Cracking a skill-specific interview, like one for Scheduling and Production Control, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Scheduling and Production Control Interview

Q 1. Explain the difference between forward scheduling and backward scheduling.

Forward scheduling and backward scheduling are two fundamental approaches to creating production schedules. They differ primarily in their starting point and how they work towards completion.

Forward Scheduling: Starts with the current time and works forward, scheduling tasks in the order they need to be completed. Think of it like a roadmap – you begin at your current location and plan the route to your destination, step-by-step. This is useful when you have readily available resources and want to maximize output as quickly as possible. For example, a bakery might use forward scheduling to determine how many batches of cookies they can bake given their existing staff and oven capacity throughout the day.

Backward Scheduling: Starts with the required completion date (due date) and works backward, scheduling tasks to meet that deadline. It’s more like working with a deadline and determining what needs to be done in reverse to meet it. This is very effective when you have a hard deadline that must be met. An example would be a construction project where the building needs to be finished for a specific opening event. The backward schedule determines the completion date of each sub-project (e.g., foundation, framing, interior work) to meet the final deadline.

The choice between forward and backward scheduling depends heavily on the project’s constraints. Forward scheduling prioritizes maximizing output, while backward scheduling prioritizes meeting a deadline. Often, a hybrid approach is the most effective.

Q 2. Describe your experience with MRP (Material Requirements Planning).

My experience with Material Requirements Planning (MRP) spans several years and diverse industrial settings. I’ve been involved in implementing, optimizing, and troubleshooting MRP systems for manufacturing environments producing everything from electronics to custom-designed furniture. MRP is crucial for managing the complexities of production planning and inventory control.

My role typically involves working closely with production managers, procurement teams, and inventory management systems. A successful implementation requires carefully defining the bill of materials (BOM), determining lead times, and establishing accurate demand forecasting. I have extensive experience in configuring and maintaining MRP software, such as using ERP systems that incorporate MRP modules. I’ve had to debug issues related to inaccurate demand forecasts, incorrect lead times, and problems in the data integrity of the BOM. For instance, I once successfully improved forecast accuracy by 15% by integrating market trend data into our MRP system, reducing inventory costs and improving on-time delivery.

Beyond basic implementation, I’m proficient in advanced MRP techniques, like capacity requirements planning (CRP), which helps in ensuring that sufficient resources are available to meet production demands. Through my experience, I’ve developed a strong understanding of the various challenges MRP systems may face and how to address them effectively.

Q 3. How do you handle production delays and prioritize tasks?

Production delays are inevitable, and effective handling requires a structured approach. My strategy begins with identifying the root cause of the delay – is it due to material shortages, equipment malfunction, unexpected quality issues, or workforce absenteeism? Once the cause is pinpointed, I work to mitigate the impact.

Prioritization is key. I use a combination of techniques like the Critical Path Method (CPM) and a weighted scoring system that considers factors such as the urgency of the order, the financial implications of delays, and the impact on subsequent tasks. For example, orders with tight deadlines or high-value products may get higher priority.

Communication is vital during delays. I keep all relevant stakeholders (e.g., customers, management, production team) informed and provide transparent updates. Depending on the severity of the delay, I may explore options like expediting materials, overtime work, or subcontracting parts of the production. It’s always important to document all steps taken to address the delay for future reference and continuous improvement.

For example, in a previous role, a machine breakdown caused a significant delay. I immediately identified the issue, contacted maintenance, and worked with the scheduling team to replan the workload, prioritizing critical orders and shifting less urgent tasks to alleviate the bottleneck. Open communication with the customer minimized disruption.

Q 4. What are some common scheduling algorithms you’re familiar with?

I’m familiar with a wide range of scheduling algorithms, each suited to different scenarios. Here are a few common ones:

- First-Come, First-Served (FCFS): Simple and easy to understand, but not always efficient as it doesn’t consider task priorities or durations.

- Shortest Processing Time (SPT): Prioritizes tasks with the shortest processing time to minimize overall completion time. This is good for minimizing average waiting time.

- Earliest Due Date (EDD): Prioritizes tasks with the earliest due dates to minimize the number of late jobs. Effective for meeting deadlines but can lead to longer average completion times.

- Critical Path Method (CPM): Identifies the longest path of tasks in a project network, highlighting the critical tasks that must be completed on time to meet the overall deadline. Allows for focus on the most important tasks.

- Priority Scheduling: Assigns priorities to tasks based on various factors (e.g., due date, importance, resource needs), allowing for flexible task sequencing based on specific needs.

The selection of the most suitable algorithm depends on the specific needs of the production environment, considering factors such as task dependencies, resource availability, and desired performance metrics (e.g., minimizing makespan, minimizing tardiness).

Q 5. Explain your experience with capacity planning and resource allocation.

Capacity planning and resource allocation are integral to effective scheduling. My experience involves assessing production capacity, identifying bottlenecks, and efficiently allocating resources to maximize output and minimize costs. This includes understanding the capabilities of our machines, workforce skills, and materials availability.

I’ve used various tools and techniques, including:

- Capacity analysis: Evaluating the maximum output of each resource (machines, personnel, etc.) to identify potential bottlenecks.

- Resource leveling: Balancing resource utilization across different tasks to avoid over- or under-utilization. This might involve rescheduling tasks or adjusting resource assignments.

- Simulation modeling: Using software tools to simulate different scheduling scenarios to test the impact of changes before implementing them in the real world. This helps to predict potential problems and optimize the resource allocation.

- What-if analysis: Exploring the impact of potential changes in demand, resource availability, or production processes.

For example, in one project, I identified a bottleneck in the assembly line due to insufficient capacity of a specific machine. By analyzing the workload and production cycle times, I was able to propose solutions such as acquiring an additional machine or optimizing the work sequence to resolve the bottleneck.

Q 6. How do you measure the effectiveness of your scheduling processes?

Measuring the effectiveness of scheduling processes is essential for continuous improvement. I use a combination of key performance indicators (KPIs) to evaluate performance:

- On-time delivery rate: The percentage of orders delivered on or before the due date.

- Throughput time: The total time it takes to complete a production process.

- Inventory turnover rate: Measures how quickly inventory is sold or used.

- Machine utilization rate: The percentage of time a machine is actively producing.

- Work-in-progress (WIP) inventory levels: The amount of partially completed work in the production process. High WIP levels indicate inefficiencies.

- Customer satisfaction: Feedback from customers regarding on-time delivery and product quality.

By tracking these KPIs over time, I can identify areas for improvement in the scheduling process. For example, consistently low machine utilization might indicate a need for better resource allocation or process optimization. Data analysis and regular reporting are critical for making data-driven decisions to enhance scheduling efficiency and overall production effectiveness.

Q 7. Describe a time you had to optimize a production schedule under tight deadlines.

In a previous role, we received a large, urgent order with a very tight deadline. The existing schedule couldn’t accommodate it without significant delays in other projects. This required immediate action and strategic problem-solving.

My approach was methodical:

- Assess the situation: I carefully analyzed the new order’s requirements, including the resources needed and the deadline. I also reviewed the current production schedule and identified potential conflicts and bottlenecks.

- Prioritize tasks: Using a weighted scoring system based on urgency, profitability, and deadline, I identified the most critical tasks related to the urgent order and adjusted the schedule accordingly.

- Resource allocation: I re-allocated resources, such as manpower and equipment, to accommodate the new order. This included discussions with different teams to secure the needed support and adjust their schedules.

- Communicate proactively: I kept all relevant stakeholders informed about the changes and potential delays on other projects, managing expectations.

- Monitor and adjust: I closely monitored progress and made necessary adjustments to the schedule as needed, addressing any unexpected delays or issues promptly.

Through this process, we successfully completed the urgent order on time without significant disruption to other projects. The key to success was the ability to quickly analyze the situation, effectively prioritize tasks, and efficiently manage resources while keeping everyone informed.

Q 8. How do you handle unexpected changes or disruptions to the production schedule?

Unexpected disruptions are inevitable in production. My approach involves a multi-step process focusing on swift response and minimizing impact. First, I immediately assess the nature and scope of the disruption – is it a machine malfunction, material shortage, or personnel issue? Then, I utilize available resources to quickly identify potential solutions. This often involves prioritizing tasks based on their criticality and available slack in the schedule. For example, if a crucial machine breaks down, we might temporarily reallocate tasks to other machines or even consider outsourcing part of the production. A key element is open communication; I inform all affected stakeholders immediately – from the production floor to management – to ensure everyone is aligned and working towards the same goal. Finally, post-incident, we conduct a thorough root cause analysis to prevent similar occurrences in the future. This might involve improving maintenance procedures, diversifying suppliers, or enhancing our overall risk management strategy.

For instance, in a previous role, a sudden supplier shortage of a key component threatened to halt an entire production line. By quickly identifying a secondary supplier, albeit at a slightly higher cost, and by negotiating overtime with our production team, we managed to mitigate the disruption and only experienced a minimal delay in shipping our products.

Q 9. What software or tools do you use for scheduling and production control?

My experience spans a variety of scheduling and production control software. I’m proficient in Enterprise Resource Planning (ERP) systems like SAP and Oracle, which provide comprehensive functionalities for managing materials, resources, and production schedules. These systems often integrate with Manufacturing Execution Systems (MES) for real-time shop floor monitoring and control. For more specialized needs, I have experience with advanced planning and scheduling (APS) software that leverages optimization algorithms to create efficient schedules, considering factors such as resource constraints, lead times, and due dates. In addition to these software solutions, I also utilize project management tools like MS Project and Jira for task management and collaboration, especially when managing multiple projects simultaneously. Choosing the right tool is dependent on the specific needs of the organization and the complexity of its production processes.

Q 10. How familiar are you with lean manufacturing principles and their impact on scheduling?

Lean manufacturing principles are fundamental to efficient scheduling and production control. The core tenets of lean – eliminating waste, improving flow, and empowering employees – directly translate into more effective scheduling strategies. For example, reducing setup times, a key lean principle, directly shortens lead times and improves schedule adherence. Similarly, implementing Kanban systems, which visualize workflow and limit work-in-progress, allows for a more predictable and responsive scheduling process. Value stream mapping, a crucial lean tool, helps identify bottlenecks and inefficiencies in the production process, enabling us to optimize schedules and resource allocation accordingly. By focusing on continuous improvement (Kaizen), we can identify areas for optimization in our scheduling processes, leading to improved efficiency and reduced waste. In essence, lean principles ensure a more agile and responsive scheduling system capable of handling unexpected changes.

Q 11. Explain your understanding of critical path analysis.

Critical Path Analysis (CPA) is a project management technique used to identify the longest sequence of tasks in a project, determining the shortest possible project duration. This ‘critical path’ determines the minimum time required to complete the project and highlights the tasks that, if delayed, will directly impact the overall project completion date. Tasks not on the critical path have some flexibility in their scheduling, known as ‘slack’. CPA helps in resource allocation by identifying the tasks that require the most attention and potentially more resources to ensure timely completion. We use various software tools or even simple Gantt charts to visually represent the project tasks and their dependencies. By analyzing the critical path, we can pinpoint potential bottlenecks and develop mitigation strategies proactively.

For example, in building a house, the foundation needs to be laid before the walls can be constructed. If the foundation work is delayed, the entire project will be delayed, regardless of how quickly the other tasks are completed. Identifying this as the critical path allows for more focused resource allocation and careful monitoring.

Q 12. How do you prioritize tasks when dealing with multiple projects simultaneously?

Prioritizing tasks across multiple projects requires a structured approach. I typically utilize a combination of methods including:

- Prioritization Matrix: Ranking projects based on urgency and importance (e.g., Eisenhower Matrix).

- Weighted Scoring System: Assigning weights to different project criteria (e.g., revenue potential, client priority, risk) to objectively compare projects.

- Dependency Analysis: Identifying interdependencies between projects to determine the optimal sequencing of tasks.

Q 13. Describe your experience with inventory management and its relationship to scheduling.

Inventory management is intrinsically linked to scheduling. Efficient inventory management ensures that the right materials are available at the right time for production. Insufficient inventory can lead to production delays, while excessive inventory ties up capital and increases storage costs. My approach involves utilizing various inventory control techniques, including Just-In-Time (JIT) inventory, which aims to minimize inventory levels by receiving materials only when needed. This requires close coordination between production scheduling and procurement. In addition to JIT, I leverage techniques like Material Requirements Planning (MRP) to determine the quantity and timing of material orders based on the production schedule. Accurate demand forecasting is also vital to avoid stockouts or overstocking. By closely monitoring inventory levels and production schedules, I aim to optimize the balance between meeting production demands and minimizing inventory holding costs.

Q 14. How do you communicate scheduling updates and changes to stakeholders?

Effective communication is critical for successful scheduling. I use a multi-faceted approach tailored to the audience and the type of update. For routine updates, I often utilize automated email notifications or dashboards providing real-time insights into schedule progress. For significant changes or disruptions, I conduct meetings, either in person or virtually, to ensure clarity and address any concerns directly. These meetings involve all relevant stakeholders – production teams, management, and clients. Visual aids, such as Gantt charts or Kanban boards, help to illustrate schedule changes and their impact. In addition, a well-documented system of records, updated regularly, acts as a single source of truth. This transparent approach fosters trust and collaboration, making the whole scheduling process smoother and more effective.

Q 15. What are some common challenges in scheduling and how have you overcome them?

Common challenges in scheduling often revolve around unpredictable events, resource constraints, and conflicting priorities. Inaccurate demand forecasting can lead to overproduction or stockouts, while unexpected machine breakdowns or material delays can disrupt the entire schedule. Furthermore, balancing competing priorities – such as meeting deadlines, minimizing costs, and ensuring high quality – can be extremely difficult.

To overcome these, I’ve employed several strategies. For instance, I’ve implemented robust buffer times into schedules to account for unforeseen delays. This might involve adding extra time for a specific task or building in contingency plans for potential disruptions. I’ve also successfully utilized techniques like Critical Path Method (CPM) to identify the most critical tasks and prioritize their execution. Finally, proactive communication and collaboration with all stakeholders – from production teams to suppliers – is crucial to ensure everyone is aware of potential issues and can contribute to solutions.

In one project, we faced significant delays due to a supplier failing to deliver raw materials on time. By using a combination of buffer time (we had already anticipated potential delays, and so, luckily, had a small buffer built in) and quickly identifying alternative suppliers, we managed to minimize the impact on the overall schedule and still meet the final deadline. This experience highlighted the importance of proactive risk management and flexible scheduling.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you balance production efficiency with quality control?

Balancing production efficiency and quality control requires a delicate equilibrium. Pushing for maximum output can compromise quality, while an overemphasis on quality might impede efficiency. The key is to integrate quality control measures directly into the production process, rather than treating them as separate entities.

My approach involves implementing quality checks at each stage of production. This allows for early detection and correction of defects, preventing the accumulation of faulty products further down the line. Statistical Process Control (SPC) techniques are invaluable in monitoring process variation and identifying potential problems before they impact quality. Moreover, empowering employees to identify and address quality issues promptly improves both efficiency and quality. By providing training and tools to employees at all levels, they feel more ownership and accountability for the work they do, driving improved quality standards.

For example, in a previous role, we implemented a system of ‘andon’ cords, allowing workers to immediately halt the production line if they detected a quality problem. This seemingly simple change dramatically reduced waste and improved overall product quality while allowing problems to be addressed quickly.

Q 17. What are your strategies for preventing bottlenecks in the production process?

Preventing bottlenecks requires a thorough understanding of the entire production process, identifying potential choke points, and implementing strategies to alleviate pressure at those points.

My approach involves using tools like Value Stream Mapping to visualize the workflow and identify areas with excessive lead times or high variability. Once bottlenecks are identified, solutions can range from adjusting the workflow, investing in additional resources (equipment or personnel), improving process efficiency, or even redesigning the product or process itself.

For example, in one manufacturing facility, we identified a bottleneck at the packaging station. By implementing a new automated packaging system and reorganizing the workstation layout, we significantly increased throughput and eliminated the bottleneck entirely. Regular monitoring and analysis of key performance indicators (KPIs), such as cycle times and throughput, are essential to proactively identify and address emerging bottlenecks before they significantly impact production.

Q 18. Describe your experience with demand forecasting and its impact on scheduling.

Demand forecasting is critical for effective production scheduling. Accurate forecasts allow us to anticipate future demand, ensuring sufficient resources are available to meet customer needs while avoiding overproduction or shortages.

I’ve utilized various forecasting techniques, including moving averages, exponential smoothing, and more sophisticated statistical models, depending on the nature of the product and the availability of historical data. The chosen model is carefully validated and refined based on its accuracy and predictive capabilities. Incorporating market trends, seasonality, and economic factors into the forecasting process also significantly enhances its precision.

The impact on scheduling is direct: a well-crafted forecast enables the creation of a production schedule that aligns with predicted demand. This minimizes inventory holding costs, reduces the risk of stockouts, and allows for efficient allocation of resources. A poor forecast, on the other hand, can lead to production inefficiencies, excessive inventory, lost sales, and even dissatisfied customers.

Q 19. How do you ensure the accuracy of your production schedules?

Ensuring the accuracy of production schedules requires a multi-faceted approach. It’s not enough to just create a schedule; it must be continuously monitored, updated, and adjusted based on real-time data.

Firstly, using accurate data from various sources, such as Material Requirements Planning (MRP) systems, and ensuring that these systems are up to date. Secondly, incorporating feedback mechanisms into the scheduling process, allowing for adjustments based on actual performance. Regular meetings to review the schedule’s progress and adjust for any variances are crucial. Lastly, utilizing appropriate software and tools for scheduling and tracking to automate data collection and analysis, making it easier to detect and address deviations.

For instance, using a software system that integrates directly with the shop floor to track machine run times and material usage in real-time, allows for constant monitoring and adjustments to the schedule when unforeseen situations arise.

Q 20. Explain your understanding of Kanban and its application in production scheduling.

Kanban is a lean manufacturing methodology that focuses on visualizing workflow and managing inventory levels. It uses a visual signaling system (often Kanban cards) to trigger production of the next item only when needed. This ‘pull’ system, as opposed to a ‘push’ system, minimizes waste by preventing overproduction.

In production scheduling, Kanban helps to optimize workflow by ensuring that production is aligned with actual demand, reducing lead times, and improving overall efficiency. By limiting work-in-progress (WIP), Kanban helps to identify bottlenecks and improve process flow. Implementing Kanban requires careful planning and stakeholder buy-in. It is important to define clearly the workflow, inventory levels, and signaling mechanisms.

In one project, implementing a Kanban system for a small assembly line reduced lead times by 40% and improved on-time delivery by 25%. The visual nature of the system also improved team communication and helped to identify and resolve issues quickly.

Q 21. Describe your experience with Gantt charts and their use in project scheduling.

Gantt charts are visual project management tools that display the schedule of tasks against time. They illustrate task dependencies, durations, and milestones, providing a clear overview of the project’s progress.

I have extensively used Gantt charts for project scheduling, particularly for complex projects with multiple interdependent tasks. They provide a clear visualization of the critical path – the sequence of tasks that determine the shortest possible project duration – allowing for effective resource allocation and identification of potential delays. Software applications help in creating and updating Gantt charts, reflecting real-time progress and adjustments.

For example, in a recent project involving the implementation of a new ERP system, the Gantt chart was instrumental in managing the different phases of the project, ensuring that tasks were completed in the correct sequence and within the allocated timeframes. Regular updates to the chart helped in monitoring progress and addressing any potential issues proactively. The visual representation of the schedule facilitated effective communication amongst the project team and stakeholders, fostering better collaboration and project success.

Q 22. How do you handle conflicting priorities between different production lines?

Conflicting priorities between production lines are a common challenge. Imagine a factory with one line producing widgets and another producing sprockets, both using the same crucial machine. Prioritization requires a structured approach. We use a combination of techniques:

- Prioritization Matrix: We create a matrix that ranks each product line based on factors like urgency (due dates, customer demand), profitability, and production capacity constraints. This allows for a clear visual understanding of which line needs priority.

- Negotiation and Collaboration: Often, there’s room for flexibility. We work with production managers to explore options like slightly adjusting production schedules, or even batching similar tasks together to maximize machine utilization. Effective communication is key.

- Resource Allocation: In cases where conflict is unavoidable, we optimize resource allocation. This may involve temporarily dedicating the shared resource (e.g., the crucial machine) to the higher-priority line, while potentially buffering the lower-priority line’s production with alternative resources or adjusted scheduling.

- Advanced Scheduling Software: Modern software solutions incorporate constraint programming and optimization algorithms to automatically find optimal schedules considering all production lines’ resource requirements and constraints. They’ll automatically suggest solutions that balance competing priorities.

Ultimately, successful conflict resolution involves a blend of data-driven decision making, proactive communication, and flexible planning to minimize disruption.

Q 23. What metrics do you use to track and analyze the performance of your scheduling system?

Tracking the performance of our scheduling system relies on a comprehensive set of key performance indicators (KPIs). These metrics provide insights into efficiency, productivity, and overall system effectiveness. We monitor:

- On-Time Delivery Rate (OTDR): This measures the percentage of orders delivered on or before their scheduled due date, giving direct insight into schedule adherence.

- Production Efficiency: This looks at the actual output versus planned output. A high efficiency rate suggests effective scheduling and resource utilization.

- Lead Time: We track the time it takes to complete an order from beginning to end, aiming for continuous improvement in this area. Reduced lead times signify optimized workflows.

- Inventory Turnover: This ratio helps us assess how effectively we manage inventory levels. Efficient scheduling minimizes holding costs while avoiding stockouts.

- Machine Utilization: We track the percentage of time each machine is actively working, which helps us identify bottlenecks and opportunities for improvement in resource allocation.

- Total Cost: A broad metric encompassing labor, materials, and overhead costs, helping us to evaluate the overall cost-effectiveness of the scheduling system.

We use data visualization tools like dashboards to track these KPIs in real-time, enabling us to quickly identify deviations from plan and take corrective action.

Q 24. Explain your understanding of the theory of constraints and its relevance to scheduling.

The Theory of Constraints (TOC) is a management paradigm that focuses on identifying and systematically improving the constraint—the single most limiting factor—within a system. In scheduling, this translates to finding the bottleneck in the production process and optimizing around it. For example, in a factory, the bottleneck might be a particular machine or a specific work process.

Relevance to Scheduling: TOC’s principles directly impact scheduling by:

- Identifying Bottlenecks: Through data analysis, we pinpoint the constraint in our production system.

- Exploiting the Constraint: Once identified, we focus on maximizing the throughput of the bottleneck by optimizing its utilization and efficiency. This might include process improvements, maintenance scheduling, or even dedicated staffing.

- Subordinating Everything Else to the Constraint: All other parts of the production process are adjusted to support the bottleneck’s optimal performance.

- Elevating the Constraint: Long-term solutions involve investing in upgrading or replacing the bottleneck to increase capacity. This might involve acquiring new equipment or implementing innovative technologies.

- Warning: Don’t let inertia become a constraint: Regularly review your constraints, as they can shift over time.

By focusing on the constraint, TOC helps optimize the entire production system’s throughput and profitability. It shifts the focus from optimizing individual parts to optimizing the whole.

Q 25. Describe your experience with implementing new scheduling software or systems.

I have extensive experience implementing new scheduling software and systems. My approach is methodical and involves:

- Needs Assessment: First, a thorough assessment of the existing system’s shortcomings and future requirements is crucial. This usually involves interviews with stakeholders, analyzing current data, and benchmarking best practices.

- Software Selection: Based on the needs assessment, I help select software that aligns with the organization’s needs and budget. This includes evaluating features, scalability, integration capabilities, and vendor support.

- Data Migration: Migrating data from the old system to the new one is a critical step. This requires careful planning and execution to ensure data integrity and accuracy.

- Training and Implementation: Providing comprehensive training to staff is vital for successful adoption. A phased implementation approach allows for a smooth transition and minimizes disruption to ongoing operations.

- Testing and Validation: Rigorous testing and validation are crucial to ensure the new system performs as expected. This includes both unit and integration testing before going live.

- Post-Implementation Monitoring: After the rollout, continuous monitoring and fine-tuning are needed to ensure optimal performance and address any emerging issues.

For example, in a previous role, we implemented an advanced MES (Manufacturing Execution System) that integrated shop floor data directly with our ERP system. This significantly improved scheduling accuracy and real-time visibility across the entire production process.

Q 26. How do you manage change requests and maintain schedule integrity?

Change requests are inevitable in production environments. To manage them while maintaining schedule integrity, I use a formal change management process:

- Formal Request Process: All change requests are submitted through a formal system, including a description of the change, its impact on the schedule, and justification.

- Impact Assessment: The proposed change is carefully assessed for its impact on existing schedules, resource allocation, and overall production goals. This often requires simulation or analysis using scheduling software.

- Prioritization and Scheduling: Requests are prioritized based on urgency, impact, and alignment with business objectives. The schedule is then adjusted to accommodate approved changes, minimizing disruption where possible.

- Communication and Collaboration: Keeping all stakeholders informed about changes is critical. Transparency prevents misunderstandings and ensures everyone is on the same page.

- Version Control: Using version control allows tracking all schedule changes, facilitating rollback if necessary and providing a history of modifications.

- Contingency Planning: For significant changes, developing contingency plans is essential to mitigate potential delays or disruptions.

Imagine a sudden increase in demand for a product. Using our established process, we analyze the impact, adjust the schedule, communicate the necessary changes to the relevant teams, and possibly implement overtime to ensure timely fulfillment without compromising the overall production plan.

Q 27. How familiar are you with Six Sigma methodologies and their application to production control?

I am very familiar with Six Sigma methodologies and their application to production control. Six Sigma is a data-driven approach focused on minimizing defects and variability in processes. Its tools and techniques are extremely useful in improving scheduling efficiency.

- DMAIC (Define, Measure, Analyze, Improve, Control): This is the core methodology used to identify and eliminate defects in processes. In scheduling, we can use DMAIC to identify the causes of schedule delays or inefficiencies, implement improvements, and monitor the results.

- Control Charts: These are used to monitor process stability and identify deviations from the target schedule. This allows for early detection of problems and prevents small issues from escalating into larger problems.

- Process Mapping: Creating a visual representation of the scheduling process helps identify bottlenecks and areas for improvement. This allows for streamlined workflows and reduced lead times.

- Failure Mode and Effects Analysis (FMEA): This is a proactive technique for identifying potential issues before they arise. In scheduling, we can use FMEA to anticipate potential disruptions and develop contingency plans.

For example, using DMAIC to analyze late deliveries, we might find inconsistent machine maintenance as a root cause. Implementing a preventive maintenance schedule would then be an improvement step, leading to greater schedule adherence and fewer late deliveries.

Q 28. Describe your experience with data analysis and its role in improving scheduling efficiency.

Data analysis is indispensable for improving scheduling efficiency. By leveraging data, we gain insights into the effectiveness of our scheduling processes and identify areas for improvement.

- Historical Data Analysis: Analyzing past scheduling data reveals trends, patterns, and common issues. This allows us to proactively address recurring problems and avoid making the same mistakes.

- Predictive Analytics: Using advanced statistical techniques and machine learning algorithms, we can predict future demand, resource availability, and potential bottlenecks. This allows for more proactive and accurate scheduling.

- Simulation and Modeling: Simulating different scheduling scenarios helps to evaluate the impact of changes and optimize resource allocation. This avoids costly trial-and-error approaches.

- Root Cause Analysis: When schedule deviations occur, data analysis helps us understand the root causes, enabling targeted improvements rather than superficial solutions.

For instance, by analyzing historical data on machine breakdowns, we might discover a specific machine prone to failure at a particular time. This allows for preventative maintenance scheduling and improved machine uptime, resulting in a more reliable schedule.

Key Topics to Learn for Scheduling and Production Control Interview

- Master Production Scheduling (MPS): Understand the process of creating a high-level production plan, considering demand forecasts, inventory levels, and capacity constraints. Practical application: Explain how you would adjust an MPS in response to unexpected material delays.

- Capacity Planning and Resource Allocation: Learn to analyze production capacity, identify bottlenecks, and efficiently allocate resources (personnel, equipment, materials) to optimize production flow. Practical application: Describe a scenario where you optimized resource allocation to meet a tight deadline.

- Material Requirements Planning (MRP): Master the principles of MRP to effectively manage inventory, schedule procurement, and ensure timely availability of materials for production. Practical application: Explain how you would handle a situation where a critical material is running low.

- Scheduling Techniques (e.g., Gantt Charts, Critical Path Method): Familiarize yourself with various scheduling techniques and their applications in managing projects and production schedules. Practical application: Discuss the advantages and disadvantages of different scheduling methods in different production scenarios.

- Inventory Management Techniques: Explore different inventory management strategies (e.g., Just-in-Time, Kanban) and their impact on production efficiency and costs. Practical application: Explain how you would implement a JIT system in a manufacturing environment.

- Lean Manufacturing Principles: Understand and apply lean principles to eliminate waste, improve efficiency, and optimize the production process. Practical application: Describe a scenario where you identified and eliminated waste in a production process.

- Production Control Metrics and KPIs: Learn to track and analyze key performance indicators (KPIs) to monitor production efficiency, identify areas for improvement, and measure overall performance. Practical application: Discuss relevant KPIs for evaluating the success of a production control system.

- Problem-Solving and Troubleshooting: Develop your ability to identify and resolve production issues, such as scheduling conflicts, material shortages, and equipment malfunctions. Practical application: Describe your approach to troubleshooting a production delay caused by a machine breakdown.

Next Steps

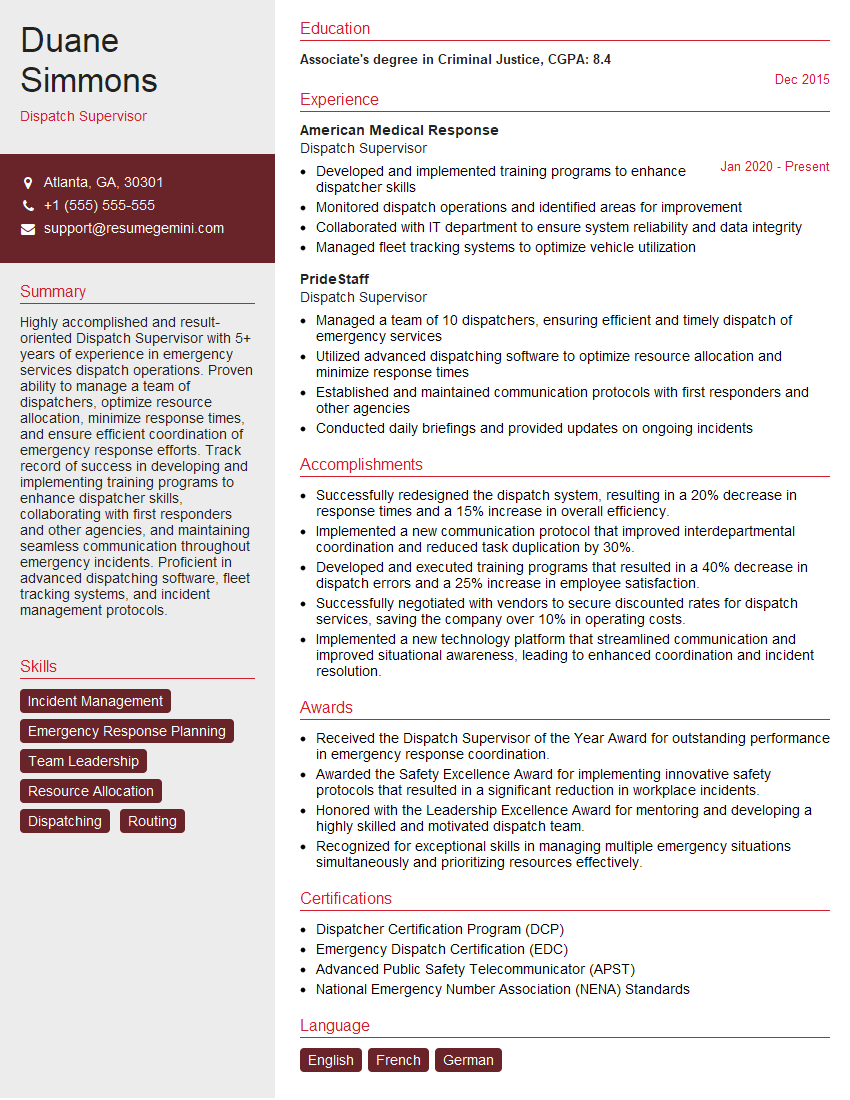

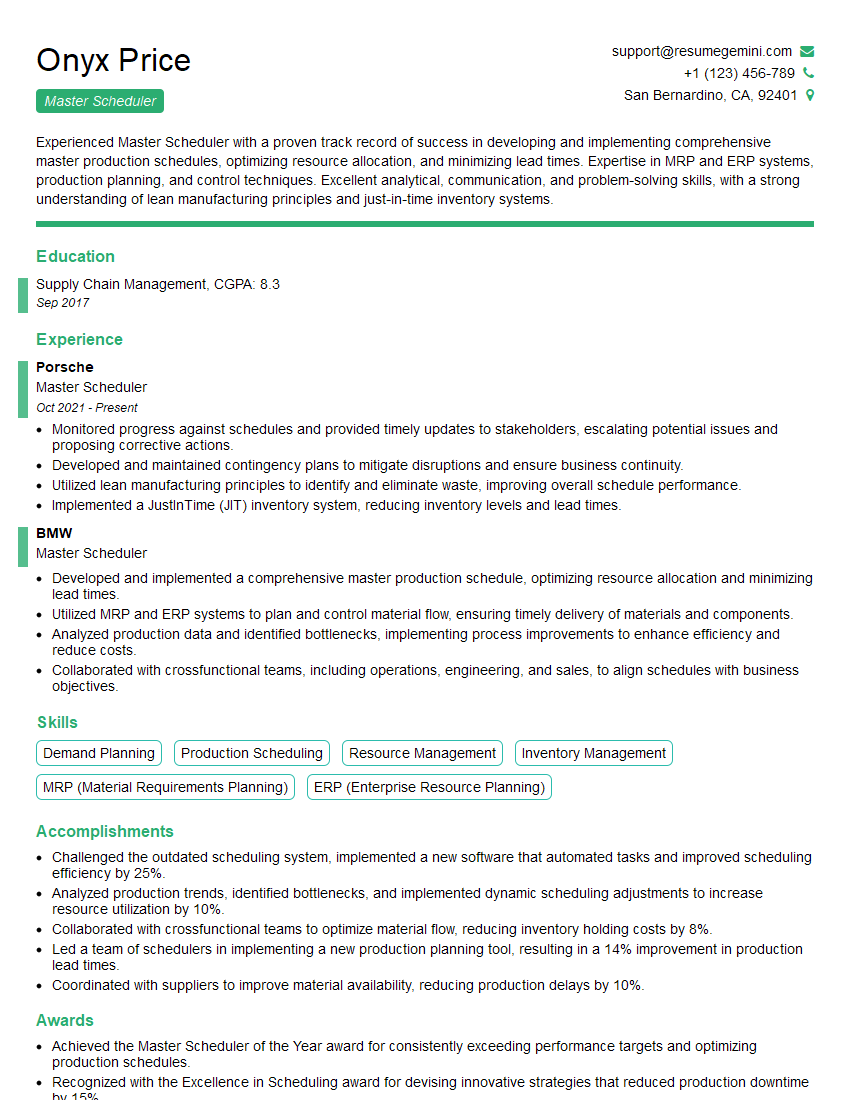

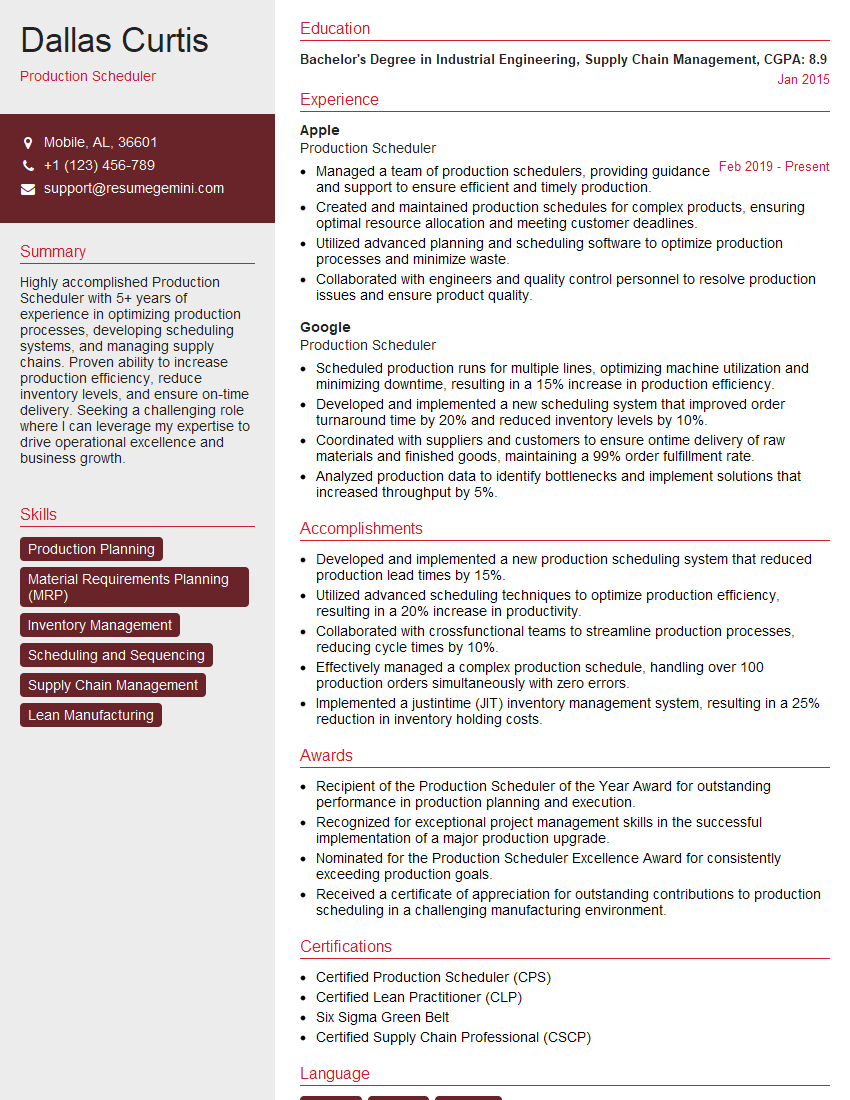

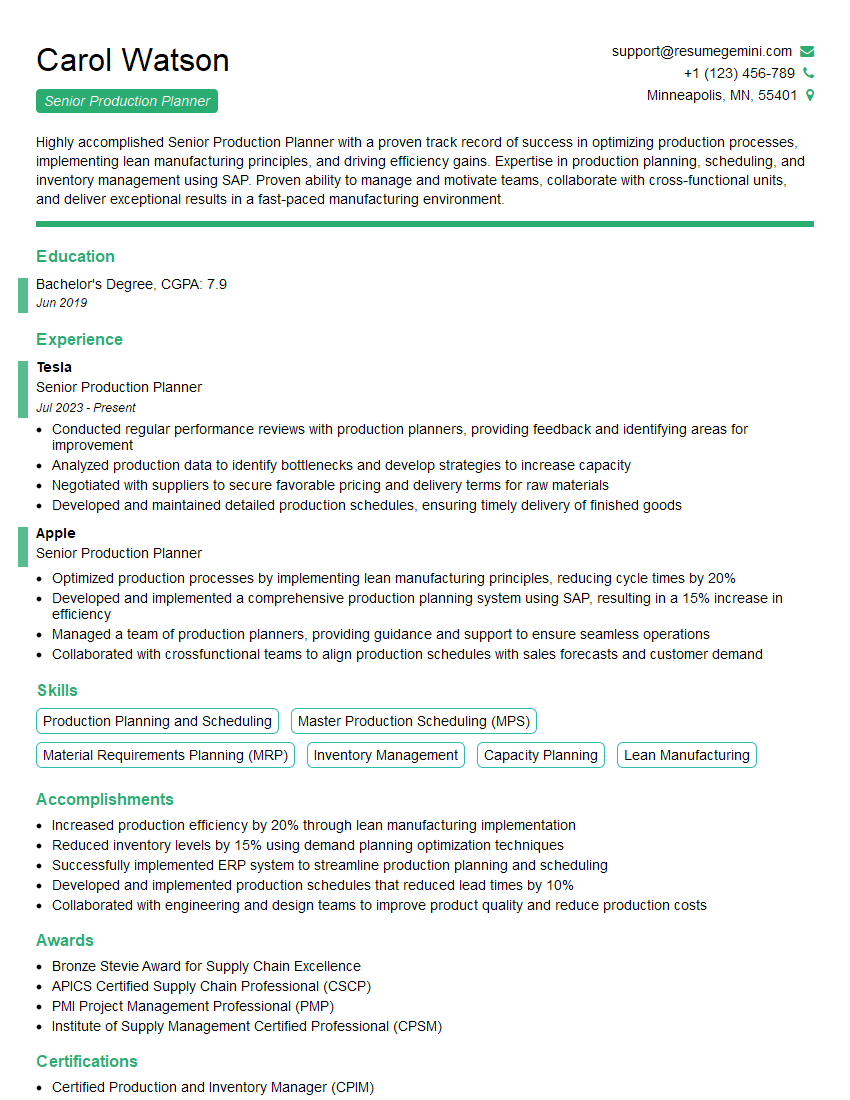

Mastering Scheduling and Production Control is crucial for career advancement in manufacturing, operations, and supply chain management. It demonstrates your ability to optimize processes, improve efficiency, and contribute significantly to a company’s bottom line. To maximize your job prospects, focus on creating an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. They provide examples of resumes tailored to Scheduling and Production Control, allowing you to showcase your expertise and secure your dream role.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good