Cracking a skill-specific interview, like one for Loading and Unloading of Freight, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Loading and Unloading of Freight Interview

Q 1. Describe your experience with different types of freight (e.g., palletized, loose, oversized).

My experience encompasses a wide range of freight types. I’ve handled everything from neatly palletized goods, easily moved with forklifts and pallet jacks, to loose, unpackaged items requiring more careful manual handling and potentially custom solutions for securement. Oversized freight, requiring specialized equipment and permits, is also a significant part of my background. For example, I’ve overseen the loading of large industrial machinery onto lowboy trailers, requiring meticulous planning to distribute weight evenly and prevent damage. Working with palletized goods is efficient and straightforward, while loose items need careful assessment to prevent shifting and damage during transport. Oversized loads are particularly challenging and demand close collaboration with drivers and specialized equipment operators.

- Palletized Freight: Efficient, standardized, easily managed with forklifts.

- Loose Freight: Requires careful manual handling, strategic placement to prevent shifting.

- Oversized Freight: Needs specialized equipment (cranes, lowboy trailers), detailed planning, and permits.

Q 2. What safety procedures do you follow when loading and unloading freight?

Safety is paramount in loading and unloading operations. My procedures always begin with a thorough risk assessment of the job, including the type of freight, equipment to be used, and environmental factors. This assessment drives the implementation of specific safety protocols. For instance, I always ensure proper PPE (Personal Protective Equipment) is worn—safety shoes, high-visibility vests, gloves, and hard hats. Before operating any equipment, I conduct a pre-operational check to ensure it’s in perfect working order. Communication is key; I always maintain clear communication with team members and drivers. Furthermore, I meticulously follow load securement guidelines to prevent shifting or falling loads during transit. Regular safety briefings and training sessions help maintain a culture of safety awareness within the team. Finally, I strictly adhere to all company and regulatory safety standards.

Q 3. How do you prioritize tasks when multiple shipments need loading/unloading simultaneously?

Prioritization when handling multiple shipments is crucial for efficiency. I employ a system that combines urgency, delivery deadlines, and freight characteristics. I typically use a combination of factors to determine order of operations: First, I identify shipments with imminent deadlines or those with time-sensitive delivery requirements. Next, I group shipments by similar freight characteristics to optimize loading and unloading processes (e.g., all palletized goods loaded together). Finally, I consider the equipment required for each shipment; if multiple shipments require the same equipment, those will be grouped together. I create a detailed loading/unloading plan, often visualized using a spreadsheet or whiteboard, to ensure clear communication and efficient workflow. This allows my team to handle multiple shipments simultaneously without compromising safety or timelines. Imagine it like an orchestra conductor: each instrument (shipment) has its part, but the conductor (me) ensures everything plays in harmony.

Q 4. Explain your experience using material handling equipment (e.g., forklifts, pallet jacks).

I’m proficient in operating various material handling equipment, including forklifts (both sit-down and stand-up), pallet jacks, and hand trucks. I possess the necessary certifications and licenses for each piece of equipment and am regularly trained on safe operating procedures. I am comfortable working with both electric and propane-powered forklifts, understanding the nuances of each type, including weight capacities and safety regulations. My experience also includes proper use of equipment attachments like fork extensions and clamp attachments. For instance, I’ve used forklifts to efficiently load and unload palletized goods onto trucks, while pallet jacks were essential for moving smaller, less heavy pallets. I understand the importance of pre-operational checks before using any equipment, ensuring functionality and safety. Safe and efficient use of this equipment is crucial for maximizing productivity while minimizing risks.

Q 5. How do you ensure the securement of freight to prevent damage during transit?

Securement of freight is vital to prevent damage during transit. My approach utilizes appropriate techniques based on the type and characteristics of the goods. For palletized goods, I ensure proper stacking, preventing overhang or instability. For loose items, I use various methods such as dunnage (protective material), bracing, and strapping to prevent shifting and damage. Oversized loads require custom securement solutions using chains, straps, and appropriate tie-downs, always ensuring compliance with weight distribution guidelines. I meticulously document the securement procedures used for each shipment, including the type of securing materials and their placement. This documentation serves as evidence of adherence to best practices and assists in identifying potential causes of damage claims. The goal is to prevent movement during transit, protecting the shipment and mitigating potential liability.

Q 6. What is your experience with inventory management in relation to loading and unloading?

Inventory management is intrinsically linked to loading and unloading. Accurate inventory tracking ensures that the correct goods are loaded and unloaded, preventing discrepancies and delays. I’m experienced in using various inventory management systems, from simple spreadsheets to more advanced software. Before loading, I cross-reference the inventory list against the shipment manifest to confirm accuracy and identify potential issues. Upon unloading, I conduct a thorough inventory check to confirm that all goods have arrived undamaged and in the correct quantities. Any discrepancies are immediately reported and documented. This detailed process ensures accountability and helps in the efficient management of inventory, facilitating smooth logistics and minimizing losses.

Q 7. Describe a time you had to deal with a damaged shipment during loading/unloading. How did you handle it?

During a recent shipment of delicate glassware, a pallet collapsed during unloading due to improper stacking by the previous handler. Several boxes were damaged. My immediate response was to prioritize safety: we secured the area to prevent further damage or accidents. Then, I systematically documented the extent of the damage, taking photos and creating a detailed report, including the condition of the packaging. I contacted the shipper and the receiver immediately, informing them of the situation and providing the photographic evidence. Collaboratively, we determined the best course of action; the damaged goods were carefully set aside for insurance claims, and the undamaged portion was delivered. The incident prompted a review of our handling procedures to prevent similar incidents in the future, emphasizing the importance of thorough inspection of incoming pallets.

Q 8. How do you identify and handle hazardous materials during loading and unloading?

Identifying and handling hazardous materials is paramount for safety and legal compliance. It starts with proper identification using the Globally Harmonized System of Classification and Labelling of Chemicals (GHS) and the associated hazard pictograms and labels on packages. These labels clearly indicate the dangers – flammable, corrosive, toxic, etc.

My handling strategy involves several key steps:

- Visual Inspection: Carefully examine each package for damage, leaks, or missing labels. Report any anomalies immediately.

- Safety Data Sheet (SDS) Review: Before handling, I always consult the SDS for the specific material. This document provides vital information on handling procedures, emergency response, and personal protective equipment (PPE) required.

- Proper PPE: I strictly adhere to the recommended PPE, which may include gloves, respirators, eye protection, and specialized clothing.

- Designated Areas: Hazardous materials are stored and handled in designated areas, separate from other goods, to minimize risks of contamination or accidents.

- Secure Loading/Unloading: Hazardous materials are carefully secured during transportation to prevent shifting or spills. This might involve specialized packaging, bracing, or securement methods.

- Documentation: Meticulous record-keeping is crucial. I document everything, from the type of material to the handling procedures, and any incidents or near misses.

For example, during the loading of a shipment containing Class 3 flammable liquids, I would ensure that the containers are properly labeled, inspect for leaks, use appropriate spill containment measures, and wear the necessary PPE, including flame-resistant clothing and gloves. The containers would be secured with additional bracing to prevent movement during transport.

Q 9. What are your strategies for efficient loading and unloading to minimize time and resources?

Efficient loading and unloading is all about optimizing space, minimizing handling time, and preventing damage. My strategies focus on planning and execution:

- Pre-Loading Planning: I start by reviewing the shipping manifest and the dimensions of the truck or container. This allows me to create a loading plan that maximizes space utilization and ensures weight distribution is balanced.

- Optimized Sequencing: Items are sequenced for efficient loading and unloading. Items needed first are placed last to be unloaded first (FIFO).

- Proper Equipment: Utilizing forklifts, pallet jacks, conveyor belts, and other equipment significantly speeds up the process and reduces manual labor.

- Teamwork and Communication: Effective communication among the loading team is crucial. Clear instructions, assigned roles, and efficient coordination ensure smooth operation.

- Regular Maintenance: Keeping equipment in good working order minimizes downtime and prevents delays.

- Continuous Improvement: Regularly reviewing loading and unloading processes to identify bottlenecks and areas for improvement.

For instance, when loading a truck with various palletized goods, I would strategize based on weight, size and destination. Heavier items would be loaded at the bottom for stability, smaller items can fill gaps, and everything is properly secured to prevent movement.

Q 10. How familiar are you with different types of shipping containers and their loading requirements?

I’m very familiar with various shipping containers, including:

- Standard 20ft and 40ft containers: These are the most common and their loading requirements are generally straightforward, focusing on weight distribution and securing cargo to prevent shifting.

- High Cube containers: These offer increased height, beneficial for bulky, less dense items. Loading requires careful consideration of the increased center of gravity.

- Refrigerated containers (reefers): These require specialized knowledge of temperature control and appropriate placement of goods to maintain the cold chain.

- Open-top containers: These allow for overhead loading of bulky or oversized items. Securing cargo is vital to prevent loss during transit.

- Flatrack containers: These containers allow for the transport of oversized and heavy cargo, often requiring specialized lifting equipment and securement techniques.

Understanding these container types and their limitations is crucial for safe and efficient loading. For example, fragile goods would never be placed on the bottom of a standard container; they’d be placed higher up and properly padded. Similarly, understanding the weight capacity of each container type is essential to prevent overloading.

Q 11. What is your understanding of weight distribution and balance when loading trucks or containers?

Weight distribution and balance are crucial for safe transportation and prevent accidents. An unbalanced load can cause instability, leading to rollovers or damage to the cargo.

My understanding involves:

- Center of Gravity (CG): Maintaining a low CG is critical. Heavier items should be positioned lower and closer to the center of the vehicle to minimize sway.

- Weight Distribution Charts: Many vehicles have charts specifying weight limits for different areas. Adhering to these limits is essential.

- Load Shifting: During loading, I regularly check for potential load shifting. Proper bracing and securing methods are used to prevent this.

- Weight Scales: Using scales for verifying weights ensures that vehicles aren’t overloaded.

For example, when loading a truck, I’d place heavy pallets towards the center and low down, and lighter ones on top and towards the front and rear but evenly. If I notice one side is heavier than the other, I’ll adjust the load to improve balance.

Q 12. Describe your experience working with shipping manifests and Bills of Lading.

I have extensive experience working with shipping manifests and Bills of Lading. The manifest provides a detailed list of the goods being shipped, including descriptions, quantities, weights, and destinations. The Bill of Lading acts as a contract of carriage, acknowledging receipt of the goods and outlining the terms of transportation.

My use involves:

- Verification: I carefully cross-reference the manifest with the actual cargo being loaded to ensure accuracy and prevent errors.

- Tracking: The Bill of Lading is crucial for tracking shipments and verifying delivery.

- Documentation: I use the information from these documents for accurate record-keeping and reporting.

- Problem Solving: In cases of discrepancies, I work with the relevant parties to resolve issues quickly.

A real-world example might involve noticing a discrepancy between the quantity of items on the manifest and the physical inventory. I’d immediately investigate, potentially discovering a packing error. This would necessitate correcting the manifest and notifying the relevant stakeholders.

Q 13. How do you maintain accurate records of loaded and unloaded freight?

Maintaining accurate records is crucial for accountability and traceability. My methods incorporate:

- Digital Tracking Systems: Many warehouses use sophisticated systems to track shipments digitally, from the time of arrival to departure. This allows for real-time monitoring and avoids manual errors.

- Barcodes and Scanners: Using barcodes and scanners during loading and unloading ensures accurate inventory tracking and reduces manual data entry.

- Printed Manifests: Keeping signed copies of all manifests is essential for audit trails.

- Spreadsheets or Databases: I might use spreadsheets or databases to record additional information such as loading times, equipment used, and any issues encountered.

Imagine a scenario where a customer needs to verify the receipt of goods. Detailed records are essential to provide that proof. The records not only verify the movement of goods but also provide data for analysis, allowing us to optimize loading and unloading processes and identify and solve problems.

Q 14. What is your experience working in a fast-paced warehouse environment?

I thrive in fast-paced warehouse environments. My experience includes handling high volumes of freight under tight deadlines. I’ve developed strategies for prioritizing tasks, managing time effectively, and maintaining accuracy under pressure.

Key skills that allow me to excel include:

- Prioritization: The ability to identify and handle urgent tasks efficiently is key. This involves assessing priorities based on deadlines, customer needs, and the urgency of specific shipments.

- Adaptability: Fast-paced environments require adaptability. I can readily adjust to changing priorities and unforeseen issues.

- Problem-Solving: Quick and effective problem-solving is crucial. I am skilled at identifying and resolving issues that might slow down the operation.

- Teamwork: Collaboration is essential in a busy environment. I’m able to work effectively as part of a team, coordinating efforts to meet targets.

In a busy warehouse, I would maintain an overview of all the tasks at hand, making sure the most time-sensitive shipments are prioritized. By staying calm under pressure and working with my team efficiently, we ensure smooth operations even when there are disruptions.

Q 15. How do you adapt to changing priorities and unexpected delays during loading/unloading?

Adapting to changing priorities and unexpected delays is crucial in freight loading and unloading. Think of it like conducting an orchestra – you have a planned score, but sometimes instruments break or musicians are late. My approach is threefold:

- Prioritization and Re-planning: I immediately assess the impact of the change. Is it a minor adjustment or a major disruption? For minor changes, like a slight delay in one delivery, I simply readjust the loading sequence. For significant delays, I’ll contact relevant parties (dispatch, clients) to inform them and collaboratively replan, perhaps prioritizing urgent shipments. For example, if a container arrives late, I might prioritize loading other, time-sensitive containers first to minimize disruption.

- Communication is Key: Open and timely communication with all stakeholders – drivers, warehouse staff, clients – is paramount. Keeping everyone informed prevents confusion and allows for collaborative problem-solving. This minimizes frustration and maintains efficiency.

- Flexibility and Resourcefulness: I remain flexible and resourceful, adapting my strategies to the unforeseen circumstances. This might involve re-allocating personnel, utilizing different loading equipment, or exploring alternative solutions. For instance, if a forklift breaks down, I’ll quickly arrange for a replacement or adjust the loading process to minimize reliance on the damaged equipment.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with using warehouse management systems (WMS).

I have extensive experience using Warehouse Management Systems (WMS). These systems are the backbone of efficient warehouse operations, acting as a central nervous system coordinating everything from inventory management to order fulfillment and loading assignments. My experience includes:

- Inventory Management: Utilizing WMS to track inventory levels in real-time, ensuring the correct items are available for loading.

- Order Fulfillment: Using WMS to create accurate picking lists and optimize picking routes, leading to faster and more efficient order fulfillment.

- Load Planning and Optimization: WMS helps optimize loading plans by considering factors like weight distribution, item fragility, and space utilization within a vehicle. This minimizes wasted space and ensures efficient vehicle utilization.

- Reporting and Analytics: WMS provides valuable data on loading times, efficiency metrics, and potential bottlenecks, enabling data-driven improvements in processes.

For instance, in my previous role, we implemented a new WMS which reduced our loading times by 15% and minimized errors in order fulfillment, resulting in significant cost savings and improved customer satisfaction.

Q 17. How do you ensure compliance with all relevant safety regulations and company policies?

Safety is my top priority. Compliance with all safety regulations and company policies is non-negotiable. My approach involves:

- Regular Training: I actively participate in all safety training programs, staying updated on new regulations and best practices. This includes forklift operation, hazard identification, and safe lifting techniques.

- Adherence to Procedures: I strictly follow all established safety procedures, including wearing appropriate personal protective equipment (PPE), using safety equipment correctly, and adhering to speed limits within the warehouse.

- Proactive Hazard Identification: I regularly inspect the loading and unloading areas for potential hazards, such as spills, obstructions, or damaged equipment, reporting any issues immediately to my supervisor.

- Safe Lifting Techniques: I always employ proper lifting techniques to avoid injuries and ensure the safe handling of freight. This includes using mechanical aids whenever possible and following ergonomic principles.

- Emergency Procedures: I am familiar with all emergency procedures and know how to respond appropriately in case of an accident or incident.

I believe a proactive approach to safety is essential. A single accident can have devastating consequences; preventing them is everyone’s responsibility.

Q 18. Explain your understanding of load capacity and weight limits for different vehicles.

Understanding load capacity and weight limits is fundamental to safe and legal freight transportation. Different vehicles have different weight and volume capacities, influenced by factors such as vehicle type (truck, van, container), axle configuration, and local regulations.

- Gross Vehicle Weight (GVW): This refers to the maximum allowable weight of the vehicle including its load. Exceeding the GVW is illegal and dangerous.

- Payload Capacity: This is the difference between the GVW and the vehicle’s curb weight (weight of the empty vehicle). It represents the maximum weight of the freight that can be carried.

- Axle Weight Limits: Each axle has a maximum weight limit to prevent damage to roads and bridges. The weight distribution across axles must be within the specified limits.

- Cubic Capacity: This refers to the maximum volume of freight that can be loaded into the vehicle.

Before loading, I always check the vehicle’s specifications and ensure the total weight and volume of the freight are within the permitted limits. I use scales to weigh heavy freight and utilize load planners to optimize weight distribution and ensure compliance with all regulations. For example, I would never load a 20,000 lb payload into a truck with a 15,000 lb payload capacity.

Q 19. How familiar are you with proper packaging and labeling procedures for freight?

Proper packaging and labeling are crucial for protecting freight during transit and ensuring smooth, efficient handling. My familiarity includes:

- Packaging Materials: Selecting appropriate packaging materials to protect the goods from damage, considering factors like fragility, weight, and environmental conditions. This includes using sturdy boxes, protective padding, and shrink wrap where necessary.

- Packaging Techniques: Employing proper packaging techniques to ensure that items are securely packed and will withstand the rigors of transportation. This includes using appropriate cushioning and bracing to prevent shifting during transit.

- Labeling: Creating clear and accurate labels that include all necessary information such as the recipient’s address, contents, weight, handling instructions (e.g., “Fragile,” “Handle with Care”), and any hazardous material indicators.

- Hazardous Materials (Hazmat): Understanding and complying with all regulations pertaining to the transport of hazardous materials, including proper labeling, documentation, and handling procedures.

Poor packaging and labeling can lead to damage, delays, and even safety hazards. I ensure every package is properly prepared before it’s loaded.

Q 20. Describe your experience with different types of loading docks and their safety considerations.

I have experience with various types of loading docks, each with its own safety considerations:

- Level Docks: These provide a level surface between the truck and the warehouse, minimizing the risk of falls. Safety considerations include ensuring the dock leveler is properly secured and preventing gaps between the truck and the dock.

- Ramp Docks: These use ramps to bridge the gap between the truck and the warehouse. Safety considerations include ensuring ramps are properly secured and non-slippery, using handrails, and having sufficient lighting.

- Edge-of-Dock Loading: This involves loading directly from the truck bed. Safety is paramount, and extra care needs to be taken with fall protection and load stability.

Regardless of the dock type, I always ensure the area is well-lit, free of obstructions, and that appropriate safety equipment (e.g., dock bumpers, wheel chocks) is used. I always prioritize safety checks before beginning loading or unloading.

Q 21. How do you handle discrepancies between the manifest and the actual freight received?

Discrepancies between the manifest and actual freight require a systematic approach. My process involves:

- Verification: I carefully compare the manifest with the actual freight received, item by item, checking quantity, condition, and description. I use a checklist to ensure thoroughness.

- Documentation: I meticulously document any discrepancies, noting the differences between the manifest and the actual freight. This might include taking photographs or videos as evidence.

- Notification: I immediately notify my supervisor and the relevant parties (shipping company, client) about the discrepancies.

- Investigation: I assist in investigating the cause of the discrepancy. This might involve reviewing shipping documents, contacting the shipping company, or checking warehouse records.

- Resolution: I participate in resolving the discrepancy, which may involve adjusting inventory records, issuing replacements, or filing claims.

Accuracy is essential. Identifying and resolving discrepancies early prevents delays, financial losses, and potential disputes.

Q 22. What measures do you take to prevent theft or loss of freight during loading/unloading?

Preventing theft and loss during loading and unloading is paramount. It requires a multi-layered approach combining robust security measures with diligent operational practices.

- Secure Facilities: Well-lit, fenced-in loading docks with controlled access points are essential. Think of it like a high-security vault for your goods. We need to restrict access to authorized personnel only.

- CCTV Surveillance: Installing and actively monitoring CCTV cameras across the entire loading/unloading area provides a visual deterrent and allows for post-incident investigation. It’s like having 24/7 security guards watching over everything.

- Inventory Management: Precise inventory checks before, during, and after loading/unloading are critical. Using barcodes or RFID tags for tracking ensures accuracy and identifies discrepancies quickly. Imagine trying to manage a grocery store without knowing what’s on the shelves – this is the same concept, but with freight.

- Driver Verification: Thorough checks of driver identification and delivery paperwork before releasing any freight prevent unauthorized pickups. This is like verifying a customer’s identity before handing over a valuable package.

- Sealing and Documentation: Properly sealing containers and meticulously documenting the condition of the freight at each stage provides evidence in case of disputes. It’s like creating a paper trail to prove the goods were in perfect condition when they left our hands.

- Employee Training: Regular training for all staff on security protocols and loss prevention techniques is crucial. This ensures everyone is aware of their responsibilities and can recognize and report suspicious activity. It’s like having a well-trained team on a sports field, everyone knowing their role and responsibility.

Q 23. Describe your experience working with different types of lifting equipment.

I have extensive experience operating a variety of lifting equipment, from basic hand trucks and pallet jacks to sophisticated forklifts, reach trucks, and overhead cranes. My experience includes:

- Forklifts: I’m certified to operate various forklift types (e.g., sit-down, stand-up, reach trucks), ensuring safe and efficient pallet handling. I’m familiar with different load capacities and safety procedures, crucial for preventing accidents.

- Overhead Cranes: I have experience with overhead cranes, including rigging and load securing techniques for safely lifting heavy or awkwardly shaped freight. This requires precise coordination and knowledge of weight distribution to avoid tipping or damage.

- Pallet Jacks and Hand Trucks: While seemingly simple, these tools require proper technique to avoid injury and damage to goods. I can efficiently and safely move pallets and smaller items using these tools.

- Specialized Equipment: My experience also extends to using specialized lifting equipment as needed by the job, including scissor lifts, order pickers, and conveyor systems. I’m always adapting and improving my knowledge of equipment.

Safety is always my top priority when operating any lifting equipment. I meticulously follow all safety protocols, including pre-operation checks, load capacity limitations, and securing straps. I would happily provide any relevant certifications upon request.

Q 24. How do you communicate effectively with drivers, warehouse staff, and other team members?

Effective communication is the cornerstone of efficient loading and unloading operations. I strive to maintain clear and consistent communication with all stakeholders:

- Drivers: I ensure clear instructions regarding loading/unloading procedures, confirming delivery details, and addressing any concerns promptly. I always focus on using clear, concise language to avoid misunderstandings.

- Warehouse Staff: I utilize collaborative methods, such as daily briefings and task assignments, to coordinate team efforts smoothly and efficiently. I make sure every member of the team knows their role and works as part of the team.

- Other Team Members: I maintain open communication through regular updates, problem reporting, and suggestions. Effective teamwork is very important to resolve any problems that arise quickly and efficiently.

I use a variety of communication methods, including face-to-face interactions, radio communication, and digital platforms like messaging apps to ensure prompt and accurate information sharing.

Q 25. Explain your problem-solving skills related to resolving loading/unloading challenges.

Problem-solving is an integral part of my daily work. I approach challenges systematically, using a structured approach:

- Identify the Problem: Clearly define the issue – Is it a delay, damaged goods, equipment malfunction, or a procedural issue?

- Gather Information: Collect all relevant data, including witness statements, documentation, and technical information.

- Analyze the Root Cause: Determine the underlying cause of the problem. This may involve reviewing procedures, inspecting equipment, or assessing team performance.

- Develop Solutions: Brainstorm and evaluate potential solutions. Consider the feasibility, cost-effectiveness, and safety implications of each option.

- Implement the Solution: Put the chosen solution into action, ensuring proper coordination and communication with the team.

- Evaluate the Outcome: Assess the effectiveness of the solution and make adjustments as needed. Learning from past mistakes is essential for improvement.

For example, if faced with an unexpectedly high volume of freight, I would immediately reassess the loading plan, reallocate personnel, and potentially request additional equipment to ensure timely processing without compromising safety.

Q 26. How do you handle situations where freight is damaged or improperly packaged?

Handling damaged or improperly packaged freight requires a methodical approach to protect the company and the client.

- Documentation: Meticulously document all aspects of the damage, including photographs, descriptions, and the location of the damage. This is crucial for insurance claims and accountability.

- Notification: Immediately notify the relevant parties, including the shipping company, the client, and my supervisor.

- Segregation: Separate damaged goods to prevent further damage or contamination of other shipments.

- Salvage Assessment: Determine if any portion of the damaged freight can be salvaged or if it must be discarded.

- Reporting and Investigation: Complete a comprehensive damage report, outlining the circumstances, and potentially initiating an internal investigation to understand the cause of the damage. This will help prevent future similar occurrences.

The key is to act swiftly and accurately, ensuring all parties are informed and that appropriate steps are taken to address the situation and minimize further loss.

Q 27. What are your salary expectations for this role?

My salary expectations for this role are in the range of [Insert Salary Range] annually. This is based on my experience, qualifications, and the responsibilities associated with this position. I am open to discussing this further and am confident that my contributions will significantly benefit your organization.

Q 28. Do you have any questions for me?

Yes, I have a few questions. Firstly, could you elaborate on the company’s safety procedures and training programs? Secondly, what are the company’s key performance indicators (KPIs) for this role? Finally, what opportunities for professional development and advancement are available within the company?

Key Topics to Learn for Loading and Unloading of Freight Interview

- Safety Regulations and Procedures: Understanding and adhering to OSHA regulations, safe lifting techniques, and hazard identification to prevent accidents and injuries. Practical application: Demonstrating knowledge of proper use of equipment like forklifts and pallet jacks, and understanding weight distribution principles.

- Freight Handling Techniques: Efficient methods for loading and unloading various types of freight, including palletized goods, oversized items, and fragile materials. Practical application: Describing experience with different loading and unloading methods, such as using straps, shrink wrap, and other securing mechanisms.

- Inventory Management and Tracking: Accurately documenting the receipt, handling, and delivery of freight using inventory management systems. Practical application: Explaining experience with inventory tracking software or manual tracking methods, and detailing procedures for reconciling discrepancies.

- Equipment Operation and Maintenance: Safe and proficient operation of relevant equipment (forklifts, hand trucks, conveyors). Practical application: Describing experience with preventative maintenance checks and reporting malfunctioning equipment.

- Logistics and Supply Chain Understanding: Basic knowledge of the supply chain process, including the role of loading and unloading in the overall efficiency of transportation. Practical application: Explaining how efficient loading and unloading practices contribute to on-time delivery and reduced costs.

- Problem-Solving and Adaptability: Addressing unexpected challenges, such as damaged goods, incorrect shipments, or equipment malfunctions. Practical application: Describing how you’ve handled logistical problems and adapted to changing situations in previous roles.

Next Steps

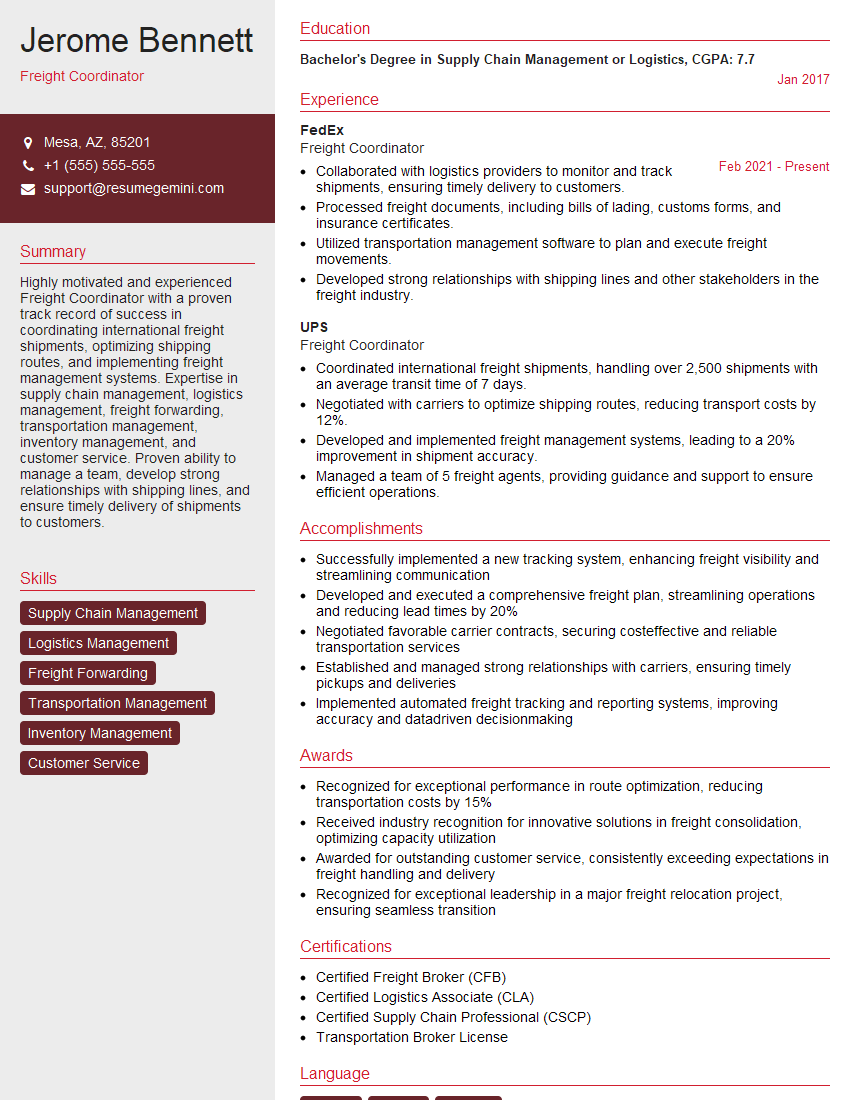

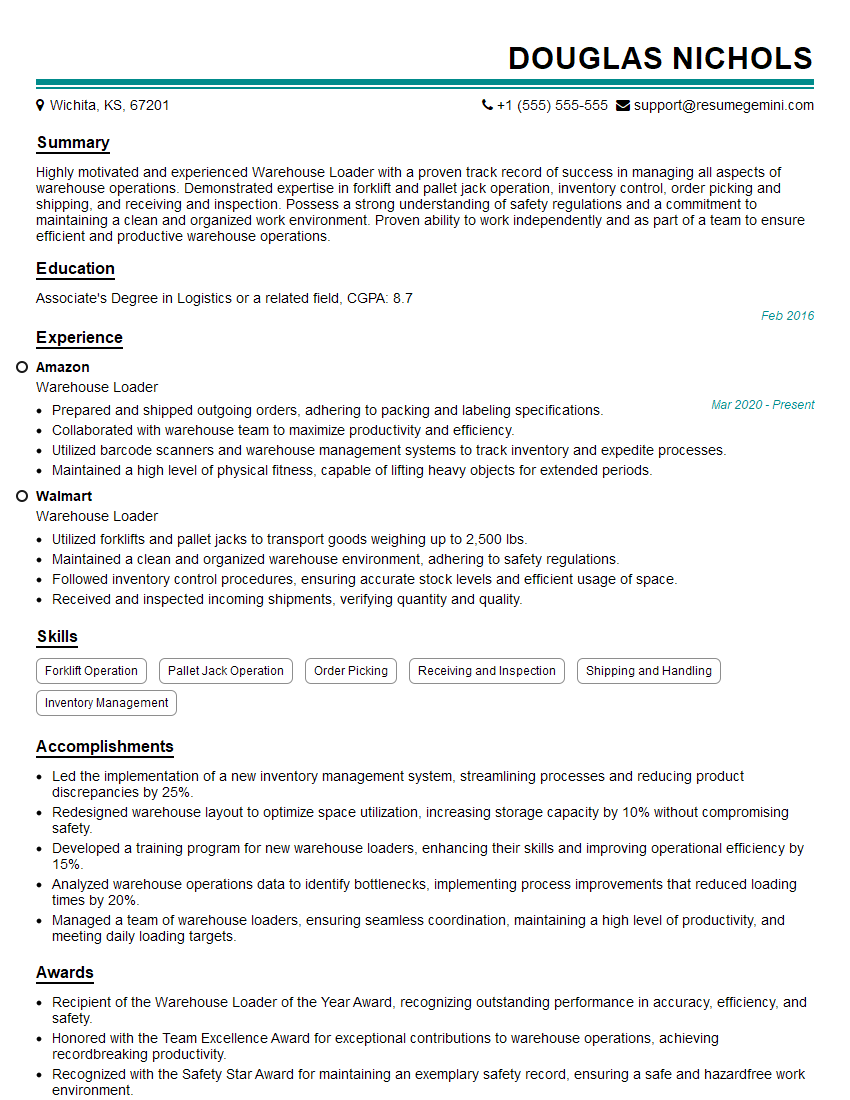

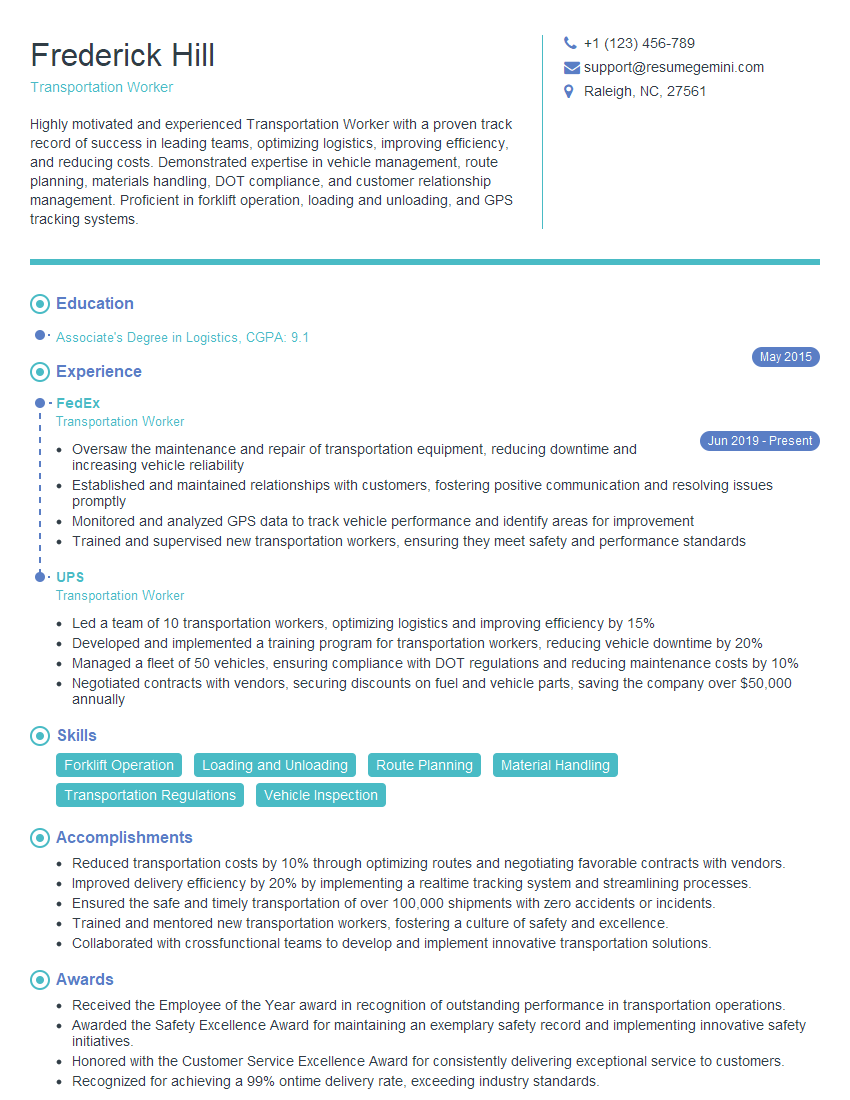

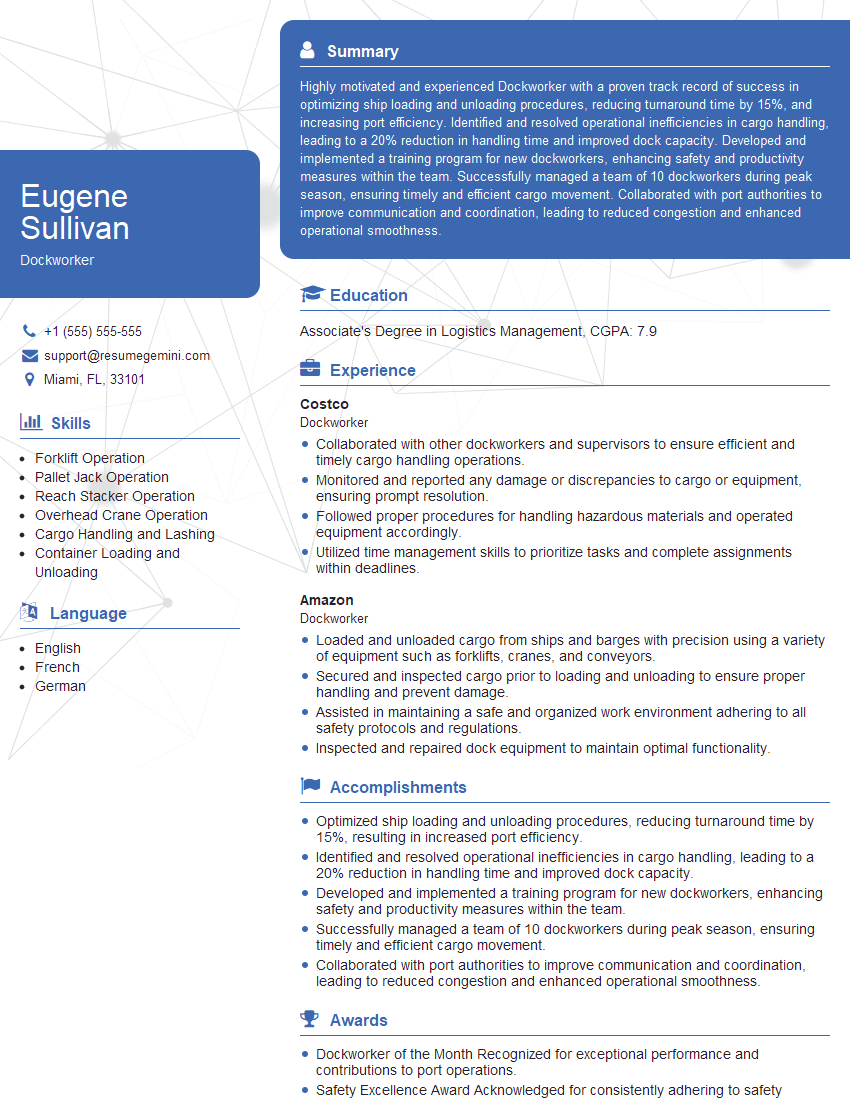

Mastering the art of loading and unloading freight is crucial for career advancement in logistics and transportation. It opens doors to higher-paying positions with increased responsibility and opportunities for growth. To maximize your job prospects, creating a strong, ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you build a professional and impactful resume, designed to get noticed by hiring managers. ResumeGemini provides examples of resumes tailored specifically to the Loading and Unloading of Freight industry, helping you present your skills and experience effectively.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good