Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Log Loading and Unloading interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Log Loading and Unloading Interview

Q 1. Describe your experience operating a log loader.

My experience operating log loaders spans over eight years, encompassing various machine types and logging environments. I’ve worked extensively with grapple loaders, both wheeled and tracked, and have proficiency in operating both smaller machines for selective logging and larger, high-capacity loaders for mass timber harvesting. I’m comfortable operating under diverse conditions, including steep slopes, challenging terrain, and varying weather conditions. For instance, during one particularly challenging project in the Pacific Northwest, I had to navigate a very dense, steep hillside using a tracked loader to efficiently extract large Douglas Fir logs while minimizing ground disturbance and ensuring the safety of the crew and the equipment. This required precise machine control and a thorough understanding of load distribution and stability.

I’m also experienced in the pre-loading preparations, including assessing log size and distribution to optimize loader placement and efficiency. I’m proficient in using the various controls and attachments, from grapple adjustments to boom positioning and ensuring accurate placement of logs onto trucks or other transport methods. I pride myself on my ability to achieve high productivity while maintaining a strict adherence to safety protocols.

Q 2. What safety procedures do you follow when loading or unloading logs?

Safety is paramount in log loading and unloading. My safety procedures are comprehensive and follow industry best practices, including:

- Pre-operational Checks: Thorough inspection of the loader, including hydraulics, brakes, lights, and grapple functionality, before commencing operations.

- Personal Protective Equipment (PPE): Consistent use of hard hats, safety glasses, hearing protection, and high-visibility clothing.

- Site Assessment: Carefully evaluating the terrain, identifying potential hazards like unstable ground, overhanging branches, or obstructions.

- Communication: Maintaining clear communication with other crew members through hand signals and two-way radios to coordinate movements and prevent accidents. For example, a designated ‘spotter’ guides the loader operator, calling out potential hazards and ensuring safe positioning of the load.

- Load Stability: Properly securing and distributing the logs on the transport vehicle to prevent shifting or rollovers.

- Emergency Procedures: Knowing and following established emergency procedures, including shutdown procedures and evacuation protocols in case of equipment malfunction or other unforeseen events.

I actively participate in safety training programs to stay updated on best practices and emerging safety technologies. I believe a proactive approach to safety is essential in mitigating risks and maintaining a safe work environment.

Q 3. How do you ensure the stability of a log load?

Ensuring the stability of a log load is critical to prevent accidents during transport. This involves several key strategies:

- Proper Loading Sequence: Loading larger logs at the bottom and progressively smaller logs on top, creating a stable base.

- Weight Distribution: Distributing the weight evenly across the transport vehicle to avoid overloading any specific area. I often visually assess the load and use the loader’s onboard scales or load indicators, if available, for accurate measurement.

- Secure Binding: Using chains, binders, or other suitable restraints to securely bind the logs together and prevent shifting during transit. The choice of restraint depends on log size, species, and transportation distance. For particularly long or heavy logs, I may use multiple binding points.

- Terrain Consideration: Adjusting the loading strategy based on the type of terrain the logs will be transported over. Steeper gradients or rough roads necessitate a more compact and secure load.

- Regular Inspection: Periodically checking the load throughout the transportation process to ensure that the logs remain stable and secure. This is vital, especially on longer hauls.

A stable log load not only prevents accidents but also improves efficiency by reducing the risk of delays or damage caused by shifting logs during transport. I take pride in my ability to consistently create safe and stable log loads.

Q 4. What are the different types of log loading equipment you’re familiar with?

My experience encompasses a range of log loading equipment, including:

- Grapple Loaders: Both wheeled and tracked, these are my primary tools. I’m proficient in operating various grapple sizes to handle different log sizes and quantities.

- Forwarders: I’ve utilized forwarders for shorter hauls, particularly in selective logging operations. These machines efficiently gather and transport logs directly to the landing area.

- Wheel Loaders: Equipped with forks or specialized attachments, these are used for stacking and handling logs at the landing area.

- Crane Loaders: Although less common in my experience, I have familiarity with crane loaders for specialized scenarios involving difficult terrain or large log volumes.

My experience extends to different makes and models of equipment, allowing me to adapt quickly to various machine specifications and operating procedures. I readily learn and adapt to new technology within the industry, enhancing efficiency and safety in my work.

Q 5. Explain your experience with different log species and their handling requirements.

Experience with diverse log species and their handling requirements is essential. My work has included handling a wide variety of species, including:

- Softwoods: Pine, Fir, Spruce – These often require different grapple adjustments due to variations in diameter and length, but their handling is generally similar.

- Hardwoods: Oak, Maple, Birch – These are denser and often require more careful handling to prevent damage to the wood or the equipment. For instance, oak logs may require more gentle manipulation to avoid cracking.

- Exotic Species: While less frequent, I’ve handled some exotic wood species, requiring research on their unique properties to ensure safe and effective handling.

Understanding the characteristics of each species, such as density, strength, and susceptibility to damage, is crucial for optimizing loading procedures and minimizing losses. I carefully consider the weight and fragility of each species when planning the load and securing the logs. For instance, I would use more caution when loading delicate hardwood species like cherry compared to more robust pines.

Q 6. How do you handle damaged or defective logs during loading/unloading?

Handling damaged or defective logs requires careful consideration of safety and efficiency. My approach involves:

- Assessment: Identifying the extent and nature of the damage (e.g., cracks, splits, decay). Severely damaged logs may require special handling to avoid further breakage.

- Segregation: Separating damaged logs from sound logs to prevent damage to the undamaged logs during loading or transport. They may be loaded separately or at the end of the load.

- Specialized Handling: Using appropriate techniques and equipment to handle damaged logs safely and efficiently without causing further harm. This may involve using smaller grapples or careful maneuvering to avoid stressing the weakened areas.

- Reporting: Documenting the damaged logs and reporting them to the appropriate personnel for further assessment and disposal. I maintain detailed records to track such instances.

My goal is to minimize waste and ensure the safety of both the crew and the equipment by implementing a structured approach to handling damaged or defective logs.

Q 7. What is your experience with log scaling and measurement?

My experience with log scaling and measurement involves both manual and electronic methods. I’m proficient in using:

- Scaling Sticks: For manual measurement of log diameter and length, ensuring accurate volume calculations.

- Electronic Measuring Devices: I’m familiar with using various electronic measuring tools that automatically calculate log volume based on diameter and length measurements, offering speed and accuracy.

- Log Scanning Systems: While I have limited direct experience operating such systems, I understand their application in large-scale operations and their capability to provide very precise and detailed log measurements.

Accurate scaling is vital for fair payment to loggers and precise inventory management for lumber mills. I meticulously record log measurements, ensuring their accuracy and consistency, to maintain transparency and support efficient business practices.

Q 8. Describe your experience with inventory management in a log yard.

Inventory management in a log yard is crucial for efficient operations and profitability. It involves tracking the volume, type, and quality of logs arriving, being processed, and leaving the yard. This requires a robust system, typically a combination of physical and digital methods.

My experience includes using both manual tracking systems (using spreadsheets and physical inventory checks) and sophisticated software solutions that integrate with scanners and scales to provide real-time data on log inventory. For example, I’ve implemented a system using RFID tags on individual log bundles, allowing for precise tracking throughout the entire process from logging to delivery. This minimizes discrepancies, reduces losses from theft or damage, and allows for better forecasting of demand and resource allocation. We also use regular cycle counts to verify the accuracy of our inventory system and address any discrepancies promptly.

A key aspect is categorizing logs by species, diameter, length, and quality grade to optimize pricing and matching customer orders. Efficient inventory management also involves strategic log placement within the yard to minimize handling time and costs during loading and unloading. Proper segregation minimizes the risk of mixing different grades or species of logs, ensuring that orders are filled correctly.

Q 9. How do you prioritize tasks during peak loading/unloading periods?

Prioritizing tasks during peak loading/unloading periods requires a systematic approach. My strategy involves a combination of factors, including pre-planning, communication, and using a first-in-first-out (FIFO) system where appropriate.

- Urgency and Deadlines: Orders with tight deadlines or urgent shipping requirements are prioritized. I use a Kanban-style board to visually manage the flow of orders.

- Customer Contracts: Contracts with specific delivery commitments are given preference to ensure contractual obligations are met and maintain strong customer relationships.

- Log Type and Condition: Some logs may be more susceptible to spoilage or deterioration requiring faster processing.

- Transportation Availability: Matching the available trucks with the appropriate log orders ensures efficient use of resources and minimizes wait times.

- Resource Allocation: This involves assigning equipment and personnel to tasks based on their skills and the task’s complexity. This might involve assigning experienced operators to challenging loads, or using smaller equipment for more precise loading of smaller orders.

Effective communication among the team is essential. I use daily briefings to share schedules, potential roadblocks and adjust the plan accordingly. Regular communication with truck drivers helps coordinate deliveries and minimize delays.

Q 10. Explain your understanding of load-bearing capacity and weight distribution.

Understanding load-bearing capacity and weight distribution is critical for safety and efficiency. Load-bearing capacity refers to the maximum weight a truck or trailer can safely carry without structural damage or exceeding legal limits. Weight distribution involves evenly spreading the weight across the axles to avoid overloading any single axle.

Improper weight distribution can lead to accidents, such as rollovers, tire blowouts, and structural damage to the truck or trailer. I ensure accurate weight measurements using scales and adhere to legal weight limits specific to the region and type of vehicle. For instance, I carefully plan the placement of logs on the trailer to achieve a balanced distribution, often visually checking for balance or using load-measuring equipment to guarantee safety. Furthermore, I consider the type of terrain the truck will navigate; rough terrain may require a more conservative approach to weight distribution. We also have a comprehensive training program on safe loading techniques, where proper weight distribution is emphasized.

Q 11. How do you maintain the efficiency of log loading/unloading operations?

Maintaining the efficiency of log loading/unloading operations requires a multifaceted approach focused on optimization and continuous improvement.

- Equipment Maintenance: Regular maintenance of loading equipment (cranes, loaders, etc.) and trucks prevents breakdowns and delays.

- Process Optimization: Analyzing the workflow to identify bottlenecks and improve efficiency (e.g., optimizing the layout of the log yard, using more efficient loading techniques).

- Technology Integration: Utilizing software and technology for real-time inventory tracking, scheduling, and communication increases efficiency and reduces manual errors. For example, load planning software can assist in optimizing the placement of logs for weight distribution and efficient loading.

- Training and Skill Development: Regularly training personnel on safe and efficient loading techniques.

- Lean Principles: Applying lean manufacturing principles to eliminate waste (e.g., reducing unnecessary movement of logs, optimizing storage space).

For instance, we implemented a new loading procedure where logs were pre-sorted by size and stacked strategically, leading to a 15% reduction in loading time. Regularly reviewing these processes allows for constant improvement.

Q 12. Describe your experience with different types of log trucks and trailers.

My experience encompasses various types of log trucks and trailers, including:

- Conventional Log Trucks: These are standard trucks with a variety of body styles designed for log hauling. Their capacity varies greatly depending on the size and number of axles.

- Bunk Trailers: These trailers have several bunks (supporting structures) to hold logs securely. Their design allows for various log lengths and diameters.

- Pole Trailers: Specialized trailers for carrying long, slender logs or poles.

- Lowboy Trailers: These trailers have a low bed height to allow easier loading and unloading of heavy loads.

Understanding the specifications of each type is vital for safe and efficient loading. This includes knowing the load limits, dimensions, and appropriate securing methods for each type of trailer. For example, I know the differences in securing logs on a bunk trailer versus a pole trailer, understanding that different methods are needed to ensure stability and prevent shifting during transit.

Q 13. How do you ensure the safety of personnel during log handling operations?

Ensuring personnel safety during log handling operations is paramount. This involves a multi-layered approach:

- Personal Protective Equipment (PPE): Mandatory use of safety helmets, high-visibility clothing, safety boots, gloves, and eye protection.

- Safe Work Procedures: Clearly defined procedures for loading, unloading, and moving logs. These include procedures for signaling, communication, and avoiding hazards.

- Regular Safety Training: Comprehensive training programs cover safe operating procedures, hazard identification, and emergency response.

- Equipment Inspections: Regular inspection of all equipment (cranes, loaders, trucks, and trailers) to ensure they are in good working order.

- Emergency Response Plan: Establishing a clear emergency response plan to handle accidents and injuries effectively.

- Designated Safe Zones: Establishing designated areas where personnel can avoid hazards during loading and unloading.

In my experience, regular safety meetings and refresher training sessions reinforce these procedures and encourage a safety-conscious culture. I’ve also implemented a system for reporting near misses and accidents, allowing us to identify and rectify potential hazards proactively.

Q 14. What are the common causes of accidents in log loading/unloading?

Accidents in log loading/unloading operations often stem from a combination of factors, including:

- Improper Loading Techniques: Incorrect weight distribution, unsecured loads, and failure to follow safe loading procedures.

- Equipment Malfunction: Failure of lifting equipment, trucks, or trailers due to poor maintenance or overloading.

- Human Error: Lack of training, fatigue, lack of communication, and failure to follow safety protocols.

- Environmental Factors: Slippery surfaces, poor visibility due to weather conditions, and uneven terrain.

- Lack of Safety Procedures: Absence of clear safety procedures or inadequate enforcement of existing procedures.

For instance, a poorly secured load can shift during transport causing an accident. Similarly, a faulty crane or improperly trained operator can lead to equipment failure or injuries. Proactive measures such as regular equipment inspections, robust safety training, and enforcement of safety procedures are vital in mitigating these risks.

Q 15. How do you address and resolve conflicts regarding log loading procedures?

Resolving conflicts during log loading procedures requires a proactive and collaborative approach. It starts with clear communication and a strong understanding of the established safety protocols and loading plans. If a disagreement arises, I would first try to understand the differing perspectives. For instance, if a disagreement occurs between the crane operator and the ground crew regarding the placement of a log, I would facilitate a discussion to identify the root cause. Perhaps the ground crew needs more time to clear an area or the crane operator needs better visual confirmation of the designated drop zone. I would then work to find a solution that ensures both safety and efficiency, perhaps involving adjustments to the loading plan or additional communication measures. Documentation of the conflict, resolution, and any changes made to procedures is essential for future reference and preventing similar issues. Finally, a post-incident review helps to learn from the experience and improve future procedures.

For example, once during a particularly hectic loading operation, a disagreement arose between the loader operator and the truck driver about the weight distribution of the logs. I stepped in, facilitated discussion, and ultimately modified the loading sequence to better accommodate the truck’s capacity, ensuring both safety and efficiency.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are your experience using different types of rigging equipment?

My experience with rigging equipment is extensive, encompassing various types used in log handling. I’m proficient with different types of slings, including wire rope slings, synthetic web slings, and chain slings, each with its specific strengths and limitations. I understand the importance of selecting the appropriate sling based on factors like log size, weight, and the type of lift. I am also experienced with different types of hooks, shackles, and other hardware necessary for secure rigging. This includes understanding proper inspection procedures to identify wear and tear, ensuring the safe operating load (SWL) of each component is not exceeded. Furthermore, I’m familiar with different types of lifting equipment such as cranes, forklifts and loaders. My experience includes using both conventional and specialized rigging gear for specific tasks like lifting logs with unusual shapes or from difficult terrain.

For example, when loading unusually long logs, I’ve successfully employed multiple wire rope slings in a bridle configuration to ensure even distribution of weight and prevent damage to the log or the rigging. I also know when to utilise spreader beams to provide better control and stability during lifting, reducing the risk of swing or tipping. My knowledge also extends to using proper knotting techniques to ensure secure fastenings.

Q 17. Describe your experience with preventative maintenance on log handling equipment.

Preventative maintenance is critical for safe and efficient log handling. My experience involves regularly inspecting all equipment, including cranes, loaders, and rigging gear, according to established checklists. These inspections cover areas like hydraulic systems (checking for leaks, proper fluid levels), engine performance (oil levels, filters), wear and tear on moving parts (chains, cables, hooks), and structural integrity (detecting cracks or damage). I’m also skilled in performing minor repairs and adjustments such as lubricating moving parts or replacing worn components. Crucially, I know when to take equipment out of service for more comprehensive maintenance or repairs by qualified technicians. Accurate record-keeping is a vital part of this process, documenting all inspections, repairs, and maintenance schedules.

For instance, we implemented a daily pre-shift inspection for all loaders. This significantly reduced downtime due to mechanical failures. We also developed a comprehensive lubrication schedule which helped prolong the lifespan of critical equipment.

Q 18. How do you communicate effectively with other workers during log handling operations?

Effective communication is paramount in log handling. I utilize a combination of methods, including hand signals (following standardized protocols), two-way radios for immediate communication over distance, and pre-job briefings to clarify the tasks and potential hazards. These briefings ensure everyone understands their roles and responsibilities. I also emphasize the importance of clear and concise language, avoiding jargon and ensuring everyone involved is on the same page. Furthermore, I actively encourage open communication – creating an environment where workers feel comfortable raising concerns or reporting potential problems without fear of reprisal. Active listening and providing clear and immediate feedback are also vital aspects of my approach.

For example, during a complex log stacking operation, I used a combination of hand signals and radio communication to guide the crane operator and ground crew, resulting in a smooth, efficient, and safe operation.

Q 19. Explain your understanding of environmental regulations related to log handling.

My understanding of environmental regulations regarding log handling is comprehensive. This includes awareness of rules concerning erosion control, preventing water pollution from spills or runoff (particularly from fuel or hydraulic fluids), minimizing soil disturbance, and handling of waste materials. I am familiar with procedures for proper disposal of materials and the relevant permits and licenses required for operation in specific areas. I also understand the importance of complying with regulations related to noise pollution and air quality, utilizing best practices to reduce noise and emission levels from equipment. Staying updated on changes in environmental regulations is an ongoing responsibility, and I actively seek out information and training to maintain compliance.

Specifically, I have experience implementing erosion control measures at loading sites, such as using sediment barriers to prevent soil from washing into waterways. I also know how to properly dispose of used oil and other hazardous waste in accordance with local regulations.

Q 20. How do you handle unexpected issues or delays during log loading/unloading?

Handling unexpected issues or delays requires a calm and decisive approach. My strategy involves first assessing the situation to identify the root cause. Is it a mechanical failure, a weather event, or a change in the operational plan? Once the problem is identified, I implement a solution based on established contingency plans (if available) and prioritizing safety. This may involve bringing in additional equipment or personnel, modifying the loading plan, or temporarily halting operations until the issue is resolved. Clear and timely communication with all involved parties is critical during these situations, keeping them informed of the problem and the steps being taken to address it. Documentation of the incident, including the cause, resolution, and any lessons learned, is also a crucial aspect of the process.

For example, we once experienced a sudden rainstorm that caused a temporary halt in loading. I immediately communicated with the supervisors and crew, re-routed equipment to protected areas, and once the storm passed, developed a modified loading plan that minimized risks caused by the muddy conditions.

Q 21. What is your experience with using load-securement devices?

I have extensive experience using various load-securement devices for logs. This includes chains, binders, straps, and specialized log bunks or cradles. I understand the crucial role these devices play in preventing log shifting during transport and ensuring safety. My experience involves selecting the appropriate securing devices based on the size, weight, and shape of the logs, as well as the type of transportation vehicle. I know the importance of proper tensioning and securing techniques to maintain adequate load restraint. Regular inspections are paramount; I check devices for wear and tear, ensuring they meet safety standards and are within their safe working load limits (SWL). Incorrect load securement can lead to serious accidents, so I meticulously follow established best practices and regulations.

For example, when securing a load of varied-sized logs onto a flatbed trailer, I utilize a combination of chains and straps, ensuring that the smaller logs are properly wedged to prevent shifting and that the larger logs are secured against potential movement, while ensuring that the load is properly distributed across the trailer.

Q 22. Describe your knowledge of different log stacking techniques.

Log stacking techniques are crucial for maximizing space, ensuring stability, and preventing damage during transportation and storage. Different techniques cater to various log sizes, types, and intended uses.

Tiering: This is the most common method, involving stacking logs in layers, like building a pyramid. Each layer is offset slightly, creating interlocking stability. Careful consideration is given to the size and weight distribution to prevent collapse. For instance, larger logs might form the base, with smaller logs on top.

Piling: Logs are stacked loosely in a pile, often used for temporary storage or smaller-scale operations. This method is less efficient in terms of space and requires careful monitoring to avoid instability.

Racking: Logs are arranged vertically, often within a rack or frame. This method is particularly useful for specific log types or when maintaining individual log identification is important. Think of a lumberyard where individual boards are racked for easy selection.

Bundling: Logs are secured together, often using chains or straps, to form a single unit for transportation. This helps maintain their stability during movement and is especially helpful for smaller diameter logs.

The choice of stacking technique depends heavily on the type of log, its final destination, the available equipment, and the terrain.

Q 23. How do you ensure the logs are properly secured during transportation?

Securing logs during transportation is paramount to prevent damage, loss, and accidents. This requires a multifaceted approach:

Proper Binding: Using strong chains, straps, or nets to firmly bind the logs together is fundamental. The binding points need to be strategically chosen to counteract any shifting or movement. I always inspect the binding material for wear and tear before each load.

Load Distribution: Even weight distribution is key. Heavier logs should be strategically placed at the base, while lighter logs are placed on top, creating a center of gravity that promotes stability. I use load-bearing calculations to optimize weight distribution.

Vehicle Suitability: The truck or trailer must be appropriate for the weight and size of the load. Overloading is unacceptable and dangerously unsafe. I always check the vehicle’s load capacity before undertaking any transport.

Weather Considerations: Extra precautions are needed in bad weather. Secure the load extra tightly in high winds and rain, and use protective tarps to prevent damage from the elements.

Imagine trying to transport a stack of books without securing them – disaster! The same principle applies to logs. The better the securing, the safer and more efficient the journey will be.

Q 24. What are your experience with log sorting and segregation?

Log sorting and segregation is a critical process affecting both the efficiency of operations and the value of the final product. This typically involves:

Species Identification: Correctly identifying the species of each log is crucial. Different species have different properties, values, and intended uses. This often involves visual inspection or laboratory analysis.

Diameter Sorting: Sorting logs by diameter ensures uniformity and facilitates efficient processing. Logs of similar diameters can be more easily handled by machinery and used for specific purposes.

Grade Classification: Logs are often graded based on their quality and defects. Higher-grade logs have fewer defects and are used for premium products.

Length Sorting: Logs are sorted according to their length, ensuring that they meet the requirements of specific applications. This improves efficiency in downstream processes.

In my experience, efficient sorting is significantly improved with the use of automated sorting equipment like optical scanners combined with smart sorting systems; this cuts down on manual labor and increases accuracy substantially.

Q 25. How do you maintain accurate records of log loading/unloading activities?

Maintaining accurate records is essential for inventory management, tracking, and regulatory compliance. This is done through a variety of methods:

Detailed Loading/Unloading Sheets: These sheets record the date, time, location, log type, quantity, vehicle number, and destination for each transaction. They are signed and dated by involved parties.

Digital Tracking Systems: Modern systems use barcodes, RFID tags, and GPS tracking to monitor logs throughout the supply chain. This offers real-time data and improves accuracy.

Inventory Management Software: Software programs help track inventory levels, monitor stock movements, and generate reports on log usage and sales.

Chain of Custody Documentation: Meticulous records are kept to trace the logs from the forest to the final destination. This is crucial for verifying legality and provenance, especially in combating illegal logging.

Imagine a supermarket without inventory records—utter chaos! Similarly, diligent record keeping is the foundation of a well-managed log operation.

Q 26. What is your experience with using different types of cranes for log handling?

My experience encompasses a range of crane types for log handling, each with its own strengths and weaknesses:

Hydraulic Cranes: These are versatile and commonly used for loading and unloading logs onto trucks and ships. Their reach and lifting capacity make them ideal for many applications.

Mobile Cranes: These are highly maneuverable and suitable for working in various locations. Their ability to move around the work site without needing to be re-positioned is a big advantage.

Overhead Cranes: These are fixed cranes found in yards and processing facilities. They offer high lifting capacity but are limited in their range of movement.

Specialized Log Grapples: These are crane attachments designed to efficiently grip and lift logs without damaging them. The choice of grapple depends on log size and shape.

The selection of the appropriate crane depends on factors like load weight, reach, terrain accessibility, and the specific needs of the job. Safety procedures, including regular inspections and operator training, are non-negotiable for all crane operations.

Q 27. Explain your understanding of the chain of custody in log handling.

Chain of custody refers to the documented path of a log from its origin in the forest to its final destination. This detailed tracking is critical for ensuring legality, sustainability, and traceability throughout the supply chain.

It involves documenting every step of the process, including:

Harvesting: Recording the location, date, and volume of logs harvested.

Transportation: Tracking the movement of logs from the forest to processing facilities and mills.

Processing: Documenting any transformations or processing steps (e.g., sawing, milling).

Sales & Distribution: Tracking the sales and movement of processed lumber or other log products.

Maintaining a robust chain of custody is crucial for compliance with environmental regulations, certification programs (such as FSC), and consumer confidence. It provides transparency and accountability throughout the entire log supply chain.

Q 28. How do you adapt your techniques for different terrain and weather conditions?

Adapting to different terrain and weather conditions is crucial for safe and efficient log handling. This involves:

Terrain Assessment: Prior to any operation, a thorough assessment of the terrain is necessary. This helps determine the appropriate equipment, access routes, and safety measures. Soft ground, steep slopes, and obstacles all need to be considered.

Equipment Selection: Choosing equipment suitable for the terrain is vital. All-terrain vehicles, specialized forestry equipment, and appropriate crane models are selected to handle the challenges presented by the terrain.

Weather Contingency Plans: Weather conditions greatly impact operations. High winds, heavy rain, snow, and ice all pose risks. Contingency plans should be in place, including potential work stoppages and the use of protective gear.

Safety Precautions: Additional safety precautions are taken in challenging conditions. This includes increased communication between workers, enhanced securing of loads, and the use of specialized safety equipment.

For example, working on a muddy slope requires different techniques and equipment compared to operating on a flat, dry surface. Adaptability and a focus on safety are essential for success in challenging environmental conditions.

Key Topics to Learn for Log Loading and Unloading Interview

- Safety Procedures and Regulations: Understanding and adhering to all relevant safety protocols, including OSHA regulations and company-specific safety guidelines. Practical application: Describing your experience with pre-shift inspections, hazard identification, and the use of personal protective equipment (PPE).

- Equipment Operation and Maintenance: Familiarity with various types of loading and unloading equipment (cranes, loaders, forklifts, etc.), including their operational procedures and basic maintenance requirements. Practical application: Explaining your experience operating specific equipment, troubleshooting minor malfunctions, and performing routine checks.

- Log Handling Techniques: Mastering efficient and safe techniques for handling logs of different sizes and weights, minimizing damage and maximizing efficiency. Practical application: Demonstrating knowledge of proper log stacking, securing, and preventing damage during transportation.

- Logistics and Planning: Understanding the logistics of log loading and unloading operations, including efficient workflow planning, inventory management, and coordination with other teams. Practical application: Describing your experience with optimizing loading sequences, managing inventory levels, and coordinating with drivers or other personnel.

- Environmental Considerations: Awareness of environmental regulations and best practices related to log handling, including minimizing soil erosion, water pollution, and waste generation. Practical application: Explaining your experience with sustainable logging practices and waste management procedures.

- Problem-Solving and Troubleshooting: Ability to identify and resolve issues that may arise during loading and unloading operations, such as equipment malfunctions, logistical challenges, or safety concerns. Practical application: Providing examples of how you have effectively addressed problems encountered during previous work experiences.

Next Steps

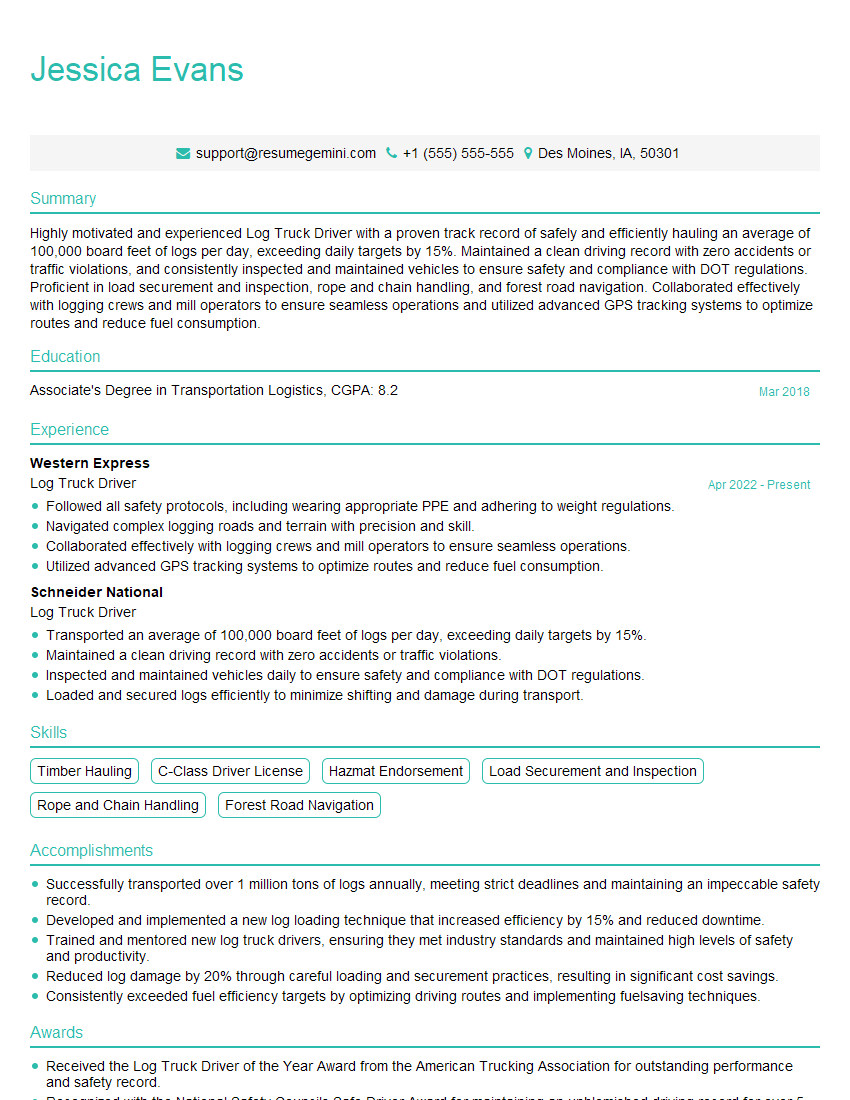

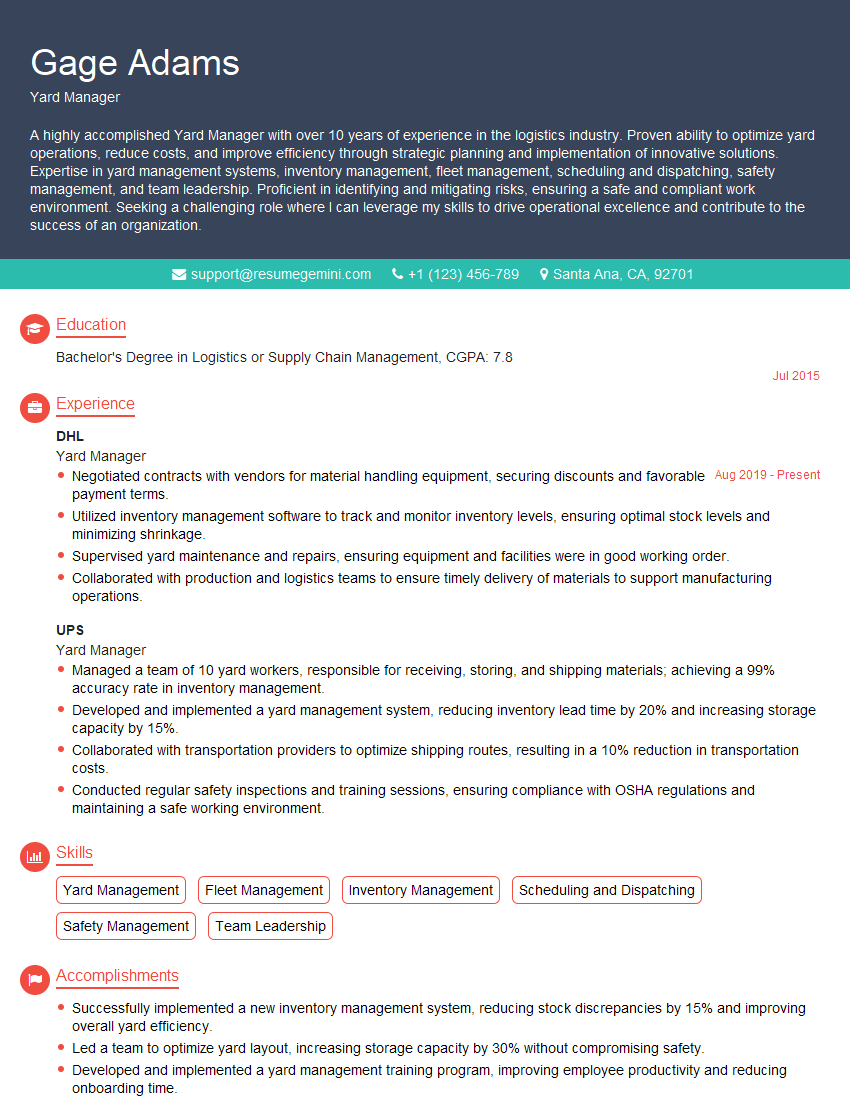

Mastering log loading and unloading techniques is crucial for career advancement in the forestry and transportation industries, offering opportunities for increased responsibility and higher earning potential. To significantly improve your job prospects, crafting an ATS-friendly resume is paramount. ResumeGemini is a trusted resource that can help you build a professional and effective resume tailored to highlight your skills and experience. Examples of resumes specifically tailored for Log Loading and Unloading positions are available to guide you. Invest the time to create a compelling resume – it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good