:

- Evapotranspiration (ET): This is the primary factor and represents the combined water loss from evaporation and plant transpiration. We use weather data, plant type, and soil characteristics to estimate ET.

- Crop Coefficient (Kc): This factor accounts for the specific water needs of the plants being irrigated. Different plants have different water requirements.

- Irrigation Efficiency (IE): This represents the percentage of water applied that actually reaches the plant’s root zone. System design, soil type, and weather conditions influence IE.

- Root Zone Depth: The depth to which the plants’ roots extend influences the volume of water required.

- Area Calculation: The total area to be irrigated needs to be accurately measured.

The formula to estimate water requirements is often expressed as: Water Requirement (inches/day) = ET * Kc / IE

After calculating the daily water requirement, we consider the application method (drip, sprinkler, etc.) to determine the flow rate and duration of irrigation. This requires converting the requirement from inches/day to gallons/hour or another relevant unit.

Q 19. Explain your understanding of various irrigation valve types and their applications.

Various irrigation valve types are available, each suited for different applications. Think of them as specialized plumbing components, each designed to control water flow in a specific way.

- Solenoid Valves: These valves are electrically operated and are commonly used in automated systems. They are reliable, relatively inexpensive, and are suitable for various pressures and flow rates. They are like electrical switches for water.

- Diaphragm Valves: These valves utilize a diaphragm to control water flow. They are less prone to clogging than solenoid valves, especially in areas with high sediment levels.

- Ball Valves: These valves feature a ball mechanism to control flow. They are durable and provide a reliable on/off control. They are less suited for frequent on/off cycles compared to solenoid valves.

- Butterfly Valves: These valves use a rotating disc to control flow. They offer a smooth flow regulation and are commonly used in larger irrigation systems or main lines.

- Check Valves: These valves prevent backflow of water. They are crucial for ensuring the unidirectional flow within an irrigation system. They prevent water from flowing back into the system and creating unwanted water pressure.

Selecting the appropriate valve type is critical for the overall system’s performance and efficiency. For instance, solenoid valves are ideal for precise control in smaller zones, while butterfly valves are often suitable for main lines with larger flow demands.

Q 20. Describe your experience with troubleshooting communication issues in an automated irrigation system.

Troubleshooting communication issues in an automated irrigation system requires a systematic approach. It’s like diagnosing a computer problem – you need to identify the source of the issue step-by-step.

My approach typically follows these steps:

- Identify the Problem: Clearly define the communication issue. Is a specific zone not responding? Is the controller not receiving data from a sensor? The more specific the identification, the easier it will be to solve.

- Check Wiring and Connections: Inspect all wiring, connectors, and terminals for loose connections, damaged cables, or short circuits. Loose connections are a common cause of communication problems.

- Verify Power Supply: Ensure that the controller and all communication devices receive adequate power. Low voltage can cause communication failures.

- Test Communication Signals: Use a multimeter or specialized testing equipment to verify that communication signals are transmitted properly between components. Check for signal strength and integrity.

- Check Controller Settings: Review the controller settings, ensuring that the communication parameters (baud rate, parity, etc.) are correctly configured. A slight misconfiguration can disrupt the entire system.

- Utilize Diagnostics Tools: Many irrigation controllers have built-in diagnostic tools that can provide valuable insights into communication errors. These tools usually provide error codes that can be cross-referenced with the documentation.

- Consult System Documentation: Refer to the system’s documentation, schematics, and manuals for troubleshooting guidance and component specifications.

Through this methodical approach, I have successfully resolved various communication issues, restoring the functionality of the irrigation system and preventing water loss or damage to the landscape.

Q 21. What are your experiences with different types of irrigation pumps and their control systems?

Irrigation pumps come in different types, each with its own characteristics and control systems. The choice of pump and its control system depends on the specific needs of the irrigation system.

- Centrifugal Pumps: These pumps are commonly used in irrigation systems due to their ability to handle large volumes of water at relatively high pressures. They are often controlled using Variable Frequency Drives (VFDs) to adjust the pump speed and optimize water delivery.

- Submersible Pumps: These pumps are placed directly within the water source, making them suitable for deep wells or reservoirs. They are often simpler to control as they typically use a simple on/off system.

- Positive Displacement Pumps: These pumps displace a specific volume of water with each stroke, making them suitable for applications requiring precise flow control. They are generally controlled by on/off switches or more advanced control systems.

- Control Systems: VFDs provide the most advanced control over centrifugal pumps, allowing for precise speed adjustment based on demand. Pressure sensors can automatically adjust the pump speed to maintain a desired pressure. Simple on/off controls can suffice for applications with less demanding flow control.

Understanding pump characteristics and control systems is key to designing and maintaining efficient irrigation systems. Using VFDs, for example, has allowed me to significantly reduce energy consumption in several projects by matching pump output to the actual water demand.

Q 22. What are your experiences with designing and implementing energy-efficient irrigation systems?

Designing energy-efficient irrigation systems is paramount for sustainability and cost savings. My approach centers around optimizing water usage and minimizing energy consumption through a combination of strategies.

- Smart Controllers: I prioritize using weather-based irrigation controllers that adjust watering schedules based on real-time weather data, eliminating unnecessary watering during rain or high humidity. This significantly reduces water waste and the energy needed to pump and distribute it. For example, I’ve successfully implemented systems using controllers with evapotranspiration sensors, leading to a 30% reduction in water usage on a recent vineyard project.

- Efficient Irrigation Technologies: I favor drip irrigation and micro-sprinkler systems over traditional sprinkler systems. These technologies deliver water directly to plant roots, minimizing evaporation and runoff, and thus requiring less energy to operate. A recent project utilizing drip irrigation for a large-scale landscaping project resulted in a 40% decrease in energy consumption compared to a sprinkler system design.

- Pump Optimization: Proper pump selection and sizing are critical. I carefully analyze water pressure needs and select energy-efficient pumps with variable frequency drives (VFDs). VFDs allow the pump to adjust its speed based on demand, minimizing energy use during periods of low demand. In one instance, implementing a VFD on a large-scale agricultural project resulted in a 25% reduction in electricity costs.

- System Monitoring and Diagnostics: I incorporate remote monitoring capabilities to detect leaks and malfunctions promptly. Early detection of issues minimizes water loss and prevents unnecessary pump operation, saving energy and water.

By integrating these strategies, I consistently deliver irrigation systems that are both effective and environmentally responsible.

Q 23. Explain your understanding of water quality and its impact on irrigation systems.

Water quality plays a crucial role in the efficiency and longevity of an irrigation system. Poor water quality can lead to significant problems, including clogged emitters, damaged pipes, and reduced plant health.

- Salinity: High salt concentrations can damage plant roots and clog emitters. Regular water quality testing is essential to monitor salinity levels. I often recommend installing filtration systems to remove salts and other suspended solids before the water enters the irrigation system.

- pH Levels: Extreme pH values (either too acidic or too alkaline) can affect nutrient availability and can corrode pipes and emitters. Regular monitoring and adjustments may be needed to maintain optimal pH levels.

- Suspended Solids: Particles like silt and clay can clog emitters and reduce the system’s efficiency. Filtration systems, properly sized for the specific water source, are critical to prevent clogging. I’ve had success using various types of filters, from sand filters to self-cleaning screen filters, depending on the water quality and the scale of the project.

- Biological Contamination: Algae and bacteria can grow within the irrigation system, potentially clogging emitters or introducing diseases to plants. Regular cleaning and disinfection of the system are vital. In certain cases, I incorporate UV sterilization methods to control biological contamination.

Understanding and addressing water quality issues are critical for designing and maintaining a robust and efficient irrigation system. Neglecting water quality can lead to costly repairs, reduced yields, and compromised plant health.

Q 24. Describe your experience working with different irrigation system manufacturers and their products.

My experience encompasses a wide range of irrigation system manufacturers and their products. I’ve worked with leading brands such as Rain Bird, Hunter, Netafim, and Toro, gaining familiarity with their various technologies and control systems.

- Rain Bird: I frequently use their weather-based controllers and drip irrigation components for residential and smaller commercial projects due to their reliability and user-friendly interfaces.

- Hunter: Their larger-scale commercial and agricultural products, including rotary sprinklers and central control systems, are often employed in my larger projects. I appreciate their robust construction and sophisticated control options.

- Netafim: Known for innovative drip irrigation technologies, their products are particularly useful for precise water delivery in high-value agricultural applications. I’ve had success integrating their pressure-compensating drippers to ensure uniform water distribution across varying terrain.

- Toro: Their diverse product line, encompassing sprinklers, valves, and controllers, provides options suitable for a wide range of project needs and budgets.

My experience with these manufacturers allows me to select the best components for a project’s specific needs, considering factors like budget, water source, soil type, and plant requirements. This ensures optimal system performance and longevity.

Q 25. How do you ensure compliance with relevant regulations and codes in irrigation design and installation?

Compliance with relevant regulations and codes is a cornerstone of my work. This involves understanding and adhering to local, state, and national standards related to water conservation, safety, and environmental protection.

- Water Rights and Permits: I ensure all projects obtain necessary water permits and comply with local water usage regulations. This involves understanding water allocation policies and incorporating water-efficient design features to minimize water consumption.

- Building Codes: I adhere to local building codes concerning irrigation system installation, including safety standards for electrical wiring, pressure ratings for pipes, and backflow prevention requirements. Backflow prevention devices are crucial to protect potable water sources from contamination.

- Environmental Regulations: I am aware of and adhere to environmental regulations related to pesticide and fertilizer use, runoff management, and water quality protection. Appropriate landscape design and irrigation practices can minimize environmental impact.

- Accessibility Standards: For public spaces, I ensure the system design complies with accessibility standards, such as providing accessible control panels and ensuring unobstructed pathways.

Maintaining compliance is an ongoing process that involves careful planning, documentation, and regular inspections throughout the project lifecycle. This ensures the system operates legally, safely, and sustainably.

Q 26. Explain your approach to training and educating clients on the operation and maintenance of automated irrigation systems.

Client training is integral to the success of an automated irrigation system. My approach involves a multi-faceted strategy focused on providing comprehensive and practical education.

- On-site Training: I conduct thorough on-site training sessions to familiarize clients with the system’s operation and features. This includes demonstrations of the control panel, explaining watering schedules, and identifying critical components.

- Written Documentation: I provide clients with comprehensive written documentation, including system diagrams, operation manuals, and troubleshooting guides. This ensures they have access to information even after the initial training session.

- Remote Access and Monitoring: Many modern systems offer remote access and monitoring capabilities. I show clients how to use these features to check the system’s status, adjust schedules, and receive alerts about potential issues. This allows for proactive maintenance and problem-solving.

- Ongoing Support: I provide ongoing support through phone, email, or scheduled maintenance visits to address questions and resolve any issues. I also encourage regular system checks and maintenance to ensure optimal performance and longevity.

My goal is to empower clients to effectively manage their irrigation systems, leading to long-term water conservation and cost savings.

Q 27. How do you stay updated on the latest advancements and technologies in irrigation automation?

Staying updated in the rapidly evolving field of irrigation automation is crucial. I actively engage in several strategies to remain current on advancements and new technologies.

- Industry Publications and Journals: I regularly read industry publications and journals to stay abreast of the latest research, innovations, and best practices. This provides valuable insights into new technologies and emerging trends.

- Industry Conferences and Workshops: Attending industry conferences and workshops provides opportunities to network with other professionals, learn from experts, and see new products firsthand. This hands-on experience is invaluable.

- Manufacturer Training Programs: I participate in manufacturer training programs to gain in-depth knowledge of new products and technologies. This ensures I am proficient in using the latest tools and techniques.

- Online Resources and Communities: I utilize online resources and professional communities to engage with colleagues and experts, share knowledge, and learn about new developments. Online forums and professional groups facilitate knowledge sharing and collaboration.

By actively pursuing these strategies, I ensure my expertise remains cutting-edge and allows me to implement the most effective and efficient solutions for my clients.

Q 28. Describe a time you had to solve a complex problem related to an irrigation system. What was the problem, what steps did you take, and what was the outcome?

One challenging project involved a large-scale agricultural irrigation system experiencing inconsistent water pressure. Initially, the problem seemed simple – a suspected leak. However, after several days of investigation, the issue proved far more complex.

- Initial Investigation: We initially inspected the entire pipeline for leaks, but found none. We checked pressure gauges at various points and confirmed the pressure was fluctuating throughout the system.

- Data Analysis: We reviewed the historical data from the irrigation controller, noticing a correlation between pressure fluctuations and specific times of day. This suggested the problem wasn’t a simple leak, but something related to the system’s operation.

- System Diagnostics: We meticulously tested each component, including pumps, valves, and pipes. We eventually identified a malfunctioning pressure-regulating valve near the main pump. The valve wasn’t properly regulating pressure, causing surges and fluctuations throughout the system.

- Repair and Replacement: The pressure-regulating valve was replaced with a new, properly calibrated unit. We then performed a complete system pressure test to ensure the problem was resolved.

- Post-Repair Monitoring: After the repair, we monitored the system for several days, verifying consistent and stable water pressure.

The outcome was a fully functional irrigation system with consistent water pressure. The initial assumption of a simple leak led to a more thorough investigation which highlighted the importance of comprehensive system diagnostics and data analysis in troubleshooting complex irrigation problems. This experience emphasized the value of patience, methodical troubleshooting, and leveraging system data in resolving complex issues.

Key Topics to Learn for Irrigation System Automation Interview

- Smart Irrigation Controllers: Understanding various controller types (e.g., weather-based, soil moisture-based, flow-based), their functionalities, programming, and troubleshooting.

- Sensor Technologies: Familiarize yourself with soil moisture sensors, rain sensors, flow meters, and other relevant sensors; understand their principles of operation, data acquisition, and integration with controllers.

- Communication Protocols: Mastering communication protocols used in irrigation automation (e.g., Modbus, BACnet, Wi-Fi, cellular) and their applications in data transmission and system control.

- Data Acquisition and Management: Learn about data logging, analysis, and visualization from irrigation systems; explore techniques for identifying trends, anomalies, and potential issues.

- System Design and Implementation: Gain knowledge of designing efficient and cost-effective irrigation automation systems, considering factors like water source, soil type, crop requirements, and budget constraints.

- Hydraulics and Fluid Mechanics: Understand the principles of water flow, pressure, and energy losses in irrigation pipelines and components; this is crucial for optimizing system performance and efficiency.

- SCADA and Automation Software: Explore different SCADA systems and software used to monitor and control irrigation networks remotely, and understand their capabilities and limitations.

- Troubleshooting and Maintenance: Develop practical troubleshooting skills to diagnose and resolve common problems in irrigation automation systems, including sensor malfunctions, communication errors, and control issues.

- Energy Efficiency and Sustainability: Understand strategies to optimize water and energy use in irrigation systems, aligning with sustainable practices and environmental regulations.

- Cybersecurity in Irrigation Systems: Explore the importance of cybersecurity measures to protect irrigation systems from unauthorized access and potential damage.

Next Steps

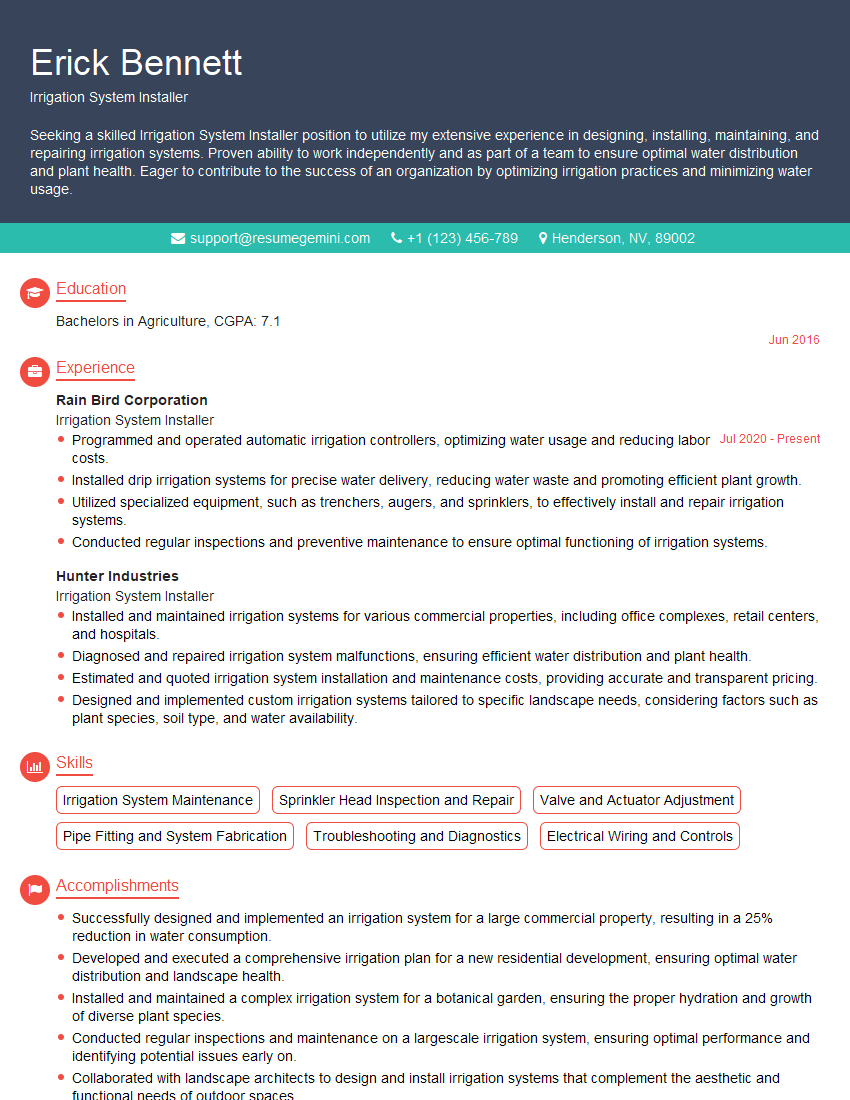

Mastering irrigation system automation opens doors to exciting career opportunities in a rapidly growing field. Demonstrating expertise in this area significantly enhances your job prospects. To increase your chances of securing your dream role, focus on crafting a highly effective, ATS-friendly resume that showcases your skills and experience. We highly recommend using ResumeGemini to build a professional resume that stands out. ResumeGemini provides you with the tools and resources to create a compelling resume and offers examples tailored specifically to the Irrigation System Automation field.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

good