Unlock your full potential by mastering the most common Log Railcar Loading interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Log Railcar Loading Interview

Q 1. Describe the process of securing logs within a railcar for optimal stability and safety.

Securing logs in a railcar for optimal stability and safety is paramount to prevent shifting during transit, which could lead to derailments or damage. This involves a combination of careful loading techniques and potentially employing specialized equipment.

The process begins with assessing log size and species. Larger, heavier logs should be placed at the bottom and towards the center of the car for better weight distribution. Smaller logs can then be placed on top, filling gaps to maximize space. Think of it like building a pyramid – a wide, stable base is crucial.

Effective binding is key. We use chains, binders, or other approved securing devices to tightly bind the logs together and to the railcar itself. These devices must be properly rated for the weight of the load. The number and placement of these securing devices depend on the log length, size, and overall load weight, as well as the type of railcar. Regular inspections during and after loading ensure everything is correctly secured.

Finally, proper documentation of the loading process is essential, including the number and type of securing devices used, their placement, and the total weight of the load. This documentation helps in case of any incidents during transport.

Q 2. What are the different types of railcars used for log transportation, and what are their respective advantages and disadvantages?

Several railcar types are used for log transportation, each with its own strengths and weaknesses.

- Gondola cars: These open-top cars are the most common. They’re versatile but require careful loading and securing due to their open design. Advantages include ease of loading and unloading, and the ability to handle logs of varying lengths. Disadvantages include greater susceptibility to weather damage and potential for log shifting.

- Well cars: These cars have a deep well or pit in the center, allowing for longer logs to be transported. They offer better protection from weather but can be more challenging to load and unload.

- Covered hopper cars: While less common for logs, these are used when protection from the elements is critical. However, they might be less efficient for loading and unloading logs.

The choice of railcar depends on several factors, including log length, diameter, volume of shipment, weather conditions, and overall transportation costs. A log hauler will assess these factors to determine the most economical and safest transportation method.

Q 3. Explain the importance of load weight distribution in log railcar loading.

Load weight distribution is critical for the stability and safety of log railcar loading. Uneven weight distribution can lead to stress on the railcar structure, causing damage or even derailment. It also impacts the effectiveness of the securing devices.

Imagine a seesaw – if all the weight is on one side, it tips over. Similarly, if the weight of the logs is concentrated on one end of the railcar, it’ll cause instability. Proper weight distribution ensures the load is evenly balanced across the railcar’s axles, minimizing stress and maximizing safety. This involves strategically positioning logs of varying sizes and weights to distribute the mass evenly. Weight scales and load planning software are frequently used to optimize distribution.

For example, heavier logs should be strategically placed near the center and lower part of the railcar, with smaller logs filling the gaps towards the sides and top, forming a stable and balanced load. This ensures the weight is properly distributed to prevent excessive pressure on any single area of the railcar.

Q 4. How do you ensure compliance with safety regulations during log railcar loading operations?

Compliance with safety regulations is non-negotiable in log railcar loading. We adhere strictly to rules and regulations set by agencies like the Association of American Railroads (AAR) and the Federal Railroad Administration (FRA).

This includes regular inspections of equipment, ensuring all securing devices meet safety standards and are properly rated for the load, and thorough training of personnel on safe loading and securing procedures. We also maintain detailed records of all loading operations, including weight measurements, securing device specifications, and any potential issues encountered. This documentation facilitates audits and ensures traceability.

Furthermore, we conduct regular safety training for all employees involved in log railcar loading, emphasizing safe work practices, proper use of equipment, and the importance of following established procedures. We prioritize a safety-first culture where employees are empowered to stop work if they identify unsafe conditions.

Q 5. What are the common challenges associated with log railcar loading, and how do you address them?

Log railcar loading presents several challenges. One common issue is log damage during transit due to shifting or inadequate securing. Another challenge is efficient loading and unloading, particularly with large volumes and varying log sizes. Inclement weather can also significantly impact operations, leading to delays and potential safety hazards.

We address these challenges through a multi-pronged approach. This includes using appropriate securing methods and technology, implementing efficient loading and unloading procedures that minimize handling, and using weather-resistant materials and protective coverings where necessary. Proper load planning, leveraging software to optimize space and weight distribution, also helps alleviate these challenges. We also invest in equipment maintenance and employee training to prevent equipment malfunctions and human error.

Q 6. What are your methods for efficient log handling and stacking within the railcar?

Efficient log handling and stacking involve optimizing space within the railcar while maintaining stability and safety. This includes using specialized equipment such as log loaders and grapple trucks to efficiently move and place logs, minimizing manual labor and reducing the risk of accidents.

Our methods focus on maximizing space utilization. We begin by loading the heaviest logs first, placing them strategically at the bottom and center for optimal weight distribution. Then, we work our way up, filling gaps with smaller logs. We utilize different stacking patterns based on log size and shape to maximize efficiency and stability. This process involves careful planning and skilled operators who understand the physics of load distribution.

Furthermore, we use appropriate equipment to ensure logs are handled without damage. This includes using grapple attachments that are designed to minimize log stress and damage during the loading and unloading process.

Q 7. How do you calculate the maximum load capacity of a log railcar?

Calculating the maximum load capacity of a log railcar is a complex process that involves several factors. First, we consult the railcar’s specifications, which indicate its weight limits and structural capacity. This data is provided by the manufacturer. We also account for the weight of the railcar itself, which needs to be subtracted from the gross weight capacity.

Next, we determine the density of the specific type of log being transported. Different species of wood have different densities, directly impacting the total weight of the logs. We then consider the volume of the railcar and the estimated packing factor, which accounts for the gaps between logs in the stack. This allows us to calculate the approximate weight of the logs that can safely fit within the railcar.

Finally, we always apply a safety factor, typically around 10-15%, to ensure we never exceed the railcar’s structural limits. This precaution leaves room for any unforeseen variations in log weight or density. Specialized software and industry standards are usually consulted in this process.

The formula is not a simple one and varies based on the specific circumstances, but it essentially involves: (Railcar Capacity - Railcar Weight) * Density of Logs * Packing Factor * Safety Factor = Maximum Log Weight

Q 8. Describe your experience with different types of log handling equipment (e.g., loaders, cranes).

My experience encompasses a wide range of log handling equipment, crucial for efficient and safe railcar loading. I’m proficient with various loaders, from grapple loaders that efficiently pick up and place log bundles, to wheeled loaders that excel in maneuvering logs across uneven terrain. I’ve also extensively used different types of cranes, including hydraulic knuckle boom cranes for precise placement of logs in railcars, and larger mobile cranes for handling exceptionally large or heavy logs. The choice of equipment depends on factors like log size, terrain conditions, and the overall loading capacity required. For example, in a situation with tight spaces and numerous smaller logs, a grapple loader would be more efficient than a large crane. Conversely, a large crane becomes essential for loading extremely long or heavy logs that are beyond the capacity of a typical loader.

My experience extends to understanding the operational nuances of each piece of equipment, including maintenance schedules, safety protocols, and limitations. This understanding ensures that the right tools are used for the job, maximizing efficiency and minimizing risks.

Q 9. How do you manage inventory and track log movement during the loading process?

Inventory management and log tracking are paramount for smooth railcar loading operations. We typically use a combination of manual and digital systems. Before loading commences, a precise inventory count is taken, noting the species, volume, and grade of each log. This information is often recorded on digital inventory management systems, allowing for real-time tracking and updating. As logs are loaded, we use scanners to register each log’s ID, location within the railcar, and destination. This provides a comprehensive record of log movement throughout the entire process.

We utilize GPS-enabled devices to track the movement of log trucks and equipment within the yard. This assists in optimizing the loading sequence and minimizing wait times. Regular reconciliation between the physical inventory and the digital records ensures accuracy and enables swift identification of any discrepancies. This prevents costly errors and streamlines the entire logistics chain.

Q 10. Explain your understanding of chain and binder usage for securing logs in railcars.

Securing logs within railcars using chains and binders is critical for preventing shifting during transit and ensuring safety. We follow stringent safety procedures to ensure proper binding. Chains are used to create a strong framework, often crisscrossing across the load to provide multiple points of restraint. The choice of chain thickness depends on the size and weight of the logs being transported. Binders, which are essentially heavy-duty straps, are then used to tightly secure the logs to the chains and to the railcar itself. It’s crucial to ensure that binders are properly tensioned—not too tight to risk damage to the logs, but tight enough to prevent movement. We employ a criss-cross pattern for optimal load stability, creating a network of secure points of contact.

Think of it like building a strong cage around the logs; the chains form the bars, and the binders are the locking mechanisms. Regular inspections of chains and binders for wear and tear are essential to prevent accidents. Damaged or weakened equipment is immediately replaced.

Q 11. What are the potential risks of improper log loading, and how do you mitigate them?

Improper log loading poses significant risks, including log shifting during transit, which can lead to derailments and damage to railcars or other infrastructure. Overloading railcars can cause structural damage and increase the risk of accidents. Logs shifting can also lead to injuries to personnel involved in loading or unloading. In addition, improper securing can lead to the loss or damage of valuable cargo.

To mitigate these risks, we strictly adhere to weight limits and load distribution guidelines. Thorough pre-trip inspections of railcars and equipment are crucial. We utilize specialized software to model load distribution and optimize the placement of logs to ensure stability. Training for all personnel on safe log handling and loading procedures is an ongoing process. We also maintain detailed records of every loading operation to monitor patterns, identify potential issues, and improve our safety practices.

Q 12. Describe your experience with pre-trip inspections of railcars and log handling equipment.

Pre-trip inspections are non-negotiable in our operations. They are a critical step in preventing accidents. For railcars, we check the structural integrity, brakes, and couplers, ensuring that they are in good working condition and safe for loading. We look for any signs of damage, leaks, or malfunctions. Similarly, pre-trip inspections of log handling equipment include checking hydraulic systems, brakes, and lifting mechanisms for proper functioning. We also verify that all safety devices, such as emergency stops and warning lights, are operational. Detailed checklists are used to ensure thoroughness and consistency, and any defects are immediately reported and rectified before loading commences.

Think of this as a health check before undertaking a crucial task – it’s preventative maintenance to ensure safety and efficiency throughout the process.

Q 13. How do you handle unexpected delays or equipment malfunctions during the loading process?

Unexpected delays and equipment malfunctions are a reality in any complex operation. Our response involves a clear protocol that prioritizes safety and minimizes downtime. If equipment malfunctions, we have backup equipment readily available to minimize delays. For example, if a loader breaks down, we have a secondary loader or crane to step in. For unexpected delays caused by external factors, such as inclement weather, we communicate proactively with all involved parties, adjusting schedules and securing the site appropriately. Our communication plan keeps stakeholders (e.g., transportation companies, logging crews) updated every step of the way to manage expectations and prevent misunderstandings.

We continuously review our procedures and train our team in problem-solving to quickly identify and resolve issues, limiting the impact of unexpected interruptions on overall efficiency.

Q 14. How do you ensure the accurate documentation of log railcar loading activities?

Accurate documentation is vital for compliance, traceability, and efficient operations. We maintain detailed records of each railcar loading operation, including the date, time, location, railcar number, log species, volume, grade, and weight. Electronic logging systems and barcode scanners are used to eliminate manual errors and ensure data integrity. We also document any maintenance activities, equipment malfunctions, delays, and any other relevant information. This information is stored securely and is readily accessible for audits or future reference. Our systems are designed to generate reports that provide a clear overview of all activities, assisting in analysis, optimization, and compliance with all applicable regulations.

This meticulous record-keeping provides a complete audit trail of every step of the loading process, offering accountability, supporting claims if necessary, and offering insights for process improvement.

Q 15. Describe your experience with different types of log species and their specific loading requirements.

Different log species have varying densities and strengths, directly impacting their loading requirements. For instance, denser woods like Douglas Fir require careful stacking to avoid exceeding weight limits per railcar, while lighter woods like Pine might allow for higher volumes. My experience encompasses working with a wide range of species, including Douglas Fir, Pine, Redwood, and Spruce. I understand the importance of species-specific knowledge, as it directly relates to maximizing load capacity while ensuring structural integrity and preventing damage during transit.

- Douglas Fir: High density necessitates careful stacking and weight distribution to meet railcar weight limits. We often utilize specialized load plans for this species.

- Pine: Lower density allows for greater volume per railcar, but proper bracing is crucial to prevent shifting and damage.

- Redwood: Its size and weight often necessitates careful planning and the use of specialized equipment for loading.

- Spruce: Similar to Pine in terms of density, but its tendency to break more easily mandates cautious handling.

I always consult species-specific guidelines and industry best practices when planning a load, ensuring the safety and efficiency of the entire process.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you manage communication and coordination with other teams involved in log transportation?

Effective communication is paramount in log railcar loading. I regularly interact with logging crews, trucking companies, rail operators, and receiving mills. I use a combination of methods to facilitate seamless coordination. This includes:

- Daily briefings: Starting each day with briefings to discuss the day’s loading plan, potential challenges, and safety concerns.

- Real-time updates: Utilizing communication tools like two-way radios and mobile phones to provide real-time updates on loading progress and any unexpected issues.

- Digital platforms: Employing project management software to share essential documents, track progress, and facilitate collaboration among different teams. This could include sharing digital copies of load plans or reporting any delays.

- Regular meetings: Holding periodic meetings with key stakeholders to review performance, identify areas for improvement, and proactively address any potential problems.

Open and proactive communication is essential to avoid delays, minimize conflicts, and ensure the smooth operation of the entire log transportation process.

Q 17. What is your experience with using technology in log railcar loading (e.g., load planning software)?

My experience includes extensive use of load planning software. These programs allow for optimization of railcar space, weight distribution, and the overall loading process. They offer features such as:

- 3D Modeling: Allows visualization of the railcar and log placement for precise load planning.

- Weight Calculation: Automatically calculates the total weight of the load, ensuring compliance with regulations.

- Species-Specific Data: Integrates species-specific density and strength data for accurate load optimization.

- Reporting and Analytics: Provides detailed reports on loading efficiency, helping to identify areas for improvement.

For example, I regularly use LogLoadPro software to plan loads, ensuring optimal weight distribution and maximum railcar capacity. The software’s ability to account for log dimensions and species properties has significantly increased our loading efficiency and reduced the risk of damage during transit.

Q 18. Describe your problem-solving approach when faced with loading challenges or constraints.

My problem-solving approach is systematic and data-driven. When faced with loading challenges, I follow these steps:

- Identify the problem: Clearly define the nature of the constraint or challenge (e.g., insufficient railcar space, weight limitations, log damage).

- Gather information: Collect relevant data, such as log dimensions, species, weight, and available railcar specifications.

- Analyze the options: Explore different solutions, considering their potential impact on safety, efficiency, and cost.

- Develop a solution: Select the most feasible and efficient solution, ensuring compliance with safety regulations.

- Implement and monitor: Implement the chosen solution and continuously monitor its effectiveness.

- Document the process: Document the problem, solution, and results to inform future decision-making.

For instance, if faced with oversized logs that don’t fit within standard railcar dimensions, I might explore solutions like using specialized railcars or modifying the loading sequence to accommodate them, always prioritizing safety.

Q 19. How do you ensure the timely and efficient completion of log railcar loading operations?

Timely and efficient log railcar loading requires careful planning and execution. My approach involves:

- Optimized scheduling: Coordinating with all stakeholders to develop a realistic schedule that accounts for potential delays and variations. This includes factoring in potential weather conditions.

- Efficient workflows: Implementing standardized loading procedures that minimize unnecessary steps and maximize productivity. This includes having pre-planned load sequences.

- Proactive problem-solving: Identifying and addressing potential challenges before they impact the loading process. This includes anticipating potential equipment malfunctions and having backup plans in place.

- Continuous improvement: Regularly reviewing loading processes and identifying areas for optimization. This might include streamlining the loading process or identifying better equipment.

Using a combination of these strategies, I consistently ensure timely and efficient completion of log railcar loading operations, often exceeding targets for trains loaded per day.

Q 20. What are the key performance indicators (KPIs) you use to measure the effectiveness of log railcar loading?

Key Performance Indicators (KPIs) are essential for measuring the effectiveness of log railcar loading. I use the following:

- Tons per hour loaded: Measures the efficiency of the loading process.

- Railcars loaded per day/shift: Indicates overall productivity and operational capacity.

- Percentage of on-time departures: Tracks adherence to the scheduled loading timeline.

- Log damage rate: Measures the effectiveness of handling procedures in preventing log damage during loading.

- Safety incidents rate: Indicates the success of safety protocols and training programs. A rate of zero is the target.

By regularly monitoring these KPIs and analyzing trends, I can identify areas for improvement and implement strategies to enhance efficiency and safety.

Q 21. How do you prioritize safety while maintaining efficiency in log railcar loading operations?

Safety is paramount in log railcar loading operations. I incorporate safety into every aspect of the process. My approach includes:

- Rigorous training: Providing comprehensive training to all personnel involved in loading, covering safe handling procedures, equipment operation, and emergency response protocols. This includes regular refresher training and competency assessments.

- Strict adherence to safety regulations: Ensuring strict compliance with all relevant safety regulations and guidelines. This includes adhering to load weight restrictions and safe operating procedures.

- Regular safety inspections: Conducting regular inspections of equipment and work areas to identify and address potential hazards. We perform both scheduled and unscheduled inspections.

- Use of safety equipment: Mandating the use of appropriate personal protective equipment (PPE), such as hard hats, safety glasses, and gloves.

- Incident reporting and investigation: Implementing a robust system for reporting and investigating safety incidents to identify root causes and prevent recurrence.

By prioritizing safety and integrating it into every aspect of the operation, I ensure that efficiency is achieved without compromising safety, creating a positive and productive work environment.

Q 22. What is your experience with load securing regulations and compliance requirements?

Load securing regulations are paramount in log railcar loading to ensure safety and prevent accidents. My experience encompasses a thorough understanding of regulations set by agencies like the Association of American Railroads (AAR) and relevant federal and state transportation departments. This includes familiarity with the detailed specifications for securing different types of logs – from small pulpwood to large timber – within various railcar types. Compliance involves meticulous documentation, pre-trip inspections, and adherence to weight limits. I’m proficient in using various securing methods, including dunnage, chains, binders, and load locks, ensuring each load meets all applicable regulations and industry best practices. For instance, I’ve been involved in audits where we meticulously reviewed our securing procedures to ensure full compliance with AAR standards and prevented potential derailments.

Regular training and updates on regulatory changes are crucial. I’ve personally participated in numerous safety workshops and training sessions focusing on load securement best practices and accident prevention. This ensures that I’m always up-to-date with the latest rules and techniques, minimizing any risks associated with non-compliance.

Q 23. Explain your familiarity with different railcar types and their technical specifications.

My familiarity with railcar types extends to various configurations designed for log transportation. This includes gondola cars (open-top cars), well cars (with a lowered center section), and specialized log cars equipped with enhanced securing mechanisms. I understand their technical specifications, such as weight capacity, dimensions, and structural integrity. For example, I’m experienced with the differences between a standard gondola and a high-capacity gondola, understanding the implications for load planning and securement techniques. Knowing the exact dimensions is vital, as it dictates how many logs, and of what size, can be safely loaded. This includes considering the center of gravity of the load to minimize risk of swaying during transport.

Furthermore, I am familiar with the different types of underframes, braking systems, and structural components that affect the safe loading of various railcars. I am also experienced with the documentation required for each railcar, including weight limits, AAR certifications, and any specific operational limitations.

Q 24. Describe your experience with various log sizes and their optimal loading configurations.

Experience with diverse log sizes and optimal loading configurations is essential for efficient and safe railcar loading. Smaller logs, like pulpwood, can be loaded more densely, often requiring specialized stacking techniques to maximize capacity while maintaining stability. Larger logs demand careful planning to avoid overhang and ensure proper weight distribution. I’ve worked with logs ranging from small diameter pulpwood to massive timber, employing different loading strategies for each. For example, large diameter logs might be strategically placed near the center of the railcar to lower the center of gravity and improve stability.

Optimizing the loading pattern involves considering factors like log diameter, length, and overall weight distribution. I utilize software and specialized load planning tools to create efficient and safe load configurations that ensure the maximum utilization of railcar space while complying with weight and safety regulations. It’s a balancing act between efficiency and safety that minimizes empty space and prevents the risk of loads shifting during transit.

Q 25. What measures do you employ to prevent damage to logs during loading and transportation?

Preventing log damage during loading and transportation requires a multi-faceted approach. Proper handling from the logging site to the railcar is crucial. We use specialized equipment like log loaders and grapple cranes to minimize impact and stress on the logs. Careful placement within the railcar is essential, preventing logs from rubbing against each other or the railcar sides. Adequate padding or dunnage is used to protect the logs and absorb any impact during transit. This might involve placing blocks of wood or other suitable material between logs and the railcar walls.

Beyond the initial loading, securement is critical. Chains, binders, and load locks are used to ensure the logs remain stationary throughout the journey. Regular inspections during the loading process and before departure help identify and address potential issues before they lead to damage. For example, I’ve witnessed instances where improper placement of dunnage caused logs to shift, leading to damage. This highlights the importance of careful planning and meticulous execution at each stage.

Q 26. How do you manage the environmental impact of log railcar loading operations?

Managing the environmental impact of log railcar loading involves minimizing soil erosion at loading sites, preventing spills of oil or fuel, and properly managing any waste generated during the process. We work closely with environmental agencies to obtain all necessary permits and adhere to their guidelines. We implement best practices to prevent soil erosion by establishing buffer zones and properly managing runoff. Careful handling of equipment prevents oil and fuel spills, protecting waterways and surrounding land. Waste materials, such as sawdust or debris, are collected and disposed of properly, minimizing environmental impact.

Sustainable practices are also prioritized, considering fuel-efficient transportation routes and optimizing railcar loading capacity to reduce overall transportation needs. This includes using appropriate technologies and techniques to reduce waste and emissions.

Q 27. How would you address a situation where a railcar is overloaded or improperly secured?

Addressing an overloaded or improperly secured railcar is a critical safety issue. The first step involves immediately halting the loading process if it’s still underway. If the railcar is already loaded, it is essential to immediately contact the relevant authorities and railway personnel. The next step is to carefully assess the situation. This involves measuring the actual weight and carefully inspecting the securement mechanisms. Depending on the severity of the issue, we might need to unload some logs, reinforce the securement, or even replace the railcar.

Thorough documentation is crucial throughout the process. We would record the reason for the issue, the corrective actions taken, and any further measures implemented to prevent similar occurrences in the future. This includes conducting a thorough review of our loading procedures to identify any weaknesses or points of failure in the process. Safety is paramount, and all actions are taken to ensure the railcar is safely unloaded or corrected before transit.

Q 28. Explain your understanding of the different types of log transportation permits and regulations.

Understanding log transportation permits and regulations is crucial. These vary based on jurisdiction (federal, state, and local). Common permits include overweight and oversized permits for loads exceeding standard weight and dimension limits. Environmental permits may be required to protect sensitive ecosystems along the transportation routes. Safety permits, demonstrating compliance with load securement and handling procedures, are frequently necessary. I’m familiar with the processes for obtaining these permits and ensuring all necessary documentation is accurate and up-to-date.

Regulations often involve specific requirements for load securement, route planning, speed limits, and notification procedures for oversized loads. I understand the specific requirements for each type of permit and ensure we comply with all applicable laws and regulations before any transportation commences. Non-compliance can lead to significant fines and delays, and potentially safety hazards. Therefore, thorough knowledge of the regulations is critical.

Key Topics to Learn for Log Railcar Loading Interview

- Railcar Types and Specifications: Understanding different railcar types (e.g., gondolas, well cars) and their capacity, dimensions, and suitability for log transportation is crucial. This includes knowledge of weight limits and safety regulations.

- Log Handling and Securing Techniques: Learn about safe and efficient methods for loading logs onto railcars, including proper placement, bracing, and securing to prevent shifting during transit. This also involves understanding different log sizes and weights and how they impact loading strategies.

- Logistics and Planning: Mastering the logistical aspects, such as scheduling, route planning, and coordinating with other teams involved in the process (e.g., trucking, forestry). This includes understanding inventory management and optimizing loading efficiency.

- Safety Procedures and Regulations: Familiarize yourself with all relevant safety regulations and protocols related to log railcar loading, including personal protective equipment (PPE) requirements and hazard identification.

- Troubleshooting and Problem-Solving: Be prepared to discuss your approach to common challenges encountered during log railcar loading, such as unexpected log dimensions or equipment malfunctions. Demonstrate your ability to think on your feet and find efficient solutions.

- Technology and Equipment: Understanding the machinery and technology used in log railcar loading (e.g., cranes, loaders, automated systems) and their operation will be beneficial. This includes basic maintenance and troubleshooting knowledge.

- Efficiency and Optimization: Explore techniques for maximizing railcar loading efficiency, minimizing downtime, and reducing waste. This includes understanding the impact of different loading methods on overall efficiency.

Next Steps

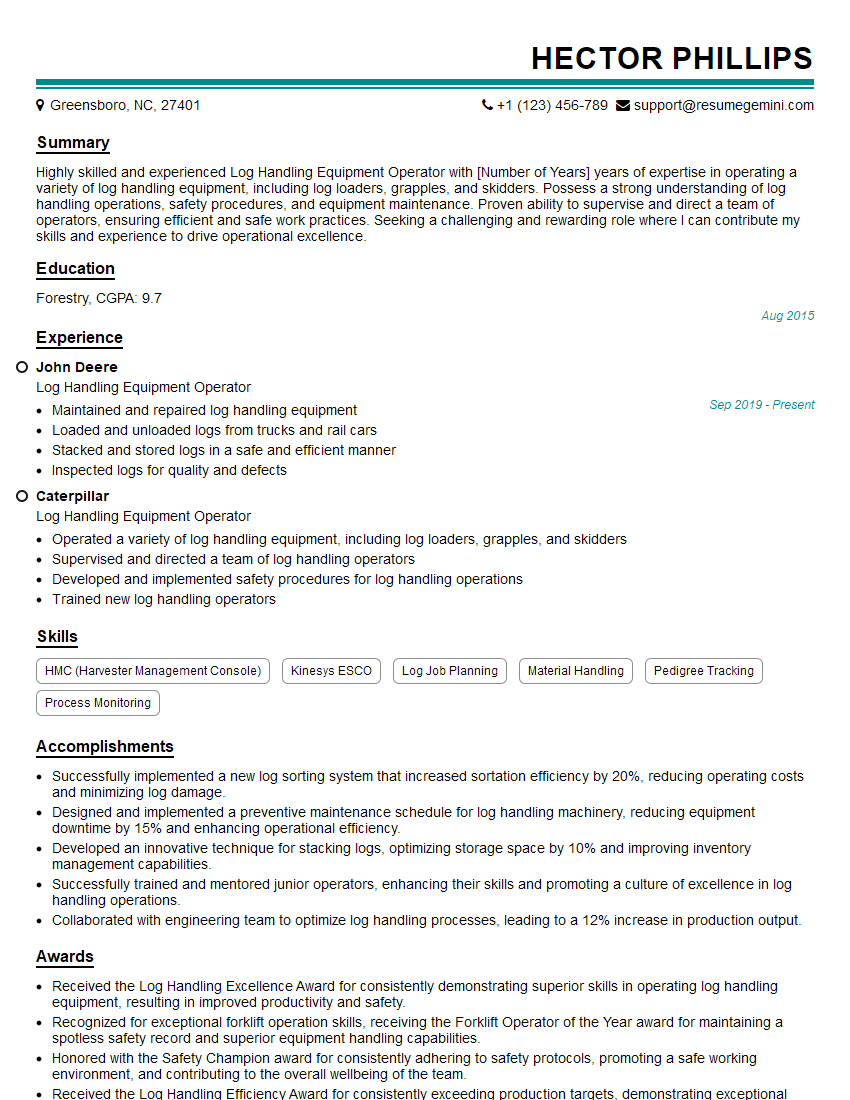

Mastering the intricacies of Log Railcar Loading positions you for significant career advancement within the forestry and transportation industries. A strong understanding of this specialized field demonstrates valuable skills in logistics, safety, and problem-solving. To significantly boost your job prospects, invest time in crafting an ATS-friendly resume that highlights your relevant skills and experience. ResumeGemini is a trusted resource to help you build a professional and impactful resume that gets noticed. Examples of resumes tailored to Log Railcar Loading are available to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good