Are you ready to stand out in your next interview? Understanding and preparing for Understanding of different types of fabrics interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Understanding of different types of fabrics Interview

Q 1. What are the key differences between natural and synthetic fibers?

The primary difference between natural and synthetic fibers lies in their origin. Natural fibers are derived from plants or animals, while synthetic fibers are manufactured from chemicals. This fundamental difference impacts their properties significantly. Natural fibers like cotton and wool offer breathability and often better drape but can be more prone to wrinkling and less durable than synthetics. Synthetic fibers like polyester and nylon are often more durable, wrinkle-resistant, and easier to care for, but they might not be as breathable or comfortable against the skin as natural fibers. Think of it like this: natural fibers are like handcrafted items – unique and often require more care, while synthetics are more like mass-produced goods – consistent and low-maintenance.

- Natural Fibers: Cotton, wool, silk, linen, hemp, etc. Originate from plants or animals; biodegradable.

- Synthetic Fibers: Polyester, nylon, acrylic, rayon, etc. Created from chemicals; typically not biodegradable.

Q 2. Explain the properties of cotton, wool, silk, and linen.

Let’s explore the properties of four key natural fibers:

- Cotton: A soft, absorbent, and breathable fiber derived from the cotton plant. It’s widely used for clothing and home textiles. However, it wrinkles easily and can shrink after washing. Think of a comfortable t-shirt – that’s often cotton.

- Wool: A naturally insulating fiber from sheep. It’s warm, moisture-wicking (it draws moisture away from the skin), and has excellent drape. However, it can be itchy for some people and requires special care to avoid shrinking. A warm winter coat is likely made from wool or a wool blend.

- Silk: A luxurious fiber produced by silkworms. It’s known for its smooth texture, lustrous sheen, and excellent drape. It’s delicate and requires gentle handling. Imagine a high-end silk scarf or a flowing evening gown – those are typically made from silk.

- Linen: A strong, durable fiber from the flax plant. It’s known for its breathability, crispness, and wrinkle resistance (relative to cotton). However, it can be prone to creasing and is relatively expensive. Think of a stylish linen shirt or a sophisticated linen suit.

Q 3. Describe the characteristics of different weave structures (e.g., plain, twill, satin).

Weave structures determine the fabric’s appearance, texture, and performance. Here are three common weave types:

- Plain Weave: The simplest weave structure, where warp and weft yarns interlace in a simple over-under pattern. It creates a stable, relatively firm fabric, suitable for sheets, shirts, and basic apparel. Think of a standard cotton sheet.

- Twill Weave: Characterized by diagonal lines produced by the yarns floating over two or more yarns before interlacing. This creates a stronger, more durable fabric with a diagonal texture. Denim is a prime example of twill weave.

- Satin Weave: Creates a smooth, lustrous surface with a long, floating warp or weft yarn. It results in a luxurious drape and often a sheen. Satin sheets or evening wear fabrics often utilize satin weave.

Q 4. How does fabric weight affect drape and garment construction?

Fabric weight significantly impacts both drape and garment construction. Heavier fabrics tend to have less drape—they hang more stiffly—while lighter fabrics drape more easily and flow gracefully. Heavier fabrics are generally more structured and might require more robust construction techniques, often involving sturdier seams and interfacing. Lighter fabrics, conversely, drape well but might require more delicate handling during construction to avoid damage.

For example, a heavy wool coat requires strong stitching to withstand the weight of the fabric, while a lightweight silk scarf might only require simple hand-stitching. This concept is crucial for pattern selection and construction methods; a lightweight pattern will likely fail with a heavy fabric.

Q 5. What are the advantages and disadvantages of using blends of fibers?

Blending fibers combines the desirable properties of different fibers to create fabrics with enhanced performance. For example, blending cotton with polyester results in a fabric that retains cotton’s softness and breathability while gaining polyester’s wrinkle resistance and durability. This offers advantages in terms of ease of care and increased longevity.

- Advantages: Improved drape, enhanced durability, wrinkle resistance, better moisture management, cost reduction.

- Disadvantages: Can be more difficult to dye consistently, may compromise the unique characteristics of individual fibers (e.g., a cotton-polyester blend might not be as breathable as pure cotton).

Q 6. Explain the concept of fabric hand and its importance in garment selection.

Fabric hand refers to the tactile feel of a fabric. It encompasses aspects like softness, smoothness, crispness, stiffness, and texture. Understanding fabric hand is crucial for garment selection because it directly impacts the overall comfort and wearing experience. A fabric with a soft hand will feel comfortable against the skin, while a crisp hand might be preferred for more formal wear. For example, a soft cashmere sweater will feel drastically different from a stiff linen shirt, influencing the wearer’s perception of the garment’s quality and suitability.

Q 7. What are common fabric finishes and their purposes?

Fabric finishes are treatments applied to fabrics to modify their properties and enhance their appearance or performance. Examples include:

- Mercerization: A treatment for cotton that improves its luster, strength, and dye absorption.

- Sanforizing: A process to prevent shrinkage in fabrics.

- Water-repellent finishes: Applied to fabrics to make them resistant to water.

- Flame-retardant finishes: Increase the fabric’s resistance to ignition.

- Softening finishes: Enhance the softness and drape of fabrics.

The purpose of these finishes is to improve the quality, performance, and appeal of the fabric, catering to specific end-use applications and consumer preferences. A wrinkle-resistant finish on a shirt, for instance, simplifies ironing and extends the garment’s usability.

Q 8. How does fabric shrinkage occur, and how can it be prevented?

Fabric shrinkage occurs due to the relaxation of fibers after weaving or knitting. Think of it like a tightly stretched rubber band – when released, it contracts. This relaxation can be caused by several factors: the initial tension during manufacturing, the absorption of water (causing fibers to swell), and the heat applied during washing or drying. Different fibers shrink to different degrees; wool and cotton are particularly prone to shrinkage.

Preventing shrinkage involves several strategies: pre-shrinking the fabric before garment construction (through processes like sanforizing), using shrinkage-resistant fibers (like certain types of polyester), and following care instructions meticulously. Always wash and dry fabrics according to the manufacturer’s recommendations, which often involve gentler cycles and lower temperatures. Air-drying is always a safer option than machine drying for many fabrics, especially those prone to shrinking.

Q 9. What are the different types of knits and their properties?

Knit fabrics are created by interlooping yarns, unlike woven fabrics which are made by interlacing yarns. There are numerous types of knits, each with distinct properties:

- Jersey: A basic knit, often used for t-shirts, with good drape and stretch. It tends to curl at the edges.

- Rib knit: Created with alternating knit and purl stitches, resulting in vertical ribs. It’s more stable and less likely to curl than jersey.

- Interlock: A more stable knit than jersey, with less stretch and a smoother face, often used for higher-quality t-shirts and underwear.

- Double knit: Two layers of knit fabric are produced simultaneously, resulting in a thicker, more durable, and less likely to unravel fabric.

- Pique: A textured knit with small raised bumps or cords, offering a slightly stiffer hand feel. Often seen in polo shirts.

These are just a few examples. The properties like stretch, durability, and drape vary significantly depending on the yarn type, stitch pattern, and finishing processes used.

Q 10. Explain the difference between warp and weft yarns.

In woven fabrics, warp and weft yarns are arranged at right angles to each other. The warp yarns are the lengthwise yarns that run parallel to the selvedge (the finished edge of the fabric). Imagine them as the foundation of the fabric. The weft yarns, also known as filling yarns, are the crosswise yarns that are interlaced with the warp yarns to create the fabric structure. Think of them as the ‘threads’ that fill in the gaps between the warp yarns.

A simple analogy would be a basket: the warp yarns are the lengthwise sticks that form the frame, and the weft yarns are the horizontal sticks woven in and out to construct the basket.

Q 11. Describe the various methods used to dye fabrics.

Fabric dyeing involves several methods, each with its advantages and disadvantages:

- Piece dyeing: The entire piece of fabric is dyed after it’s been woven or knitted. This is common for solid-colored fabrics.

- Yarn dyeing: The yarns are dyed before weaving or knitting. This allows for complex patterns and color variations like heather effects.

- Solution dyeing: The dye is added to the fiber solution before the fibers are formed. This creates exceptionally colorfast fabrics that resist fading.

- Garment dyeing: The finished garment is dyed. This allows for unique dyeing effects, but can be challenging to control.

- Printing: Dye is applied to the fabric in specific patterns or designs, creating unique prints.

The choice of method depends on factors such as cost, desired effect, fabric type, and colorfastness requirements.

Q 12. What are the different types of fabric testing methods?

Various tests assess fabric properties, ensuring quality and performance. These include:

- Tensile strength: Measures the fabric’s resistance to being pulled apart.

- Abrasion resistance: Determines the fabric’s ability to withstand rubbing and wear.

- Colorfastness: Assesses the fabric’s resistance to fading from washing, light exposure, and rubbing.

- Shrinkage: Measures the extent to which the fabric shrinks after washing and drying.

- Pilling: Evaluates the tendency of the fabric to form pills (small balls of fiber).

- Bursting strength: Measures the fabric’s resistance to pressure and rupture.

These tests help manufacturers maintain quality and meet industry standards. Results help inform design decisions and consumer expectations.

Q 13. How do you identify different types of fabrics by touch and visual inspection?

Identifying fabrics through touch and visual inspection involves a combination of observation and tactile assessment. For example:

- Visual inspection: Observe the fiber structure (e.g., smooth, textured, shiny), weave type (e.g., plain weave, twill weave), and print or dye techniques.

- Touch assessment: Feel the fabric’s texture (e.g., soft, rough, crisp), weight, drape, and hand (how it feels to the touch). A rough fabric like burlap is immediately different from a slippery satin.

Experience is key to accurately identifying fabrics. Learning to recognize the characteristics of different fiber types (cotton’s softness, wool’s warmth, linen’s texture, silk’s smoothness) is essential.

For example, a tightly woven fabric will feel firmer than a loosely woven one. A high-twist yarn will feel stronger and less likely to pill than a low-twist yarn.

Q 14. What are some common fabric defects, and how are they identified?

Several defects can occur during fabric production:

- Broken ends: Warp or weft yarns that have broken during weaving.

- Slubs: Thickened areas in the yarn.

- Holes: Missing yarns, creating gaps in the fabric.

- Knots: Knots in the yarn.

- Wrinkles and creases: Permanent wrinkles that won’t come out with ironing.

- Uneven dyeing: Inconsistent color across the fabric.

These defects are usually identified during quality control inspections. Visual inspection and sometimes specialized equipment are used to detect these flaws, ensuring the final product meets quality standards.

Q 15. Explain the relationship between fiber content and fabric performance.

The fiber content of a fabric is intrinsically linked to its performance characteristics. Different fibers possess unique properties that dictate how the resulting fabric will behave. For example, the length, strength, and fineness of fibers influence drape, durability, and wrinkle resistance.

- Cotton: Known for its absorbency, breathability, and softness, cotton is ideal for summer clothing. However, it wrinkles easily and can shrink after washing.

- Polyester: A synthetic fiber, polyester is durable, wrinkle-resistant, and water-repellent. It’s often blended with other fibers to improve their performance characteristics. A polyester-cotton blend offers the softness of cotton with improved wrinkle resistance.

- Silk: Luxurious and smooth, silk is known for its drape and sheen. However, it’s delicate and requires special care.

- Wool: Naturally warm and insulating, wool is excellent for winter garments. It’s also wrinkle-resistant but can be prone to shrinkage and requires careful cleaning.

Understanding these inherent fiber properties allows designers and manufacturers to choose the optimal fiber or blend for a specific garment and its intended use.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the environmental impacts of different fabric types?

The environmental impact of fabric production varies greatly depending on the fiber type. Some fibers are more sustainable than others, impacting water usage, energy consumption, and waste generation.

- Cotton: Conventional cotton farming is resource-intensive, requiring significant amounts of water, pesticides, and fertilizers. Organic cotton aims to reduce these environmental impacts.

- Synthetic fibers (Polyester, Nylon): Derived from petroleum, synthetic fiber production is energy-intensive and contributes to greenhouse gas emissions. Recycling initiatives are attempting to mitigate this impact.

- Natural fibers (Linen, Hemp, Bamboo): These fibers generally have a lower environmental footprint than cotton or synthetics, requiring fewer resources and producing less pollution. However, their production may still have impacts depending on farming practices.

- Recycled fibers: Utilizing recycled materials significantly reduces the environmental burden compared to virgin materials.

The entire lifecycle—from raw material production to garment disposal—must be considered when assessing the environmental impact of a fabric.

Q 17. How do you select appropriate fabrics for different garment types and end-uses?

Fabric selection is crucial for garment success. The choice depends on the garment type, end-use, and desired performance characteristics. Consider factors such as:

- Intended Use: A lightweight, breathable fabric is suitable for summer dresses, while a warm, insulating fabric is ideal for winter coats.

- Durability: Durable fabrics like canvas are better for workwear, while delicate fabrics like silk are suited for evening gowns.

- Drape: The way a fabric hangs and falls is critical; a stiff fabric is suitable for structured garments, while a flowing fabric works well for flowing designs.

- Comfort: Soft, breathable fabrics are preferred for underwear and loungewear, while moisture-wicking fabrics are ideal for sportswear.

- Cost: Different fabrics have different costs, influencing the overall garment price.

For example, a sportswear brand might choose a moisture-wicking polyester blend for its athletic apparel, ensuring comfort and performance during physical activity. Meanwhile, a designer creating formal wear may select luxurious silk or wool for its drape and luxurious feel.

Q 18. Discuss the importance of colorfastness in fabrics.

Colorfastness refers to a fabric’s ability to retain its color despite exposure to various factors like washing, sunlight, and rubbing. It’s essential for maintaining the garment’s aesthetic appeal and longevity.

Poor colorfastness can lead to fading, bleeding (color transferring to other fabrics), or discoloration, ruining the garment’s appearance. Therefore, rigorous testing is conducted to ensure that fabrics meet the required colorfastness standards. This testing includes assessing the resistance to washing, light, perspiration, and rubbing.

Consumers should always check the care label for washing instructions to avoid damaging colorfastness. Choosing fabrics with high colorfastness ratings ensures that the garment will retain its vibrant colors for a longer period.

Q 19. Describe different methods of fabric printing.

Numerous methods exist for printing on fabrics, each with its advantages and disadvantages:

- Screen Printing: A stencil is used to apply ink to the fabric. It’s cost-effective for large-scale production but less versatile for intricate designs.

- Digital Printing: Ink is directly applied to the fabric using inkjet technology. It offers high-resolution images and is ideal for small-batch production and custom designs.

- Rotary Screen Printing: Similar to screen printing but uses a cylindrical screen for faster and more efficient printing on continuous rolls of fabric.

- Heat Transfer Printing: A printed design is transferred onto the fabric using heat and pressure. It’s suitable for synthetic fabrics and allows for vivid colors.

- Block Printing: A hand-carved wooden block is used to apply ink to the fabric. It’s labor-intensive but produces unique, handcrafted results.

The choice of printing method depends on factors such as design complexity, production volume, fabric type, and budget.

Q 20. What are some common fabric care instructions?

Fabric care instructions are crucial for maintaining the garment’s quality and longevity. Common instructions include:

- Washing Temperature: Cold, warm, or hot water—indicated to prevent shrinkage and color fading.

- Washing Method: Machine wash, hand wash, or dry clean—dependent on fabric type and construction.

- Drying Method: Air dry, tumble dry low, or do not tumble dry—to prevent shrinking, damage, or color fading.

- Ironing: Iron at a low temperature or do not iron—to avoid burning or damaging the fabric.

- Bleaching: Do not bleach or bleach only with non-chlorine bleach—to avoid damaging the fibers and color.

Always check the care label before cleaning the garment to avoid damaging it.

Q 21. How does fabric flammability differ between different fibers?

Fabric flammability varies significantly depending on the fiber type. Some fibers are inherently more flammable than others.

- Natural Fibers (Cotton, Linen, Silk, Wool): These fibers are generally considered to be more flammable than synthetic fibers, especially when dry.

- Synthetic Fibers (Polyester, Nylon, Acrylic): These fibers tend to melt rather than burn, but they can still pose a fire hazard. The melting process can cause severe skin burns.

- Flame-retardant fabrics: These fabrics are treated with chemicals to improve their fire resistance. They are often used in protective clothing and upholstery.

Understanding the flammability of different fibers is crucial for selecting fabrics appropriate for various applications, especially where fire safety is paramount (e.g., children’s sleepwear, workwear in industrial settings).

Q 22. What are the advantages and disadvantages of using sustainable fabrics?

Sustainable fabrics offer significant environmental and social advantages, but also present certain challenges. Let’s break down both sides:

Advantages:

- Reduced Environmental Impact: Sustainable fabrics, such as organic cotton, hemp, Tencel (lyocell), and recycled materials, minimize the use of harmful pesticides, reduce water consumption, and lessen carbon emissions compared to conventional fabrics. For example, organic cotton farming avoids the use of synthetic fertilizers and pesticides, protecting soil health and biodiversity.

- Improved Worker Conditions: Many sustainable fabric sources prioritize fair labor practices and safe working conditions, offering better wages and benefits to workers throughout the supply chain. This contrasts sharply with some conventional fabric production, which is often associated with exploitative labor practices.

- Biodegradability and Recyclability: Some sustainable fabrics are biodegradable, meaning they decompose naturally, reducing landfill waste. Others, like recycled polyester, offer a circular economy approach by utilizing existing materials.

Disadvantages:

- Higher Cost: Sustainable fabrics are often more expensive than conventional options due to higher production costs, which reflect the ethical and environmental considerations involved.

- Limited Availability: The supply of certain sustainable fabrics can be limited, potentially affecting production scalability and lead times.

- Performance Differences: Some sustainable fabrics might have slightly different performance characteristics compared to conventional ones, requiring adjustments in design and manufacturing processes. For example, organic cotton might be less durable than conventionally grown cotton initially, though improvements are continually being made.

- Certification and Verification Challenges: Verifying the authenticity and sustainability claims of some fabrics can be challenging, requiring careful scrutiny of certifications and supply chains.

Ultimately, the decision of whether to use sustainable fabrics involves weighing these advantages and disadvantages carefully, considering the project’s budget, timeline, and ethical priorities.

Q 23. Describe your experience with different fabric sourcing processes.

My experience encompasses a wide range of fabric sourcing processes, from direct sourcing from farms and mills to working with established suppliers and agents. I’ve been involved in:

- Direct Sourcing: This involves establishing relationships with farmers and mills, providing direct oversight of the production process and ensuring adherence to quality and sustainability standards. This gives great control but requires significant investment in relationship building and due diligence.

- Supplier Relationships: Working with established suppliers offers access to a broader range of fabrics, streamlined processes, and established quality control measures. This reduces the risk of supply chain disruptions, but requires careful selection of suppliers to ensure ethical and quality standards are met. I’ve built strong relationships with several key suppliers over the years, understanding their capabilities and specializing in specific fabrics.

- Agent-Based Sourcing: Agents act as intermediaries, connecting buyers with suppliers, often streamlining the process and offering access to unique or hard-to-find fabrics. However, managing agent relationships requires trust, clear communication, and potentially higher costs.

- Recycled Fabric Sourcing: I have significant experience sourcing recycled fabrics, requiring a thorough understanding of the recycling process and the material’s origin to ensure the quality and composition claims are legitimate. This frequently involves analyzing pre-consumer and post-consumer waste streams.

My approach always emphasizes transparency, traceability, and ethical considerations throughout the sourcing process, ensuring alignment with both the project’s needs and sustainability goals.

Q 24. Explain your understanding of fabric costing and pricing.

Fabric costing and pricing is a complex process involving numerous factors. The final price reflects the raw material costs, manufacturing costs, transportation, duties, and profit margins.

- Raw Material Costs: This is the base cost of the fiber, which varies greatly depending on the type of fiber (cotton, silk, polyester, etc.), its quality, and market conditions. For example, the price of organic cotton is typically higher than conventionally grown cotton.

- Manufacturing Costs: This includes costs associated with yarn spinning, weaving or knitting, dyeing, finishing, and any other specialized processes. The complexity of the fabric structure and the finishing requirements heavily impact these costs.

- Transportation Costs: Transportation from the mill to the manufacturing facility and then to the final destination adds to the overall cost. Shipping costs vary greatly depending on distance and mode of transportation.

- Duties and Taxes: Depending on the origin and destination of the fabric, import duties and taxes might be levied.

- Profit Margins: Each entity in the supply chain (farmer, mill, supplier, manufacturer) adds a profit margin to the cost, contributing to the final price.

Understanding these cost components is crucial for effective negotiation with suppliers and for accurate budgeting in garment production. Accurate costing requires careful analysis of the entire supply chain, and experienced professionals will incorporate contingency planning for fluctuations in raw material pricing and transportation costs.

Q 25. How do you stay current with the latest trends in fabric technology?

Staying current in fabric technology requires a multifaceted approach:

- Trade Publications and Journals: I regularly read industry publications such as Textile World and Textile Today to keep abreast of the latest innovations and trends.

- Industry Conferences and Trade Shows: Attending events like Premiere Vision and Kingpins provides invaluable insights into new fabric technologies and trends. Networking with industry peers and suppliers provides direct access to information.

- Online Resources and Databases: Websites, online databases, and research papers offer up-to-date information on fabric technologies and sustainable materials.

- Supplier Relationships: Maintaining close contact with fabric suppliers allows for early access to new developments and information on emerging technologies.

- Continuous Learning: I actively participate in workshops and training sessions to deepen my knowledge and stay ahead of technological advancements.

This multi-pronged approach ensures I remain at the forefront of the industry’s evolution and can make informed decisions about fabric selection and implementation.

Q 26. How would you assess the quality of a fabric sample?

Assessing fabric quality involves a systematic approach that considers various factors:

- Fiber Content: Examining the fiber content determines the fabric’s inherent properties like strength, drape, and durability. For example, the length of cotton fibers directly influences the quality and strength of the cotton fabric.

- Yarn Construction: Inspecting the yarn structure reveals details about its twist, thickness, and evenness. A uniform yarn construction results in a higher quality fabric.

- Fabric Construction: The weave or knit structure impacts the fabric’s drape, texture, and durability. Examining the density and uniformity of the weave is vital.

- Weight and Drape: Measuring the fabric’s weight and observing its drape provide insight into its overall quality and suitability for specific applications. A heavier weight typically suggests greater durability.

- Colorfastness: Testing colorfastness to washing, light, and rubbing is crucial, especially for garments. Poor colorfastness can result in fading or discoloration.

- Hand Feel: Subjectively evaluating the fabric’s texture and feel provides valuable information about its softness, smoothness, and overall quality.

- Shrinkage and Stretch: Determining the fabric’s shrinkage and stretch properties ensures its dimensional stability after washing and wearing.

Beyond these tests, I often use advanced testing equipment to analyze fabric strength, abrasion resistance, and other critical properties. The specific tests used depend on the fabric’s intended application.

Q 27. What is your experience with working with different fabric suppliers?

My experience working with fabric suppliers spans various sizes and locations, from small, specialized mills to large international corporations. I value:

- Ethical Sourcing: I prioritize suppliers committed to ethical labor practices, environmental responsibility, and fair pricing.

- Quality Control: Thorough quality control procedures are essential, including regular inspections and testing throughout the supply chain.

- Reliability and Responsiveness: Reliable suppliers provide consistent quality and timely delivery, while being responsive to my needs and inquiries.

- Transparency: I seek transparency in pricing, sourcing practices, and production processes. This builds trust and fosters long-term relationships.

- Innovation and Adaptability: Suppliers who are constantly innovating and are able to adapt to changing market demands are critical partners for any long-term collaboration.

Building strong relationships with trustworthy suppliers is paramount. Regular communication, mutual respect, and shared commitment to quality are key elements of a successful collaboration.

Q 28. Describe a time you had to troubleshoot a fabric-related issue in a garment production.

During a garment production run, we encountered unexpected pilling (small balls of fiber) on a knitted sweater made from a new blend of recycled polyester and wool. This was a significant issue as pilling significantly reduces the perceived quality of the garment.

Troubleshooting Steps:

- Problem Identification and Analysis: We identified the pilling issue through internal quality control inspections and customer feedback. Microscopic analysis revealed the cause was the uneven fiber length and processing of the recycled polyester, leading to weak fiber ends prone to pilling.

- Supplier Collaboration: We immediately contacted the fabric supplier to discuss the issue. They provided the detailed composition and processing information of the recycled polyester.

- Alternative Solutions Exploration: We investigated several solutions, including changing the fabric blend (e.g., increasing the wool content), adjusting the knitting parameters, and exploring post-processing treatments to reduce pilling.

- Testing and Validation: Samples with modified blends and processing techniques were produced and tested to determine the effectiveness of each solution. We focused on tests evaluating pilling resistance (e.g., Martindale abrasion test).

- Implementation and Monitoring: After extensive testing, a modified blend with improved fiber processing and a post-processing treatment significantly reduced the pilling issue. The revised specification was implemented, and further monitoring confirmed the solution’s effectiveness.

This experience highlighted the importance of thorough fabric testing and close collaboration with suppliers throughout the production process to ensure the final product meets the desired quality standards.

Key Topics to Learn for Understanding of Different Types of Fabrics Interview

- Natural Fibers: Understanding the properties (strength, drape, absorbency, durability) of cotton, wool, silk, linen, and their variations. Consider their suitability for different garment types and end uses.

- Synthetic Fibers: Exploring the characteristics of nylon, polyester, acrylic, rayon, and spandex. Learn about their advantages (e.g., durability, wrinkle resistance, cost-effectiveness) and limitations (e.g., breathability, environmental impact).

- Fabric Construction: Gain knowledge of different weave structures (plain, twill, satin) and their influence on fabric properties. Understand knit vs. woven fabrics and their applications.

- Fabric Finishes: Learn about common finishes like mercerization, sanforizing, and water-repellent treatments and their effects on fabric performance and feel. Be prepared to discuss the impact of these finishes on the final product.

- Fabric Blends: Analyze the properties of blended fabrics and how the combination of different fibers impacts the overall characteristics. Be able to explain why certain blends are chosen for specific garments.

- Fabric Testing and Quality Control: Understand basic fabric testing methods used to assess quality, strength, and other relevant properties. Discuss how these tests inform decisions in the manufacturing process.

- Sustainability and Ethical Sourcing: Discuss environmentally friendly and ethically sourced fabrics. Be prepared to discuss the growing importance of sustainable practices within the textile industry.

- Identifying Fabrics: Develop the ability to distinguish different fabrics through touch, visual inspection, and basic tests. This practical skill demonstrates a deep understanding of fabric properties.

Next Steps

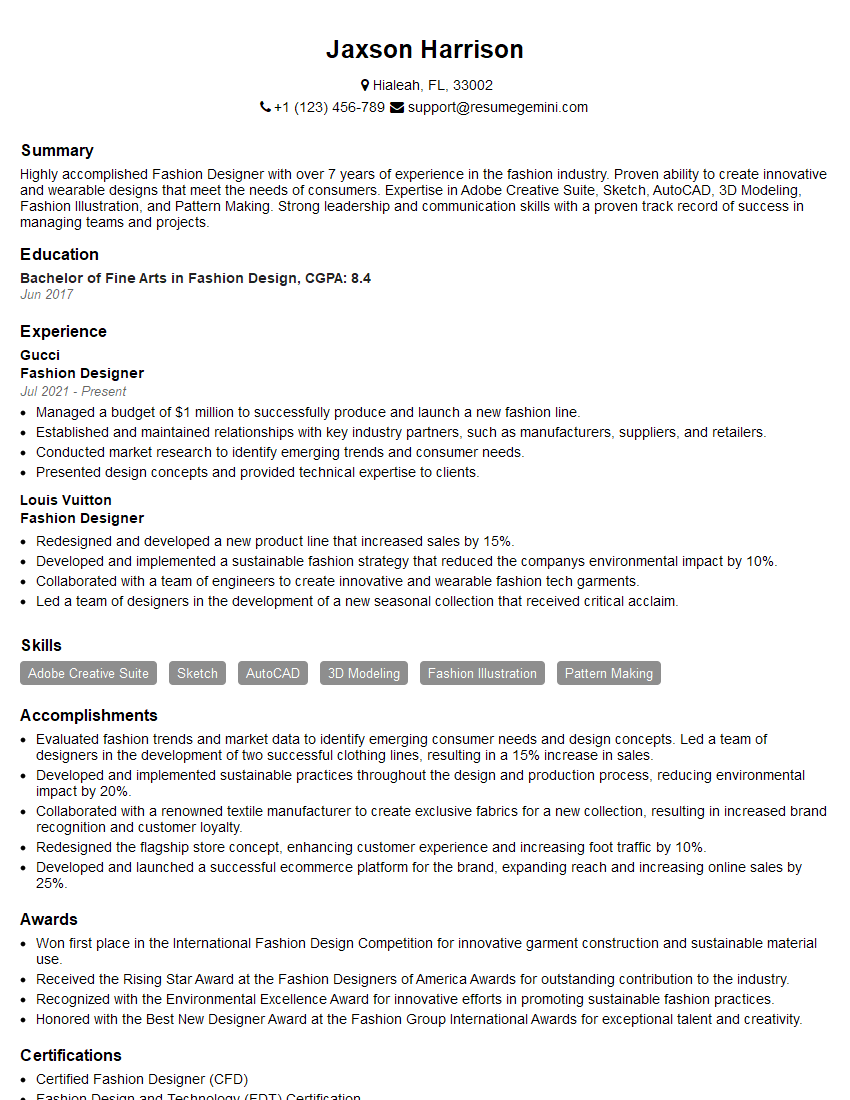

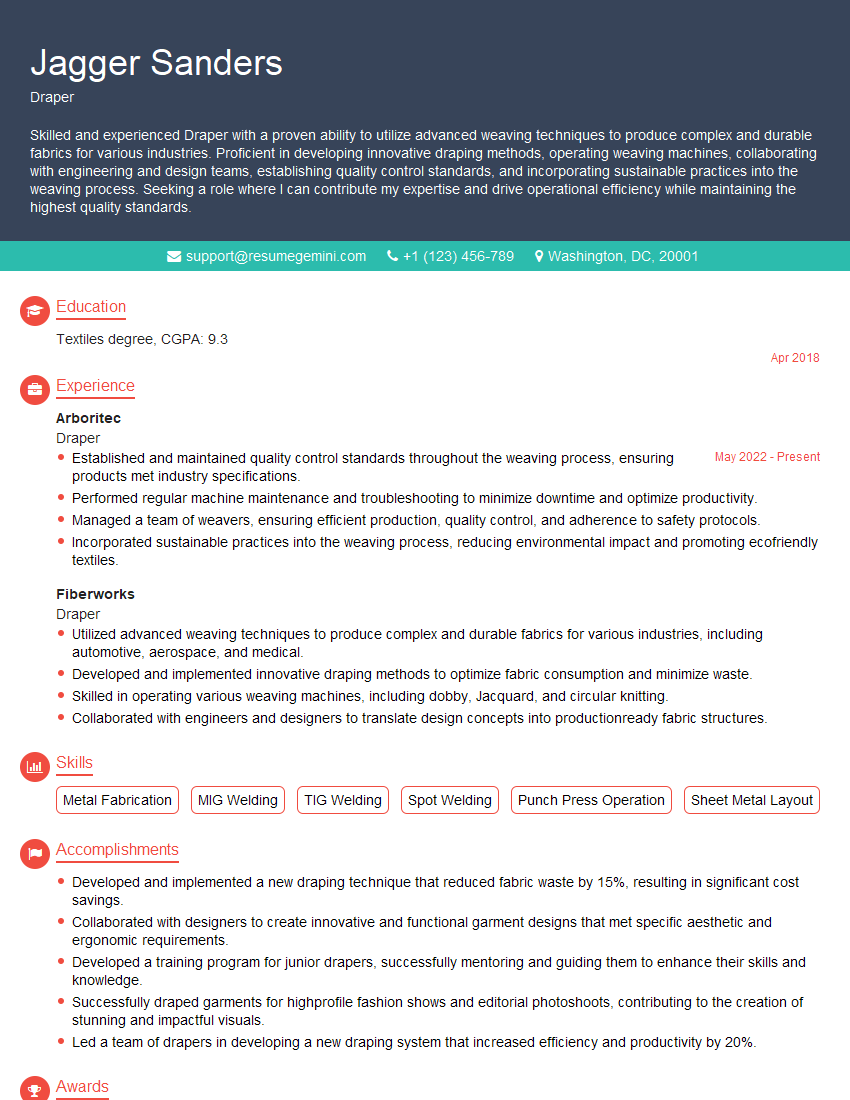

Mastering the understanding of different types of fabrics is crucial for career advancement in the textile and apparel industries. A strong grasp of these concepts demonstrates expertise and problem-solving skills highly valued by employers. To significantly boost your job prospects, create an ATS-friendly resume that highlights your knowledge and experience. ResumeGemini is a trusted resource to help you build a professional and impactful resume that catches the eye of recruiters. We provide examples of resumes tailored to showcasing expertise in understanding different types of fabrics to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).