Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Process Engineering Analysis interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Process Engineering Analysis Interview

Q 1. Explain your understanding of process flow diagrams (PFDs) and piping and instrumentation diagrams (P&IDs).

Process Flow Diagrams (PFDs) and Piping and Instrumentation Diagrams (P&IDs) are essential tools in process engineering. Think of them as blueprints for a chemical plant or any process facility. A PFD is a simplified representation of the process, showing the main equipment, process streams, and their interconnections. It’s like a high-level overview, focusing on the major process steps and material balances. It doesn’t show intricate details like pipe sizes or instrument locations.

In contrast, a P&ID provides a much more detailed representation. It includes all the equipment, piping, instrumentation (valves, sensors, controllers), and control loops. Imagine zooming in from the PFD to the P&ID; you’ll see every pipe, valve, and instrument, allowing for detailed design and construction. It’s crucial for understanding the process’s control and safety systems.

Example: A PFD for a distillation column might show the feed stream, distillate, and bottoms streams, along with the column itself. A P&ID would then detail the individual valves controlling these streams, the temperature and pressure sensors monitoring the column, and the control system regulating the column’s operation.

Q 2. Describe your experience with process simulation software (e.g., Aspen Plus, HYSYS).

I have extensive experience using process simulation software, primarily Aspen Plus and HYSYS. These tools are invaluable for designing, optimizing, and troubleshooting processes. My experience ranges from steady-state simulations for process design to dynamic simulations for evaluating process control strategies and safety systems.

For example, I’ve used Aspen Plus to model a complex refinery process, predicting product yields and optimizing operating parameters to maximize profitability. In another project, using HYSYS, I simulated a chemical reactor to investigate different operating conditions and catalyst choices to improve conversion and selectivity. The ability to run ‘what-if’ scenarios virtually is crucial in reducing risks and costs associated with physical experimentation.

Beyond simulation, I’m proficient in using these tools for data analysis, report generation, and presentation of results to clients and stakeholders.

Q 3. How do you identify bottlenecks in a process flow?

Identifying bottlenecks in a process flow involves a systematic approach. Think of a bottleneck as a constraint limiting the overall process throughput or efficiency. It’s like a narrow section in a highway that slows down traffic. To find these bottlenecks, I typically follow these steps:

- Process Mapping: I start by thoroughly understanding the process, often using PFDs and P&IDs, and creating a detailed process flow diagram that shows all steps, materials, and times.

- Data Analysis: I collect relevant data on process variables such as throughput, yield, cycle times, and downtime for each step. This data might come from sensors, historical records, or plant operations.

- Capacity Analysis: I analyze the capacity of each unit operation in the process, comparing its capacity to the actual demand. Any unit operating at its maximum capacity, and limiting the overall throughput, represents a potential bottleneck.

- Simulation (if needed): Process simulation software can help to pinpoint bottlenecks by running simulations under different conditions and identifying where limitations occur.

Example: In a chemical plant producing a certain product, if the reactor is consistently operating at 100% capacity while other units have spare capacity, the reactor is likely the bottleneck, limiting overall production.

Q 4. What are the key performance indicators (KPIs) you would use to evaluate process efficiency?

The Key Performance Indicators (KPIs) I use to evaluate process efficiency depend on the specific process, but some common ones include:

- Throughput: The amount of product produced per unit time.

- Yield: The ratio of actual product produced to the theoretical maximum.

- Conversion: The fraction of reactants converted to products.

- Selectivity: The ratio of desired product to undesired byproducts.

- Overall Equipment Effectiveness (OEE): A comprehensive metric combining availability, performance, and quality.

- Cost per unit: A crucial economic indicator reflecting manufacturing efficiency.

- Downtime: The time a process is not running due to maintenance, repairs, or other causes.

By tracking these KPIs over time, I can monitor process performance, identify areas for improvement, and measure the effectiveness of optimization efforts.

Q 5. Explain your approach to process optimization and improvement.

My approach to process optimization and improvement is iterative and data-driven. It usually involves these steps:

- Problem Definition: Clearly identify the area or aspect of the process that needs improvement and establish specific, measurable, achievable, relevant, and time-bound (SMART) goals.

- Data Collection and Analysis: Gather relevant process data to understand the current state and identify areas for improvement. Use statistical methods to analyze the data and highlight critical parameters.

- Root Cause Analysis: Use techniques such as Fishbone diagrams (Ishikawa diagrams) or 5 Whys to identify the root causes of inefficiencies.

- Solution Development and Evaluation: Develop potential solutions and evaluate their feasibility and impact using simulations or pilot studies. This might involve changing operating parameters, upgrading equipment, or implementing new control strategies.

- Implementation and Monitoring: Implement the selected solution, monitoring KPIs to track progress and measure the effectiveness of the improvement.

- Continuous Improvement: Process optimization is an ongoing effort; continuous monitoring and adjustments are essential for maintaining efficiency and adapting to changing conditions.

Example: I once improved the yield of a chemical reaction by optimizing the reactor temperature and pressure profile using Aspen Plus simulations. This resulted in a significant increase in production and reduced manufacturing costs.

Q 6. How do you handle process deviations and unexpected events?

Handling process deviations and unexpected events requires a structured approach emphasizing safety and efficiency. My response depends on the severity and nature of the event, but generally involves:

- Immediate Response: Prioritize safety and take immediate actions to mitigate any immediate risks. This may involve shutting down equipment, activating emergency systems, or alerting relevant personnel.

- Diagnosis: Identify the root cause of the deviation or event using process monitoring data and historical records. Use techniques like fault tree analysis to trace the problem back to its origins.

- Corrective Actions: Implement appropriate corrective actions to restore the process to normal operating conditions. This may involve adjusting operating parameters, repairing equipment, or changing process procedures.

- Investigation and Preventative Measures: Thoroughly investigate the event to determine its cause and implement preventative measures to reduce the likelihood of similar events occurring in the future. This might involve modifying control systems, improving operator training, or enhancing maintenance procedures.

- Documentation: Record all aspects of the event, including the response actions taken and the lessons learned. This information can be used to improve future responses and prevent similar occurrences.

Example: If a pressure surge occurs in a process line, immediate actions could involve shutting down the affected section to prevent equipment damage. Following the event, we would investigate the root cause (a faulty valve, for example) and implement preventative actions such as improved valve maintenance or upgrading to a more robust system.

Q 7. Describe your experience with process control strategies (e.g., PID control).

I have significant experience with process control strategies, particularly PID (Proportional-Integral-Derivative) control. PID controllers are widely used because of their versatility and effectiveness in regulating process variables. A PID controller continuously measures a process variable (like temperature or pressure) and adjusts a manipulated variable (like valve position or flow rate) to maintain the process at the desired setpoint.

Proportional (P) control provides a response proportional to the error between the setpoint and the measured variable. Integral (I) control addresses persistent errors by integrating the error over time. Derivative (D) control anticipates future errors based on the rate of change of the error. The combination of these three modes allows for precise and stable control.

Beyond PID control, I’m familiar with advanced control strategies, including model predictive control (MPC) and cascade control. These are more complex but are often necessary for highly interactive and dynamic processes.

Example: In controlling the temperature of a chemical reactor, a PID controller continuously monitors the reactor temperature. If the temperature deviates from the setpoint, the controller adjusts the flow rate of cooling water to correct the deviation. The proportional term provides immediate correction, the integral term eliminates offset, and the derivative term prevents overshoot and oscillations.

Q 8. What are your experiences with process safety analysis (e.g., HAZOP, PHA)?

Process safety analysis (PSA) is crucial for identifying and mitigating potential hazards in process systems. My experience encompasses both HAZOP (Hazard and Operability Study) and PHA (Process Hazard Analysis) methodologies. HAZOP employs a systematic, guided word-based approach, using guidewords (e.g., ‘more,’ ‘less,’ ‘no,’ ‘part of’) to explore deviations from design intent. I’ve led numerous HAZOP studies, meticulously documenting potential hazards, identifying causes, consequences, and recommending mitigations. For instance, in a chemical plant project, a HAZOP revealed a potential for overpressure in a reactor due to an unexpected exothermic reaction. This led to the implementation of a safety relief valve and improved temperature control systems. PHA, while broader in scope, often incorporates techniques like What-If analysis and Fault Tree Analysis to assess risks. I’ve used PHA to evaluate existing facilities, identifying areas for improvement and ensuring compliance with safety standards. A recent example involved a refinery where a PHA identified a vulnerability related to pipeline corrosion. This led to a comprehensive pipeline inspection program and the implementation of corrosion mitigation strategies.

Q 9. Explain your understanding of mass and energy balances in process systems.

Mass and energy balances are fundamental to process engineering. They’re based on the principles of conservation of mass and energy: mass and energy cannot be created or destroyed, only transformed. A mass balance tracks the flow of mass into, out of, and within a process system. This is crucial for determining production rates, optimizing feedstock usage, and identifying material losses. For example, in designing a distillation column, a mass balance ensures that the mass of feed equals the sum of the distillate and bottoms products. Similarly, an energy balance accounts for all forms of energy (heat, work, potential, kinetic) within a system. This helps determine heating and cooling requirements, energy efficiency, and potential for energy recovery. Think of a power plant: an energy balance assesses the conversion of chemical energy (from fuel combustion) into electrical energy, accounting for heat losses and other energy transfers.

In practice, I use these balances extensively in process simulations and process design. Software like Aspen Plus or HYSYS allow for creating detailed models that automatically solve mass and energy balances, allowing for optimization and prediction of system performance under different conditions.

Q 10. How do you validate process models?

Validating process models is essential to ensure they accurately represent the real-world process. This involves comparing model predictions to actual process data. I typically use a multi-step approach:

- Data Acquisition: Gathering high-quality data from the actual process. This involves determining appropriate sampling locations, frequencies, and durations.

- Model Calibration: Adjusting model parameters to minimize discrepancies between model predictions and actual data. This often involves iterative procedures using techniques such as regression analysis.

- Model Verification: Checking the model’s internal consistency and ensuring that its equations and algorithms are correctly implemented.

- Validation: Comparing the calibrated model’s predictions to independent data sets not used in the calibration process. This helps to assess the model’s predictive capability and generalizability.

Statistical metrics, such as the root mean squared error (RMSE) and R-squared value, are used to quantify the agreement between model predictions and experimental data. If the model doesn’t perform satisfactorily, it may require modifications to the model structure, parameters, or data acquisition strategies. For example, in optimizing a reactor’s operating conditions, I would compare the model’s predicted conversion rates against actual experimental measurements to ensure accuracy before deploying the new settings.

Q 11. Describe your experience with statistical process control (SPC).

Statistical Process Control (SPC) is a powerful technique for monitoring and controlling process variability. I’ve extensively utilized control charts, such as X-bar and R charts (for variables data) and p-charts and c-charts (for attribute data), to track process parameters and identify potential out-of-control conditions. Control charts provide visual representations of process data, allowing for timely detection of shifts in the mean or increases in variability. For example, in a manufacturing plant, I’ve used X-bar and R charts to monitor the diameter of manufactured parts, quickly identifying deviations from specifications and preventing the production of defective items. Beyond basic control charts, I’m experienced with more advanced SPC techniques, including capability analysis and process improvement methodologies like DMAIC (Define, Measure, Analyze, Improve, Control) using Six Sigma principles. I’ve successfully implemented SPC in various applications, resulting in reduced process variability, improved product quality, and reduced waste.

Q 12. How do you use data analysis to improve process efficiency?

Data analysis plays a crucial role in improving process efficiency. I leverage various techniques, depending on the data available and the specific goals. For instance, I often utilize regression analysis to identify correlations between process parameters and output variables. This could involve determining the optimal operating temperature to maximize yield in a chemical reaction. Similarly, principal component analysis (PCA) can help reduce data dimensionality and identify key variables affecting process performance. I also frequently employ time series analysis to understand process trends and predict future behavior. This is particularly useful in predictive maintenance, allowing for the anticipation of equipment failures and scheduling preventative maintenance before they occur. For example, by analyzing historical data on equipment vibration levels, I can predict when a pump is likely to fail, minimizing downtime and maintenance costs.

Q 13. Explain the concept of process capability and how it’s measured.

Process capability refers to a process’s ability to consistently produce output that meets specified requirements. It’s measured by comparing the process’s natural variability to the tolerance limits defined by specifications. Common metrics include Cp (process capability index) and Cpk (process capability index considering the process mean’s location relative to the target). Cp assesses the process’s potential capability by comparing the process spread (usually 6 standard deviations) to the specification width (upper specification limit – lower specification limit). Cpk considers both the spread and the centering of the process distribution. A Cpk value greater than 1.33 generally indicates a capable process, meaning it’s likely to produce output within specifications most of the time. In a manufacturing setting, if the Cpk for a critical dimension is below 1.33, process improvements like machine adjustments or operator training might be necessary to enhance capability and reduce the production of non-conforming units.

Q 14. How do you ensure compliance with regulatory requirements in process engineering?

Ensuring compliance with regulatory requirements is paramount in process engineering. This involves a multi-faceted approach:

- Staying Updated: Regularly reviewing and understanding relevant regulations and standards, such as OSHA, EPA, and industry-specific guidelines.

- Documentation: Maintaining meticulous records of process designs, operating procedures, safety assessments, and training programs.

- Risk Assessment: Conducting thorough risk assessments to identify and mitigate potential environmental and safety hazards. This may involve implementing safety instrumented systems (SIS).

- Audits and Inspections: Participating in regular internal and external audits and inspections to ensure compliance and identify areas for improvement.

- Training: Providing comprehensive training to personnel on safe operating procedures, emergency response, and environmental protection measures.

In practice, I work closely with regulatory agencies and internal compliance teams to ensure all projects adhere to the applicable rules and regulations. A recent project involved designing a wastewater treatment system compliant with local discharge permits. We meticulously documented the system’s design, performed a detailed environmental impact assessment, and implemented monitoring systems to ensure ongoing compliance.

Q 15. Describe your experience with process instrumentation and sensors.

My experience with process instrumentation and sensors spans a wide range of technologies and applications. I’m proficient in selecting, installing, calibrating, and troubleshooting various instruments crucial for process monitoring and control. This includes pressure transmitters (like diaphragm seals and capacitive sensors), temperature sensors (thermocouples, RTDs, and infrared sensors), flow meters (Coriolis, vortex shedding, and orifice plates), and level sensors (ultrasonic, radar, and hydrostatic pressure).

For instance, in a recent project involving a continuous stirred-tank reactor (CSTR), I was responsible for integrating a new laser-based particle size analyzer to monitor the product quality in real-time. This required careful consideration of the sensor’s installation location, signal conditioning, and integration with the existing Distributed Control System (DCS). I also had to ensure accurate calibration and account for potential interferences from the reactor’s operating conditions.

Beyond the hardware, I’m skilled in interpreting the data these sensors provide. Understanding sensor limitations, including drift, hysteresis, and noise, is crucial for accurate process monitoring and decision-making. I routinely use statistical process control (SPC) techniques to analyze sensor data and identify potential problems before they escalate.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you troubleshoot process problems?

Troubleshooting process problems is a systematic process requiring a blend of technical expertise and analytical thinking. My approach typically follows these steps:

- Gather data: This involves reviewing historical data from the DCS, examining sensor readings, and observing the process visually. I also interview operators to gather qualitative information about the issue’s onset and any related events.

- Identify symptoms: Clearly define the deviation from normal operating conditions. What specific variables are out of specification? What are the consequences of this deviation?

- Develop hypotheses: Based on the symptoms and my understanding of the process, I develop potential causes for the problem. This often involves considering factors like equipment malfunction, operator error, changes in feedstock quality, and environmental conditions.

- Test hypotheses: Through experiments, simulations, or data analysis, I systematically test the potential causes. This may involve making adjustments to the process, replacing components, or performing detailed diagnostics.

- Implement corrective actions: Once the root cause is identified, appropriate corrective actions are implemented. This might include repairing equipment, adjusting control parameters, revising operating procedures, or even redesigning parts of the process.

- Document findings: Thorough documentation of the problem, the troubleshooting process, and the corrective actions is crucial for continuous improvement and to prevent similar issues in the future.

For example, during a recent production issue where yield was unexpectedly low, I systematically investigated several hypotheses. Through data analysis, I found a correlation between a subtle change in feedstock composition and the reduced yield. Adjusting the reactor temperature and residence time resolved the issue.

Q 17. What are the different types of process control loops?

Process control loops are the backbone of automated process control. They consist of a feedback mechanism that continuously monitors a process variable and adjusts a manipulated variable to maintain the controlled variable at its setpoint. There are several types:

- Proportional (P): This simple control loop corrects the error proportionally to its magnitude. It’s easy to implement but can suffer from offset (a steady-state error).

- Proportional-Integral (PI): Adds an integral term to eliminate offset. The integral action sums the error over time and adjusts the output to remove any persistent deviation.

- Proportional-Integral-Derivative (PID): Incorporates a derivative term to anticipate future errors based on the rate of change. This improves response time and reduces overshoot.

- Cascade Control: Employs a master and slave loop where the output of the master loop controls the setpoint of the slave loop. This is useful when manipulating a primary variable indirectly affects a secondary variable that needs tight control.

- Feedforward Control: Anticipates disturbances before they affect the process variable. It uses a measurement of a disturbance variable to adjust the manipulated variable proactively. This improves response time and reduces the burden on the feedback loop.

The selection of the appropriate control loop depends on the specific process characteristics and performance requirements. A complex system might employ a combination of these control strategies to achieve optimal control.

Q 18. Explain your understanding of root cause analysis techniques.

Root cause analysis (RCA) is crucial for preventing recurring problems. I’m experienced with various techniques including:

- 5 Whys: A simple yet effective method of repeatedly asking “why” to drill down to the root cause. It’s useful for straightforward problems but may be insufficient for complex issues.

- Fishbone Diagram (Ishikawa Diagram): A visual tool that helps brainstorm potential causes categorized by factors like manpower, machinery, materials, methods, measurements, and environment. This is a great brainstorming tool for collaborative RCA.

- Fault Tree Analysis (FTA): A top-down, deductive approach that starts with an undesired event (the top event) and works backwards to identify the contributing factors. It uses Boolean logic to determine the probability of the top event occurring.

- Failure Mode and Effects Analysis (FMEA): A proactive technique to identify potential failure modes and their effects. It assesses the severity, occurrence, and detectability of each failure mode to prioritize risk mitigation efforts.

My preference often depends on the complexity of the situation. For a relatively simple problem, the 5 Whys might suffice. However, for complex, multi-faceted issues, I usually favor a Fishbone diagram or FTA to ensure thorough investigation.

Q 19. Describe your experience with project management in a process engineering context.

My project management experience in process engineering involves leading and contributing to projects from conception to commissioning. I’m proficient in using project management methodologies like Agile and PRINCE2. This includes defining project scopes, developing detailed schedules, managing budgets, allocating resources, and leading cross-functional teams.

In a recent project focused on upgrading a distillation column, I was responsible for managing all aspects, from initial feasibility studies to final acceptance testing. This involved collaborating with engineers from multiple disciplines (process, mechanical, electrical, instrumentation), procurement specialists, contractors, and operators. I successfully delivered the project on time and within budget, resulting in a significant improvement in product purity and energy efficiency.

I utilize project management software like MS Project to track progress, manage risks, and facilitate communication within the team. I’m also adept at using Earned Value Management (EVM) techniques to monitor project performance and make necessary adjustments.

Q 20. How do you communicate technical information effectively to non-technical audiences?

Communicating technical information to non-technical audiences requires simplifying complex concepts without sacrificing accuracy. My approach involves:

- Using clear and concise language: Avoiding jargon and technical terms whenever possible. If necessary, I define them in simple terms.

- Employing visuals: Diagrams, charts, and other visuals can effectively convey complex information in an easily digestible format.

- Relating to real-world examples: Using analogies and relatable examples helps non-technical audiences understand the relevance and importance of the information.

- Tailoring the message to the audience: Understanding the audience’s prior knowledge and interests is crucial for effective communication.

- Active listening and feedback: Encouraging questions and feedback allows for clarification and ensures the message is understood.

For example, when presenting a process optimization plan to a management team, I would focus on the key performance indicators (KPIs) like improved yield, reduced energy consumption, and cost savings, rather than delving into the intricate details of the process models.

Q 21. What are your experiences with different process unit operations (e.g., distillation, reaction, heat exchange)?

My experience encompasses various process unit operations, including:

- Distillation: I’ve worked on the design, optimization, and troubleshooting of various distillation columns, including tray and packed columns. I’m familiar with different column configurations, such as azeotropic and extractive distillation, and have experience using simulation software like Aspen Plus to model and optimize these processes.

- Reaction Engineering: I’ve designed and analyzed various chemical reactors, including batch, continuous stirred-tank reactors (CSTRs), and plug flow reactors (PFRs). This includes determining reactor size, selecting optimal operating conditions, and analyzing reaction kinetics.

- Heat Exchange: I’m experienced in designing and selecting heat exchangers (shell and tube, plate, etc.), performing heat and material balances, and addressing issues like fouling and scaling. I have utilized software packages to simulate and optimize heat exchanger networks.

In a previous project involving the synthesis of a pharmaceutical intermediate, I was responsible for designing a CSTR to achieve the desired conversion and selectivity. This involved analyzing reaction kinetics, selecting the appropriate reactor type and size, and designing the control system to maintain the desired temperature and pressure.

Q 22. Explain your understanding of different types of process reactors.

Process reactors are vessels where chemical reactions occur. Their design significantly impacts reaction efficiency, product yield, and overall process economics. Reactor types are broadly categorized based on their operating mode and design features.

- Batch Reactors: These reactors are charged with reactants, allowed to react for a specified time, and then discharged. Think of a cooking pot – you add ingredients, cook, and then serve. They are simple to operate but less efficient for large-scale production.

- Continuous Stirred-Tank Reactors (CSTRs): Reactants continuously flow into and out of a well-mixed tank. Imagine a continuously churning milkshake machine. These are ideal for liquid-phase reactions requiring good mixing and temperature control. However, they usually result in lower conversions per pass compared to other reactor types.

- Plug Flow Reactors (PFRs): Reactants flow through a long tube or pipe with minimal mixing. It’s like a river flowing – minimal back mixing occurs. PFRs are efficient for gas-phase reactions or when high conversion per pass is needed, but achieving uniform temperature and flow can be challenging.

- Fluidized Bed Reactors: These use gas to fluidize a bed of solid catalyst particles. Think of a bubbling fluidized sand bed. Ideal for gas-solid reactions, offering high surface area and excellent heat transfer.

The choice of reactor depends on factors like reaction kinetics, heat transfer requirements, scalability, and cost. For instance, a batch reactor might be suitable for small-scale pharmaceutical production, while a CSTR is better suited for large-scale polymerization.

Q 23. Describe your experience with process scale-up and scale-down.

Process scale-up and scale-down involve transitioning a process from one scale to another. Scale-up typically moves from lab-scale to pilot plant and then to full-scale industrial production. Scale-down aims to reproduce industrial processes at a smaller scale for research and development purposes or troubleshooting.

My experience involves several successful scale-up projects. For example, I worked on scaling up a bioreactor process for producing a specific enzyme. This involved careful consideration of factors like the ratio of surface area to volume, mixing efficiency, and heat transfer. We had to ensure that the mass and heat transfer limitations that were not apparent at the lab scale were addressed in the larger bioreactor. We used computational fluid dynamics (CFD) simulations to optimize the impeller design and ensure adequate mixing in the larger vessel.

Scale-down presents different challenges. It’s critical to maintain geometric and dynamic similarity to accurately represent the larger process. We often have to use advanced techniques like miniaturization and microfluidic devices to achieve similar hydrodynamic conditions. This involves careful selection of materials and processes to ensure the smaller model mimics the large-scale process behavior.

Q 24. How do you handle uncertainty and risk in process design?

Uncertainty and risk are inherent in process design. We address them using a structured approach involving Hazard and Operability Studies (HAZOP), Failure Mode and Effects Analysis (FMEA), and quantitative risk assessment.

HAZOP systematically identifies potential hazards and operability problems using a structured guideword approach. FMEA identifies potential failure modes and their consequences. Quantitative risk assessment assigns probabilities and consequences to each identified hazard to prioritize mitigation efforts.

For example, in designing a high-pressure reactor, we would use HAZOP to identify potential pressure vessel failures, considering scenarios like material fatigue, corrosion, and operator error. FMEA would evaluate the consequences of each failure and implement safety features like pressure relief valves and emergency shutdown systems. Quantitative risk assessment might involve evaluating the probability of a failure and the potential for catastrophic consequences, which helps prioritize the allocation of resources for safety upgrades. These techniques ensure that our designs are robust and account for uncertainties.

Q 25. What are some common challenges in process engineering and how have you overcome them?

Process engineering is rife with challenges. One common issue is achieving optimal reaction yields and selectivity while maintaining acceptable operating costs. Another common challenge is integrating sustainability into the process design.

In one project, we faced difficulty achieving the desired conversion rate in a catalytic reaction. After detailed analysis, we identified that the catalyst deactivation was a significant factor. We addressed this by optimizing the catalyst regeneration process and by modifying the reactor operating conditions. This involved experimenting with different temperatures, pressures, and flow rates to find the optimal balance between conversion, selectivity and catalyst lifespan. This improved the conversion rate, extended the catalyst life, and significantly reduced operating costs.

Another challenge involved minimizing waste generation. We employed process intensification techniques such as using microreactors which increased reaction efficiency, reduced waste generation, and ultimately enhanced sustainability. The use of alternative solvents and innovative separation techniques also played a crucial role in minimizing environmental impact.

Q 26. Describe your experience with process economics and cost analysis.

Process economics and cost analysis are crucial for evaluating the feasibility and profitability of a project. This involves estimating capital costs (equipment, construction), operating costs (raw materials, utilities, labor), and revenue projections. We use several techniques, including discounted cash flow (DCF) analysis, to evaluate profitability and return on investment.

In a recent project, we performed a detailed cost analysis to compare two different process designs for producing a chemical product. One design used conventional equipment, while the other incorporated process intensification techniques. The initial capital cost of the process intensification design was higher, but the operating costs, particularly energy consumption, were considerably lower. The DCF analysis showed that the process intensification design offered a significantly higher net present value (NPV) and return on investment, making it the economically preferable option despite the higher upfront costs.

Such analysis requires a deep understanding of equipment costs, utility pricing, and market conditions, requiring collaboration between engineers and financial analysts.

Q 27. Explain your understanding of sustainable process engineering principles.

Sustainable process engineering emphasizes minimizing environmental impact and resource consumption throughout the entire life cycle of a process. This involves designing processes that reduce waste generation, use renewable energy sources, and minimize greenhouse gas emissions. Key principles include:

- Atom economy: Maximizing the incorporation of all starting materials into the final product, minimizing waste generation.

- Energy efficiency: Minimizing energy consumption throughout the process.

- Waste minimization: Reducing waste generation through process optimization and innovative separation techniques.

- Use of renewable resources: Substituting fossil fuels with renewable energy sources and using renewable raw materials.

- Pollution prevention: Designing processes that avoid generating pollutants in the first place.

In practice, sustainable principles are integrated into all aspects of the design, from selecting environmentally benign solvents to optimizing reaction conditions to reduce energy use. Life cycle assessments (LCAs) are crucial tools for evaluating the overall environmental impact of a process.

Q 28. Describe your experience with process modeling and design using software

I have extensive experience using process modeling and simulation software, including Aspen Plus, COMSOL, and MATLAB. These tools are invaluable for designing, optimizing, and troubleshooting chemical processes.

For example, in a recent project, we used Aspen Plus to simulate a complex distillation column for separating a multi-component mixture. The software allowed us to optimize the column design to achieve the desired separation efficiency while minimizing energy consumption. We could easily adjust parameters like the number of trays, reflux ratio, and feed location to evaluate their impact on performance. The simulations helped us avoid costly trial-and-error experimentation.

Furthermore, COMSOL has been vital in creating detailed models of microfluidic devices, allowing us to simulate flow patterns, mass transport, and heat transfer within microchannels. This is essential for designing and optimizing microreactors and other miniaturized process equipment. MATLAB is utilized for data analysis, algorithm development, and control systems design.

The ability to model and simulate processes before construction significantly reduces risks and costs, contributing to efficient and successful projects.

Key Topics to Learn for Process Engineering Analysis Interview

- Process Modeling and Simulation: Understanding different modeling techniques (steady-state, dynamic), software applications (Aspen Plus, MATLAB), and model validation methods is crucial. This allows you to demonstrate your ability to predict and optimize process behavior.

- Mass and Energy Balances: Mastering the application of these fundamental principles to various process scenarios is essential. Be prepared to solve problems involving reactors, separators, and heat exchangers, showcasing your problem-solving skills.

- Thermodynamics and Phase Equilibria: A strong grasp of thermodynamic principles and phase behavior is critical for analyzing and optimizing process efficiency. Practical applications include designing separation processes and understanding reaction kinetics.

- Process Control and Instrumentation: Familiarity with control loops, instrumentation, and process automation is key. Be ready to discuss different control strategies and their impact on process stability and performance.

- Process Optimization and Design: Demonstrate your understanding of techniques like linear programming, optimization algorithms, and process intensification. Showcase your ability to design and improve process efficiency and sustainability.

- Process Safety and Hazard Analysis: Discuss your understanding of safety procedures, hazard identification, and risk assessment methodologies (HAZOP, FTA). This showcases your commitment to safe and responsible engineering practices.

- Data Analysis and Interpretation: Highlight your proficiency in analyzing process data, identifying trends, and using statistical methods to improve process understanding and decision-making.

Next Steps

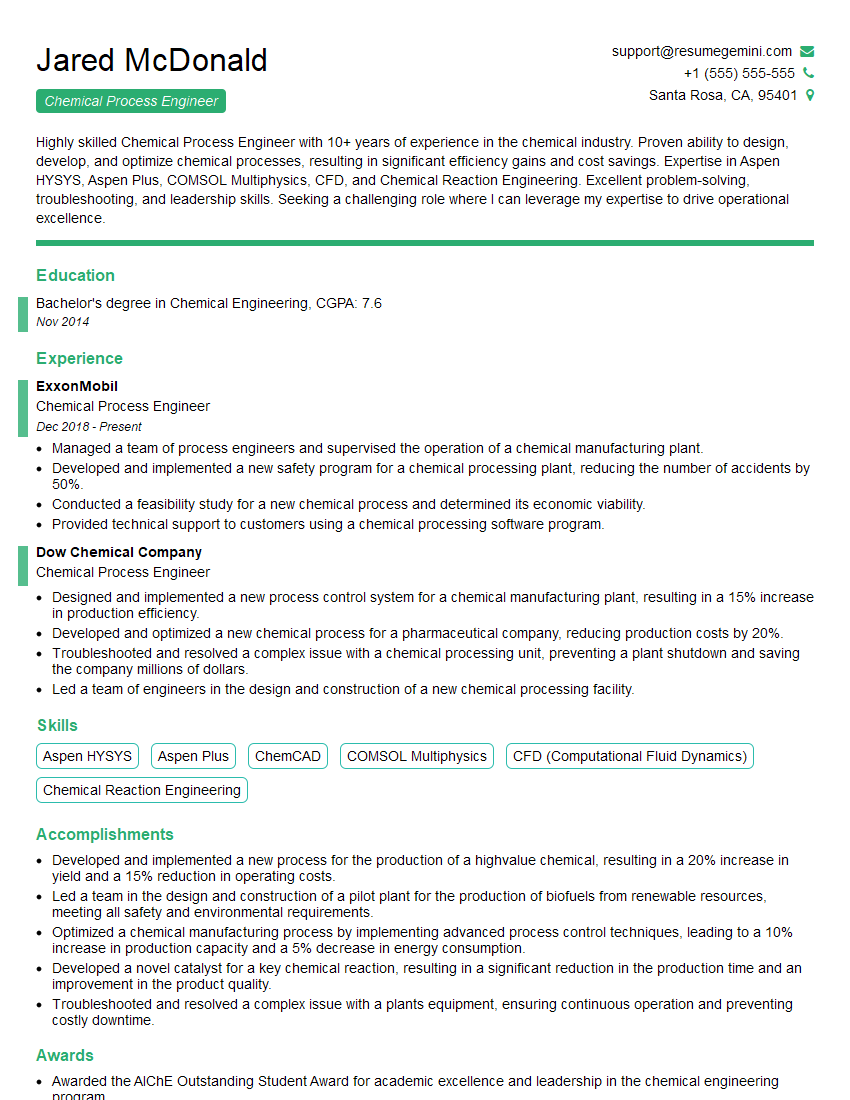

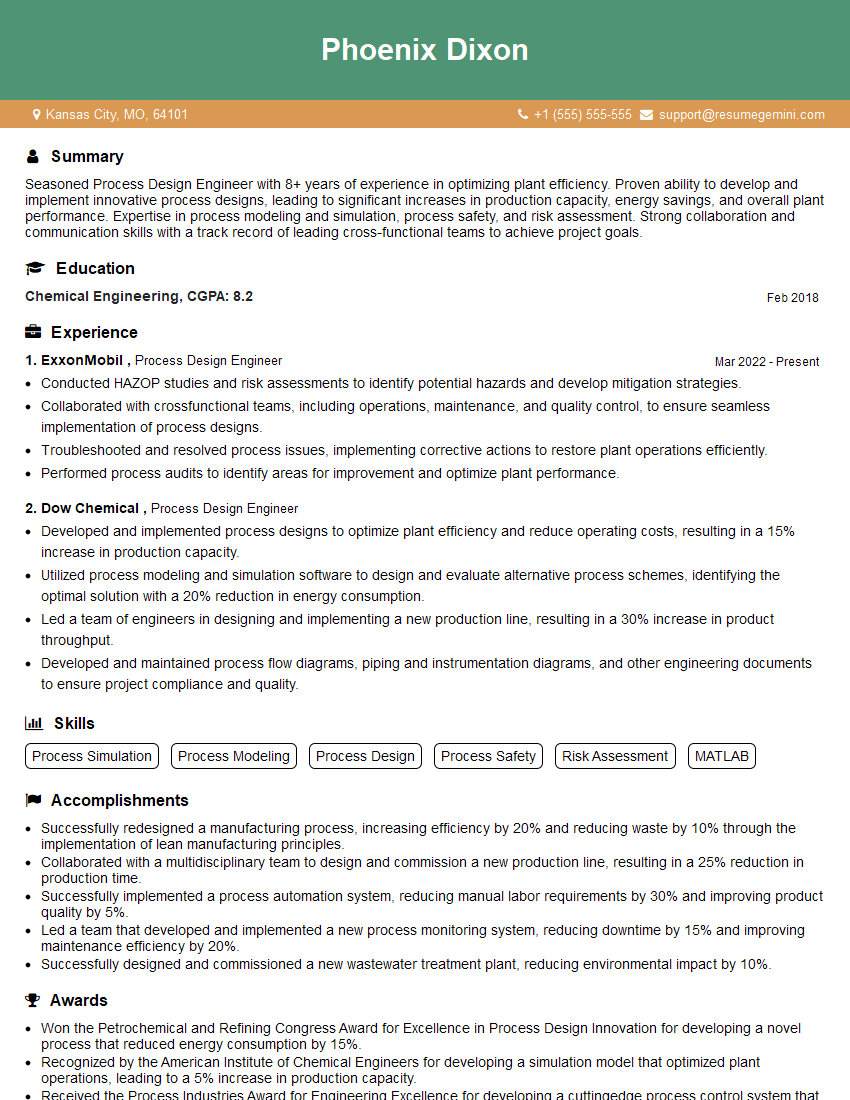

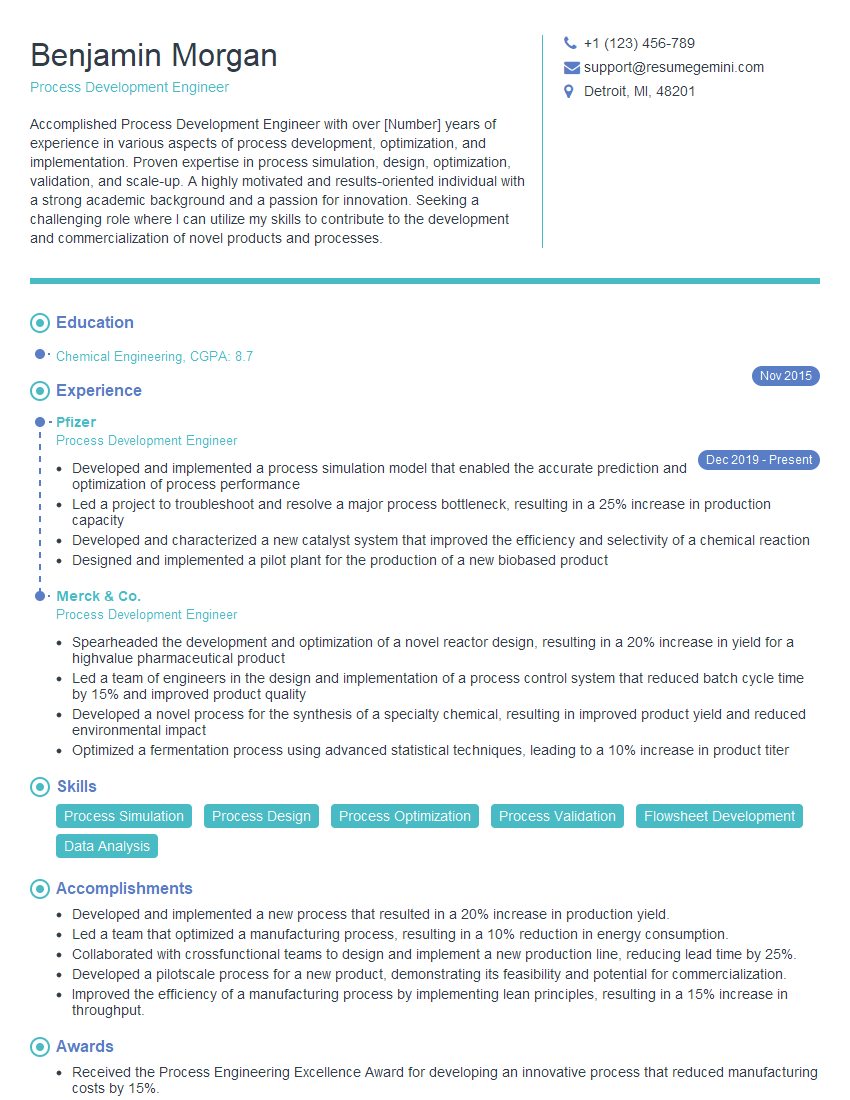

Mastering Process Engineering Analysis opens doors to exciting career opportunities in various industries, offering significant growth potential and rewarding challenges. To maximize your job prospects, a well-crafted, ATS-friendly resume is essential. This ensures your application gets noticed by recruiters and hiring managers. We strongly recommend using ResumeGemini to build a professional and impactful resume that highlights your skills and experience effectively. ResumeGemini provides examples of resumes tailored to Process Engineering Analysis, giving you a head start in creating a compelling application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good