Unlock your full potential by mastering the most common Screen Printing Setup interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Screen Printing Setup Interview

Q 1. Explain the steps involved in setting up a screen printing press.

Setting up a screen printing press involves a methodical approach to ensure a smooth and efficient printing process. It’s like preparing a finely tuned machine for a specific task. Think of it as assembling a high-precision instrument, where each step is crucial for the final output.

- Screen Preparation: First, you need to securely attach the screen to the press using the appropriate clamps. Make sure the screen is taut and free from any wrinkles that could cause inconsistencies in the print. Imagine stretching a canvas – you want it perfectly smooth and even.

- Screen Alignment: Accurately align the screen with the platen (the printing surface). Misalignment leads to misregistration – a common printing flaw. We use registration marks (small reference points on the screen and artwork) to guarantee perfect alignment. Think of it like aligning two pieces of a jigsaw puzzle; precision is key.

- Ink Setup: Prepare your inks according to the job specifications. This often involves mixing colors and adjusting viscosity (thickness). The ink viscosity is crucial; it determines the flow and print quality. Think of it like the consistency of paint; too thick, and it won’t flow properly; too thin, and it’ll be messy.

- Squeegee Positioning: Position the squeegee at the correct angle and pressure. This is crucial for even ink distribution and crisp prints. Imagine a painter using a brush – the angle and pressure determine the stroke and the final image.

- Press Adjustment: Adjust the press settings such as off-contact (the space between the screen and the substrate) and stroke length as needed. The off-contact controls the ink deposit, similar to how the distance of a spray nozzle determines paint coverage.

- Test Print: Always perform a test print before starting a full production run to check for any issues like misregistration or ink consistency problems. A test run saves you time and resources in the long run.

Q 2. Describe the different types of screen printing inks and their applications.

Screen printing inks come in various types, each suited to specific substrates and applications. Choosing the right ink is crucial for achieving the desired look, feel, and durability. It’s like choosing the right paint for a project – the wrong type will affect the final result.

- Plastisol Inks: These are the most common, known for their vibrant colors, opacity, and durability. They’re excellent for t-shirts and other textiles and create a raised, tactile print.

- Water-Based Inks: Environmentally friendly and soft to the touch, these inks are better suited for sensitive fabrics and often require a curing process.

- Discharge Inks: Designed to remove color from the garment before applying a new color, creating a unique effect on darker-colored fabrics.

- UV-Curable Inks: These inks cure (harden) instantly under UV light, making them ideal for fast turnaround times and a variety of substrates including plastics and metals.

- Solvent-Based Inks: Offering excellent adhesion to various materials, these are often used in industrial applications where durability is crucial. However, they often require specialized ventilation due to their volatile nature.

Q 3. How do you ensure proper screen tension during setup?

Proper screen tension is paramount for consistent ink flow and preventing screen distortion during printing. Think of it as tuning a guitar string – the right tension ensures optimal sound. Too loose, and the sound is muddy; too tight, and the string breaks.

We achieve proper tension using a screen stretching device or frame. This process involves carefully stretching the mesh over the frame and securing it tightly, ensuring even tension across the entire screen. We often use a tensiometer to measure the exact tension. This ensures a consistent print across the entire surface and prevents issues like pinholes or ink bleed.

Improper tension can cause a variety of problems, including blurry prints, uneven ink deposit, and screen damage. Addressing tension issues early can save significant time and rework.

Q 4. What are the common causes of screen misregistration and how do you correct them?

Screen misregistration, where colors don’t align perfectly, is a common problem in screen printing. It’s like trying to perfectly align multiple stamps – even a slight misalignment ruins the image. There are several causes:

- Inaccurate Screen Alignment: Improper placement of the screens during setup is the most common culprit.

- Shifting Screens: Screens can shift during the printing process, especially if the press isn’t properly adjusted or if the screens aren’t securely clamped.

- Incorrect Registration Marks: Inaccurate or poorly printed registration marks on the screen and artwork lead to misalignment.

- Platen Issues: An uneven or damaged platen can also contribute to misregistration.

To correct misregistration, you need to systematically check each possible cause. First, ensure proper screen alignment using registration marks, paying close attention to securing the screens and adjusting the press. Re-checking the platen for any damage is also crucial. Often, a test print with adjustments can fix the problem. Persistent issues may require adjusting the artwork or creating new screens.

Q 5. Explain the importance of proper squeegee pressure and angle.

Squeegee pressure and angle significantly impact print quality. It’s like wielding a paintbrush – the right pressure and angle create smooth, even strokes.

Squeegee Pressure: Too little pressure leads to uneven ink deposit and light prints. Too much pressure can cause the ink to seep under the stencil, resulting in blurry prints or screen damage. The ideal pressure ensures that the ink is evenly transferred across the substrate, creating a clean and sharp print. It’s a balance—enough pressure to transfer the ink fully, but not so much as to damage the screen or substrate.

Squeegee Angle: The angle, typically around 45 degrees, affects ink distribution. A steeper angle results in more ink deposit, while a shallower angle leads to thinner prints. This is adjustable based on ink viscosity and desired print thickness. It’s a matter of finding the balance based on the specific ink and substrate being used.

Finding the ideal pressure and angle often requires some experimentation and fine-tuning for each job.

Q 6. How do you determine the appropriate ink viscosity for a print job?

Determining the correct ink viscosity is essential for a clean, sharp print. It’s like adjusting the consistency of frosting – too thick, and it’s hard to spread; too thin, and it’s runny.

Viscosity is typically measured using a Zahn cup or a similar tool. The ideal viscosity depends on factors such as the mesh count of the screen, the design complexity, and the type of ink. A thicker ink is generally needed for finer details and high mesh counts. Thinner inks are preferred for larger areas and lower mesh counts.

Ink viscosity can be adjusted by adding a thinner or retarder, depending on whether you need to increase or decrease its flow. A test print is vital to verify the desired ink flow and final result before starting a large-scale printing run.

Q 7. What are the safety precautions you take when setting up and operating a screen printing press?

Safety is paramount in screen printing. Just like any machinery, screen printing presses pose potential hazards if not handled with care.

- Eye Protection: Always wear safety glasses or goggles to protect your eyes from flying ink or debris.

- Gloves: Use appropriate gloves to protect your hands from inks, which can be irritating or even harmful depending on their chemical composition.

- Ventilation: Ensure adequate ventilation to minimize exposure to ink fumes, especially when working with solvent-based inks.

- Proper Lifting Techniques: Use proper lifting techniques to avoid strain when moving screens and other heavy equipment.

- Machine Guards: Make sure all safety guards are in place and functioning correctly on the printing press to avoid entanglement or injuries.

- Fire Safety: Be aware of fire hazards associated with certain inks and solvents and maintain proper fire safety measures.

- Cleanliness: Maintain a clean and organized workspace to avoid accidents and improve efficiency. Regularly cleaning the press minimizes potential hazards.

Following these safety precautions not only protects the operator but also ensures a smooth and efficient printing process, preventing delays and accidents.

Q 8. Describe your experience with different types of screen printing presses (e.g., manual, automatic).

My experience encompasses a wide range of screen printing presses, from manual single-station presses ideal for small-scale projects and experimentation, to fully automatic multi-station carousel presses capable of high-volume production. With manual presses, I’ve honed my skills in precise registration and ink control, understanding the nuances of pressure and squeegee technique. This hands-on experience provides a deep understanding of the printing process itself. On the other hand, working with automatic presses has exposed me to the intricacies of machine setup, including optimizing print speed, ink delivery systems, and flash curing integration. I’m comfortable troubleshooting issues across various press types, from simple adjustments to complex mechanical repairs.

For example, I’ve successfully set up and operated a Vastex V-252 manual press for small batch runs of custom t-shirts, achieving excellent print quality and consistency. In a larger production setting, I managed a M&R automatic press, significantly increasing throughput while maintaining high standards for accuracy and color fidelity. This diverse experience gives me a comprehensive view of the capabilities and limitations of each press type.

Q 9. How do you troubleshoot common screen printing press malfunctions?

Troubleshooting screen printing press malfunctions requires a systematic approach. I typically start by visually inspecting the press for obvious issues like loose parts, worn components, or ink build-up. Then, I systematically work through potential problems based on the nature of the malfunction. Is the press not feeding correctly? Are there registration issues? Are there inconsistent print quality issues?

For instance, if the press isn’t feeding properly, I might check the timing belts for wear or damage, ensure the feeder mechanism is clean and free of obstructions, or inspect the power supply for irregularities. If I’m experiencing poor registration, I might adjust the micro-registration screws, check the screen tension, or examine the platen for any defects. Inconsistent ink distribution might indicate problems with the squeegee blade, ink viscosity, or the screen mesh itself.

I believe in preventative maintenance to minimize malfunctions. Regularly cleaning and lubricating the press are crucial to its longevity and optimal performance. Documentation of maintenance schedules and repairs is also vital for ongoing operational efficiency.

Q 10. Explain the process of preparing screens for printing (e.g., coating, exposure, washing).

Screen preparation is a critical step that directly impacts print quality. It involves several key stages: coating, exposure, and washing.

- Coating: This involves applying a photosensitive emulsion to the screen mesh using a scoop coater or a trough coater to ensure even distribution and coating thickness. The emulsion acts as a light-sensitive barrier, allowing for the creation of the print image. The type of emulsion used (direct or indirect) depends on the complexity of the design and the printing technique employed.

- Exposure: After the emulsion dries, the coated screen is exposed to a strong UV light source through a film positive (a transparent film with the design in opaque areas) that creates a stencil. UV light hardens the emulsion in the exposed areas, while the unexposed areas remain soft and can be washed away. Precise exposure time is critical to prevent under-exposure (resulting in weak images) or over-exposure (leading to harsh edges and blockages).

- Washing: Once exposed, the screen is washed under running water to remove the unexposed emulsion, revealing the stencil that will form the print image. A pressure washer is often used for this purpose, requiring careful control to prevent damage to the stencil.

Proper screen preparation ensures sharp, clean prints with accurate detail. Incorrect coating can lead to pinholes or uneven ink distribution, while under or over exposure results in distorted images. My experience ensures that each of these steps is executed with meticulous attention to detail and quality.

Q 11. How do you maintain the cleanliness and condition of your screen printing equipment?

Maintaining clean and well-conditioned screen printing equipment is paramount for both quality and longevity. This involves regular cleaning procedures and preventative maintenance practices.

After each print run, I thoroughly clean the press, including the platen, squeegee, and ink trays. Any residual ink needs to be removed using appropriate solvents. The screens themselves require regular cleaning to remove dried ink and debris, often using a screen cleaning solution and a brush or pressure washer. I perform a full cleaning of the press at least once a week and conduct more thorough deep cleaning on a monthly basis. Regular lubrication of moving parts and inspection for wear and tear are also crucial. Keeping detailed records of cleaning and maintenance helps me proactively address potential problems.

For example, a consistent cleaning schedule prevents ink build-up that could cause registration issues or clog the print head. Regular lubrication ensures smooth operation and reduces wear and tear on moving parts, extending the life of the equipment. This proactive approach minimizes downtime and maintains consistent print quality.

Q 12. What is your experience with different printing techniques (e.g., halftone, spot color)?

My experience includes various screen printing techniques, each offering unique possibilities.

- Halftone printing: This technique uses tiny dots of varying sizes and density to simulate continuous tones, enabling the reproduction of photographic images in screen printing. I understand the importance of screen ruling (dots per inch) and its impact on image resolution.

- Spot color printing: This involves using pre-mixed inks to achieve specific colors, often defined by a Pantone color code. Accuracy in color matching is crucial, and I’m skilled in mixing inks to meet exact color specifications.

- Multi-color printing: This requires precise registration to align multiple colors accurately, demanding careful alignment and setup of screens.

Understanding the strengths and limitations of each technique is essential for selecting the best approach for a given project. For instance, halftone printing is best for images with gradual tonal changes while spot color is ideal for designs requiring specific color fidelity and consistency. I adapt my technique to the project’s specific needs.

Q 13. How do you calculate the amount of ink needed for a particular print run?

Calculating ink requirements involves several factors: design complexity, print area, number of prints, and ink coverage. There’s no single formula, but a systematic approach is essential.

First, I estimate the total print area for each color. Then, I consider the ink coverage—how much of the print area is actually inked. A design with a lot of solid color will require more ink than a design with thin lines or transparent areas. The number of prints needed multiplies this area. Finally, I account for ink loss from cleaning, setup, and waste. For example, if I need 100 prints and each print requires 10ml of ink, I would increase that amount by at least 10% to account for losses. Experience helps refine this estimation, and I’ve developed a good sense of how much ink each project will consume. Maintaining accurate records of ink usage from previous projects also helps optimize future estimates.

Q 14. Explain your experience with color matching and separation.

Color matching and separation are crucial for achieving accurate and consistent prints, especially in multi-color projects.

Color matching often involves using a Pantone color matching system, referencing color swatches to select the closest ink matches. Sometimes, slight adjustments are needed to fine-tune the mix, depending on the substrate and printing conditions. I employ color separation techniques, either manually or digitally, to determine which colors need to be printed on which screen. Precise registration ensures that all the colors align accurately during printing. For example, in a four-color process (CMYK), four separate screens are created, one for each color channel (cyan, magenta, yellow, and black).

Digital color separation software can significantly improve accuracy and consistency. It allows for fine adjustments to color values and provides better control over the final output. I’m skilled in using both manual and digital color separation methods, adapting my approach to the complexity of the project and the available resources. My experience with color management ensures that final prints accurately reflect the original design.

Q 15. Describe your experience with various types of screen mesh and their applications.

Choosing the right screen mesh is crucial for achieving optimal print quality. The mesh count (threads per inch, or TPI) directly impacts the detail and ink deposit. Higher mesh counts (e.g., 156 TPI) allow for finer detail and are ideal for intricate designs and small text, but they require more pressure and can be slower. Lower mesh counts (e.g., 43 TPI) are better for printing large, bold graphics or designs that require a thicker layer of ink. They are more forgiving and faster but lack the precision of higher counts.

- Low Mesh Counts (e.g., 43-61 TPI): Used for large, bold graphics on fabrics like t-shirts or tote bags where a heavier ink deposit is desired. Think of printing a large logo on a sweatshirt.

- Medium Mesh Counts (e.g., 86-110 TPI): A versatile choice suitable for a broad range of designs, finding a balance between detail and ink deposit. Great for prints with moderate detail on t-shirts or posters.

- High Mesh Counts (e.g., 156-230 TPI): Best for fine detail, intricate designs, and halftones, suitable for designs with small text or photographic images on higher-quality apparel.

- Specialty Meshes: Some meshes are designed for specific applications, like printing on difficult-to-print fabrics or using specialty inks.

For example, I once had a project requiring extremely fine lines in a detailed illustration for a high-end fashion brand. We opted for a 230 TPI mesh to achieve the required level of detail and sharpness. Conversely, when printing large, bold designs on tote bags for a local festival, we used a 43 TPI mesh for a faster and more robust print.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are your methods for ensuring consistent print quality throughout a large print run?

Maintaining consistent print quality throughout a large run requires meticulous attention to detail and a systematic approach. It’s like baking a cake – you need the same ingredients and process each time!

- Screen Preparation: Ensuring each screen is properly tensioned and free of debris. Any inconsistencies in the mesh can lead to variations in the print.

- Ink Consistency: Mixing inks in large batches to ensure uniform color and viscosity across the entire run. Regularly checking viscosity and adjusting as needed. Using a viscosity cup can help with consistency.

- Squeegee Technique: Maintaining a consistent pressure and speed when pulling the squeegee across the screen. Training and regular quality checks of prints are essential.

- Press Settings: Keeping the press’s pressure, off-contact, and other settings consistent throughout the run. Calibrating the press is crucial, and keeping a record of these settings helps.

- Substrate Consistency: Checking fabric for variations in thickness or texture. Different substrates can absorb ink differently, necessitating adjustments.

- Regular Print Checks: Taking periodic test prints and visually inspecting them to identify and correct any potential issues early on.

For instance, during a recent run of 5000 t-shirts, we implemented a system of taking a test print every 100 shirts and visually comparing them to the initial approved print. This allowed for early detection and correction of any deviations in ink deposit, color, or registration.

Q 17. How do you handle different fabric types in screen printing?

Different fabrics require adjustments to the screen printing process to achieve optimal results. Think of it like painting on different surfaces – you’d use different techniques for canvas vs. wood.

- Cotton: A standard, relatively easy-to-print fabric. Typically requires standard inks and printing pressures.

- Polyester: Requires specialized plastisol inks designed for polyester fabrics to ensure proper adhesion and prevent cracking. May require a higher curing temperature.

- Blends: May require testing different inks and printing techniques to find the best results, depending on the blend percentage.

- Sensitive Fabrics: Delicate fabrics like silk or rayon might require lower printing pressure and softer squeegees to prevent damage.

For example, I recently printed on a blend of 50% cotton and 50% polyester. Standard plastisol inks worked well, but we had to slightly adjust the curing process to ensure full curing on the polyester fibers. For a silk scarf project, we used a softer squeegee and applied very gentle pressure to avoid damaging the fabric.

Q 18. Describe your experience with flash curing and curing processes.

Flash curing and full curing are essential steps in screen printing that ensure the ink adheres properly and the print is durable and long-lasting.

- Flash Curing: A low-temperature, short-duration curing process that partially dries the ink, allowing for the printing of multiple colors without smearing. Think of it as setting the ink before adding the next layer.

- Full Curing: A high-temperature, longer-duration curing process that fully polymerizes the ink, making the print permanent and resistant to washing and wear. This is essential for long-lasting results.

The specifics of both flash and full curing depend on the type of ink used. Plastisol inks usually require higher temperatures and longer curing times than water-based inks. I’ve worked with both conveyor belt dryers for large runs and flash cure units for smaller projects, always ensuring the appropriate temperature and dwell time for the specific ink in use. Incorrect curing can lead to cracked prints or prints that wash out easily, ruining the end product.

Q 19. How do you manage inventory of inks, screens, and other supplies?

Effective inventory management is key to smooth screen printing operations. Just like a well-stocked kitchen, you need the right ingredients to avoid delays. We use a combination of methods:

- Inventory Tracking Software: We use software to track stock levels of inks, screens, and other supplies, providing real-time data on what’s in stock and what needs reordering. This prevents running out of crucial materials during production.

- FIFO System: A ‘First In, First Out’ system is crucial to ensure inks don’t expire. Older inks are used first to minimize waste and prevent color inconsistencies.

- Regular Stock Checks: Physical inventory checks are conducted regularly to verify stock levels and identify discrepancies. This ensures the software remains accurate.

- Supplier Relationships: Maintaining strong relationships with reliable suppliers allows for timely replenishment and ensures quality materials are available.

For example, our inventory software sends automatic alerts when stock levels of a particular ink fall below a certain threshold, allowing us to order more before running out. This prevents production delays and ensures consistent color across multiple projects.

Q 20. Explain your experience working with different types of substrates.

Screen printing can be applied to a wide variety of substrates, each presenting unique challenges and requiring different techniques. Like using different brushes for different paints.

- Textiles: T-shirts, sweatshirts, tote bags, etc., are the most common substrates. Different fabrics (cotton, polyester, blends) require specific ink choices and printing parameters.

- Paper and Cardboard: Printing on paper and cardboard requires water-based or specialized inks to prevent the substrate from warping or absorbing the ink unevenly.

- Wood and Metal: These substrates may require pretreatment (like a primer) and special inks designed for adhesion to these surfaces.

- Plastics: Plastic substrates can be more challenging to print on due to their potential to warp or release gases during the curing process. Special low-cure inks may be required.

For instance, when printing on wood panels, we used a specialized primer to help the ink adhere better and prevent it from soaking into the wood grain. The type of primer and ink selection depends on the type of wood and the desired finish.

Q 21. How do you ensure the safety of yourself and your colleagues during the screen printing process?

Safety is paramount in screen printing. We follow strict procedures to minimize risks to ourselves and our colleagues:

- Proper Ventilation: Well-ventilated areas are crucial to minimize exposure to ink fumes and other chemicals. We use exhaust fans and work in spaces with adequate airflow.

- Personal Protective Equipment (PPE): Gloves, eye protection, and respirators are always worn when handling inks and chemicals. This protects against skin irritation, eye damage, and inhalation of harmful particles.

- Safe Handling of Chemicals: Following the manufacturer’s instructions carefully for all inks and chemicals, including proper storage and disposal.

- Emergency Procedures: Having readily available safety data sheets (SDS) and emergency response plans in place in case of accidents or spills.

- Regular Maintenance of Equipment: Regularly checking and maintaining our equipment ensures safe operation, prevents breakdowns, and avoids potential hazards.

For example, we always have a spill kit readily available in case of ink spills, and we conduct regular training sessions to refresh our team on safety procedures. Our goal is to ensure a safe and healthy work environment for everyone.

Q 22. Describe your experience with pre-press preparation for screen printing jobs.

Pre-press preparation in screen printing is crucial for a successful print run. It’s like meticulously preparing a recipe before cooking – the better the prep, the better the final product. This stage involves several key steps:

Film Separations: Converting the artwork (usually a digital file) into individual films, one for each color in the design. This ensures each color is printed accurately and in the correct registration (alignment).

Film Output: Printing these separations onto high-resolution film positives. This step demands precise detail as any imperfections will show up on the final print. I use high-resolution film printers capable of producing sharp, clean separations.

Proofing: Creating a physical proof, often using a smaller-scale test print, to verify color accuracy and registration before proceeding to screen preparation. This is invaluable in avoiding costly mistakes later.

Screen Preparation: This includes coating the screens with emulsion, exposing them to light through the film positives to create the image, and washing away the unexposed emulsion to reveal the design. This demands careful attention to detail to prevent defects such as pinholes or clogged areas.

For example, I once worked on a project with a complex design involving gradients and fine details. Thorough pre-press preparation, including careful film creation and multiple test prints, ensured perfect color transitions and crisp lines in the final print, avoiding expensive re-runs.

Q 23. What software are you familiar with for creating and preparing screen printing designs?

I’m proficient in several software packages essential for screen printing design and preparation. My expertise includes:

Adobe Illustrator: This is my go-to software for creating vector-based artwork. Its precision and scalability are critical for producing high-quality screen printing designs. I frequently use it for creating sharp lines, intricate details, and accurate color separations.

Adobe Photoshop: Used for raster-based image editing, color correction, and retouching. It’s invaluable for preparing photographic images for screen printing, ensuring optimal color balance and resolution. I use it to fine-tune images before separating them for printing.

CorelDRAW: Another vector-based program, often used as an alternative to Illustrator. Its ability to handle complex designs and precise color separations makes it a valuable tool.

RIP Software (Raster Image Processor): Essential for preparing the final output files for film exposure, ensuring proper resolution and color profile.

For instance, when preparing artwork with many fine details, I would use Illustrator to ensure the lines are crisp and scalable to the size of the print. Then, I’d use Photoshop to adjust color balance and ensure the images have the proper resolution for screen printing.

Q 24. How do you handle emergency situations or equipment malfunctions?

Handling emergencies is a critical skill in screen printing. My approach is systematic and prioritizes safety and minimizing downtime.

Assessment: First, I quickly assess the nature of the malfunction. Is it a minor issue, or something requiring immediate attention and perhaps a call to a technician?

Troubleshooting: I draw on my experience to troubleshoot common problems. For example, a clogged screen might be remedied with a thorough cleaning; a malfunctioning dryer might have a simple fix like a tripped circuit breaker. I always refer to equipment manuals for detailed troubleshooting instructions.

Safety First: If the problem involves potential safety hazards (like electrical malfunctions), I prioritize safety, immediately turning off the equipment and contacting qualified personnel.

Alternative Solutions: If a critical piece of equipment fails, I explore alternative solutions to maintain productivity. This could involve adjusting the workflow or using backup equipment if available.

Documentation: After resolving the issue, I document the problem, the solution, and any preventative measures that can be taken to avoid similar problems in the future. This helps to improve efficiency and reduce downtime.

For example, during a rush job, our dryer malfunctioned. After confirming the problem wasn’t a simple fix and ensuring everyone was safe, I adjusted the workflow, prioritizing orders that didn’t require the dryer until the repair was completed. Communication was key to maintaining customer satisfaction during the unexpected downtime.

Q 25. What is your experience with quality control checks throughout the screen printing process?

Quality control is paramount in screen printing. I implement checks at every stage of the process to ensure consistent, high-quality results.

Pre-Press Inspection: Thorough review of the artwork and films to catch any errors before screen production.

Screen Inspection: Checking the screens for pinholes, clogged areas, or any other defects after emulsion coating and exposure. Any irregularities are immediately addressed.

Ink Consistency: Regularly checking the viscosity and color consistency of the inks. This ensures a uniform print throughout the run.

Registration Checks: Throughout the print run, I verify accurate registration, ensuring each color is precisely aligned.

Spot Checks: Taking periodic samples from the print run to check color accuracy and consistency. This helps catch potential issues before they become widespread problems.

Final Inspection: A final quality check of the complete print run to ensure all pieces meet standards before packaging and shipment.

If an issue is found during any of these checks, I immediately investigate the cause, correct the problem, and monitor subsequent prints to verify the correction. A systematic approach to quality control is essential for delivering high-quality products and maintaining a good reputation.

Q 26. Describe your problem-solving skills in relation to screen printing challenges.

Problem-solving is integral to screen printing. My approach is systematic and data-driven.

Identify the Problem: Clearly define the issue. Is it a color mismatch, registration problems, ink consistency issues, or something else?

Gather Information: Collect relevant data. This might include examining the artwork, the screens, the inks, and the printing equipment. Consider factors such as print speed, pressure, and squeegee technique.

Develop Solutions: Based on the gathered information, brainstorm potential solutions. This could involve adjusting ink viscosity, changing the screen mesh count, tweaking the printing pressure or speed, or even replacing a defective screen.

Test and Evaluate: Test the proposed solutions and evaluate their effectiveness. I carefully document the results to track progress and ensure the chosen solution works.

Implement and Monitor: Once a satisfactory solution is identified, implement it consistently across the print run and continuously monitor the results to prevent future recurrences.

For example, I once encountered inconsistent color reproduction on a large order. By systematically analyzing the inks, screens, and printing settings, I identified a slight variation in ink viscosity. After adjusting the ink and carefully monitoring the prints, the issue was resolved, preventing a significant setback.

Q 27. How do you stay updated with the latest advancements and techniques in screen printing?

Staying current in the screen printing industry is crucial. I actively engage in several methods to remain updated:

Industry Publications and Websites: I regularly read trade magazines and websites dedicated to screen printing, keeping abreast of new technologies, techniques, and best practices. This helps me understand trends and innovations in the field.

Trade Shows and Conferences: Attending industry events allows me to learn about the latest equipment, inks, and techniques firsthand and network with other professionals.

Online Courses and Workshops: I participate in online courses and workshops focusing on advanced techniques, such as water-based printing or specialty inks. This helps to continuously develop my skills and expertise.

Networking with Peers: I actively participate in online forums and communities, exchanging ideas and best practices with other professionals in the field.

For instance, recently I learned about a new type of eco-friendly ink from an industry publication and quickly integrated it into my workflow, enhancing my company’s commitment to sustainable practices.

Key Topics to Learn for Screen Printing Setup Interview

- Screen Preparation: Understanding different screen mesh counts, emulsion application techniques, and proper exposure methods for optimal print results. Practical application includes troubleshooting exposure issues and achieving consistent emulsion thickness.

- Image Preparation and Film Positives: Creating accurate and high-resolution film positives, including color separation techniques and understanding the importance of proper registration marks. Practical application involves working with design software and preparing files for screen printing.

- Ink Selection and Mixing: Knowledge of different ink types (plastisol, water-based, discharge), their properties, and appropriate mixing techniques for achieving desired color and viscosity. Practical application includes color matching and troubleshooting print inconsistencies related to ink.

- Press Setup and Registration: Understanding the mechanics of screen printing presses, including proper screen clamping, off-contact adjustments, and achieving accurate registration between colors. Practical application involves setting up the press for different print jobs and troubleshooting registration issues.

- Squeegee Technique and Print Pressure: Mastering proper squeegee pressure, angle, and speed to achieve consistent ink deposit and avoid defects. Practical application includes understanding the impact of different squeegee techniques on print quality.

- Troubleshooting and Quality Control: Identifying and resolving common screen printing problems such as pinholes, clogging, and misregistration. Practical application involves implementing quality control measures throughout the printing process.

- Safety Procedures and Equipment Maintenance: Understanding and adhering to safety protocols related to ink handling, press operation, and equipment maintenance. Practical application involves performing routine maintenance tasks and identifying potential safety hazards.

Next Steps

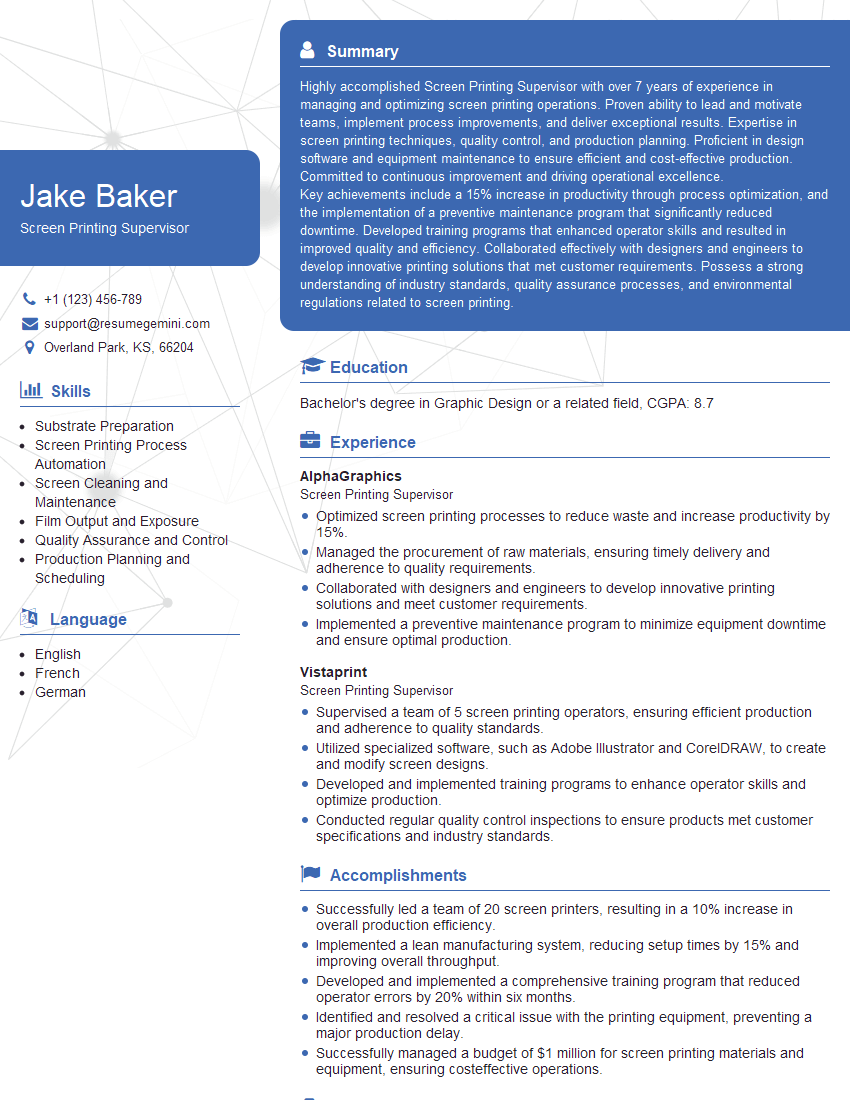

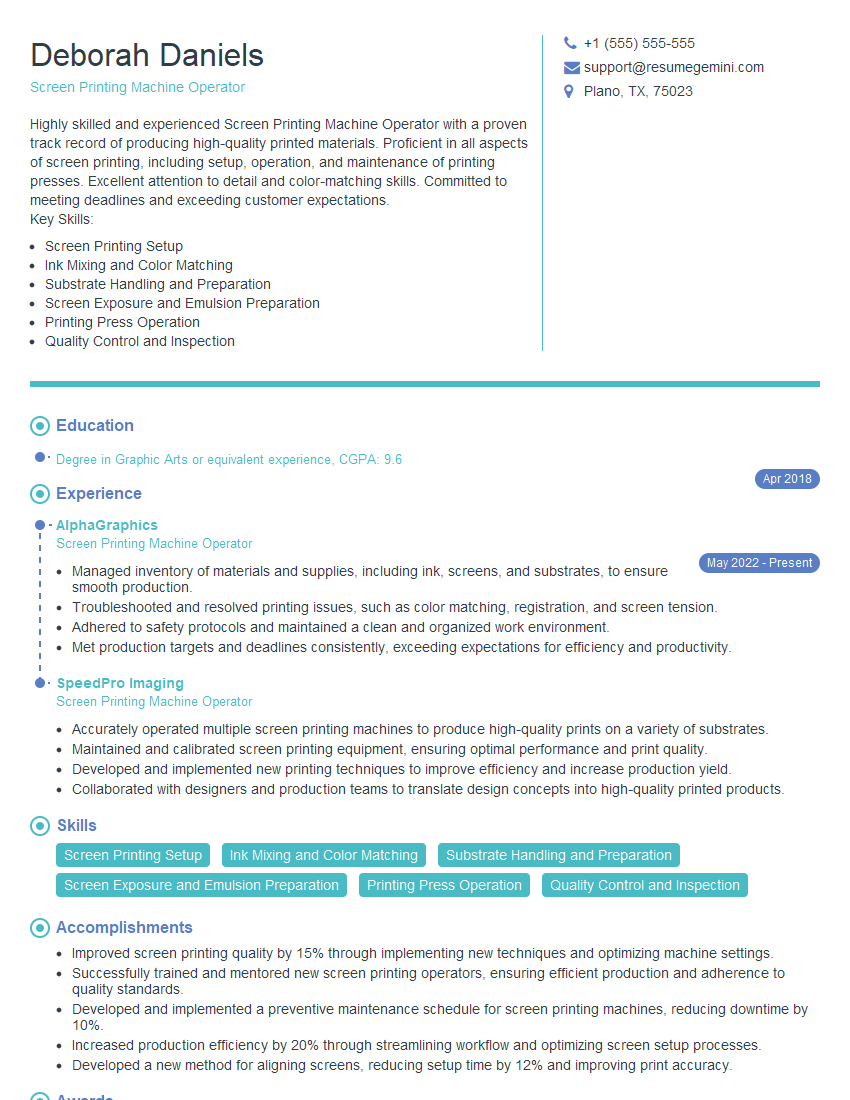

Mastering screen printing setup is crucial for a successful and rewarding career in the graphic arts industry. Proficiency in this area significantly increases your value to employers and opens doors to more challenging and well-compensated roles. To maximize your job prospects, it’s essential to have an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource for building professional resumes that get noticed. They offer examples of resumes tailored to Screen Printing Setup, helping you present your qualifications in the best possible light. Take the next step towards your dream job today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good