Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Operations Planning and Execution interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Operations Planning and Execution Interview

Q 1. Describe your experience with capacity planning.

Capacity planning is the process of determining the resources needed to meet future demand. It involves forecasting future needs, analyzing current resources, and identifying gaps. This is crucial for optimizing resource allocation and preventing bottlenecks.

In my previous role at Acme Corp, we used a combination of historical data analysis, predictive modeling, and Monte Carlo simulations to forecast demand for our flagship product. We then mapped this demand against our existing production capacity, considering factors like machine uptime, labor availability, and raw material supply. This analysis highlighted a potential shortfall in production capacity during peak seasons. To address this, we implemented a phased approach: first, optimizing existing machinery to increase efficiency by 15%; second, investing in additional equipment and hiring temporary staff; and finally, exploring partnerships with contract manufacturers for overflow.

The result was a significant reduction in lead times, improved customer satisfaction, and a minimized risk of lost sales due to capacity constraints.

Q 2. How do you handle unexpected disruptions in the operational process?

Unexpected disruptions are inevitable in operations. My approach involves a multi-pronged strategy built on proactive planning, robust contingency measures, and swift reactive response. Think of it like a well-equipped fire department – preparedness is key.

- Proactive Planning: This includes identifying potential risks (e.g., supplier delays, equipment failures, natural disasters) and developing preemptive mitigation strategies. Regular risk assessments are essential.

- Contingency Planning: Establishing backup suppliers, alternative production processes, and robust communication channels are crucial. This ensures that we can quickly adapt to changing circumstances.

- Reactive Response: When a disruption occurs, a swift and organized response is vital. This involves a well-defined incident management process, clear communication across teams, and efficient prioritization of tasks to minimize the impact.

For example, during a recent supplier strike, we leveraged our pre-established relationship with an alternate supplier, incurring only a minor delay in production. Our proactive risk assessment and contingency planning allowed us to navigate the crisis effectively, with minimal impact on our customers.

Q 3. Explain your approach to inventory management.

Inventory management is about balancing the costs of holding inventory against the risks of stockouts. My approach centers around optimizing inventory levels to meet demand while minimizing storage costs and obsolescence. This is achieved through a combination of techniques.

- Demand Forecasting: Accurate forecasting is crucial for determining optimal stock levels. I use a variety of forecasting methods, including time series analysis, moving averages, and exponential smoothing, tailoring the approach to the specific product and its demand patterns.

- Inventory Control Systems: Implementing a robust inventory control system (like ABC analysis, which categorizes inventory based on value and usage) allows for efficient tracking and management of stock levels. Regular cycle counting ensures accuracy.

- Just-in-Time (JIT) Inventory: Where appropriate, I strive to minimize inventory holding costs by employing JIT principles. This involves procuring materials and components only as needed, reducing storage space and the risk of obsolescence.

In a previous project, I implemented an ABC analysis that identified 20% of our inventory items accounting for 80% of the value. By focusing our management efforts on this critical 20%, we significantly reduced our inventory holding costs while maintaining sufficient stock of high-demand items.

Q 4. What metrics do you use to measure operational efficiency?

Measuring operational efficiency requires a comprehensive set of metrics that reflect various aspects of the process. These metrics should be aligned with overall business objectives.

- On-Time Delivery Rate (OTDR): Measures the percentage of orders delivered on time, reflecting the reliability of the operational process.

- Production Efficiency: This can be measured by calculating output per unit of input (e.g., units produced per labor hour). This reveals productivity levels.

- Inventory Turnover Rate: Shows how quickly inventory is sold or used. A higher rate typically indicates efficient inventory management.

- Lead Time: The time it takes to fulfill an order, from order placement to delivery. Shorter lead times indicate efficiency.

- Defect Rate: The percentage of defective products produced, indicating quality control effectiveness.

- Total Cost of Ownership (TCO): Considers all costs associated with owning and operating an asset, from acquisition to disposal.

By regularly monitoring these metrics, we can identify areas for improvement and track the effectiveness of implemented changes. Using dashboards and reporting tools facilitates this process and allows for data-driven decision-making.

Q 5. Describe a time you improved operational processes. What was the impact?

In my previous role, we experienced significant delays in our order fulfillment process due to inefficient warehouse operations. I implemented a Lean methodology approach focusing on eliminating waste and streamlining workflow.

This involved:

- Value Stream Mapping: Identifying all steps in the order fulfillment process, highlighting areas of waste (e.g., unnecessary movement, excessive inventory).

- 5S Methodology: Implementing 5S (Sort, Set in Order, Shine, Standardize, Sustain) to optimize warehouse layout and organization.

- Kaizen Events: Conducting regular improvement workshops with warehouse staff to identify and implement small, incremental changes.

The impact was dramatic. We reduced order fulfillment time by 30%, decreased warehouse space needs by 15%, and improved employee morale and productivity. This improved efficiency translated directly into increased customer satisfaction and reduced operational costs.

Q 6. How do you prioritize tasks in a high-pressure environment?

Prioritization in high-pressure environments requires a structured approach and strong decision-making skills. I typically use a combination of methods:

- Eisenhower Matrix (Urgent/Important): Categorizing tasks based on urgency and importance allows for focused attention on critical activities. This helps avoid getting bogged down in less important tasks.

- MoSCoW Method: Classifying requirements as Must have, Should have, Could have, and Won’t have provides a clear framework for prioritizing tasks based on their impact and feasibility.

- Dependency Analysis: Identifying task dependencies helps establish a logical sequence of execution, preventing bottlenecks and ensuring efficient workflow.

Furthermore, effective communication and delegation are crucial. Keeping stakeholders informed and assigning tasks to the most appropriate individuals ensures efficient use of resources and minimizes delays.

Q 7. What is your experience with forecasting and demand planning?

Forecasting and demand planning are critical for effective operations planning. My experience encompasses various forecasting techniques, from simple moving averages to more sophisticated statistical models.

I have extensive experience using:

- Time Series Analysis: Analyzing historical data to identify trends and seasonality patterns, enabling more accurate predictions.

- Regression Analysis: Identifying relationships between demand and influencing factors (e.g., price, promotions, economic indicators) to improve forecast accuracy.

- Causal Forecasting: Considering external factors impacting demand, such as economic conditions or competitor actions.

- Collaborative Planning, Forecasting, and Replenishment (CPFR): Working with suppliers and customers to share demand information and improve forecast accuracy.

In one project, we implemented a CPFR system, which resulted in a 20% reduction in forecast error and a significant improvement in supply chain efficiency. This demonstrated the power of collaborative forecasting in improving overall planning accuracy and reducing waste.

Q 8. Explain your understanding of Lean methodologies.

Lean methodologies are a collection of practices aimed at eliminating waste and maximizing value in any process. Think of it as streamlining a manufacturing process to produce the highest quality product with the least amount of effort and resources. It’s built on the philosophy of continuous improvement, focusing on what adds value from the customer’s perspective and ruthlessly removing everything else.

Key principles include:

- Value: Defining value from the customer’s point of view is paramount.

- Value Stream Mapping: Visually mapping the entire process to identify wasteful steps.

- Flow: Optimizing the flow of work to minimize bottlenecks and delays.

- Pull: Producing only what is needed, when it’s needed, avoiding overproduction.

- Perfection: Continuously striving for improvement through feedback loops and data analysis.

In a real-world scenario, I used Lean principles to optimize a warehouse picking process. By mapping the current state, we identified unnecessary movements and re-organized the warehouse layout, resulting in a 20% reduction in picking time and improved order fulfillment accuracy.

Q 9. How familiar are you with Six Sigma principles?

Six Sigma is a data-driven methodology focused on minimizing variation and defects in a process. Think of it as creating a highly precise manufacturing process where imperfections are extremely rare. It uses statistical tools to identify root causes of defects and implement solutions to improve process capability.

My familiarity extends to applying DMAIC (Define, Measure, Analyze, Improve, Control) methodology. I’ve successfully led projects using Six Sigma, for example, reducing customer complaints related to a specific product defect by over 80%. We used control charts to monitor the process after implementation, ensuring sustained improvement.

The key phases of DMAIC involve:

- Define: Clearly defining the problem and project goals.

- Measure: Collecting data to quantify the problem’s magnitude.

- Analyze: Identifying the root causes of the defects.

- Improve: Implementing solutions to address the root causes.

- Control: Monitoring the improved process to ensure sustained improvements.

Q 10. Describe your experience with project management within an operations context.

My project management experience within an operations context is extensive. I’ve led numerous projects involving process improvement, capacity planning, and new product launches. I typically utilize Agile methodologies, such as Scrum, to manage these projects, adapting to changing requirements and prioritizing tasks effectively.

For instance, I managed a project to implement a new ERP system. This involved coordinating with various departments, managing timelines, risks, and resources, and ensuring seamless integration with existing systems. We used a phased rollout approach to minimize disruption and achieved successful implementation ahead of schedule and under budget. Key to success was regular stakeholder communication and transparent progress reporting.

Q 11. How do you ensure effective communication within your team and across departments?

Effective communication is crucial in operations. I utilize a multi-faceted approach. This includes regular team meetings, both formal and informal, to discuss progress, challenges, and solutions. I also leverage various communication tools, such as email, instant messaging, and project management software, for efficient information sharing.

To ensure cross-departmental communication, I actively participate in interdepartmental meetings and establish clear communication channels. I also maintain open-door policies, encouraging team members and colleagues to reach out with any questions or concerns. Transparency and clear, concise communication are key to avoiding misunderstandings and ensuring everyone is aligned.

Q 12. How do you identify and resolve operational bottlenecks?

Identifying and resolving operational bottlenecks requires a systematic approach. I typically start by analyzing process flow and data to pinpoint areas with high wait times, low throughput, or high defect rates. Tools like value stream mapping, process capability analysis, and bottleneck analysis are invaluable in this process.

Once a bottleneck is identified, I delve into root cause analysis to understand the underlying issues contributing to the problem. This often involves collecting data, interviewing stakeholders, and conducting workshops. Solutions can range from process re-engineering and technological upgrades to staff training and improved resource allocation. For example, we discovered a bottleneck in our packaging process due to inadequate equipment. By investing in new, automated equipment, we significantly increased throughput and reduced production lead time.

Q 13. What is your experience with supply chain management?

My experience in supply chain management includes demand forecasting, inventory management, procurement, and logistics. I have a strong understanding of supply chain dynamics and the importance of collaboration with suppliers and distributors. I have experience optimizing inventory levels to minimize holding costs and reduce stockouts, ensuring timely delivery of goods to customers.

For example, I implemented a just-in-time inventory system for a key component, significantly reducing our inventory holding costs while maintaining sufficient supply. This required close collaboration with our supplier to ensure reliable delivery schedules and effective communication on demand fluctuations.

Q 14. Describe your approach to risk management in operations.

My approach to risk management in operations is proactive and systematic. It starts with identifying potential risks through various methods, such as brainstorming sessions, risk assessments, and historical data analysis. Once identified, I evaluate the likelihood and impact of each risk and prioritize them based on their severity.

Mitigation strategies are developed and implemented to address each risk, taking into account cost-benefit analysis. These strategies can include contingency planning, process improvements, insurance coverage, and investment in new technologies. Regular monitoring and review of the risk profile are crucial to ensure the effectiveness of implemented strategies and to adapt as new risks emerge.

For instance, we identified the risk of supplier disruption due to geopolitical instability. To mitigate this, we diversified our supplier base and implemented a robust inventory management system to buffer against potential shortages.

Q 15. How do you measure the success of an operational improvement initiative?

Measuring the success of an operational improvement initiative requires a multi-faceted approach, going beyond just gut feeling. We need to define clear, measurable, achievable, relevant, and time-bound (SMART) goals before implementing any changes. Then, we track key performance indicators (KPIs) to assess the impact.

For example, if we’re aiming to reduce production lead times, we might track metrics like cycle time, throughput, and on-time delivery rate. A successful initiative would show significant improvement in these KPIs. We also need to consider qualitative factors like employee satisfaction and overall process efficiency.

- Quantitative Metrics: These are numerical measures such as cost reduction, defect rate, productivity increase, and customer satisfaction scores.

- Qualitative Metrics: These encompass less easily quantifiable aspects like improved employee morale, better communication, and enhanced collaboration.

Let’s say we implemented a new inventory management system. Success wouldn’t just be measured by a lower inventory holding cost (a quantitative metric), but also by improved order fulfillment speed and a reduction in stockouts (more quantitative metrics) and increased employee satisfaction with the new system (a qualitative metric). A balanced scorecard approach is highly effective to encompass all these aspects.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What software or tools are you proficient in for operations planning and execution?

My proficiency in software and tools for operations planning and execution spans several categories. For planning, I’m highly adept at using project management software like Microsoft Project and Jira to create detailed project plans, track progress, and manage resources effectively. I’m also experienced with enterprise resource planning (ERP) systems such as SAP and Oracle, crucial for integrated planning and execution across various departments.

For execution and monitoring, I rely heavily on business intelligence (BI) tools like Tableau and Power BI to visualize data, identify trends, and track KPIs. I also use data analytics platforms like Python with libraries such as Pandas and NumPy for more in-depth analysis. In terms of supply chain management, I have hands-on experience with tools such as Blue Yonder and JDA.

My experience with these tools allows me to not only execute plans but also to identify and troubleshoot bottlenecks, ultimately improving operational efficiency. For example, using Tableau, I was able to pinpoint a specific stage in our production process that was causing significant delays, allowing us to allocate more resources and shorten lead times.

Q 17. How do you handle conflicting priorities in operations?

Conflicting priorities are inevitable in operations. My approach involves a structured prioritization process using techniques like the Eisenhower Matrix (urgent/important), which helps to categorize tasks effectively. This allows me to focus on the most critical tasks first, ensuring that time and resources are allocated strategically. Communication is key; transparency with stakeholders regarding the prioritization process is crucial to manage expectations.

For example, if a critical project deadline conflicts with a routine maintenance task, I’d evaluate the potential impact of delaying each. If the project delay would lead to significant financial losses or reputational damage, it would take precedence. This prioritization decision should be clearly communicated to all involved.

Negotiation and collaboration also play significant roles. Finding win-win solutions that don’t completely sacrifice any of the priorities is the ideal outcome. Sometimes this might mean re-scoping projects, re-allocating resources, or seeking external support. Regularly reviewing and adjusting priorities is also important as situations change.

Q 18. Explain your experience with data analysis in an operational context.

Data analysis is fundamental to effective operations. My experience involves using data to identify trends, optimize processes, and make data-driven decisions. I’ve worked extensively with large datasets to analyze key performance indicators (KPIs), pinpoint areas for improvement, and measure the impact of implemented changes.

For instance, in a previous role, we used regression analysis to identify the key factors driving customer churn. We discovered that slow response times to customer inquiries were a major contributor. This insight led to the implementation of a new customer service system, which resulted in a significant reduction in churn rates. Another example involved using statistical process control (SPC) charts to monitor production processes and identify potential quality issues before they impacted the customer.

My skills encompass data cleaning, data transformation, statistical analysis, and data visualization. I’m proficient in various statistical software packages and programming languages including Python (with libraries like Pandas, NumPy, and Scikit-learn) and SQL, enabling me to handle complex datasets and extract valuable insights.

Q 19. Describe your experience with budget management in an operations role.

Budget management is crucial for operational success. My experience involves developing and managing operational budgets, forecasting expenses, and tracking actual spending against the budget. I have a strong understanding of cost accounting principles and am skilled in identifying cost savings opportunities. I’ve used various budgeting methods, including zero-based budgeting and activity-based budgeting, depending on the specific needs of the organization.

In a past role, I successfully managed a budget of $5 million for a large-scale project. This involved meticulous tracking of expenses, regular reporting to stakeholders, and proactive management of potential budget overruns. For example, by implementing a more efficient procurement process, we were able to save over $100,000. We achieved this by negotiating better rates with vendors, streamlining the purchase order process, and implementing stricter inventory controls.

I’m also proficient in using various financial planning and analysis (FP&A) software tools and techniques to ensure accuracy, transparency, and accountability in budget management.

Q 20. How do you ensure compliance with regulatory requirements in operations?

Ensuring compliance with regulatory requirements is paramount in operations. My approach involves a proactive and systematic process. First, I make sure I’m thoroughly familiar with all relevant regulations and industry standards applicable to the operations. This often requires collaboration with legal and compliance departments to stay updated on any changes.

I establish clear procedures and protocols to ensure compliance at every stage of the operational process. This includes implementing internal controls, conducting regular audits, and training employees on relevant regulations. Documentation is crucial; maintaining accurate and up-to-date records is essential for demonstrating compliance.

For example, in a previous role dealing with food processing, we implemented rigorous quality control checks and sanitation protocols to meet FDA regulations. Regular audits were conducted to ensure we were meeting all requirements and to identify any potential areas for improvement. Any non-compliance issues were addressed promptly and thoroughly documented.

Furthermore, investing in a robust compliance management system and staying informed about emerging regulations are critical components of my approach.

Q 21. How do you build and maintain effective relationships with stakeholders?

Building and maintaining strong relationships with stakeholders is essential for successful operations. My approach is built on open communication, active listening, and mutual respect. I strive to understand the needs and perspectives of all stakeholders, including employees, customers, suppliers, and senior management.

Regular communication is key. I utilize various communication channels, from formal meetings and presentations to informal one-on-one conversations, to ensure everyone is informed and engaged. I also actively seek feedback to ensure that expectations are met and any issues are addressed promptly.

For example, in a past project, I proactively held regular meetings with the project team, keeping them informed of progress, addressing concerns, and fostering a collaborative environment. I also made sure to keep senior management informed of any potential risks or challenges. Building trust and rapport with each stakeholder group helps to foster collaboration and overcome challenges effectively.

Q 22. How familiar are you with different scheduling techniques (e.g., Kanban, MRP)?

Scheduling techniques are crucial for optimizing operations. My familiarity spans various methodologies, each suited to different contexts. Kanban, for instance, is a visual system ideal for managing workflow in agile environments. It uses a Kanban board to track tasks through different stages (e.g., To Do, In Progress, Done), limiting work in progress to improve efficiency and reduce bottlenecks. Think of it like a supermarket checkout – only a certain number of customers are allowed in the queue at once, ensuring smooth flow. Material Requirements Planning (MRP), on the other hand, is a more deterministic approach, focusing on planning the procurement and production of materials based on a master production schedule. It’s excellent for manufacturing environments with complex bills of materials and long lead times. Imagine a car manufacturer using MRP to ensure they have the right number of tires, engines, and seats available to assemble vehicles according to the sales forecast. Other techniques I’m proficient in include Critical Path Method (CPM) for project scheduling, and Drum-Buffer-Rope (DBR) for managing constrained resources within a production system. The choice of technique depends heavily on the specific operational context and the nature of the work.

Q 23. What is your experience with implementing new technologies in operations?

I have extensive experience implementing new technologies across various operational settings. In my previous role, we transitioned from a legacy ERP system to a cloud-based solution. This involved a multi-phased approach encompassing detailed planning, stakeholder engagement, rigorous testing, and comprehensive training for the team. The new system drastically improved data visibility, streamlined processes, and reduced manual errors. For instance, automated inventory tracking significantly minimized stockouts and overstocking, leading to a considerable cost saving. Another project involved the integration of robotic process automation (RPA) into our order fulfillment process. This automated several repetitive tasks, freeing up staff to focus on higher-value activities like customer service and process improvement. In each case, successful implementation hinged on meticulous change management, robust communication, and a clear understanding of the technology’s capabilities and limitations.

Q 24. Describe a time you had to make a difficult decision that impacted operations.

During a significant production surge, we faced a critical shortage of a key component. The initial plan was to expedite delivery from our primary supplier, but this proved unrealistic due to unforeseen delays. I had to decide between halting production, potentially jeopardizing crucial deadlines and customer relationships, or sourcing the component from an alternative, higher-cost supplier. I opted for the latter, analyzing the financial implications and communicating transparently with all stakeholders. This involved negotiating favorable terms with the alternative supplier, adjusting the production schedule to minimize delays, and explaining the situation to affected clients. While it resulted in a temporary increase in costs, it prevented a much larger disruption to the business and preserved our reputation for timely delivery. Post-incident analysis revealed a weakness in our supply chain risk management strategy, prompting improvements in supplier diversification and contingency planning.

Q 25. How do you deal with resistance to change within an operations team?

Resistance to change is common, especially within established teams. My approach focuses on fostering collaboration and understanding. I begin by actively listening to concerns, acknowledging the team’s experience and expertise, and explaining the rationale behind the change. This often involves demonstrating the benefits of the change through clear data and visual aids. I emphasize how the change will improve their work environment, not just the bottom line. For example, introducing new software might seem daunting, but highlighting features that will simplify their tasks or reduce their workload can help gain buy-in. Training and support are essential; providing ample opportunities for the team to learn the new processes and systems is crucial. I also involve team members in the implementation process, empowering them to contribute to the solution and feel ownership of the outcome. Finally, I celebrate early successes to reinforce positive change and build momentum.

Q 26. Describe your experience with root cause analysis.

Root cause analysis (RCA) is a systematic approach to identifying the underlying causes of problems, rather than simply addressing symptoms. My experience leverages various techniques, including the 5 Whys method, Fishbone diagrams, and Fault Tree Analysis (FTA). For example, using the 5 Whys to investigate a recurring production delay, I might ask: Why was the production line stopped? (Machine malfunction). Why did the machine malfunction? (Lack of preventative maintenance). Why wasn’t preventative maintenance performed? (Insufficient training for technicians). Why was there insufficient training? (Lack of budgetary allocation). Why was there a lack of budgetary allocation? (Incorrect initial project budget). This process reveals a systemic issue in budgeting and training, leading to targeted corrective actions rather than solely focusing on repairing the machine. Thorough RCA ensures effective problem-solving, preventing recurrence, and improving overall operational efficiency.

Q 27. How do you ensure operational resilience?

Operational resilience involves the ability of an organization to withstand and recover from disruptions. It requires a multi-faceted approach. Firstly, robust risk management is key; identifying and assessing potential threats (e.g., supply chain disruptions, cyberattacks, natural disasters) is critical. This often involves scenario planning and developing contingency plans. Secondly, diversification is crucial; relying on a single supplier or distribution channel leaves the organization vulnerable. Thirdly, strong communication and collaboration are essential; during disruptions, clear and timely communication both internally and externally ensures swift responses and coordinated actions. Finally, a culture of continuous improvement encourages regular review and refinement of operational processes, identifying areas for improvement and enhancing overall resilience. This might include investing in redundancy systems, developing robust IT security protocols, and establishing strong relationships with multiple suppliers. Regular exercises simulating various disruptions help test response capabilities and identify areas needing further improvement.

Q 28. Explain your understanding of different production planning strategies.

Production planning strategies aim to balance supply and demand effectively. Make-to-stock (MTS) involves producing goods in anticipation of demand, ideal for products with stable, predictable demand. Think of a grocery store stocking shelves with commonly consumed items. Make-to-order (MTO) produces goods only after receiving a customer order, suitable for customized or high-value items, like bespoke furniture. Assemble-to-order (ATO) combines elements of both; partially finished goods are kept in inventory, with final assembly occurring upon receiving customer orders – like a computer manufacturer holding various components ready for assembly to specific customer configurations. Engineer-to-order (ETO) involves designing and manufacturing products to unique customer specifications, common in industries like aerospace or shipbuilding. The choice of strategy depends on factors like product complexity, demand variability, lead times, and inventory costs. Effective planning requires accurate demand forecasting, capacity planning, and efficient inventory management to achieve optimal resource utilization and minimize costs.

Key Topics to Learn for Operations Planning and Execution Interview

- Demand Planning & Forecasting: Understanding various forecasting methods (e.g., moving average, exponential smoothing), their applications, and limitations. Analyzing historical data to predict future demand and optimizing inventory levels.

- Production Scheduling & Capacity Planning: Mastering techniques for scheduling production runs efficiently, considering capacity constraints, material availability, and lead times. Understanding different scheduling algorithms and their impact on production output.

- Inventory Management: Exploring different inventory control models (e.g., EOQ, MRP), understanding their pros and cons, and applying them to optimize inventory levels, minimizing costs, and preventing stockouts.

- Supply Chain Optimization: Analyzing the entire supply chain to identify bottlenecks and areas for improvement. Understanding concepts like lean manufacturing, Six Sigma, and supply chain risk management.

- Performance Measurement & KPI’s: Familiarizing yourself with key performance indicators (KPIs) relevant to operations planning and execution, such as on-time delivery, production efficiency, and inventory turnover. Understanding how to track, analyze, and improve these metrics.

- Process Improvement Methodologies: Understanding and applying methodologies like Lean, Six Sigma, and Kaizen to streamline operations, reduce waste, and improve efficiency. Be prepared to discuss real-world examples of process improvement projects.

- Project Management Fundamentals: Demonstrating an understanding of project management principles, including planning, execution, monitoring, and control, as they relate to operational projects.

Next Steps

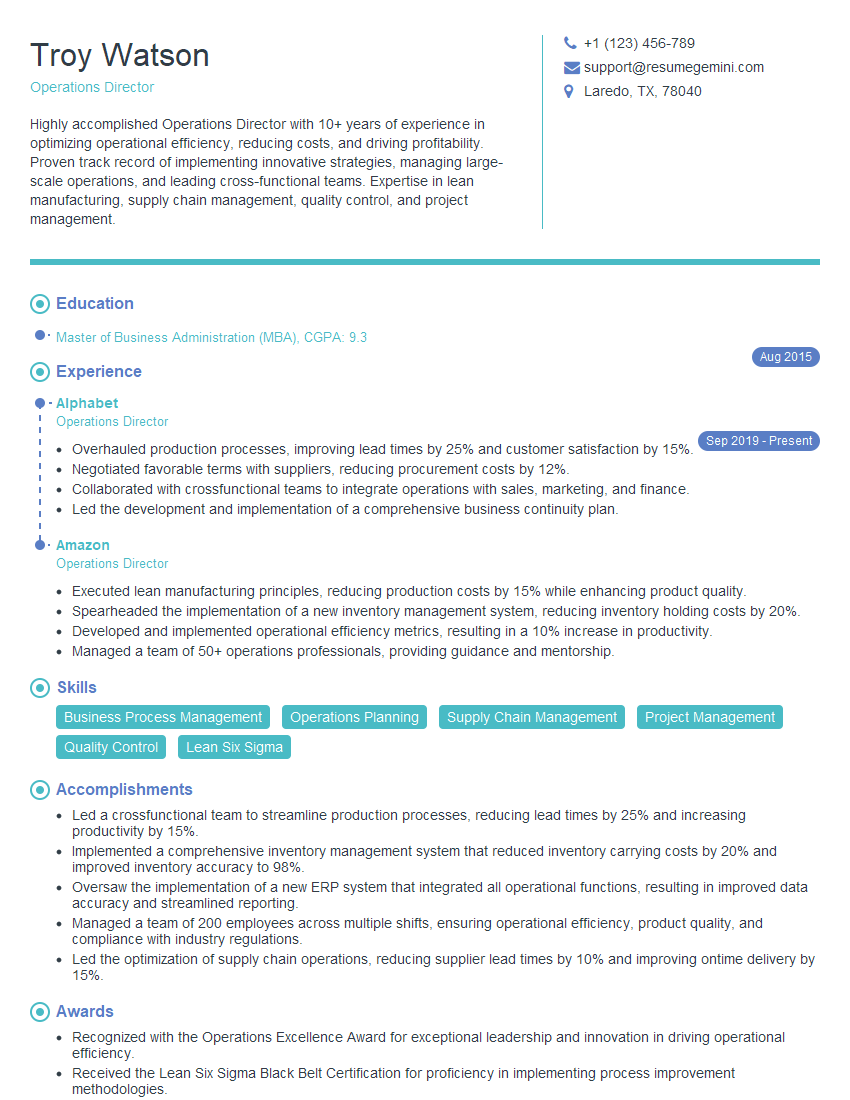

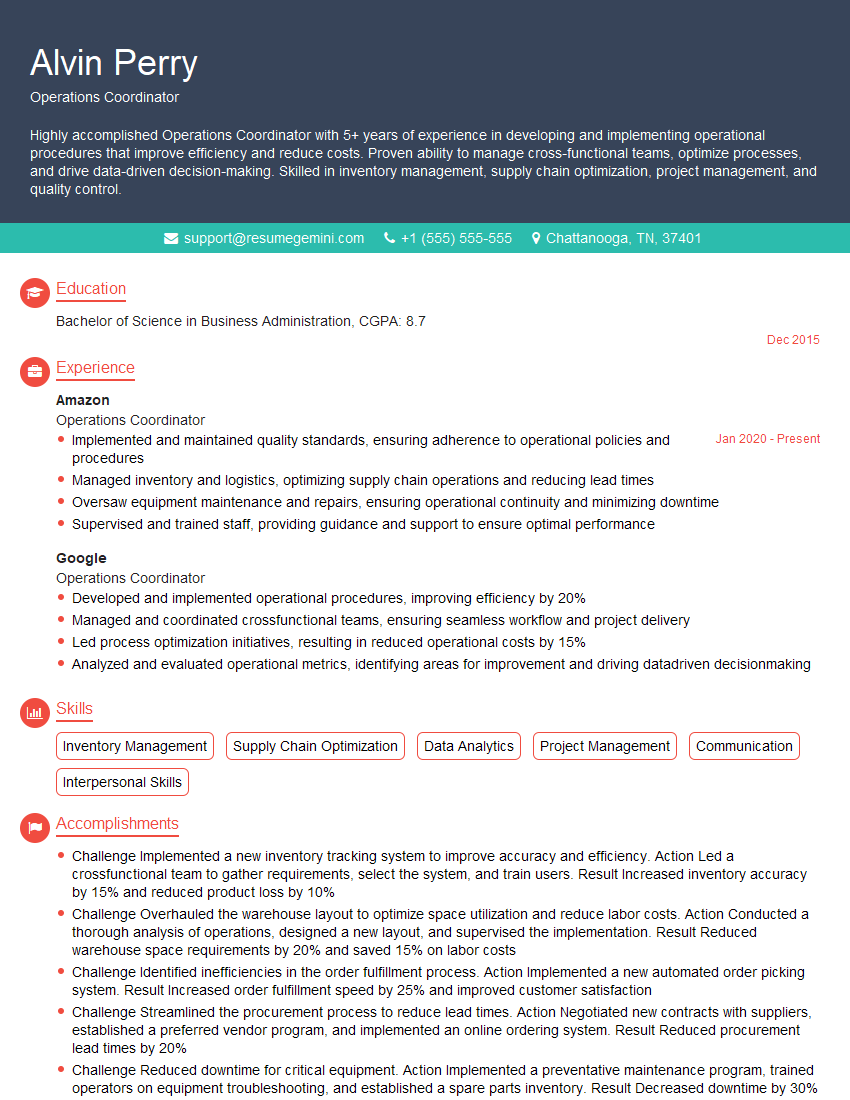

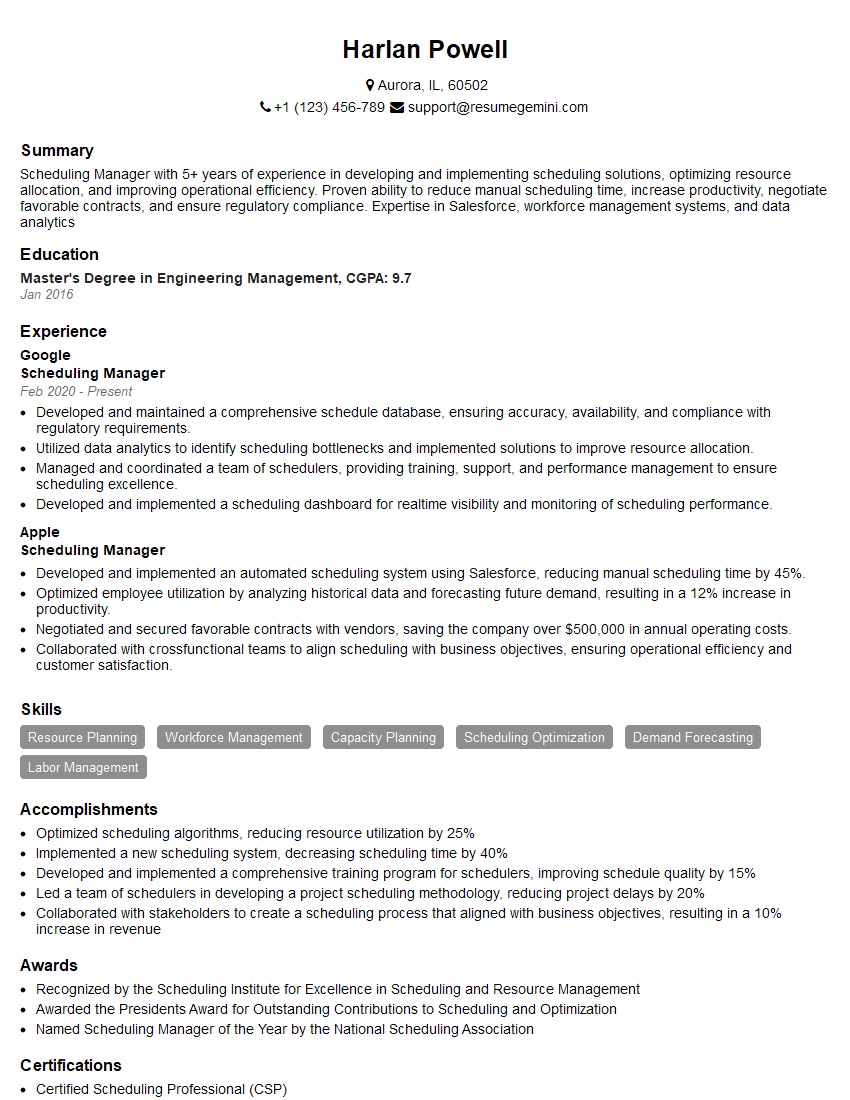

Mastering Operations Planning and Execution opens doors to exciting career opportunities with significant growth potential. Demonstrating expertise in these areas significantly strengthens your candidacy and positions you for leadership roles within organizations. To maximize your job prospects, crafting a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your skills and experience effectively. Examples of resumes tailored to Operations Planning and Execution roles are available to guide you. Invest time in creating a compelling resume; it’s your first impression and a key to unlocking your career aspirations.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good