The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Transonic Flow Simulation interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Transonic Flow Simulation Interview

Q 1. Explain the differences between subsonic, transonic, supersonic, and hypersonic flows.

The speed of a flow relative to the speed of sound determines its classification. Subsonic flow is slower than the speed of sound (Mach number < 1), characterized by smooth, gradual changes in pressure and velocity. Supersonic flow is faster than the speed of sound (Mach number > 1), where abrupt changes occur, forming shock waves. Transonic flow sits in between, encompassing speeds around the speed of sound (Mach number approximately 0.8 to 1.2), exhibiting a complex mixture of subsonic and supersonic regions within the flow field. Hypersonic flow represents extremely high speeds, typically Mach 5 or higher, where significant thermal effects come into play. Think of a passenger jet being subsonic, a fighter jet potentially transonic or supersonic, and a spacecraft re-entering the atmosphere being hypersonic.

- Subsonic: Smooth flow, gradual pressure changes.

- Transonic: Mixture of subsonic and supersonic regions, shock waves possible.

- Supersonic: Shock waves present, abrupt changes.

- Hypersonic: Extremely high speeds, significant heat transfer.

Q 2. Describe the phenomenon of shock waves in transonic flow.

In transonic flow, shock waves appear as abrupt changes in pressure, temperature, and velocity. They form when the flow accelerates locally to supersonic speeds and then decelerates back to subsonic speeds. This deceleration process generates a compression wave that steepens into a discontinuity, known as a shock wave. The strength of the shock wave depends on the Mach number and the flow geometry. A stronger shock leads to greater energy dissipation in the form of heat. Imagine throwing a pebble into a calm lake; the initial disturbance creates ripples, similar to how compression waves form. However, in transonic flow, these waves can coalesce into a strong shock wave, like a larger splash.

These shocks can be either normal (perpendicular to the flow) or oblique (angled to the flow), depending on the angle of the supersonic flow region relative to the surface. The presence of shock waves leads to increased drag and can cause significant structural stresses on aerospace vehicles.

Q 3. What are the challenges associated with simulating transonic flows using CFD?

Simulating transonic flows using Computational Fluid Dynamics (CFD) presents several unique challenges. The primary difficulty stems from the mixed subsonic and supersonic nature of the flow field. This necessitates numerical schemes capable of handling both smooth and discontinuous solutions. The nonlinearity of the governing equations (Euler and Navier-Stokes) exacerbates this problem, resulting in convergence issues and potential instability. Furthermore, the presence of shock waves introduces significant challenges in grid resolution and numerical diffusion. Accurate capturing of shock waves without excessive numerical diffusion requires very fine meshes near the shock, increasing computational expense.

- Mixed Subsonic/Supersonic flow: Requires sophisticated numerical schemes.

- Nonlinearity: Can lead to convergence issues and instabilities.

- Shock Wave Capturing: Needs fine meshes to avoid numerical diffusion.

- Turbulence modeling: Accurate representation of turbulence is crucial, but challenging.

Q 4. What turbulence models are commonly used in transonic flow simulations, and what are their limitations?

Several turbulence models are employed in transonic flow simulations, each with its own strengths and limitations. The choice depends heavily on the specific application and computational resources. Common models include:

- k-ε model: A relatively simple two-equation model, computationally inexpensive, but can be inaccurate near shocks and in regions of separation.

- k-ω SST model: An improved version of the k-ε model, better performance in boundary layers and separation regions, but still might be inaccurate near very strong shocks.

- Detached Eddy Simulation (DES): A hybrid approach combining RANS and LES (Large Eddy Simulation) offering reasonable accuracy at a moderate computational cost, but its performance can be sensitive to mesh resolution.

- Large Eddy Simulation (LES): Resolves the large scales of turbulence directly, offering high accuracy but comes with significant computational costs and often requires highly refined meshes.

Generally, the limitations involve balancing accuracy with computational cost. Simpler models are faster but less accurate, while more sophisticated models demand more resources.

Q 5. How do you handle the computational cost of simulating transonic flows?

Managing the computational cost of transonic flow simulations involves employing strategies to optimize the computational process. These include:

- Adaptive mesh refinement (AMR): Refine mesh only in regions of high gradients (near shocks), reducing the overall number of cells.

- Multigrid methods: Accelerate convergence by solving the equations on multiple grid levels simultaneously.

- Implicit schemes: Allow for larger time steps compared to explicit schemes, reducing simulation time. However, they can require more memory.

- High-performance computing (HPC): Utilizing parallel computing architectures to distribute computational load across multiple processors dramatically reduces overall simulation time.

- Reduced-order modeling (ROM): Creating simplified models that capture essential flow features with much lower computational costs. This typically involves generating a low-dimensional representation of the high-dimensional CFD model.

The best strategy often involves a combination of these techniques, tailored to the specific problem and available resources.

Q 6. Explain the concept of critical Mach number and its significance in transonic flow.

The critical Mach number (Mcrit) is the freestream Mach number at which the local flow velocity first reaches Mach 1 somewhere on the body’s surface. It marks the onset of transonic flow, where both subsonic and supersonic regions coexist. Its significance lies in its impact on aerodynamic characteristics. Below Mcrit, the flow remains entirely subsonic. Above Mcrit, the flow becomes increasingly complex, with shock waves appearing and significantly impacting drag and lift. For example, exceeding Mcrit can lead to a rapid increase in drag, limiting the efficiency of an aircraft. Therefore, careful consideration of Mcrit is crucial in aircraft design. Engineers actively work to minimize drag penalties associated with transonic flow by optimizing the shape of aircraft components.

Q 7. Describe different numerical schemes used for solving the Euler and Navier-Stokes equations in transonic flow simulations.

Several numerical schemes are employed to solve the Euler and Navier-Stokes equations in transonic flow simulations. The choice depends on factors like accuracy requirements, computational cost, and the presence of shocks. Common schemes include:

- Finite Difference Methods: Discretize the equations on a structured grid using difference operators. Examples include central difference schemes (e.g., Lax-Wendroff) and upwind schemes (e.g., Roe scheme, flux-vector splitting). Upwind schemes handle shocks better than central difference methods.

- Finite Volume Methods: Discretize the equations over control volumes, offering flexibility for complex geometries. They are widely used, and popular choices include the Roe flux difference splitting and the Osher scheme, which are designed to handle shocks accurately.

- Finite Element Methods: Discretize the equations using element-wise basis functions, providing versatility for complex geometries and boundary conditions. However, they can be computationally more expensive than finite volume methods.

For shock capturing, methods like artificial viscosity or flux limiters are often incorporated into these schemes to control numerical oscillations near discontinuities without excessive smearing of the shocks. The selection of an appropriate scheme involves careful consideration of its ability to handle the mixed subsonic/supersonic nature of transonic flows, its shock capturing capability, and its computational efficiency.

Q 8. How do you validate and verify your transonic flow simulations?

Validating and verifying transonic flow simulations is crucial to ensure the accuracy and reliability of our predictions. Verification focuses on whether the code solves the equations correctly, while validation assesses if the simulation accurately represents the real-world phenomenon.

Verification often involves:

- Code Verification: We use techniques like method of manufactured solutions (MMS) where we insert a known solution into the governing equations and verify if the solver reproduces it accurately. Discrepancies highlight potential coding errors.

- Grid Convergence Study: We systematically refine the mesh and observe the convergence of the solution. A properly converged solution should show minimal change with further refinement.

Validation relies on comparing simulation results with experimental data:

- Comparison with Experimental Data: We compare key parameters like pressure coefficients, Mach number distributions, and shock locations from the simulation against experimental measurements from wind tunnels or flight tests. The closer the match, the higher the confidence in the simulation’s accuracy.

- Uncertainty Quantification: We quantify uncertainties associated with both the experimental data and the numerical simulation (e.g., mesh resolution, turbulence modeling). This helps us understand the range of possible solutions and the level of confidence we can place in the results.

For example, in simulating flow over an airfoil, we might compare the predicted lift and drag coefficients against wind tunnel measurements. Significant discrepancies would trigger further investigation of the simulation setup, mesh quality, or turbulence model.

Q 9. What is the role of mesh refinement in improving the accuracy of transonic flow simulations?

Mesh refinement plays a pivotal role in improving the accuracy of transonic simulations, especially around regions of high gradients like shocks. In transonic flow, small changes in pressure and velocity can lead to significant changes in the flow structure. A coarse mesh may fail to adequately capture these sharp changes, leading to inaccurate shock location and strength.

Refining the mesh near shocks allows the simulation to resolve these discontinuities more accurately. This is often done using adaptive mesh refinement (AMR) techniques. AMR dynamically refines the mesh only in areas where high gradients are detected, improving accuracy without incurring the computational cost of uniformly refining the entire mesh.

Imagine trying to draw a sharp line with a thick marker versus a thin one. The thick marker misses the detail, like a coarse mesh missing the shock details. A refined mesh is analogous to using a thin marker to precisely capture the details.

However, over-refinement can be computationally expensive. A good balance needs to be found between accuracy and computational efficiency through grid independence studies. We run simulations with progressively finer meshes, until the solution converges to within an acceptable tolerance, showing that further refinement does not significantly alter the solution.

Q 10. Explain the concept of artificial viscosity and its application in transonic simulations.

Artificial viscosity is a numerical technique used in computational fluid dynamics (CFD) to stabilize simulations, particularly in transonic flows where shocks can cause oscillations and numerical instability. In reality, shocks are inherently dissipative, but the numerical schemes used to solve the governing equations may not inherently capture this dissipation.

Artificial viscosity adds a small amount of viscosity to the numerical solution, effectively smoothing out sharp gradients and stabilizing the solution. This doesn’t mean we are simulating a more viscous flow; instead, it’s a mathematical trick to help the solver converge to a stable solution. Think of it as a numerical lubricant to prevent the simulation from ‘grinding to a halt’.

Different methods exist to introduce artificial viscosity, often expressed as a term added to the governing equations. These techniques vary in complexity and the way they add artificial viscosity; some methods adapt the amount of viscosity added based on local flow conditions.

The appropriate level of artificial viscosity is crucial; too little may lead to unstable oscillations and inaccurate solutions, while too much can over-smooth the solution and obscure important flow features.

Q 11. How do you handle boundary conditions in transonic flow simulations?

Handling boundary conditions in transonic simulations is critical as they significantly influence the solution. Inaccurate or inappropriate boundary conditions can lead to erroneous results. We carefully select boundary conditions based on the specific problem and the surrounding environment.

For example, at the far-field boundaries (boundaries sufficiently far from the object of interest), we often specify freestream conditions (velocity, pressure, temperature). At the surface of the object, we may apply no-slip conditions (velocity is zero at the surface) and adiabatic (no heat transfer) or isothermal (constant temperature) conditions. The choice is largely guided by the physical problem at hand.

Special care is required for outflow boundaries where the flow leaves the computational domain. Improper outflow conditions can cause reflections of disturbances back into the domain. To mitigate this we often use non-reflecting boundary conditions or outflow conditions that allow a smooth exit of the flow, preventing numerical artefacts that can disrupt the solution.

Moreover, symmetry boundary conditions can be utilized for problems featuring symmetry.

Q 12. What are the common types of boundary conditions used in transonic flow simulations?

Common boundary conditions in transonic flow simulations include:

- Inlet Boundary Conditions: Specify the inflow velocity, pressure, temperature, and turbulence properties. These conditions represent the freestream flow entering the computational domain.

- Outlet Boundary Conditions: Allow for the outflow of fluid from the computational domain. Common types include pressure-based (specify a static pressure), convective (allows flow to smoothly exit without reflections), or characteristic boundary conditions.

- Wall Boundary Conditions: Applied at solid surfaces. No-slip conditions (zero velocity at the wall) are usually employed, along with either adiabatic (no heat transfer) or isothermal (constant temperature) thermal conditions.

- Symmetry Boundary Conditions: Used for symmetric geometries to reduce computational costs by modeling only half the geometry.

- Periodic Boundary Conditions: Used when the flow is periodic, for example in simulations of turbomachinery blades.

The appropriate selection of boundary conditions is crucial for accurate and meaningful results.

Q 13. Describe the role of experimental data in validating CFD simulations of transonic flow.

Experimental data plays a vital role in validating CFD simulations of transonic flow, providing a crucial benchmark for assessing the accuracy and reliability of the numerical predictions. Without this validation, simulations remain theoretical exercises with unknown accuracy.

Experimental data, typically acquired through wind tunnel testing, provides measurements of flow quantities like pressure distribution, Mach number, and forces (lift and drag) on the object under investigation. These measurements are then compared directly with the corresponding results from the CFD simulation.

The degree of agreement between the simulation and experiment serves as a measure of validation. Discrepancies may indicate issues with the CFD model (numerical scheme, turbulence model, mesh resolution), the experimental setup, or both. For example, a discrepancy in shock location might necessitate a refinement of the mesh or the use of a more appropriate turbulence model. It is important to thoroughly analyze these discrepancies.

Analyzing the uncertainties associated with both the experiment (measurement errors) and the simulation (numerical errors) is crucial for a proper validation assessment.

Q 14. Explain the concept of shock capturing and shock fitting methods.

Shock capturing and shock fitting are two distinct methods used to handle shocks in transonic flow simulations. Shocks are discontinuities in flow properties, and accurately resolving them is critical for simulation accuracy.

Shock Capturing: This method utilizes numerical schemes that implicitly capture the shock as a smooth transition. The shock is represented by a rapid but continuous change in flow properties across several grid cells. This approach is simpler to implement but can suffer from numerical diffusion and may not accurately resolve the shock thickness and location. Examples include various high-resolution schemes like TVD (Total Variation Diminishing) or WENO (Weighted Essentially Non-Oscillatory) schemes.

Shock Fitting: This method explicitly locates and tracks the shock. The shock is treated as a distinct entity. The flow is solved separately on either side of the shock, and jump conditions across the shock are imposed to ensure conservation. Shock fitting generally provides higher accuracy for shock location and strength, but it’s significantly more complex to implement and can be computationally expensive, especially for unsteady flows with moving shocks.

The choice between shock capturing and shock fitting depends on the specific problem, desired accuracy, and computational resources. For many engineering applications, shock capturing is sufficient. However, for scenarios demanding high accuracy, such as detailed analysis of shock waves, shock fitting might be necessary.

Q 15. What are the common sources of error in transonic flow simulations?

Errors in transonic flow simulations stem from several sources, broadly categorized as numerical, modeling, and physical uncertainties. Numerical errors arise from the discretization of governing equations (like the Navier-Stokes equations), mesh quality, and the choice of numerical scheme. For example, using a low-order scheme can lead to significant numerical diffusion and smearing of shock waves, critical features in transonic flows. Modeling errors come from simplifications made in representing the physics. This includes turbulence modeling (e.g., choosing an inappropriate turbulence model like k-epsilon for complex separated flows), neglecting real gas effects (air at transonic speeds isn’t exactly an ideal gas), and inaccurate boundary condition specifications. Finally, physical uncertainties relate to the inherent lack of precise knowledge of inlet conditions, surface roughness, or even the precise geometry of the aircraft wing.

- Numerical Errors: Insufficient mesh resolution near shocks can lead to inaccurate shock capture. Poor mesh quality (skewness, aspect ratio) degrades solution accuracy.

- Modeling Errors: Using a simplified turbulence model for a complex flow may lead to inaccurate predictions of drag and lift.

- Physical Uncertainties: Small variations in surface roughness can significantly impact the flow, yet are difficult to precisely model.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you identify and diagnose errors in transonic flow simulations?

Diagnosing errors requires a systematic approach. First, we verify the mesh quality: high aspect ratios or skewed cells can cause significant errors. Next, we examine the solution itself. Are there any non-physical oscillations or unrealistic gradients? Shock waves should be captured sharply, not smeared out. Convergence history is crucial; slow or non-convergence indicates a problem. Comparing results with experimental data or results from other validated codes helps pinpoint discrepancies. Grid refinement studies are essential to assess the impact of mesh resolution on the solution’s accuracy. For instance, if refining the mesh doesn’t significantly alter the results, it suggests numerical errors are not the primary source of inaccuracy. Visualization tools are invaluable. Examining pressure, Mach number, and density contours can highlight regions of potential errors. Residual plots should decay to a specified level, indicating convergence. Finally, systematic code verification techniques, like comparing the simulation results with analytical solutions for simplified cases, are necessary.

Q 17. What are some advanced techniques for improving the accuracy and efficiency of transonic flow simulations?

Several advanced techniques enhance transonic flow simulations. Higher-order numerical schemes (e.g., essentially non-oscillatory (ENO) or weighted essentially non-oscillatory (WENO) schemes) provide sharper shock resolution with less numerical diffusion compared to lower-order schemes. Adaptive mesh refinement (AMR) focuses computational resources on regions of high gradients (e.g., near shocks), increasing accuracy without excessive mesh density. Implicit methods, while computationally more expensive per iteration, allow for larger time steps, accelerating convergence. Multigrid methods accelerate convergence by solving the problem on multiple grid levels simultaneously. For viscous effects, detached eddy simulation (DES) or large eddy simulation (LES) provide more accurate turbulence modeling than RANS models for complex separated flows. Using more sophisticated equations of state that accurately reflect real gas effects improves results, particularly near the sonic region where density changes are significant. Furthermore, incorporating advanced boundary layer models near walls improves the prediction of skin friction and heat transfer.

Q 18. Explain the concept of compressibility effects in transonic flow.

Compressibility effects are significant in transonic flows because the flow speed approaches the speed of sound. As the flow accelerates to sonic conditions (Mach number near 1), density changes become significant. This contrasts with incompressible flows where density is assumed constant. These density changes influence pressure gradients and ultimately, the flow behavior. For example, a small increase in velocity near the speed of sound produces a substantial increase in pressure and density, leading to the formation of shock waves – abrupt changes in pressure, temperature, and density – that dissipate energy. The presence of these shocks is a defining characteristic of transonic flow and necessitates advanced numerical techniques for accurate simulation.

Q 19. Describe the influence of Reynolds number on transonic flow simulations.

The Reynolds number (Re) quantifies the ratio of inertial forces to viscous forces in a flow. In transonic simulations, Re strongly influences the boundary layer behavior. A higher Re indicates a thinner boundary layer and a more significant role for turbulence. This impacts shock wave-boundary layer interactions which are crucial in transonic flows. For instance, a shock wave interacting with a turbulent boundary layer can lead to flow separation, significantly affecting lift and drag characteristics. Accurately resolving the boundary layer requires sufficient mesh resolution, particularly at high Re. The choice of turbulence model also becomes critical at higher Reynolds numbers. Simple models may not capture the complexities of turbulent flow at such conditions, leading to inaccurate results.

Q 20. How do you account for viscous effects in transonic flow simulations?

Viscous effects, primarily in the boundary layer near solid surfaces, are accounted for by solving the Reynolds-Averaged Navier-Stokes (RANS) equations, or, for more complex flows, large eddy simulations (LES) or detached eddy simulations (DES). These equations explicitly incorporate the viscous terms, modeling the shear stresses. The challenge lies in modeling the turbulent stresses, often done through turbulence models (like k-epsilon, k-omega SST). The selection of the appropriate turbulence model is crucial for accuracy. The resolution of the boundary layer is another important factor; a sufficiently fine mesh is needed near the walls to resolve the velocity gradients accurately. Wall functions are often used to bridge the gap between the first mesh point and the wall to avoid resolving the very thin viscous sublayer, improving computational efficiency. Incorporate wall functions with caution, as they make assumptions about the boundary layer profile. For very high Reynolds numbers or flows with complex separation, LES or DES offer higher accuracy but significantly increase computational cost.

Q 21. Explain the differences between structured and unstructured meshes in transonic flow simulations.

Structured meshes consist of regularly ordered cells, typically quadrilaterals in 2D and hexahedra in 3D. They are easy to generate for simple geometries but become difficult and inefficient for complex shapes. Unstructured meshes, on the other hand, use a variety of cell shapes (triangles, quadrilaterals in 2D; tetrahedra, hexahedra, prisms in 3D) and are more flexible for complex geometries. Structured meshes are advantageous for simpler geometries due to their efficiency in solving the governing equations and their ease of implementation of higher-order numerical schemes. However, unstructured meshes provide greater flexibility for modeling complex shapes. The choice depends on the complexity of the geometry and the desired accuracy. For very complex geometries, unstructured meshes are almost necessary, even though the solution algorithm might be more computationally intensive. In transonic simulations with complex geometries such as aircraft wings or airfoils with flaps, unstructured meshes are often preferred because of their ability to resolve complex flow features effectively. However, they require more computational resources than structured meshes.

Q 22. What are the advantages and disadvantages of different meshing techniques for transonic flow?

Meshing is crucial in transonic flow simulations because it directly impacts accuracy and computational cost. The choice depends on the complexity of the geometry and the desired level of detail. Common techniques include structured, unstructured, and hybrid meshes.

- Structured meshes are highly ordered and easy to generate for simple geometries. They offer excellent computational efficiency but can struggle with complex shapes, requiring extensive manual intervention or the use of sophisticated mesh generation algorithms to handle intricate details like sharp corners. This can lead to inaccuracies and mesh skewness issues impacting results near these features.

- Unstructured meshes are more flexible and can adapt to complex geometries more easily. However, they generally require more computational resources than structured meshes due to the irregularity in cell arrangement. They excel in resolving fine details, resulting in higher accuracy for complex configurations. Generating high-quality unstructured meshes for transonic flows requires careful attention to cell size distribution, aspect ratio, and smoothness.

- Hybrid meshes combine the advantages of both structured and unstructured approaches. For instance, a structured mesh could be employed for the smooth regions of the airfoil, while an unstructured mesh handles the wake and complex areas. This provides a compromise between accuracy and efficiency, enabling focused mesh refinement where it’s most needed. However, managing hybrid meshes can increase complexity in the mesh generation process.

The choice of meshing technique often involves a trade-off between accuracy, computational cost, and ease of mesh generation. The mesh resolution, particularly near shock waves and boundary layers, heavily influences the simulation accuracy. Too coarse of a mesh will miss crucial flow features, while excessive refinement adds unnecessary computation time.

Q 23. Describe different types of solvers used for transonic flow simulations (e.g., implicit vs. explicit).

Transonic flow simulations utilize various solver types, each with its strengths and weaknesses. A key distinction lies between implicit and explicit solvers:

- Implicit solvers solve the governing equations simultaneously for all points in the computational domain. This allows for larger time steps, leading to faster convergence but can require more memory and more complex computations for each iteration. They are generally preferred for steady-state transonic simulations as they are robust and provide stable solutions for large time steps.

- Explicit solvers solve the governing equations sequentially at each point. They are easier to implement but usually require smaller time steps for stability, leading to longer computation times. Explicit solvers are often better suited for transient or unsteady simulations where capturing dynamic flow changes is crucial.

Beyond the implicit/explicit dichotomy, different numerical schemes are employed to discretize the governing equations (Navier-Stokes equations). Common schemes include finite volume, finite difference, and finite element methods. Each approach has its advantages and disadvantages concerning accuracy, computational cost, and suitability for various flow regimes. For instance, higher-order schemes such as MUSCL (Monotone Upstream-centered Schemes for Conservation Laws) are often preferred for capturing shocks accurately in transonic flows, but their computational cost is higher compared to lower-order schemes.

Q 24. Explain the concept of convergence in transonic flow simulations.

Convergence in a transonic flow simulation refers to the state where the solution no longer changes significantly with further iterations of the solver. It indicates that the numerical solution has reached a stable approximation to the actual physical flow. In other words, the residuals — the difference between the left and right-hand sides of the governing equations at each point — decrease to a specified tolerance. Reaching convergence is crucial because it ensures the solution represents a valid physical solution and is not simply an artifact of the numerical method.

Achieving convergence in transonic simulations can be challenging due to the presence of shock waves and their non-linear behaviour. The flow can oscillate and struggle to reach a steady state. Effective convergence requires careful selection of solver parameters and numerical schemes, a well-refined mesh, and appropriate boundary conditions.

Q 25. How do you assess the convergence of your transonic flow simulations?

Assessing convergence involves monitoring several key parameters throughout the simulation:

- Residuals: Plotting the residuals over iterations provides a clear indication of the solution’s trend. The residuals should decrease to a pre-defined tolerance (usually several orders of magnitude below the initial value). A plateau or erratic behavior in the residual plot suggests convergence issues that need attention.

- Lift and drag coefficients: For airfoil simulations, the convergence of lift and drag coefficients is a crucial indicator. Fluctuations in these values, after the initial transient period, suggest that the simulation hasn’t reached a steady state. These values should stabilize within a defined tolerance as the simulation converges.

- Flow field variables: Examining the convergence of key flow variables like Mach number, pressure, and density at specific points within the domain provides additional insights. Their values should also reach a steady state as the simulation converges.

It’s important to remember that visual inspection of the flow field is essential. A converged solution should exhibit physically realistic flow features such as smooth streamlines (except at shocks) and proper shock locations. Often, a combination of quantitative (residuals, coefficients) and qualitative (visual inspection) checks is necessary to confidently declare convergence.

Q 26. Describe your experience with different CFD software packages used for transonic flow simulations.

My experience encompasses several industry-standard CFD packages. I’m proficient in ANSYS Fluent, OpenFOAM, and XFOIL. Each package offers unique capabilities and strengths for transonic flow simulations.

- ANSYS Fluent is a robust, commercially available package providing a wide range of turbulence models, meshing options, and post-processing tools, making it suitable for complex geometries and flow conditions. Its user-friendly interface and extensive documentation make it well-suited for both experienced users and those new to the field.

- OpenFOAM is an open-source CFD toolbox known for its flexibility and extensibility. It allows for custom solver development and advanced features like adaptive mesh refinement. While it requires a steeper learning curve due to its command-line interface and flexibility, it offers greater customization and allows for highly specialized solutions.

- XFOIL is a specialized panel code specifically designed for airfoil analysis. While simpler than the other packages, it provides rapid results suitable for preliminary design studies and quick estimations of aerodynamic characteristics of airfoils in transonic flight. However, it is less suited for complex three-dimensional geometries and the inclusion of viscous effects.

My choice of software depends on the specific project requirements, considering factors like geometry complexity, computational resources, required accuracy, turnaround time, and available expertise. Often, I might use XFOIL for preliminary investigations then proceed to ANSYS Fluent or OpenFOAM for more detailed and computationally intensive simulations.

Q 27. Explain how you would approach a transonic flow simulation problem for a specific airfoil or aircraft component.

Approaching a transonic flow simulation for an airfoil or aircraft component involves a systematic workflow.

- Geometry Preparation: The geometry needs to be cleaned and prepared for mesh generation. This includes removing any inconsistencies or errors in the CAD model.

- Mesh Generation: A suitable mesh is generated using the chosen technique (structured, unstructured, or hybrid) considering the flow characteristics. Fine meshing is required near leading and trailing edges, as well as around expected shock locations. The goal is to balance computational cost and accuracy.

- Solver Setup: The appropriate solver type (implicit or explicit), turbulence model (e.g., k-ω SST, Spalart-Allmaras), and numerical scheme are selected based on the flow characteristics and desired level of detail. Boundary conditions like freestream velocity, pressure, and temperature are defined.

- Simulation Run: The simulation is run, monitoring convergence parameters (residuals, lift and drag coefficients). If convergence issues arise, adjustments to the mesh, solver parameters, or turbulence model are made.

- Post-processing and Validation: Once converged, the results are post-processed to extract relevant aerodynamic data such as lift, drag, pressure distribution, and Mach number contours. These results are validated against experimental data or other computational results, if available.

The choice of turbulence model is important because transonic flows are often turbulent and accurately capturing turbulence’s impact on shock waves and boundary layers is crucial. The use of higher-order schemes and careful mesh design near shock waves improves the accuracy of shock capture.

Q 28. Describe a time you encountered a challenging transonic flow simulation problem and how you overcame it.

I once encountered significant challenges simulating the transonic flow around a highly swept wing with a complex leading-edge geometry. The initial simulations exhibited inconsistent shock wave behavior and poor convergence. The problem stemmed from inadequate mesh resolution and the presence of highly skewed mesh cells near the sharp leading edge.

My approach to resolving this involved a multi-pronged strategy:

- Mesh Refinement: I systematically refined the mesh in regions near the leading edge and around the anticipated shock locations. The use of adaptive mesh refinement (AMR) was also considered to ensure that sufficient mesh resolution was available in areas experiencing high flow gradients.

- Mesh Quality Improvement: I investigated the mesh quality parameters and implemented strategies to improve cell aspect ratios and reduce skewness. Techniques like local mesh smoothing and re-meshing near the leading edge proved to be beneficial.

- Solver Parameter Tuning: I explored various turbulence models and numerical schemes and optimized solver parameters like under-relaxation factors, until I found a stable configuration that reliably captured the shock structure.

- Shock Capturing Techniques: Employing techniques like artificial viscosity or high-resolution schemes helped to stabilize the shock capturing process and improved the simulation’s accuracy.

Through iterative refinement of the mesh, solver parameters, and techniques for shock capturing, I successfully resolved the convergence issues and obtained a physically consistent and accurate simulation. This experience highlighted the importance of understanding the interactions between the mesh, solver, and numerical schemes in achieving reliable transonic flow simulations.

Key Topics to Learn for Transonic Flow Simulation Interview

- Fundamentals of Compressible Flow: Understanding Mach number, shock waves, and isentropic relations is crucial. Focus on the transition from subsonic to supersonic flow regimes.

- Governing Equations: Familiarize yourself with the Euler and Navier-Stokes equations and their application to transonic flows. Understanding the limitations and assumptions of each is vital.

- Numerical Methods: Mastering numerical techniques used to solve the governing equations, such as Finite Volume Method (FVM), Finite Difference Method (FDM), or Finite Element Method (FEM), is essential. Understanding their strengths and weaknesses in the context of transonic flow is key.

- Grid Generation and Mesh Refinement: Learn about different meshing techniques and their impact on accuracy and computational efficiency, especially near shock waves.

- Shock Wave Phenomena: Deeply understand the formation, properties, and interaction of shock waves in transonic flows. Be prepared to discuss oblique and normal shocks.

- Boundary Conditions: Understand and be able to apply appropriate boundary conditions for various transonic flow problems, such as inflow, outflow, and wall boundary conditions.

- Validation and Verification: Know how to validate simulation results against experimental data or analytical solutions and understand the importance of grid independence studies.

- Practical Applications: Prepare examples of how transonic flow simulation is applied in aerospace engineering (e.g., airfoil design, nozzle design), automotive engineering (e.g., aerodynamic drag reduction), or other relevant fields.

- Turbulence Modeling: Understand the impact of turbulence on transonic flows and the different turbulence models used in simulations (e.g., k-ε, k-ω SST).

- Problem-Solving and Troubleshooting: Practice identifying and troubleshooting common issues encountered in transonic flow simulations, such as convergence problems, numerical instability, and inaccurate results.

Next Steps

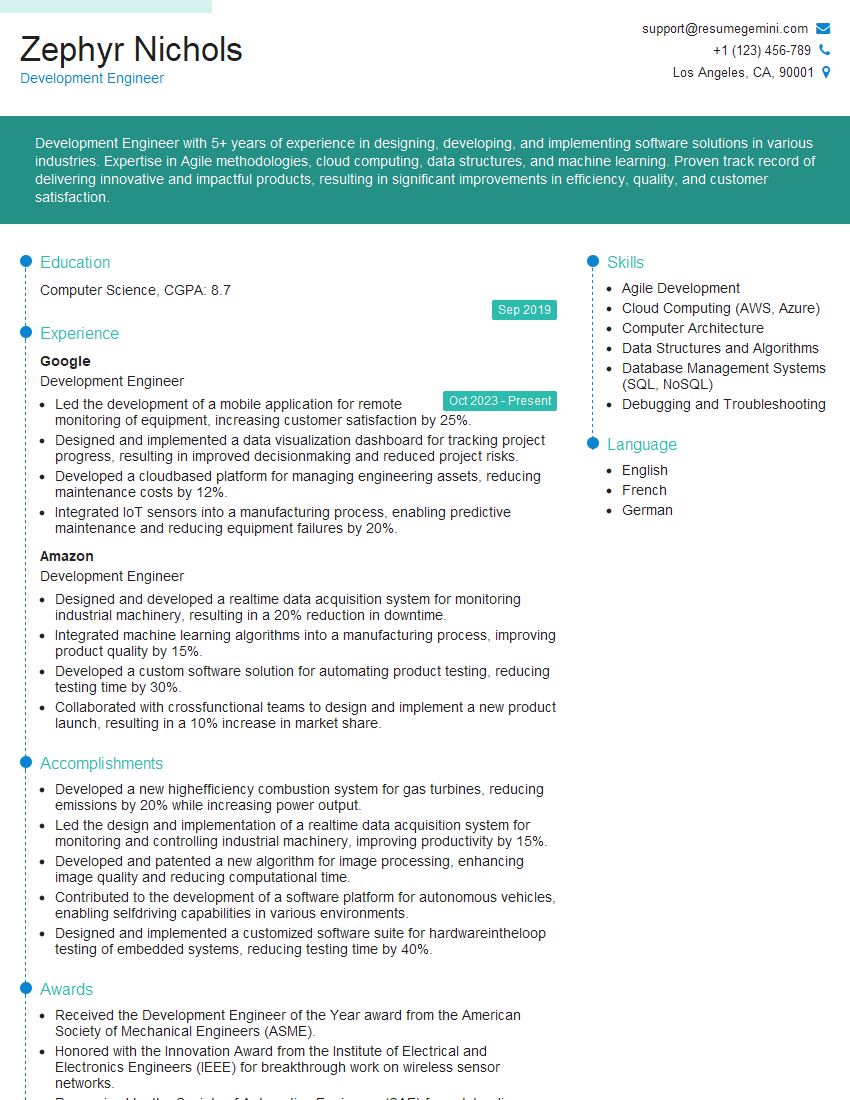

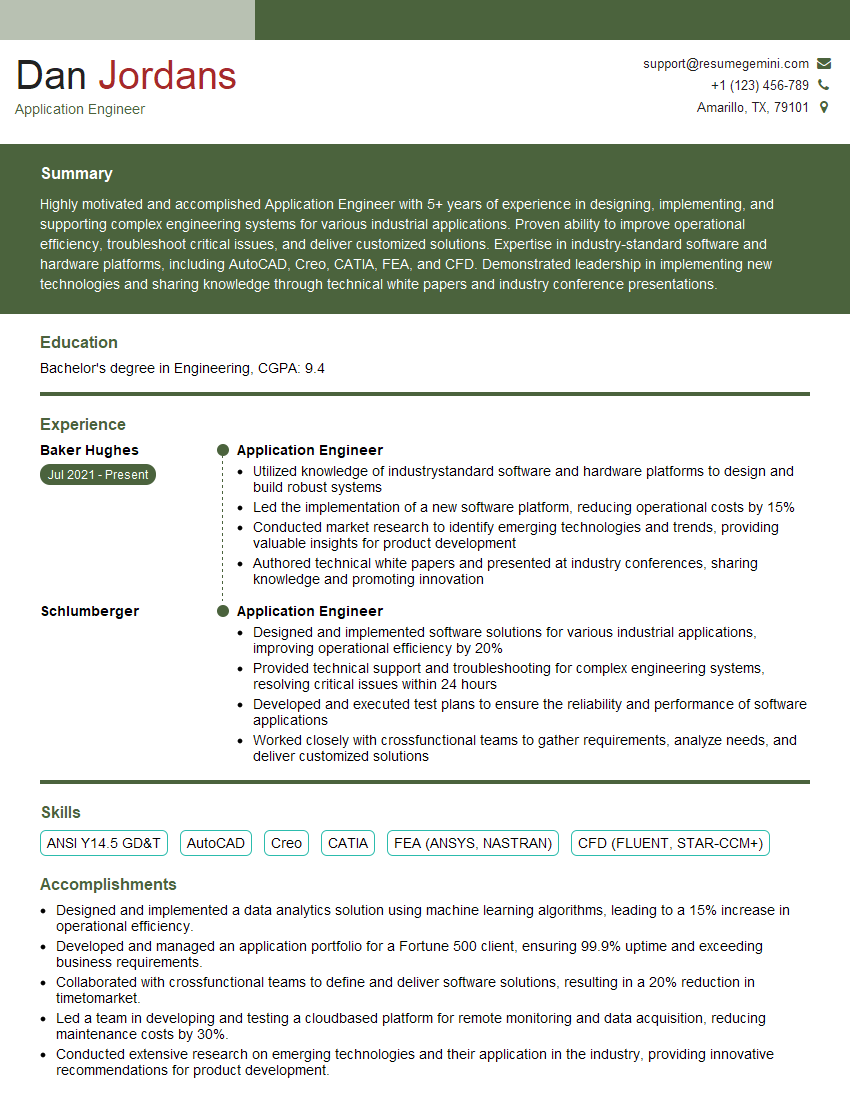

Mastering transonic flow simulation opens doors to exciting and rewarding careers in various engineering fields. It demonstrates a high level of technical expertise and problem-solving skills highly sought after by employers. To maximize your job prospects, creating an ATS-friendly resume is crucial. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your skills and experience effectively. Examples of resumes tailored to showcase expertise in Transonic Flow Simulation are available to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good