The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Pattern Design and Development interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Pattern Design and Development Interview

Q 1. Explain the difference between a sloper and a block pattern.

Both slopers and block patterns are foundational elements in patternmaking, serving as the base for designing garments, but they differ significantly in their purpose and complexity. A sloper is a basic, foundational pattern piece representing the body’s shape. Think of it as a personalized ‘blank canvas’ – a simplified, close-fitting pattern for a specific body size and shape. It captures essential body measurements, reflecting the wearer’s individual contours. It’s typically created using draping or flat pattern techniques and doesn’t include design details like seam allowances or style features. In contrast, a block pattern is a more developed pattern based on a sloper, but it incorporates design elements, such as seam allowances, darts, and basic style features. Essentially, a block pattern is a sloper that’s been adapted for a particular garment type (e.g., a basic bodice block, a sleeve block, or a skirt block). It’s more detailed than a sloper and acts as the foundation for further design modifications.

Analogy: Imagine building a house. The sloper is like the foundation – it provides the basic shape and structure. The block pattern is like the framing – it adds the basic walls and rooms, ready for further customization and design.

Q 2. Describe your experience with various patternmaking methods (e.g., draping, flat pattern making).

My patternmaking experience encompasses both draping and flat pattern making techniques. Draping, a three-dimensional process, allows for a superior fit, especially for complex designs or unique body shapes. I’ve extensively used draping to create patterns for garments with intricate silhouettes, ensuring precise shaping and drape on the body. For example, I successfully draped a pattern for a flowing evening gown, achieving a perfect, graceful fall. Flat pattern making, on the other hand, is a two-dimensional technique using measurements and calculations. This method is efficient for simpler styles and allows for greater precision in grading for multiple sizes. I frequently employ flat pattern making for creating basic shirt and trouser patterns, relying on accurate calculations to ensure consistent sizing across different ranges.

Furthermore, I am also proficient in using various techniques in conjunction with each other to create a balance between fit and efficiency.

Q 3. How do you address fit issues during the patternmaking process?

Addressing fit issues is a crucial part of the patternmaking process. My approach is iterative and involves a combination of techniques. First, I meticulously analyze the fit of the muslin (a test garment made from inexpensive fabric). I pay close attention to areas like the shoulder, bust, waist, and hipline, noting any pulling, gaping, or unwanted wrinkles. Using these observations, I make adjustments to the pattern pieces directly. For instance, if the shoulders are too tight, I may add width to the shoulder seam. If the garment gaps at the waist, I might need to adjust the waist darts or add shaping. Second, I rely on standard fit adjustments, such as adding or removing fullness in specific areas. Third, I may make specific alterations to the pattern, such as pivoting, slashing, and spreading, which are more advanced techniques that require a deep understanding of garment construction and body mechanics. I always create a new muslin after each round of pattern adjustments to confirm the fit is improved before finalizing the pattern.

Q 4. What CAD software are you proficient in (e.g., Gerber, Lectra, Optitex)?

I’m proficient in several CAD software packages, including Gerber Accumark and Optitex. My expertise with Gerber Accumark allows for efficient grading and marker making, streamlining the production process significantly. I’ve used it extensively to manage large-scale pattern production, creating variations for various sizes and reducing fabric waste through optimized marker plans. Optitex’s 3D design capabilities are equally valuable. I use it to visualize and refine designs before physical production, thereby reducing prototyping iterations and ensuring the final product aligns precisely with the initial design vision. My proficiency in both 2D and 3D CAD enhances my ability to handle various patternmaking projects, from simple to highly complex garments.

Q 5. Explain your experience with grading patterns for various sizes.

Grading patterns is a crucial skill requiring precision and understanding of body proportions. My experience involves manually grading patterns and using CAD software for automated grading. Manual grading requires detailed knowledge of measurement changes between sizes, and involves making adjustments proportionally to ensure consistent style and fit. I’ve manually graded patterns across a wide size range (XXS-XXXL), ensuring that the proportions are accurate and consistent throughout the range. Using CAD software, like Gerber Accumark, allows me to efficiently grade patterns for a large number of sizes, while maintaining control over the grading rules and ensuring accurate scaling across the size range. The ability to fine-tune grade rules helps maintain the design integrity across different sizes.

Q 6. How do you ensure pattern accuracy and consistency?

Ensuring pattern accuracy and consistency is paramount. My approach involves several key steps. First, I meticulously check all measurements and calculations throughout the patternmaking process. Second, I use precise cutting and sewing techniques when constructing muslins, paying attention to details like seam allowances and grainlines. Third, I employ quality control checks at various stages, starting with the initial sloper, through muslin fittings, and finally the final pattern. Fourth, I utilize digital tools, such as CAD software, which provide built-in tools for consistency and accuracy checks. By utilizing these tools, I can reduce human error, saving time and resources.

Beyond this, I maintain a detailed documentation system, including sketches, technical drawings, and digital files, to ensure reproducibility and traceability. This allows for easy reference and revisits during the development stages, guaranteeing consistency if the pattern needs to be reproduced later.

Q 7. Describe your process for creating a pattern from a sketch or technical drawing.

Creating a pattern from a sketch or technical drawing is a multi-step process that begins with a thorough analysis of the design. I start by interpreting the design elements, noting key features, silhouette, and construction details. Then, I transfer the essential design information into a technical drawing, ensuring accuracy of proportions and measurements. Next, I determine the appropriate patternmaking method (draping or flat pattern) depending on design complexity. In case of flat pattern, I establish the basic block pattern for the garment type. Then, I add design features, such as darts, seams, and other elements, based on the design. The construction process requires careful consideration of fabric drape, ease, and body movement. I create a muslin based on the developed pattern, evaluate the fit, and then make necessary adjustments as explained in previous answers. I repeat this process until the desired fit and aesthetic are achieved. Finally, I create a final pattern, including seam allowances, markings, and clear instructions for construction.

Q 8. How do you handle pattern adjustments for different fabrics?

Fabric type significantly impacts pattern adjustments. Different fabrics have varying degrees of drape, stretch, and stability. For example, a woven fabric like cotton will behave differently than a knit fabric like jersey. My approach involves understanding the fabric’s properties before making any adjustments.

- Drape: A fabric with good drape, like silk charmeuse, requires less ease (extra fabric for comfort and movement) than a stiff fabric like canvas. I’d adjust ease based on the drape. Too much ease with a stiff fabric will create bulk; too little with a drapey fabric will restrict movement.

- Stretch: Knit fabrics have stretch, woven fabrics do not. I account for this by adjusting seam allowances or even the pattern pieces themselves. A stretch knit needs less seam allowance to avoid puckering.

- Stability: Fabrics vary in their stability. A stable fabric like linen holds its shape better than a fluid fabric like rayon. The pattern pieces may require slight alterations to account for this. For unstable fabrics, I often use interfacing to add support.

I typically create a muslin (a test garment) from a less expensive fabric similar to the final choice to check the fit and make adjustments before cutting into my final fabric. This ensures a proper fit tailored to the fabric’s unique properties. I meticulously document these adjustments for future use with similar fabrics.

Q 9. Explain your experience with marker making and fabric efficiency.

Marker making is a crucial skill for maximizing fabric efficiency and minimizing waste. My experience involves creating efficient marker layouts using both manual techniques and software like Optitex or Lectra. I’m adept at nesting pattern pieces to minimize fabric usage and strategically account for fabric grain and nap.

Fabric efficiency is a key concern. I strive to create markers that achieve the best yield – the maximum number of garments cut from a given length of fabric. This involves careful planning, considering factors like fabric width, pattern piece orientation, and fabric grain.

For example, I once worked on a project where the client required significant cost savings. Through meticulous marker making and optimizing the pattern layout, I reduced fabric waste by 15%, resulting in considerable cost savings for the client. I prioritize minimizing fabric waste not just for economic reasons but also as part of sustainable practices in garment production.

Q 10. What are your strategies for troubleshooting pattern fit issues?

Troubleshooting pattern fit issues requires a systematic approach. I begin by identifying the specific problem area—is it too tight in the bust, too long in the sleeve, or pulling across the shoulders? Then I work through a process of elimination:

- Visual Inspection: Carefully examine the garment on the body, noting areas of pulling, gaping, or wrinkles.

- Body Measurements: Compare the garment measurements to the body measurements. Discrepancies highlight areas needing adjustment.

- Grainline Check: Ensure the grainline is aligned correctly; misalignment can lead to significant fit problems.

- Ease Adjustment: Too much or too little ease can affect the fit. I adjust the ease by adding or removing fabric, depending on the issue.

- Pattern Adjustments: Depending on the issue, I might make adjustments to the pattern itself. For example, a swayback adjustment addresses excess fabric at the lower back.

I find using a combination of techniques and using a muslin is the most effective way to address fit issues. I often make small adjustments, one at a time, trying on the muslin after each change to assess the impact. This iterative approach helps to pinpoint the exact adjustments needed.

Q 11. How familiar are you with different types of pattern adjustments (e.g., ease, balance, grainline)?

I have extensive experience with various pattern adjustments, including ease, balance, and grainline. Understanding these adjustments is fundamental to creating well-fitting garments.

- Ease: Ease is the extra fabric added to the pattern to allow for comfort and movement. Different types of ease include ease for fit, comfort ease, design ease (to create shaping or volume). I carefully calculate the appropriate amount of ease for different garment styles and fabric types. Too much ease leads to baggy garments; too little leads to tight, uncomfortable ones.

- Balance: Balance refers to the harmony of the garment’s proportions. I adjust balance by altering the pattern pieces to ensure the garment hangs correctly and looks pleasing on the body. This might involve adjustments to shoulder slope, armhole depth, or neckline shape.

- Grainline: Grainline refers to the lengthwise and crosswise yarns of the fabric. The grainline significantly impacts fabric drape and stability. I always ensure the pattern pieces are aligned with the correct grainline to avoid distortion and enhance the garment’s final appearance. Fabric with a noticeable nap (e.g., velvet) requires particularly careful attention to grainline.

I’ve successfully implemented these adjustments in numerous projects, adapting my approach depending on the garment style, fabric type, and client requirements.

Q 12. Describe your experience working with different types of fabrics (e.g., woven, knit, stretch).

My experience encompasses a broad range of fabrics, including wovens, knits, and stretch fabrics. Each requires a different approach to pattern making and construction.

- Woven Fabrics: Woven fabrics like cotton, linen, silk, and wool are generally stable and non-stretchy. Patterns for woven fabrics often have more structured silhouettes.

- Knit Fabrics: Knit fabrics like jersey, rib knit, and double knit have varying degrees of stretch. Patterns for knits require consideration of this stretch, often using narrower seam allowances and sometimes including techniques like negative ease.

- Stretch Fabrics: Stretch fabrics, including many synthetic blends, combine woven and knit characteristics. I need to carefully assess the type of stretch (two-way or four-way) to adjust the pattern appropriately. They sometimes require more complex design elements to account for their flexible properties.

My expertise lies in adapting my techniques to each type of fabric. I understand the draping, handling, and stability properties of each, allowing me to create patterns and choose appropriate construction methods that will result in professional-quality garments.

Q 13. How do you manage and organize your pattern files and data?

Organizing pattern files and data is critical for efficiency and accuracy. I use a combination of digital and physical organization systems.

- Digital Organization: I utilize a cloud-based storage system (like Dropbox or Google Drive) to store digital pattern files (in formats like PDF or AI). I employ a clear and consistent file naming system. For example, I might use

[GarmentType]_[DesignName]_[Date]_[Version](e.g.,Dress_FloralSummer_20240301_v2.pdf). This makes it simple to locate and retrieve the correct version of a pattern. - Physical Organization: I also maintain a physical archive for hard copies of essential patterns and technical sketches. They are organized by garment type, season, or client. This allows for quick access to patterns even when offline.

- Spreadsheet Database: I use spreadsheets to track project details including fabric requirements, costing, and production notes. This creates a reliable record for each pattern and its history.

This dual approach ensures both accessibility and data integrity. I regularly back up my digital files to prevent data loss.

Q 14. How do you prioritize tasks and meet deadlines in a fast-paced environment?

Prioritizing tasks and meeting deadlines in a fast-paced environment is a skill I’ve honed over many years. My approach involves a combination of planning, time management, and communication.

- Prioritization Matrix: I use a prioritization matrix (like the Eisenhower Matrix – Urgent/Important) to categorize tasks based on their urgency and importance. This allows me to focus on the most critical tasks first.

- Detailed Project Breakdown: For large projects, I break them down into smaller, manageable tasks. This helps me stay organized and track progress more efficiently.

- Time Blocking: I allocate specific time blocks for particular tasks. This structured approach helps to avoid task switching and improve focus.

- Regular Communication: Open communication with my team and clients is crucial. Regular updates ensure everyone is aligned and potential problems are identified early.

- Contingency Planning: I build in buffer time to account for unexpected delays or issues. This ensures I can still meet deadlines even if things don’t go exactly as planned.

I’ve found that proactive planning and effective communication are key to staying on top of things and delivering high-quality work on time, even under pressure.

Q 15. Describe your experience with patternmaking for different garments (e.g., tops, bottoms, dresses).

My patternmaking experience spans a wide range of garments, from basic tops and bottoms to complex dresses and outerwear. I’m proficient in drafting patterns from scratch using both flat patternmaking techniques and draping methods. For tops, I’ve worked extensively with various sleeve constructions, necklines, and fit adjustments, creating patterns for everything from simple t-shirts to intricate blouses. With bottoms, my expertise includes creating patterns for trousers, skirts, and shorts, considering factors like waistbands, pockets, and fly fronts. My experience with dresses encompasses various styles – A-line, sheath, fit-and-flare – requiring consideration of bodice construction, skirt styles, and overall balance. I’m comfortable adapting existing patterns and creating variations to achieve specific design goals.

For instance, I recently developed a pattern for a structured blazer. This involved creating a sloper (a basic pattern block), then modifying it to include darts, shoulder pads, and lapels. The process demanded precise measurements and careful attention to detail, resulting in a well-fitting, professional-quality pattern.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your understanding of different seam allowances and their importance.

Seam allowance is the extra fabric added to the raw edges of pattern pieces before sewing. It’s crucial for a number of reasons. The standard seam allowance is typically 5/8 inch (1.5 cm), but this can vary based on the fabric, garment type, and construction method. A smaller seam allowance might be used for delicate fabrics or when creating a very fitted garment, while a larger allowance may be preferable for heavier fabrics or when additional space is needed for ease of sewing.

The importance of consistent seam allowances cannot be overstated. Inconsistent seam allowances can lead to ill-fitting garments, unbalanced seams, and overall poor garment quality. They impact the final size and shape of the garment. Accurate seam allowances are essential for achieving precise fit and professional results.

- 5/8 inch (1.5cm): Standard for most garments.

- 1/4 inch (0.6cm): Used for fine fabrics or delicate details.

- 1/2 inch (1.2cm): Used for heavier fabrics or seams requiring more strength.

For example, a 1/4-inch seam allowance will result in a smaller finished garment than a 5/8-inch allowance, even if the pattern pieces themselves are identical.

Q 17. How do you collaborate with other team members (e.g., designers, sample makers)?

Collaboration is key in the patternmaking process. I work closely with designers to translate their sketches and ideas into functional patterns. This involves discussions on fit, style, and construction details. Regular communication ensures the pattern reflects the designer’s vision and technical requirements. With sample makers, I provide detailed pattern instructions and specifications, helping them understand the construction process. Feedback from sample makers helps identify any potential issues with the pattern’s fit or construction before mass production. Open communication, active listening and constructive feedback are crucial for successful collaboration. I believe in a team-oriented approach, where everyone’s expertise contributes to the final product.

For example, I recently worked with a designer on a new dress collection. We held several meetings to discuss fit preferences, style details, and construction challenges. Once the patterns were drafted, I collaborated with the sample maker to address minor adjustments based on the fit and construction feedback.

Q 18. Describe your experience with quality control procedures for patterns.

Quality control is a critical step in patternmaking to ensure accuracy and consistency. My quality control procedures begin with meticulous pattern drafting, followed by careful checking of measurements and grading. This includes verifying the accuracy of grading scales across different sizes and checking for any distortions. Next, test garments are made to assess the fit and evaluate any areas that need adjustment. This involves fitting the garment on a body form or a live model and making note of any issues with fit, drape, or construction. Following this, I review and revise the pattern based on the feedback obtained, and repeat the process until the pattern meets the quality standards. Throughout the process, I maintain detailed records to ensure traceability and accountability.

Q 19. What are some common mistakes to avoid when creating patterns?

Several common mistakes can negatively impact pattern quality. One frequent error is neglecting to accurately measure and grade patterns for different sizes. This can lead to significant fit issues. Another mistake is overlooking seam allowances, resulting in ill-fitting garments or difficulties during construction. Incorrect grainlines can also cause issues with fabric drape and overall appearance. Finally, not adequately testing patterns before mass production can result in costly errors that need to be rectified later. It’s crucial to pay careful attention to details, meticulously check measurements, and always test patterns to avoid these common pitfalls.

Q 20. How do you stay updated with the latest trends and technologies in patternmaking?

Staying updated in patternmaking requires a multi-pronged approach. I regularly attend industry conferences and workshops to learn about new techniques and technologies. Trade publications and online resources, such as blogs and tutorials, provide valuable insights into current trends and best practices. Furthermore, I actively participate in online forums and communities to connect with other professionals and learn from their experiences. Exploring innovative software and CAD (computer-aided design) systems allows me to improve my efficiency and explore advanced patternmaking techniques. Continuous learning is essential for maintaining my expertise in this ever-evolving field.

Q 21. Explain your experience with creating patterns for plus-size garments.

Creating patterns for plus-size garments requires a deeper understanding of body proportions and fit adjustments. Unlike standard sizing, plus-size patterns need careful consideration of different body types and variations. The process involves adjusting the base pattern to accommodate a larger bust, waist, hip circumference, and often altering the length of the garments. This often requires adjustments in areas like the shoulder slope, armhole depth, and dart placement. Additionally, careful consideration is given to ease and comfort, which may require modifications to accommodate body curves. Understanding the nuances of plus-size body types and adapting patterns to provide a flattering and comfortable fit is essential for success in this area.

For example, creating a plus-size dress might involve significantly increasing the ease allowance in the bodice to accommodate a larger bust and ensure a comfortable fit. The sleeve cap height might need to be adjusted to account for a fuller upper arm. These are examples of critical adjustments needed to ensure a flattering and well-fitting garment.

Q 22. How familiar are you with industrial sewing machines and their applications?

My familiarity with industrial sewing machines extends beyond basic operation; I possess a comprehensive understanding of their mechanics, capabilities, and limitations. I’m proficient in using various types of industrial sewing machines, including single-needle, double-needle, overlock, coverstitch, and blindstitch machines. This expertise allows me to select the optimal machine for a given fabric and pattern detail, maximizing efficiency and achieving superior stitch quality. For instance, when working with delicate silks, I’d opt for a machine with a fine needle and adjustable stitch length to prevent damage. Conversely, for heavier denim, a robust machine with a strong feed dog is essential to manage the fabric’s thickness effectively. My experience also encompasses troubleshooting common machine issues, performing basic maintenance, and understanding the importance of proper needle and thread selection based on the fabric’s weight and type.

Q 23. Describe your experience with creating patterns for different body types and shapes.

Creating patterns for diverse body types is a core aspect of my work. I achieve this through a combination of techniques. Firstly, I utilize slopers – basic block patterns – which serve as the foundation for various designs. These slopers are carefully drafted and adjusted to accommodate different body measurements and proportions. Secondly, I employ grading techniques to scale patterns up or down in size, maintaining consistent design features across different sizes. This requires a meticulous approach, ensuring appropriate adjustments are made to accommodate changes in body circumference and length. For example, creating a pattern for a plus-size garment involves careful grading to ensure sufficient ease and a comfortable fit. Finally, I incorporate design elements that are inherently accommodating, like princess seams or dropped waistlines, to flatter a wider range of shapes. I constantly refer to fit charts and industry standards, and I actively seek feedback from diverse groups to refine my patterns and ensure inclusivity. I have worked on projects designing patterns for maternity wear, plus-size clothing, and adaptive clothing, requiring extensive attention to the unique needs and body shapes involved.

Q 24. How do you utilize technology to improve your patternmaking process?

Technology plays a significant role in enhancing my patternmaking process. I utilize Computer-Aided Design (CAD) software such as OptiTex or Lectra, enabling me to create accurate, scalable, and easily modified patterns. These programs allow for precise measurements, grading, and manipulation of pattern pieces, eliminating manual drafting’s time-consuming and error-prone aspects. For example, grading a size 10 pattern to a size 16 takes mere minutes in CAD software, compared to hours of manual work. Furthermore, CAD software allows for efficient digital pattern manipulation, enabling quick prototyping and visualization of designs before physical cutting and sewing. 3D pattern design and simulation are also integrated into my workflow, which helps eliminate the guesswork regarding drape and fit, saving valuable time and resources. I also use digital tools to manage pattern files, creating a structured system to efficiently store, retrieve, and collaborate on patterns using cloud-based storage.

Q 25. How do you handle feedback and critiques on your patterns?

Handling feedback is crucial. I approach critiques constructively, viewing them as opportunities for improvement. I actively seek feedback from various sources, including fit models, pattern testers, and potential clients. When receiving feedback, I carefully analyze each comment, focusing on the specifics rather than emotional responses. For instance, rather than simply dismissing a critique as “subjective,” I examine whether the issue points to a drafting error, an inadequate grading process, or a problem with the instruction clarity. Based on the feedback, I prioritize issues and create a list of revisions. If necessary, I might conduct further fitting sessions or modify the pattern pieces according to my findings. Through an iterative process of refinement, I strive to create patterns that meet both the functional and aesthetic needs of my clients.

Q 26. What are your preferred methods for documenting pattern changes and revisions?

Maintaining detailed records of pattern changes is essential for traceability and future modifications. I utilize a combination of digital and physical methods. Digitally, I maintain version control using a CAD system which automatically saves revisions. Each version is annotated with the date, the changes implemented, and the person who made the changes. Physically, I keep hard copies of all pattern pieces, labeled clearly with version numbers and amendment details. I also maintain a detailed logbook outlining the progression of pattern development; it contains sketches, notes on fitting sessions, images, and comprehensive descriptions of each change. This dual system ensures that all modifications are clearly documented and easily retrievable, reducing potential confusion and streamlining future design work.

Q 27. How do you ensure the sustainability and ethical sourcing of materials?

Sustainability and ethical sourcing are paramount in my work. I prioritize using eco-friendly fabrics like organic cotton, recycled materials, or innovative sustainable blends. I actively research and source materials from suppliers committed to ethical labor practices and environmental responsibility. Transparency is key; I often work with suppliers who can provide detailed information on their production processes and certifications regarding fair labor standards. I also incorporate sustainable design practices in the cutting process, minimizing waste through optimized pattern layouts. Leftover fabrics are often repurposed for smaller projects, samples, or donated to craft organizations. Promoting transparency and responsible sourcing is not only beneficial for the environment but also crucial for building trust with clients who value ethically produced garments.

Q 28. Describe your experience working with 3D pattern design software.

My experience with 3D pattern design software is extensive. I’m proficient in using various software packages to create virtual prototypes and simulate garment drape and fit. This drastically reduces the need for multiple physical prototypes, saving both time and materials. The ability to visualize the garment in 3D allows for early identification of potential fit issues or design flaws, facilitating efficient problem-solving. For example, I might use 3D simulation to check the drape of a flowing skirt on a virtual model with different body types, allowing me to make adjustments before cutting the fabric. This technology also permits creative exploration of various design options with minimal impact on time and resources. The ability to virtually manipulate fabric textures and properties enhances the overall design process, making for more informed and precise decision-making. I’m adept at utilizing this technology to create more accurate and well-fitting garments and effectively present the designs to clients.

Key Topics to Learn for Pattern Design and Development Interview

- Pattern Construction Techniques: Understanding various methods like draping, flat pattern making, and sloper creation. Practical application includes adapting base patterns for different styles and sizes.

- Grading and Sizing: Mastering techniques to accurately scale patterns for various sizes, ensuring consistent fit and proportion. This includes understanding different grading systems and methods.

- Pattern Alterations and Adjustments: Developing skills in identifying and correcting fit issues, adapting patterns for individual body types, and making design modifications to existing patterns. This requires a strong understanding of garment construction and fit.

- Fabric Selection and its Impact on Pattern: Understanding how fabric properties (drape, stretch, weight) influence pattern design and construction. Practical applications include choosing appropriate patterns and adjustments based on the chosen fabric.

- Computer-Aided Design (CAD) Software: Familiarity with industry-standard CAD software for pattern making and grading. This includes understanding digital pattern manipulation and design techniques.

- Pattern Making for Specific Garments: Deep understanding of pattern construction for various garment types (e.g., dresses, shirts, trousers, jackets). Practical application: showcasing proficiency in creating patterns for different complexities and styles.

- Technical Design and Specification: Creating clear and concise technical specifications for patterns, including measurements, notes, and construction details. This is crucial for effective communication with production teams.

- Problem-solving and Troubleshooting: Demonstrating the ability to diagnose and resolve pattern-related issues, such as fit problems, construction challenges, and fabric-related limitations. This often involves critical thinking and creative problem-solving.

Next Steps

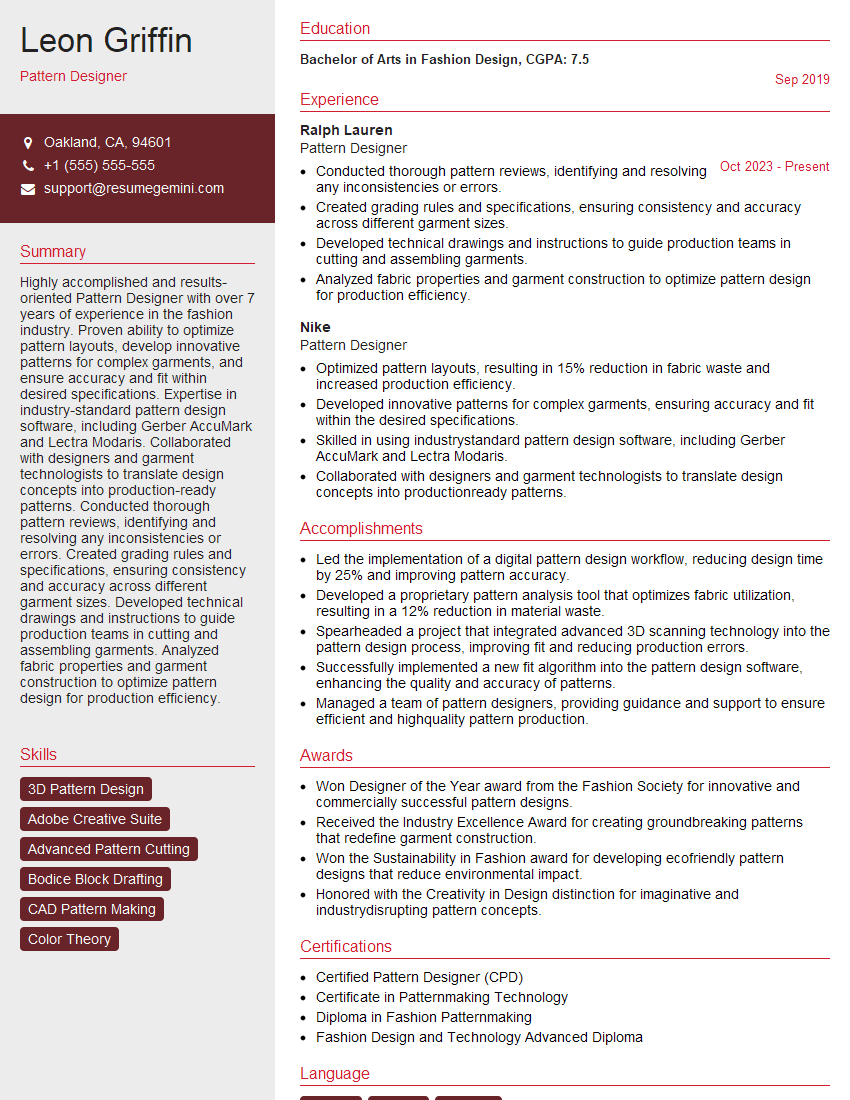

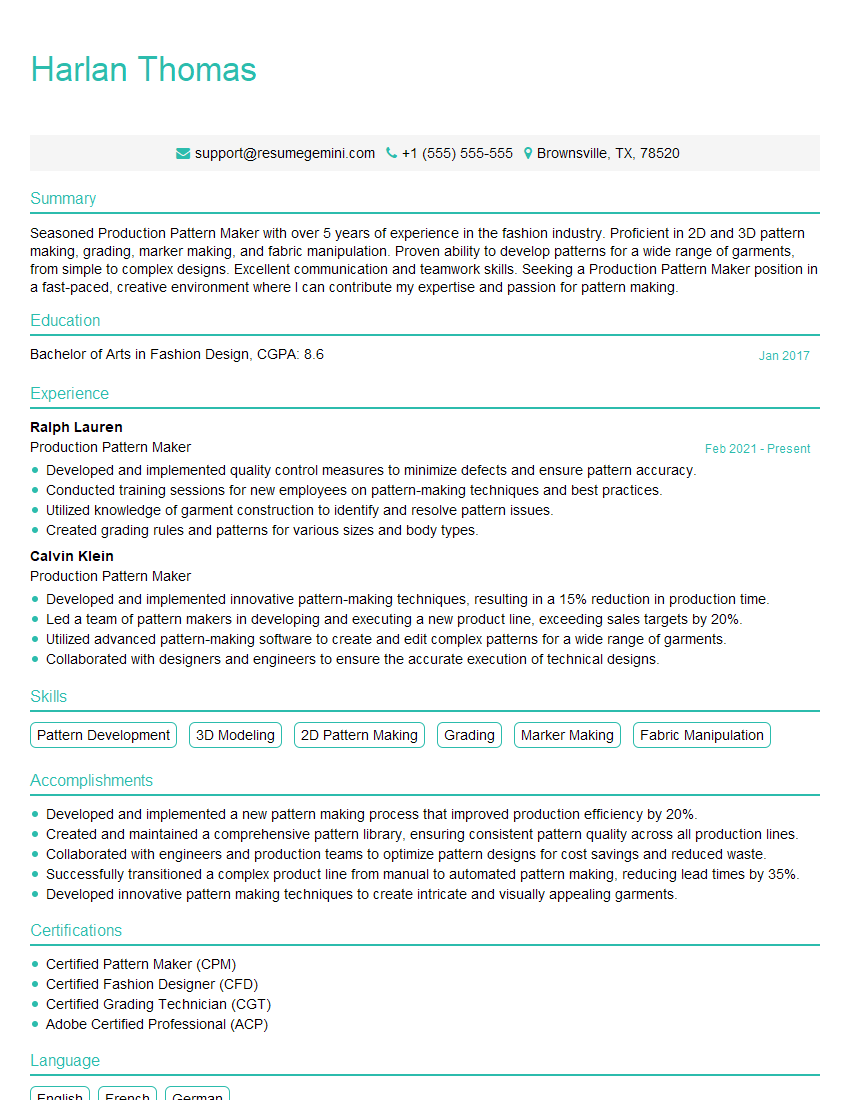

Mastering Pattern Design and Development is crucial for career advancement in the fashion and apparel industry. A strong understanding of these concepts opens doors to exciting opportunities and higher earning potential. To enhance your job prospects, creating an ATS-friendly resume is essential. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your skills and experience effectively. Examples of resumes tailored to Pattern Design and Development are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good