Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Knowledge of Die Casting Processes interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Knowledge of Die Casting Processes Interview

Q 1. Explain the difference between high-pressure and low-pressure die casting.

The primary difference between high-pressure and low-pressure die casting lies in how the molten metal is injected into the die. High-pressure die casting, also known as HPDC, uses a high-velocity piston to force molten metal into the die cavity under extremely high pressure (typically 1000-2000 psi). This results in very fine surface details and excellent dimensional accuracy but also generates a lot of heat and requires robust machinery. Think of it like squeezing toothpaste from a tube with great force – the metal is rapidly forced into every crevice of the mold. Low-pressure die casting, conversely, uses gravity or a low-pressure pump to fill the die cavity. It’s much gentler on the machine and the metal, resulting in less porosity and improved mechanical properties, but it limits the complexity of shapes that can be cast and may result in slightly less detailed surface finishes. Imagine pouring water gently into a mold compared to forcefully injecting it.

In short: HPDC prioritizes speed, high detail, and thin wall sections, while LPDC favors improved mechanical properties, lower porosity, and potentially larger castings.

Q 2. Describe the various die casting alloys and their applications.

A wide range of alloys are used in die casting, each chosen based on the desired properties of the final product. Here are some prominent examples:

- Aluminum Alloys: Widely used due to their lightweight nature, excellent corrosion resistance, and good castability. Applications span automotive parts (engine blocks, transmission cases), consumer electronics housings, and aerospace components. Specific alloys like 380 and 383 are particularly common.

- Zinc Alloys: Known for their superior surface finish, dimensional stability, and ease of machining. Commonly employed in decorative items, automotive parts (door handles, trim), and electrical components.

- Magnesium Alloys: The lightest of all structural metals, offering excellent strength-to-weight ratio. Primarily used in automotive and aerospace industries for components requiring lightweight designs. AZ91D is a frequently used alloy.

- Copper Alloys: Offer high thermal and electrical conductivity, excellent corrosion resistance, and high strength. Used in electrical connectors, plumbing fittings, and various industrial components. Brass and bronze are common choices.

- Tin-Lead Alloys: (Although facing increasing environmental restrictions) Historically used for applications requiring high corrosion resistance and low melting points. Applications include soldering and some specialized electrical components.

The selection of alloy is a critical design decision, influenced by factors such as cost, performance requirements, and recyclability.

Q 3. What are the common defects found in die castings and their causes?

Die casting, while efficient, is susceptible to several defects. Understanding these is crucial for quality control.

- Porosity: Gas bubbles trapped within the casting, leading to reduced strength and permeability. Caused by insufficient venting, improper metal treatment, or rapid cooling.

- Cold Shut: Incomplete fusion of two streams of molten metal, creating a weak point in the casting. Results from insufficient metal flow, low casting temperature, or die design flaws.

- Shrinkage: Volume reduction as the metal solidifies, leading to internal voids or surface depressions. Caused by inadequate feeding of molten metal or rapid cooling.

- Misruns: Incomplete filling of the die cavity. Often due to insufficient pressure, low metal temperature, or poor gating system design.

- Surface Defects: Rough surfaces, cracks, or pitting. These are caused by various factors, including die wear, improper die lubrication, or entrapped air.

Careful control of process parameters, regular die maintenance, and thorough inspection are essential to minimize these defects.

Q 4. How do you control the dimensional accuracy of die castings?

Dimensional accuracy in die casting is critical for proper assembly and functionality. It’s controlled through a combination of approaches:

- Precise Die Design: Careful CAD design with accurate tolerances and consideration for thermal expansion and contraction during the casting process.

- Die Material and Construction: High-quality steel dies with proper heat treatment are crucial for dimensional stability and wear resistance.

- Controlled Casting Parameters: Maintaining consistent metal temperature, injection pressure, and cooling rates is essential for minimizing dimensional variations.

- Die Temperature Control: Maintaining optimal die temperature prevents excessive expansion and contraction, enhancing dimensional accuracy.

- Post-Casting Machining: In some cases, minor machining is done after casting to correct any deviations from the target dimensions.

- Statistical Process Control (SPC): Regular monitoring and analysis of casting dimensions using SPC techniques identify and correct any trends or deviations.

A well-planned and executed process incorporating these elements ensures consistently accurate castings.

Q 5. Explain the role of gating and venting in the die casting process.

Gating and venting are crucial elements of the die casting process that significantly impact the quality of the final product.

Gating: The gating system guides the molten metal from the shot sleeve into the die cavity. It controls the flow rate, direction, and pressure of the molten metal. A well-designed gating system ensures complete filling of the cavity while minimizing turbulence and air entrapment. Think of it as a carefully planned highway system for the molten metal to reach its destination smoothly.

Venting: The venting system consists of small channels or grooves in the die that allow for the escape of trapped air and gases. Without adequate venting, these gases can be incorporated into the casting leading to defects like porosity and blowholes. It’s like providing escape routes for air to prevent congestion.

Careful consideration of gating and venting designs is essential for producing sound castings free from defects. The design is often iterative, relying on simulations and experiments to optimize metal flow and air escape.

Q 6. Describe the different types of die casting machines.

Die casting machines are categorized primarily by the method of metal injection:

- Cold Chamber Machines: The molten metal is ladled into the shot sleeve before injection. They offer greater control over metal temperature and are suitable for alloys with high melting points.

- Hot Chamber Machines: The molten metal is held in a reservoir connected directly to the shot sleeve. These are faster and more suitable for low melting point alloys like zinc.

- Low-Pressure Machines: Utilize gravity or low-pressure pumps to fill the die. This results in denser castings with fewer defects but with limitations on the complexity of the cast shapes. These are discussed further in question 1.

Within these categories, machines vary in size, clamping force, and injection pressure, reflecting the size and complexity of castings produced.

Q 7. What are the safety precautions to be taken during die casting operations?

Die casting operations involve working with molten metal at high temperatures and pressures, requiring stringent safety precautions:

- Personal Protective Equipment (PPE): Employees must wear appropriate PPE, including heat-resistant gloves, safety glasses, and face shields to protect against splashes and burns.

- Emergency Shut-off Systems: Easily accessible emergency stop buttons should be readily available at each machine.

- Proper Ventilation: Adequate ventilation is crucial to remove fumes and harmful gases generated during the casting process.

- Machine Guards: Machines should be fitted with appropriate guards to prevent accidental contact with moving parts.

- Lockout/Tagout Procedures: Strict lockout/tagout procedures should be followed during maintenance or repairs to prevent accidental activation.

- Fire Safety Measures: Fire extinguishers appropriate for metal fires should be strategically placed.

- Training and Education: Employees must receive thorough training on safe operating procedures and emergency response protocols.

A culture of safety, combined with rigorous adherence to these protocols, is essential for preventing accidents and injuries in a die casting environment.

Q 8. How is the quality of die castings ensured?

Ensuring the quality of die castings involves a multifaceted approach encompassing the entire process, from design and material selection to production and inspection. It’s like baking a cake – you need the right ingredients, the correct recipe, and precise execution to achieve a perfect result.

- Material Selection: Using high-quality alloys with consistent chemical composition is crucial. Variations can lead to defects like porosity or cracking. We carefully analyze material certificates to ensure compliance with specifications.

- Die Design and Manufacturing: Precise die design and meticulous manufacturing are fundamental. Imperfections in the die can directly translate into defects in the castings. Finite Element Analysis (FEA) is often employed to optimize die design and prevent problems like hot tearing.

- Process Parameter Control: Maintaining tight control over parameters like die temperature, injection pressure, and melt temperature is essential. Variations here can lead to dimensional inconsistencies, surface imperfections, or internal defects. We use sophisticated sensors and automated control systems to ensure consistent process parameters.

- Inspection and Testing: Rigorous inspection and testing are paramount. This involves visual inspection, dimensional measurements, metallurgical analysis (to detect porosity or cracks), and mechanical testing (to verify strength and other properties). We utilize both manual inspection and automated systems like CMM (Coordinate Measuring Machine) for high accuracy.

- Continuous Improvement: Employing statistical process control (SPC) and regularly reviewing processes helps identify areas for improvement and proactively prevent defects. We use data-driven decision-making to refine our processes and continually enhance quality.

Q 9. What is the significance of die temperature control in die casting?

Die temperature control is absolutely critical in die casting. Think of it like controlling the oven temperature when baking: too hot, and you burn the cake; too cold, and it won’t cook properly. In die casting, the die temperature directly impacts several key aspects:

- Filling: A properly controlled die temperature ensures consistent and complete filling of the die cavity, minimizing porosity and cold shuts (where the metal doesn’t completely fuse).

- Solidification: Appropriate die temperature influences the cooling rate of the molten metal, impacting the microstructure and mechanical properties of the final casting. Too rapid cooling can lead to internal stresses and cracking, while too slow cooling can result in a coarse microstructure.

- Dimensional Accuracy: Maintaining a stable die temperature is essential for producing castings with consistent and accurate dimensions. Temperature fluctuations can cause dimensional variations.

- Die Life: Careful temperature control extends the life of the die by reducing thermal stress and wear. Excessive temperature variations can lead to premature die failure.

- Surface Finish: The die temperature affects the surface finish of the casting. A well-controlled temperature leads to a smoother, more consistent surface.

We use sophisticated temperature control systems, including automated feedback loops and thermal barrier coatings on the dies, to maintain precise temperature control.

Q 10. Explain the process of die casting tooling design and maintenance.

Die casting tooling design and maintenance are complex but crucial aspects of the process. It’s like designing and maintaining the mold for our ‘cake’.

- Design Phase: This involves using CAD software to create a detailed 3D model of the die, incorporating features like cooling channels, ejector pins, and parting lines. FEA is used extensively to simulate the filling process, stress distribution, and potential problems. Careful consideration is given to material selection (tool steels with high wear resistance), and manufacturability.

- Manufacturing Phase: The die is then manufactured through machining, EDM (Electrical Discharge Machining), or other advanced techniques. High precision is required to achieve the desired tolerances and surface finish.

- Maintenance Phase: Regular maintenance is vital to extend die life and maintain casting quality. This includes:

- Regular Inspection: Visual inspection for wear, cracks, or erosion.

- Cleaning: Removing residual metal and debris after each production run.

- Polishing and Repair: Polishing worn areas and repairing minor damage using welding or other techniques. For significant damage, die refurbishment or replacement may be necessary.

- Lubrication: Applying appropriate lubricants to reduce friction and wear.

Preventive maintenance is key—regular inspections and minor repairs prevent costly downtime and premature die failure. We maintain detailed records of die usage and maintenance to track performance and plan for future maintenance.

Q 11. How do you troubleshoot common die casting problems?

Troubleshooting die casting problems requires a systematic approach. It’s like detective work—we need to gather clues and systematically eliminate possibilities.

- Identify the Problem: Precisely define the nature of the defect (e.g., porosity, cold shuts, dimensional inaccuracies, surface defects). Gather data including visual inspection, measurements, and any available process data.

- Analyze the Process Parameters: Examine all relevant parameters (melt temperature, injection pressure, die temperature, etc.) to identify deviations from the norm. Data logging systems and statistical process control (SPC) charts are invaluable here.

- Check the Die Condition: Inspect the die for wear, cracks, erosion, or other damage. This could be the root cause of many problems.

- Examine the Material: Ensure the alloy composition is correct and meets specifications. Variations in material properties can significantly impact casting quality.

- Assess the Lubrication: Insufficient or improper lubrication can lead to various casting defects. Ensure that the right type and quantity of lubricant are used.

- Consider External Factors: Environmental conditions, operator errors, and machine malfunctions can also contribute to defects.

A systematic approach, combined with experience and thorough documentation, is crucial for effective troubleshooting. We often use Pareto charts to identify the vital few factors contributing to the majority of problems.

Q 12. Describe the role of lubricants and their impact on the die casting process.

Lubricants play a vital role in the die casting process, acting as a buffer between the molten metal and the die. Think of them as a protective layer, preventing metal adhesion and reducing friction and wear.

- Reducing Friction and Wear: Lubricants reduce friction between the molten metal and the die surface, minimizing wear and tear on the die. This extends the die’s life and reduces the risk of casting defects caused by die imperfections.

- Preventing Metal Adhesion: They prevent the molten metal from sticking to the die surface, ensuring easy ejection of the casting and preventing surface defects. Without proper lubrication, castings might stick to the die and be damaged during ejection.

- Improving Surface Finish: Lubricants can improve the surface finish of the castings, leading to a smoother and more aesthetically pleasing product. The quality of the lubricant influences the surface texture.

- Controlling Die Temperature: Certain lubricants can help control the die temperature, ensuring consistent and optimal cooling rates. This affects the microstructure and mechanical properties.

Choosing the right lubricant is crucial, considering factors like the alloy being used, the die material, and the desired surface finish. We select lubricants based on thorough testing and analysis of their performance characteristics.

Q 13. What are the environmental concerns associated with die casting?

Die casting, while highly efficient, does present some environmental concerns that need careful management. It’s important to consider the impact on the environment throughout the entire lifecycle.

- Emissions: The melting process can release harmful gases and particulate matter into the atmosphere. Proper ventilation and emission control systems are essential. We adhere to strict environmental regulations for air quality.

- Waste Generation: Die casting generates various types of waste, including scrap metal, used lubricants, and machining debris. Recycling and proper waste disposal are crucial to minimize environmental impact. We actively recycle scrap metal and utilize responsible waste management practices.

- Water Usage: The process may require water for cooling, cleaning, and other purposes. Water conservation and responsible water management practices are key. We actively pursue water-efficient processes.

- Energy Consumption: Die casting is an energy-intensive process. Using energy-efficient equipment and optimizing process parameters can reduce energy consumption and our carbon footprint. We continuously strive to improve energy efficiency in our operations.

We believe in sustainable manufacturing and are committed to minimizing our environmental impact through continuous improvement and adherence to stringent environmental regulations. We regularly audit our operations for environmental compliance and continuously seek ways to lessen our environmental footprint.

Q 14. Explain the concept of shot sleeve and its function.

The shot sleeve, also known as a shot bushing or injection sleeve, is a crucial component in die casting machines, particularly in high-pressure die casting. Think of it as the nozzle that precisely delivers the molten metal into the die cavity.

Its function is to:

- Control Metal Flow: The shot sleeve accurately guides and controls the flow of molten metal from the gooseneck (the channel connecting the melting pot to the die) into the die cavity. This ensures consistent filling of the cavity.

- Prevent Metal Splashing: It prevents the molten metal from splashing or prematurely solidifying before entering the die cavity.

- Maintain Pressure: The shot sleeve helps maintain the injection pressure required for proper die filling.

- Protect the Die: By controlling the metal flow, it protects the die from erosion and premature wear, extending its lifespan.

The shot sleeve is typically made of wear-resistant materials and needs regular inspection and replacement to ensure optimal performance. Improper shot sleeve operation can lead to various casting defects. Regular maintenance ensures optimal function and prevents casting quality issues.

Q 15. How is the molten metal temperature controlled in the die casting process?

Molten metal temperature control in die casting is crucial for achieving high-quality castings. It directly impacts the fluidity, filling of the die cavity, and the final mechanical properties of the part. Temperature is typically monitored and controlled using a combination of methods.

- Thermocouples: These sensors are placed within the molten metal holding furnace and provide a continuous reading of the temperature. This allows for precise adjustments to the heating elements to maintain the desired temperature range.

- Temperature Controllers: These are sophisticated devices that regulate the heating elements based on the thermocouple readings. They employ feedback loops to ensure stability and minimize fluctuations.

- Metal Preheaters: In some processes, preheating the metal before it enters the casting machine further enhances temperature control and minimizes thermal shock to the die.

- Insulation: Maintaining proper insulation of the molten metal holding system is vital to minimize heat loss and maintain a stable temperature.

For example, aluminum die casting typically operates within a very narrow temperature window – usually between 680°C and 720°C – to guarantee optimal fluidity and prevent defects such as porosity or cold shuts. Variations outside this range will require adjustments to the heating system to bring the temperature back within the defined parameters.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the different types of die casting dies?

Die casting dies are complex tools engineered for precision and durability. They come in various types, mainly categorized by their construction and the casting method they support.

- Permanent Mold Dies: These are typically made from high-strength materials like steel and are reusable. They are often used in high-pressure die casting. These are designed for longer production runs and offer superior dimensional accuracy compared to other methods.

- Expendable Mold Dies: These dies are used for a single casting operation. Examples include investment casting and lost-foam casting. These methods may be favored for complex geometries that are difficult to produce using permanent mold dies.

- Hot Chamber Dies: Used in die casting, these dies have the molten metal directly injected from a reservoir that is a part of the casting machine. Primarily used for lower melting point metals like zinc and lead-based alloys.

- Cold Chamber Dies: In this process, the molten metal is ladled into the injection chamber before injection. This method is more common for aluminum and magnesium alloys.

The choice of die type depends on factors such as the metal being cast, the complexity of the part, production volume, and cost considerations. For instance, a high-volume production of simple aluminum parts might use a hot chamber die, while a lower volume production of a complex shape in steel might use a cold chamber permanent mold die.

Q 17. Explain the importance of proper die cleaning and maintenance.

Proper die cleaning and maintenance are paramount for maintaining die life, ensuring consistent casting quality, and minimizing downtime. Neglecting this aspect can lead to significant production losses and increased costs.

- Cleaning: After each casting cycle, the die needs thorough cleaning to remove residual metal, oxide layers, and other debris. Specialized cleaning agents, blasting media (such as shot peening), and ultrasonic cleaning are often employed. Removing these materials prevents build-up which can affect dimensional accuracy and potentially damage the die.

- Lubrication: Applying die release agents is crucial. These lubricants minimize friction between the molten metal and the die surfaces, preventing sticking, improving surface finish, and extending the die’s life.

- Inspection: Regular inspection for wear, cracks, or other damage is critical. This involves checking for erosion, scoring, or deformation of the die cavity. Early detection of problems allows for timely repairs or replacements, minimizing disruption of production.

- Repair and Maintenance: Minor repairs, such as welding or machining, might be possible to extend the die’s lifespan. However, for significant damage, die replacement will be necessary.

Think of the die as a precision instrument – regular maintenance is akin to servicing a car engine. Neglecting this can lead to catastrophic failure, just as neglecting a car’s engine maintenance can lead to significant and costly repairs.

Q 18. Describe the process of die casting automation and its benefits.

Die casting automation enhances efficiency and consistency in the production process. Several aspects can be automated:

- Die Casting Machines: Modern die casting machines are highly automated, with programmable controls managing injection pressure, speed, and holding time. This ensures consistency across castings.

- Material Handling: Automated systems manage the handling of molten metal, ingots, and finished castings. Robots handle the removal of castings from the die, reducing human intervention and improving safety.

- Die Lubrication and Cleaning: Automated systems can apply lubricants and clean the die, ensuring consistent quality and reducing downtime.

- Quality Control: Automated vision systems and dimensional measurement tools integrate into the process to inspect the castings and identify defects in real-time. This reduces human error and enhances quality control.

The benefits of automation include increased productivity, improved casting quality, reduced labor costs, enhanced safety, and consistent production parameters. For example, an automated system could produce hundreds of castings per hour with minimal variation in quality, compared to a manual process that would be significantly slower and less consistent.

Q 19. What are the different types of casting defects and their causes?

Several defects can occur during die casting. Understanding their causes is crucial for preventative measures.

- Cold Shut: Two streams of molten metal fail to fuse properly, resulting in a weak seam. This is often due to insufficient molten metal temperature or injection pressure.

- Porosity: Presence of air bubbles or gas pockets within the casting, leading to reduced strength and potential leaks. This can be caused by high gas content in the molten metal, improper venting of the die, or insufficient melt temperature.

- Shot Sleeve: A solidified piece of metal on the casting surface. This is often caused by insufficient lubrication or die wear.

- Surface Cracks: Cracks appearing on the casting surface due to internal stresses, caused by rapid cooling or improper alloy selection.

- Short Shot: The die cavity isn’t fully filled, resulting in an incomplete casting. This is usually caused by low injection pressure or speed, or insufficient molten metal.

Identifying the root cause of a defect requires careful analysis, often involving microscopic examination and process parameter review. Addressing the underlying cause, rather than simply treating the symptom, is vital to prevent recurrence.

Q 20. How do you measure the dimensional accuracy of a die casting part?

Measuring the dimensional accuracy of a die casting part is essential for ensuring it meets specifications. This involves employing a range of precision measurement techniques.

- Coordinate Measuring Machines (CMMs): These highly accurate devices can measure the dimensions of complex parts to within micrometers. They provide detailed information on the part’s geometry.

- Optical Comparators: These instruments project an enlarged image of the part onto a screen, enabling precise measurement of dimensions and surface features.

- Gauges: Specialized gauges, including calipers, micrometers, and height gauges, provide rapid and convenient measurements for specific dimensions.

- Laser Scanners: These provide fast and non-contact methods for generating point clouds, which can then be used to create a precise 3D model of the part. This allows for comparison against the CAD model to assess dimensional accuracy.

The choice of method depends on the complexity of the part, the required precision, and the available equipment. For instance, simple parts might be measured using calipers, while complex shapes might necessitate the use of a CMM for comprehensive dimensional analysis.

Q 21. What is the role of a die casting process engineer?

A die casting process engineer plays a critical role in optimizing the entire die casting process, from design to production. Their responsibilities span various areas:

- Process Optimization: They work on improving efficiency, reducing defects, and lowering production costs by analyzing process parameters and making necessary adjustments.

- Die Design Review: They provide input on die design to ensure manufacturability, reduce casting defects, and improve die life.

- Material Selection: They help select the appropriate alloys and lubricants for optimal casting results.

- Troubleshooting: They diagnose and resolve issues related to casting defects, equipment malfunctions, and process inconsistencies.

- Quality Control: They ensure adherence to quality standards and implement appropriate quality control measures.

- Process Monitoring and Data Analysis: They use data from the production process to identify trends, predict potential problems, and make proactive adjustments.

In essence, the die casting process engineer acts as the process expert, continuously working to improve and optimize the efficiency, quality, and cost-effectiveness of the casting operation. They bridge the gap between design and manufacturing, ensuring that the product meets the desired specifications while minimizing production challenges.

Q 22. Describe the process of designing and manufacturing die casting tooling.

Designing and manufacturing die casting tooling is a complex process requiring precision and expertise. It starts with the part design, which is meticulously analyzed for manufacturability. This involves considering factors like wall thickness, draft angles (the slight taper needed for part removal), and ejection mechanisms. Then, a 3D model of the die is created, often using CAD software. This model is used to create a CNC (Computer Numerical Control) program for machining the die.

The die itself consists of two main parts: the cavity (female die) and the core (male die). These are typically made from high-strength tool steels, chosen for their heat resistance and durability. The manufacturing process is meticulous, involving milling, drilling, and EDM (Electrical Discharge Machining) for intricate details. After machining, the die undergoes heat treatment to enhance its hardness and wear resistance. Finally, the die is assembled, incorporating features like ejector pins (to push the casting out), cooling channels (to control the cooling rate), and runners (channels that direct molten metal into the cavity). Throughout this entire process, rigorous quality checks are performed to ensure dimensional accuracy and surface finish.

For example, designing a die for a complex automotive part would involve extensive FEA (Finite Element Analysis) simulations to predict stress and strain during the casting process, ensuring the die’s longevity. The chosen steel grade would be critical, possibly a high-speed steel for superior abrasion resistance. The cooling channels would be carefully designed to achieve the ideal cooling rate for the part’s geometry to minimize defects like porosity and shrinkage.

Q 23. What are the different types of die casting processes?

There are several die casting processes, each with its own advantages and disadvantages. The most common are:

- High-pressure die casting (HPDC): This is the most prevalent method, using high pressure (up to 20,000 psi) to inject molten metal into the die cavity. This results in high-quality castings with excellent dimensional accuracy and surface finish. It’s ideal for complex shapes and high-volume production.

- Low-pressure die casting (LPDC): In this method, molten metal is poured into a cavity under low pressure. This process reduces metal turbulence and porosity, resulting in denser castings. It’s often preferred for larger and more intricate parts.

- Vacuum die casting: This technique involves casting under vacuum conditions to remove air and gases from the molten metal, further reducing porosity and improving casting quality. It’s used for applications where high integrity and freedom from defects are paramount.

- Semi-solid die casting (SSD): This involves injecting a partially solidified metal slurry into the die. It offers benefits like reduced porosity and improved mechanical properties compared to traditional methods.

The choice of process depends on the part’s design, material, required quality, and production volume. For instance, a small, intricate electronic component might be ideally suited to HPDC, while a large, complex automotive part might benefit from LPDC or even a combination of methods.

Q 24. Explain the principles of heat transfer in die casting.

Heat transfer in die casting is crucial for achieving high-quality castings. The process involves rapid cooling of the molten metal within the die cavity. This cooling rate affects the solidification process and ultimately the final properties of the casting. The principles governing this heat transfer are primarily conduction and convection.

Conduction: Heat is transferred directly from the molten metal to the die walls. The rate of conduction is influenced by the thermal conductivity of both the molten metal and the die material, as well as the thickness of the die walls and the contact area between the metal and the die. Thicker die walls with lower thermal conductivity will result in slower cooling.

Convection: This involves the movement of heated fluid (molten metal) within the die cavity. Efficient cooling channels in the die facilitate convection, ensuring uniform cooling. The design and location of these channels directly impact the cooling rate and the possibility of achieving consistent solidification throughout the casting. Inefficient cooling can lead to defects like hot tears or shrinkage porosity.

Imagine pouring hot water into a thin metal cup versus a thick ceramic mug. The thin metal cup cools down much faster due to its high thermal conductivity and thin walls, just as a thin-walled die would produce faster cooling of the casting.

Q 25. What are the different methods for surface finishing of die castings?

Surface finishing of die castings is essential for achieving the desired aesthetic appeal and functional performance. Several methods are available, each suitable for different needs:

- Tumbling: Parts are placed in a rotating barrel with abrasive media to remove burrs and improve surface finish. It’s a cost-effective method for achieving a relatively smooth surface.

- Vibratory Finishing: Similar to tumbling, but uses a vibratory motion to polish the parts. This provides a finer finish than tumbling.

- Shot blasting: Abrasive media is propelled at high velocity against the surface, achieving a rougher finish, often used to prepare surfaces for painting or powder coating.

- Electroplating: A thin layer of metal is deposited onto the surface, enhancing corrosion resistance and appearance. Common examples include chrome plating or nickel plating.

- Powder coating: A dry powder is applied electrostatically and cured in an oven, providing a durable and aesthetically pleasing coating.

- Painting: Liquid paint is applied, offering a wide range of colors and finishes.

The choice of method depends on the required surface finish, the desired properties (corrosion resistance, wear resistance), and cost considerations. For example, a highly polished chrome finish might be desired for a luxury car component, while a simple paint finish might suffice for a less visible industrial part.

Q 26. How do you optimize the die casting process for cost-effectiveness?

Optimizing the die casting process for cost-effectiveness requires a multifaceted approach. It’s about balancing quality, speed, and efficiency without compromising the final product’s integrity.

- Die Design Optimization: Efficient die designs minimize material waste, reduce cycle times, and improve casting quality, all contributing to lower production costs. Clever gating systems and runner designs can reduce material usage and improve metal flow.

- Material Selection: Choosing the right alloy can significantly impact the casting process. Using less expensive materials while maintaining the required mechanical properties can reduce material costs.

- Process Parameter Optimization: Careful control of parameters such as injection pressure, injection speed, and die temperature can minimize defects, improve yield, and reduce scrap. This requires meticulous monitoring and adjustments based on real-time data.

- Automation: Implementing automation in various stages of the process, such as die handling, part ejection, and quality control, improves productivity and reduces labor costs. Robotics can play a crucial role here.

- Preventive Maintenance: Regular maintenance of the die casting machine and tooling extends their lifespan, minimizing downtime and repair costs.

For example, implementing a lean manufacturing approach within a die casting facility can significantly improve overall efficiency by streamlining workflows and reducing waste. Continuous improvement initiatives, such as Kaizen events, can help identify and eliminate inefficiencies throughout the entire process.

Q 27. What are the latest advancements in die casting technology?

Recent advancements in die casting technology are focused on improving efficiency, precision, and sustainability.

- 3D Printing of Dies: Additive manufacturing (3D printing) is increasingly used to create dies, particularly for prototypes and low-volume production. This allows for rapid prototyping and complex die geometries that are difficult to achieve using traditional machining methods.

- Improved Die Materials: Advanced die materials with enhanced heat resistance and wear resistance are constantly being developed, extending die lifespan and reducing maintenance costs.

- Smart Manufacturing Technologies: Integration of sensors and data analytics enables real-time process monitoring and control. This helps in optimizing the casting process, minimizing defects, and improving overall efficiency. Predictive maintenance algorithms can also optimize maintenance schedules.

- High-Velocity Injection Systems: Newer injection systems allow for faster injection speeds, shortening cycle times and increasing production output.

- Sustainable Practices: Efforts are being made to reduce energy consumption and waste generation throughout the process. This involves using more energy-efficient equipment, adopting closed-loop systems for metal recycling, and employing more sustainable die materials.

For instance, the use of AI in die casting is gaining traction. AI-powered systems can analyze large datasets from the casting process to identify patterns and anomalies, allowing for predictive maintenance and early detection of potential problems. This minimizes downtime and ensures consistent product quality.

Q 28. Explain the process of quality control in die casting

Quality control in die casting is crucial to ensure consistent product quality and meet customer specifications. It involves a multi-stage approach, starting from the initial design and extending to the final inspection.

- Incoming Material Inspection: Raw materials, including molten metal and die materials, are inspected to verify their properties and compliance with specifications.

- Die Inspection: Regular inspection of the die for wear, damage, and dimensional accuracy ensures consistent casting quality. This includes checking for wear on the cavity and core, as well as the condition of ejector pins and cooling channels.

- Process Monitoring: Key parameters like injection pressure, temperature, and cycle time are continuously monitored using sensors and data acquisition systems. Deviations from established parameters are immediately addressed.

- In-Process Inspection: Castings are inspected at various stages of the production process to detect defects early. This might involve visual inspection, dimensional checks, and destructive or non-destructive testing methods.

- Final Inspection: Finished castings undergo a thorough inspection to verify compliance with customer specifications and quality standards. This includes dimensional checks, surface finish evaluation, and mechanical property testing.

- Statistical Process Control (SPC): SPC methods are employed to monitor and control process variability, ensuring consistent casting quality over time. Control charts are used to track key parameters and identify any trends or anomalies.

Imagine a scenario where a die casting company producing automotive parts fails to maintain proper quality control. Defective parts could lead to catastrophic failures, resulting in significant financial losses and reputational damage. A rigorous quality control system is therefore critical to prevent such events.

Key Topics to Learn for Your Die Casting Processes Interview

Ace your next interview by mastering these key areas of die casting knowledge. We’ve broken down the essential concepts to help you showcase your expertise.

- Die Casting Processes Overview: Understand the different types of die casting (high-pressure, low-pressure, etc.), their applications, and their relative advantages and disadvantages. Be prepared to discuss the entire process flow, from design to finished product.

- Material Selection and Properties: Demonstrate knowledge of various alloys used in die casting (aluminum, zinc, magnesium, etc.) and how their properties influence the casting process and final product characteristics. Discuss factors affecting material selection for specific applications.

- Die Design and Construction: Explain the critical aspects of die design, including gating systems, venting, cooling systems, and ejection mechanisms. Discuss the materials used in die construction and their impact on die life and casting quality.

- Process Parameters and Optimization: Understand the influence of key parameters such as injection pressure, injection speed, die temperature, and holding time on the quality of the castings. Discuss methods for optimizing these parameters to achieve desired results.

- Quality Control and Inspection: Explain various quality control methods used in die casting, including visual inspection, dimensional measurements, and destructive/non-destructive testing. Discuss common defects and their root causes.

- Troubleshooting and Problem Solving: Be prepared to discuss common problems encountered in die casting (e.g., porosity, cold shuts, cracks) and your approach to identifying and resolving these issues. Highlight your analytical and problem-solving skills.

- Safety and Environmental Considerations: Demonstrate awareness of safety protocols and environmental regulations related to die casting operations, including handling of molten metals and waste management.

Next Steps: Boost Your Career Prospects

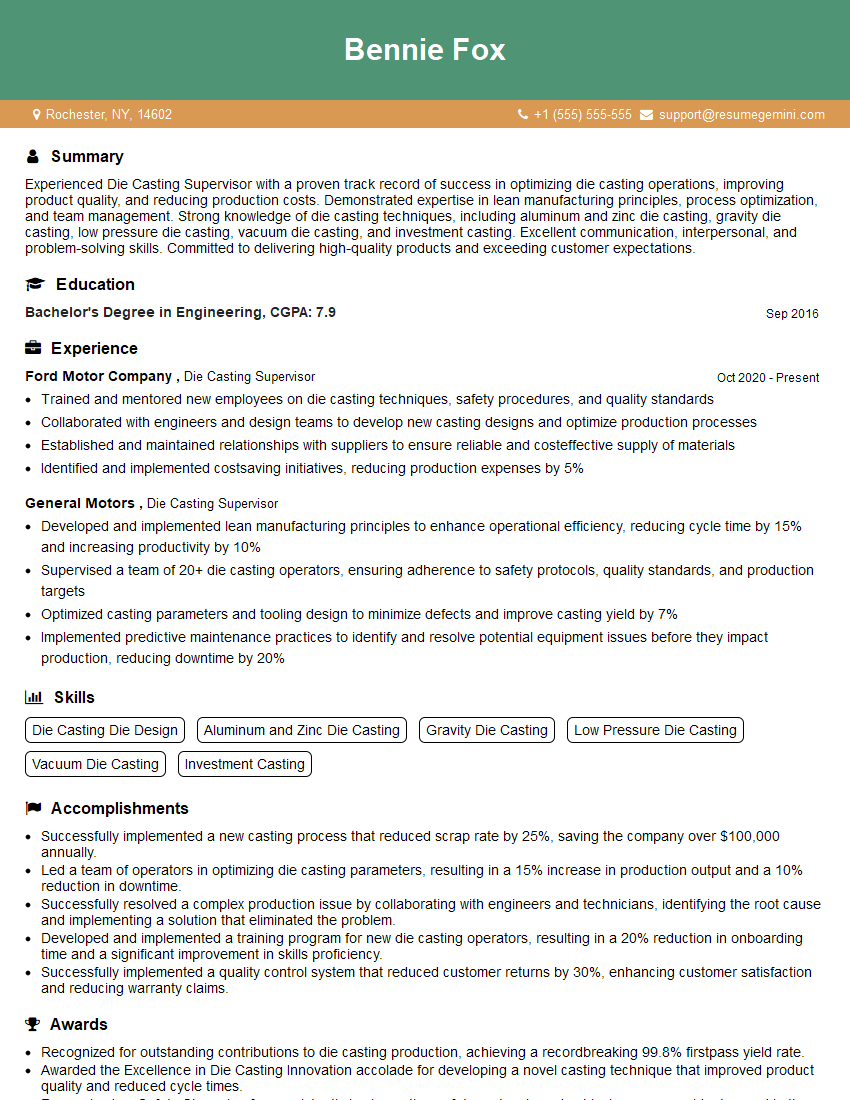

Mastering die casting processes is crucial for career advancement in manufacturing and engineering. A well-crafted resume is your key to unlocking opportunities. Make sure yours is ATS-friendly to ensure it gets seen by recruiters. ResumeGemini is a trusted resource to help you build a professional and effective resume that highlights your skills and experience. We provide examples of resumes tailored specifically to professionals with Knowledge of Die Casting Processes to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good